An electric back cover durability test bench

A durable test, electric technology, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve problems such as poor economy, high cost, delayed test progress, etc., to reduce test costs, simple structure, and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

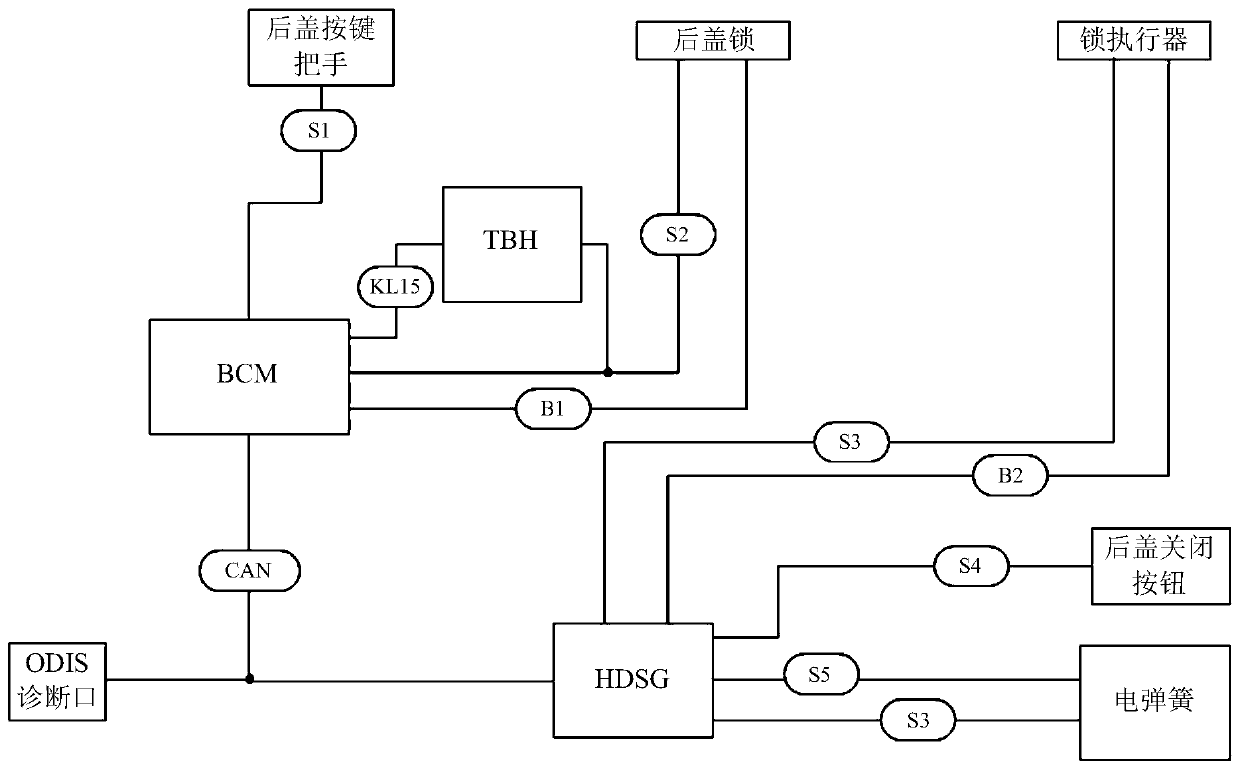

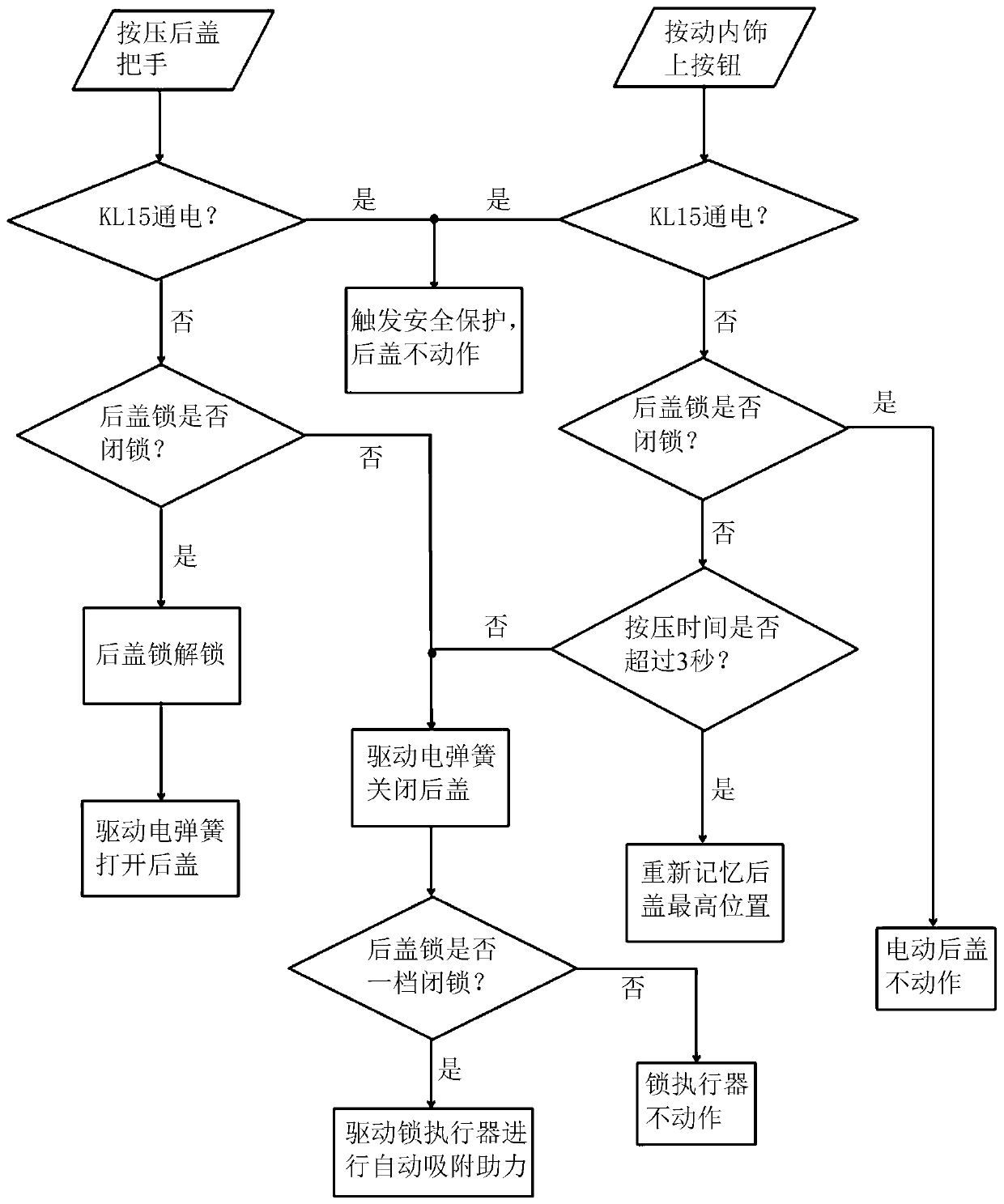

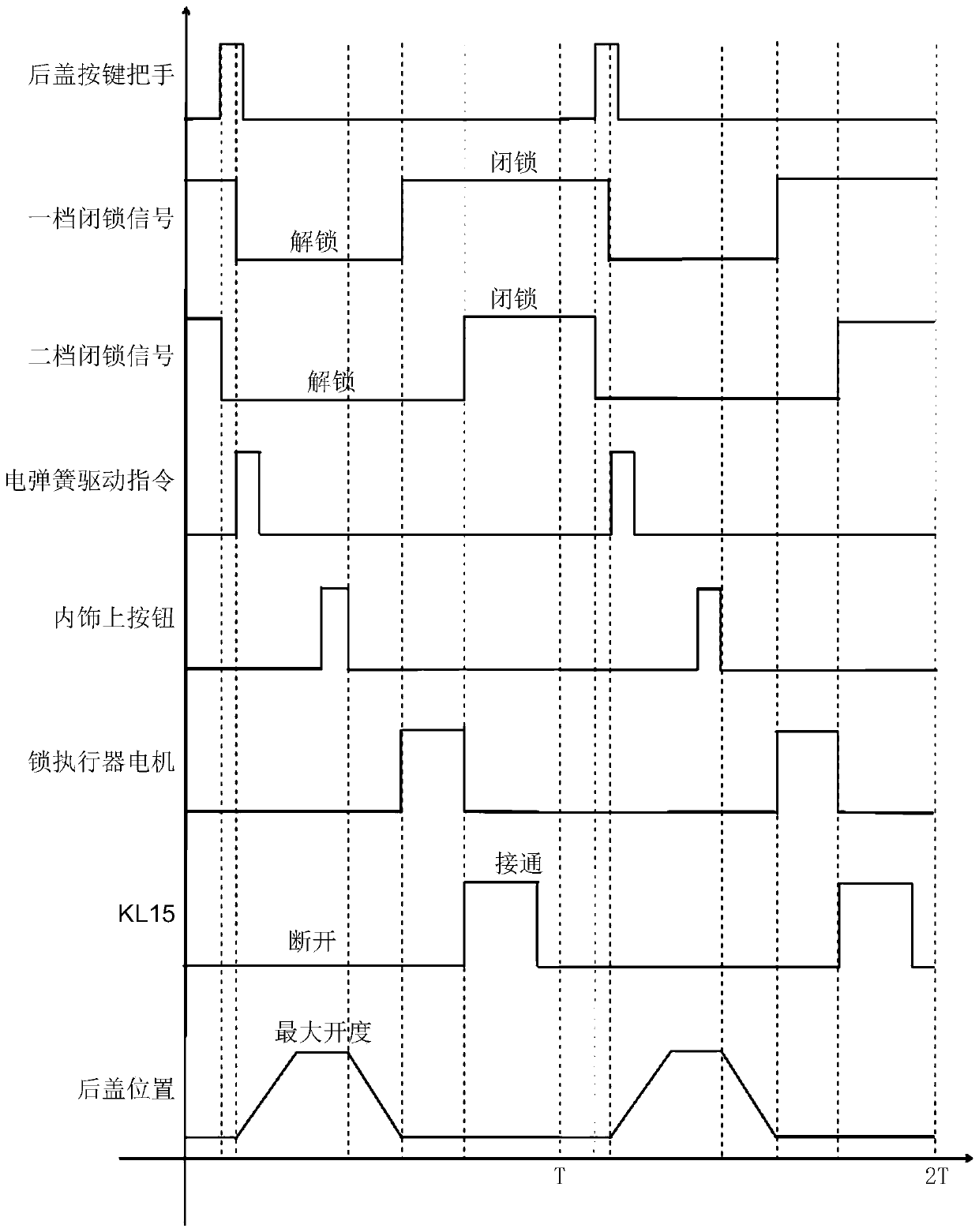

[0019] figure 1 It shows the connection structure of the embodiment of the electric back cover durability test bench of the present invention. See figure 1 , the stand of the present embodiment includes a rear cover button handle, a rear cover lock, a lock actuator, a rear cover closing button, an electric spring, a rear cover controller (HDSG), a body controller (BCM) and a non-vehicle controller (TBH ). The connection relationship between these components is: BCM is connected to the back cover button handle through the trigger signal line S1 of the handle button, BCM is connected to TBH through a pin (for example, KL15 pin), and BCM is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com