Patents

Literature

41results about How to "Avoid experiment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

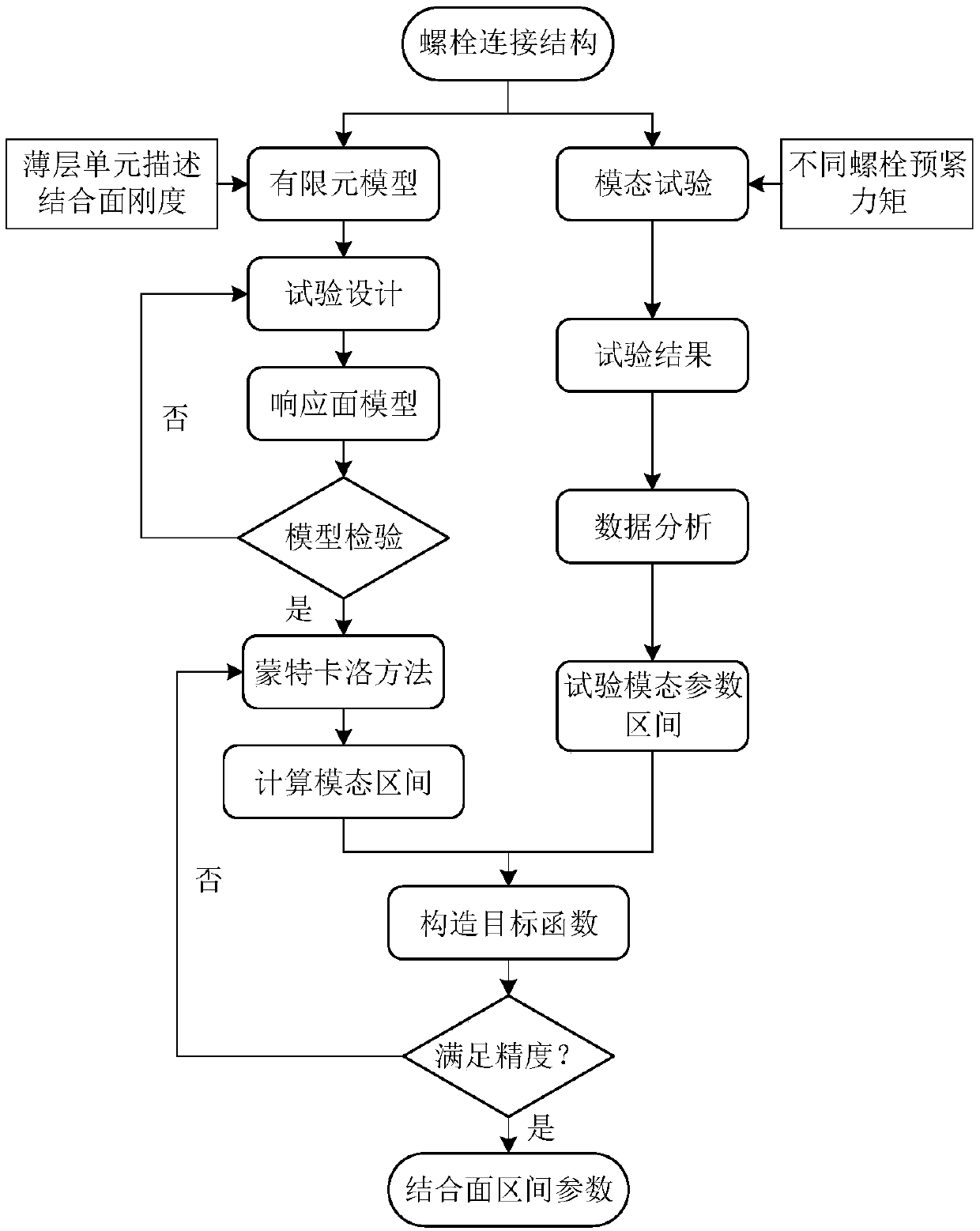

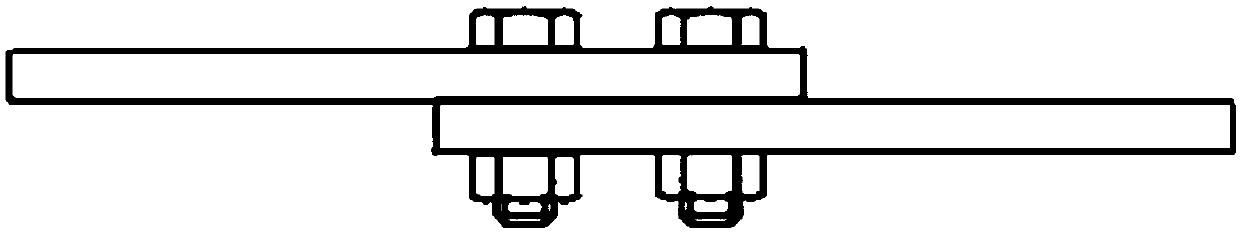

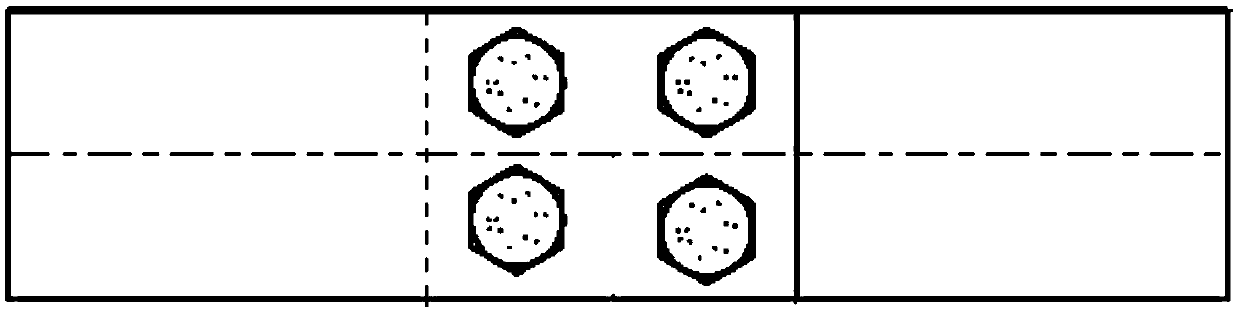

Bolt connection joint surface stiffness identification method considering uncertainty

InactiveCN108763684AImprove modeling efficiencyImproving the Efficiency of Structural Uncertainty Dynamics AnalysisGeometric CADDesign optimisation/simulationElement modelThin layer

The invention relates to a bolt connection joint surface stiffness identification method considering the uncertainty. The method comprises the following steps of S1, building a finite element model ofa bolt connection structure according to geometrical parameters and material parameters of a connected piece and a bolt connecting piece; S2, carrying out a modal test on bolt connection structures under different pre-tightening torques to obtain structural interval uncertainty modal parameters, namely, obtaining a test mode parameter interval; S3, on the basis of the finite element model of thebolt connection structure, building a response surface model between material parameters of a thin-layer unit and dynamic characteristics of the structure; S4, in combination with the response surfacemodel and a Monte Carlo method, obtaining a calculation mode parameter interval; and S5, building an objective function according to the test mode parameter interval and the calculation mode parameter interval, identifying an interval of the material parameters of the thin-layer unit of a joint surface, and realizing an equivalent finite element model of the bolt connection structure of the thin-layer unit. The problem of the uncertainty of the joint surface stiffness in numerical simulation of the bolt connection structure in engineering is solved.

Owner:SOUTHEAST UNIV

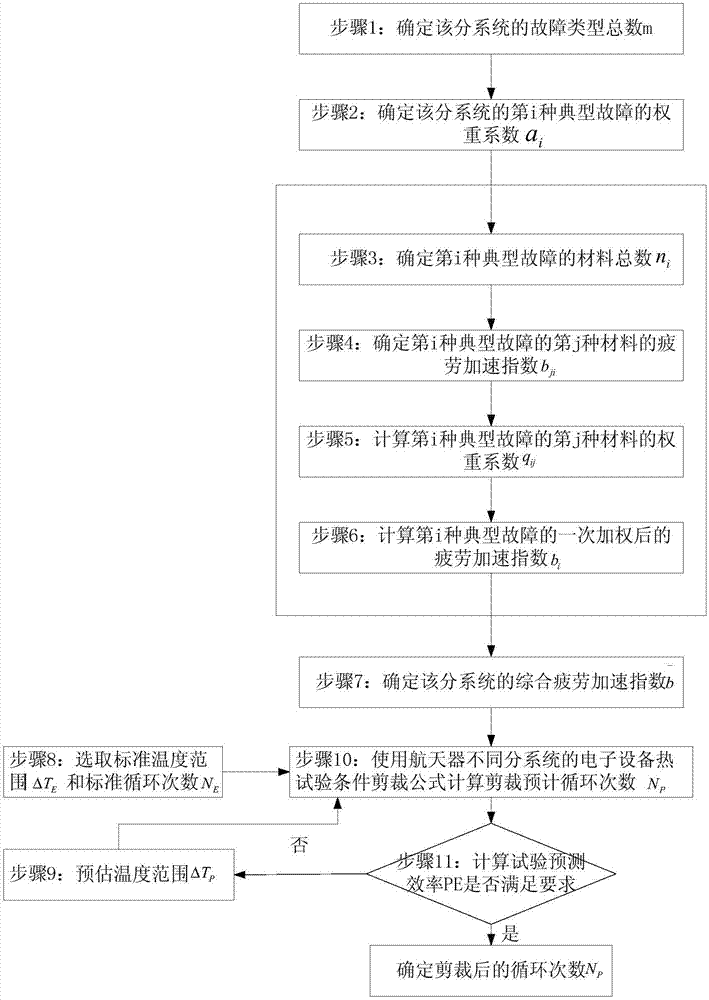

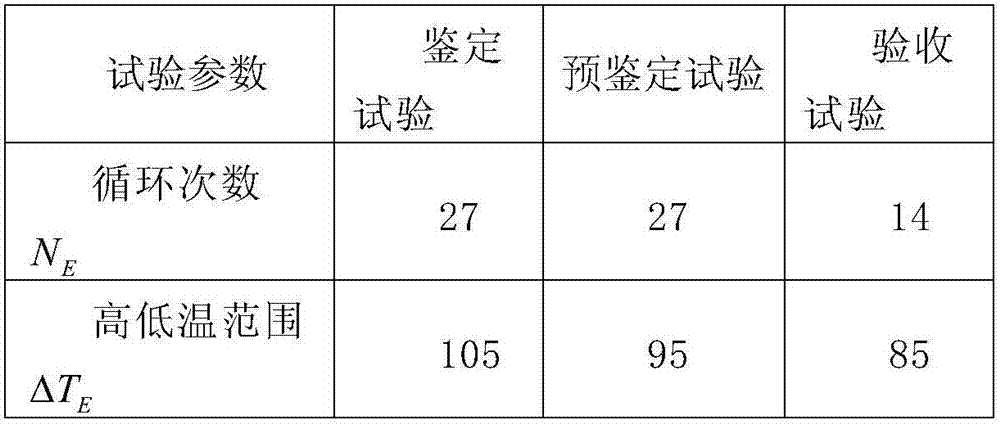

Method for determining rationality of thermal cycling test condition cutting of spacecraft electronic equipment

ActiveCN107545089ACost controlSolve the failure types that cannot cover all types of spacecraftSpecial data processing applicationsThermal fatigueModel parameters

The invention discloses a thermal cycling test condition cutting method suitable for different spacecraft electronic equipment. Based on the statistical law of historical fault distribution and thermal fatigue faults of a subsystem and a single-machine stage of an spacecraft, a comprehensive fatigue acceleration index is obtained by using a re-weighting method, and determining criteria and acquisition methods of underlying model parameters of the spacecraft are also provided. According to the thermal cycling test condition cutting method disclosed by the invention, the problem that a thermalcycling test condition cutting formula in MIL-STD-1540B and GJB 1027-2005 'Test Requirements for Launch Vehicles, Upper Stages and Spacecrafts' cannot cover the fault types of all types of the spacecrafts and all types of the subsystems can be solved, and the cost of the spacecrafts can be controlled on the basis of avoiding over-tests and under-tests.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

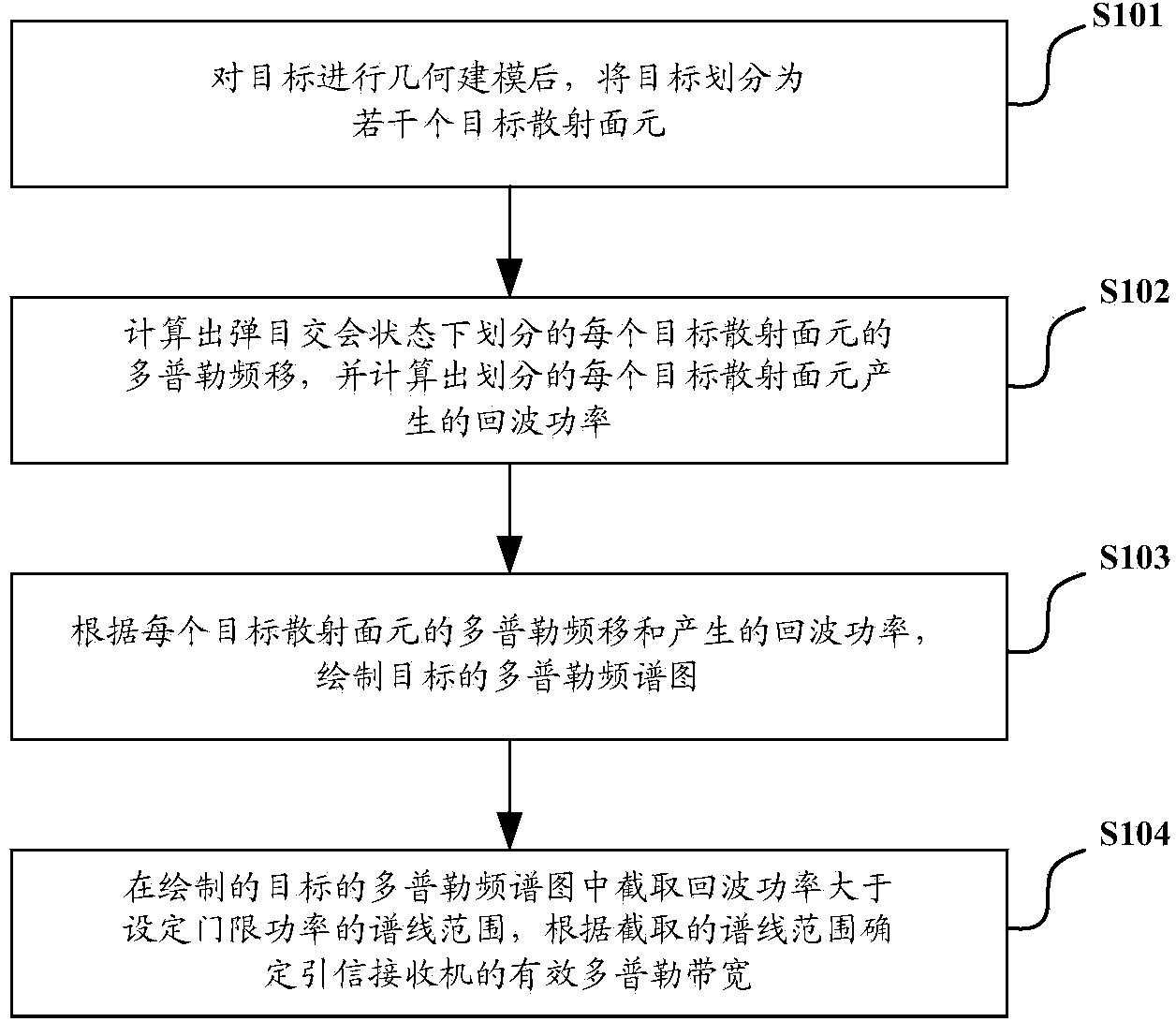

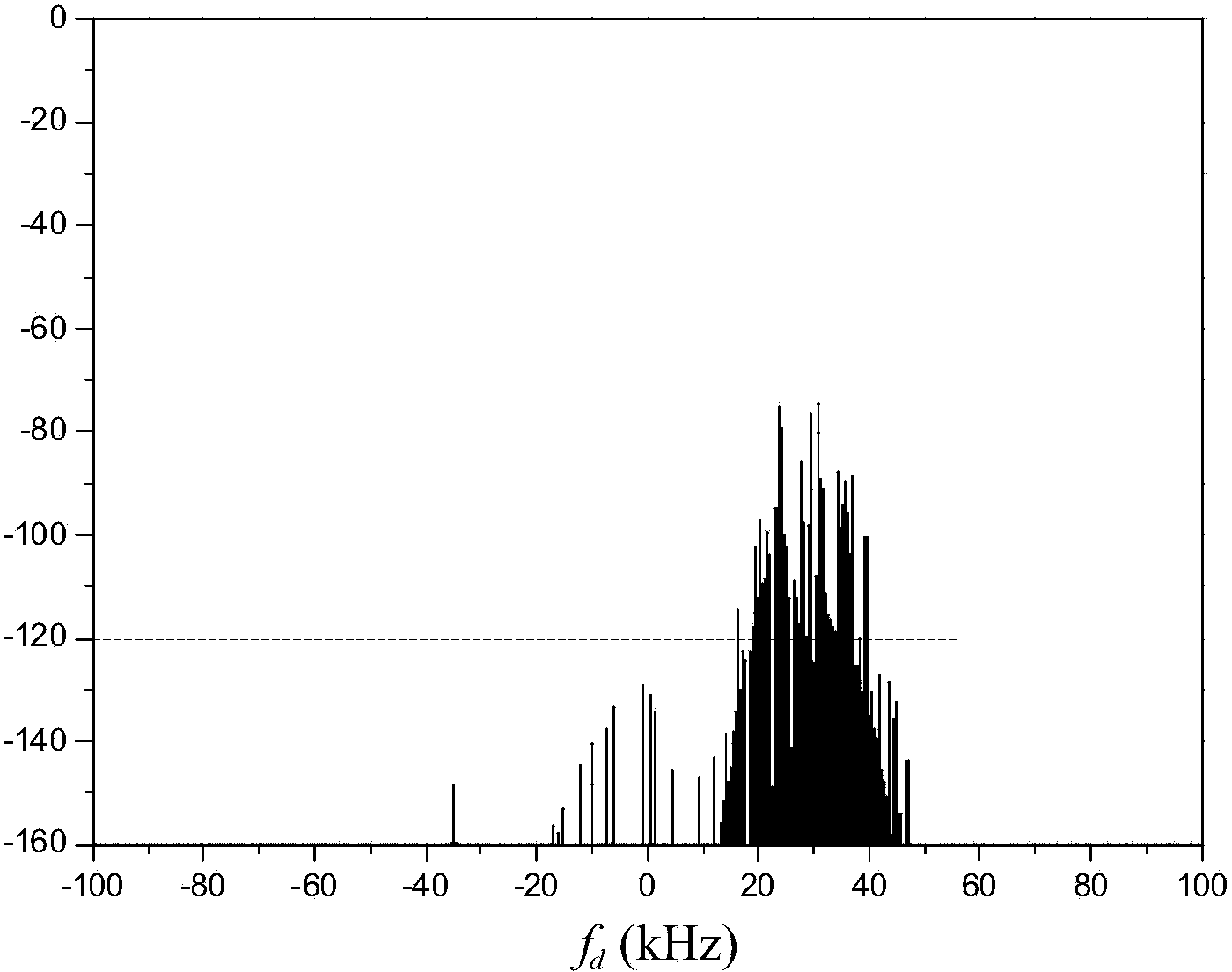

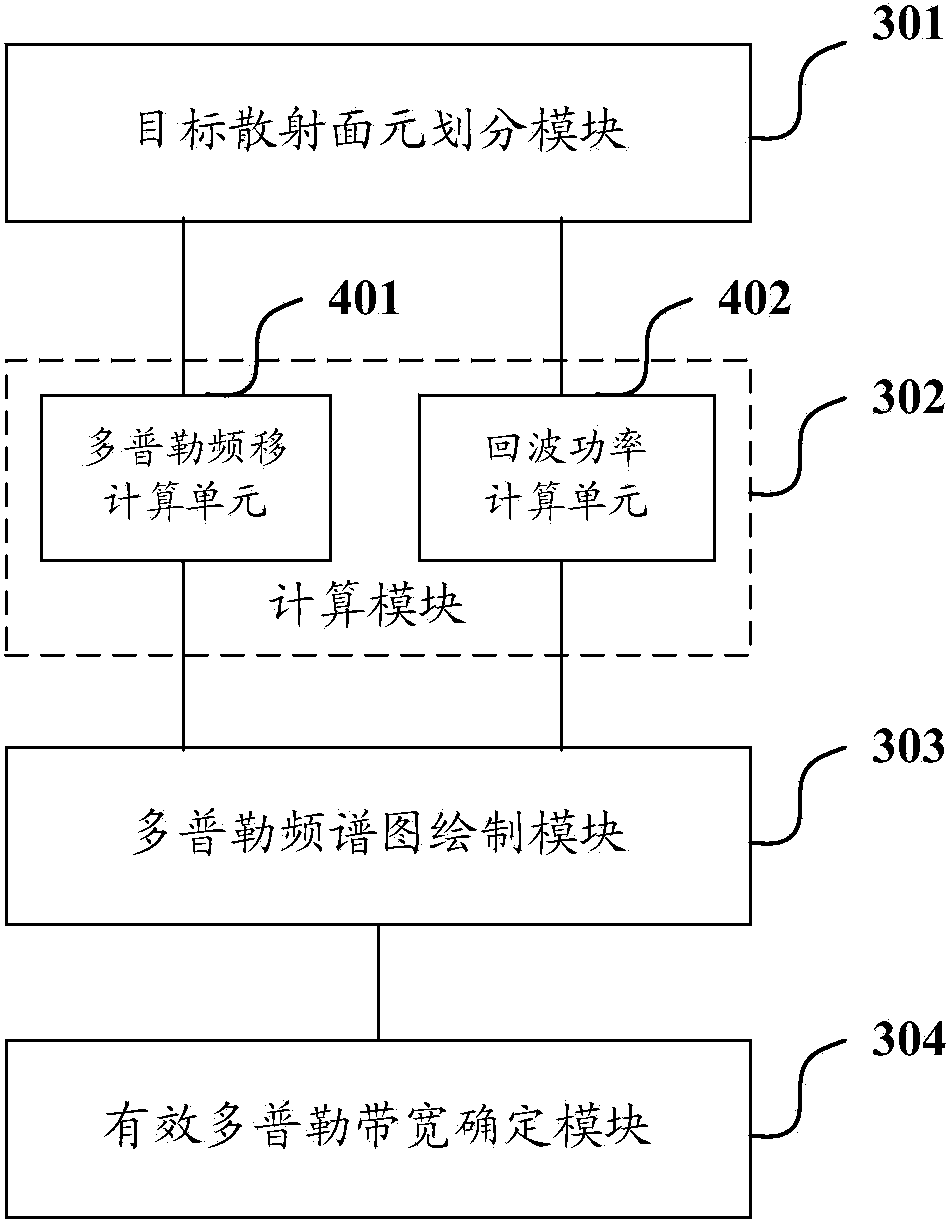

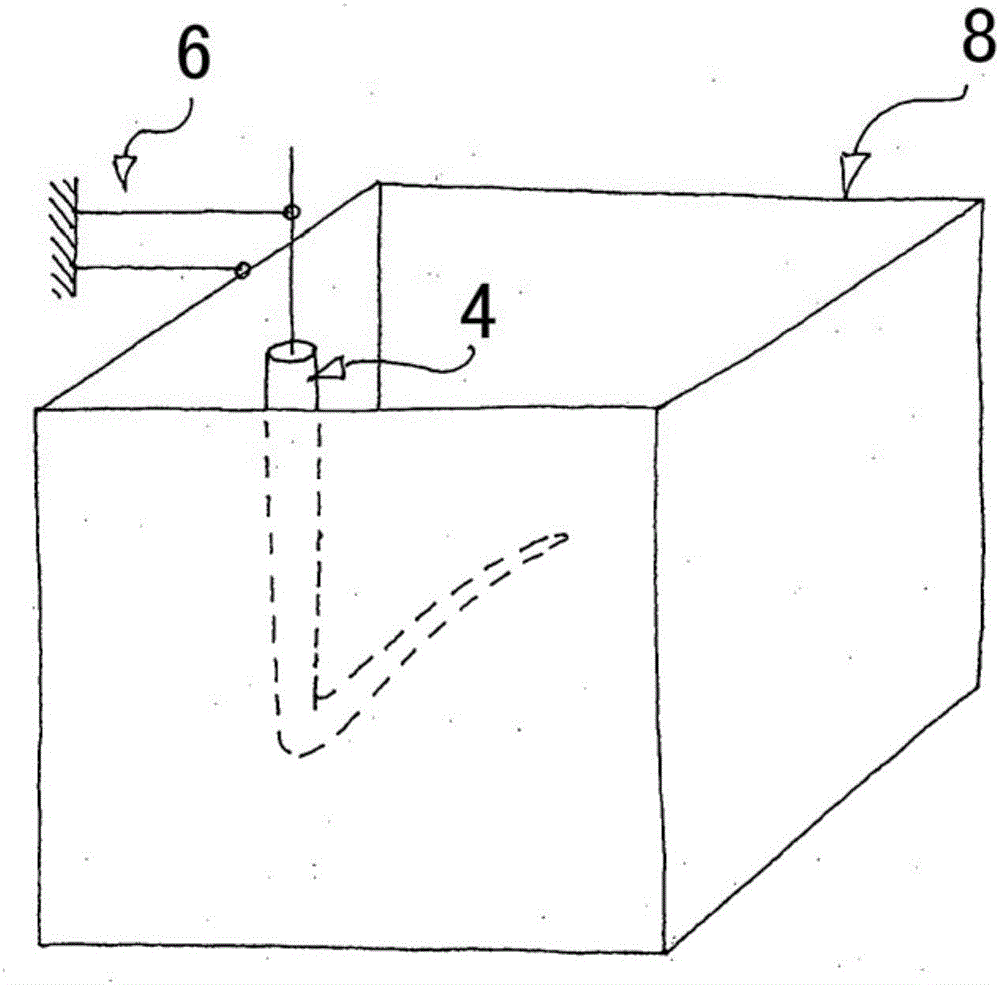

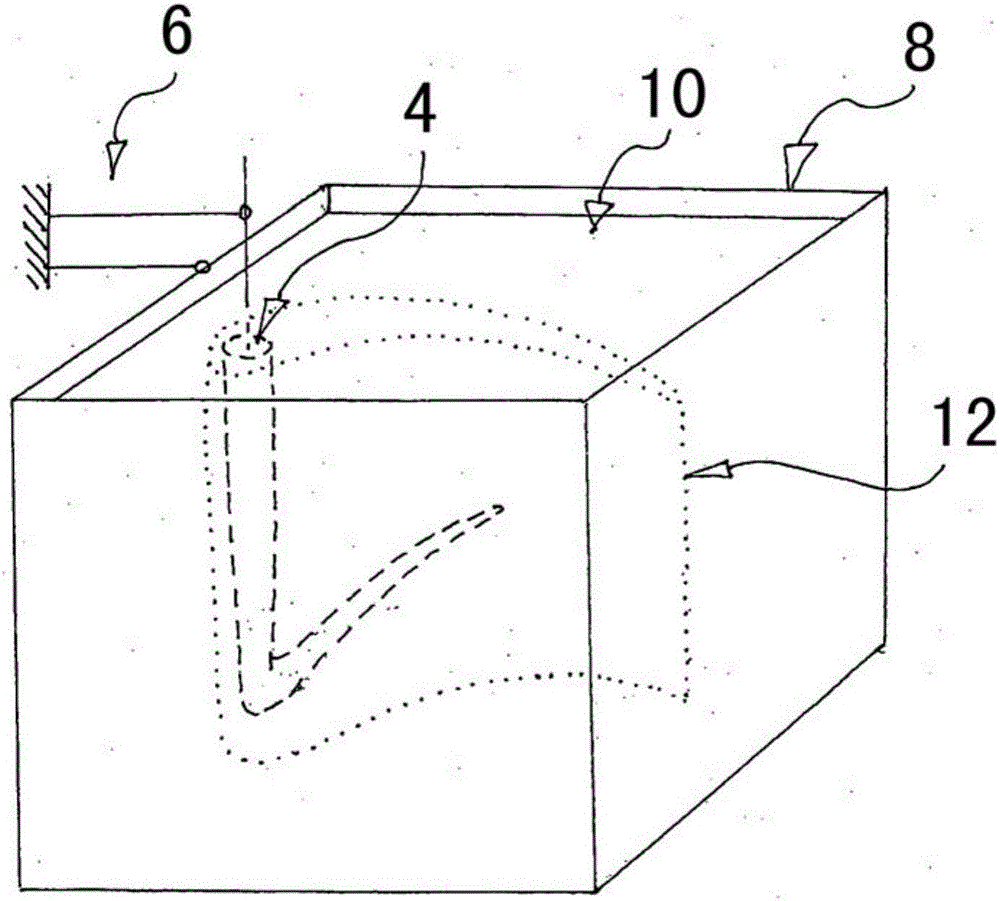

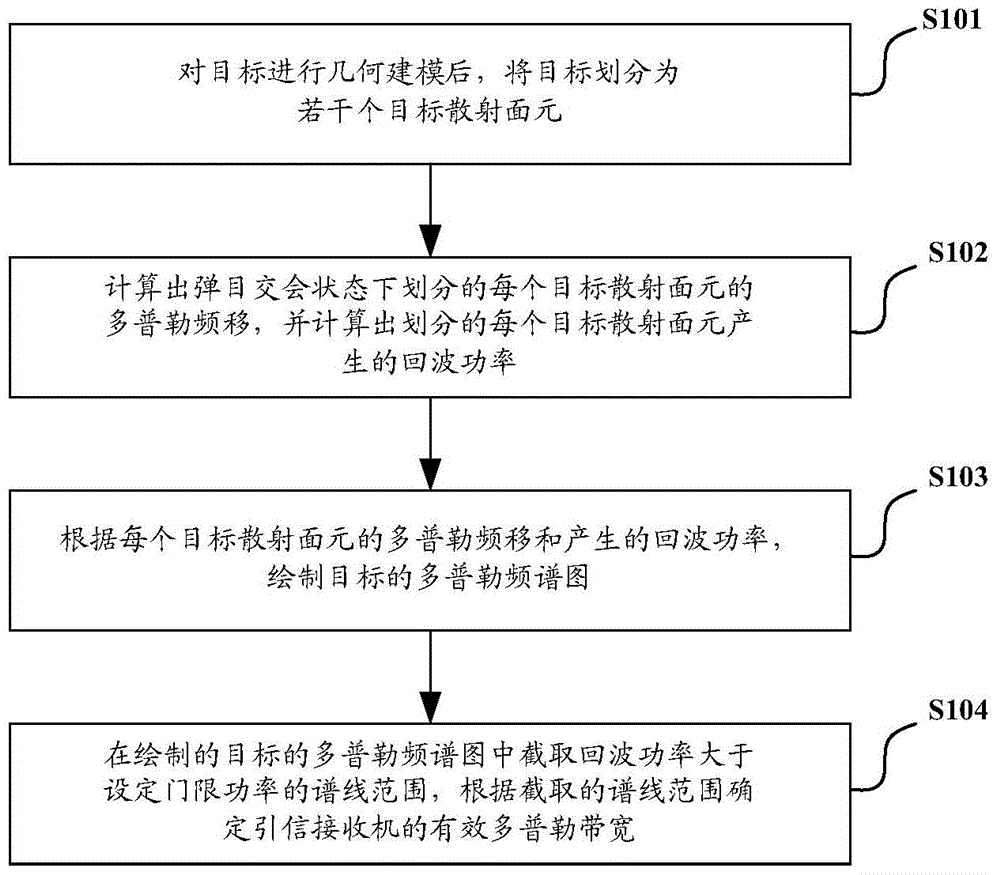

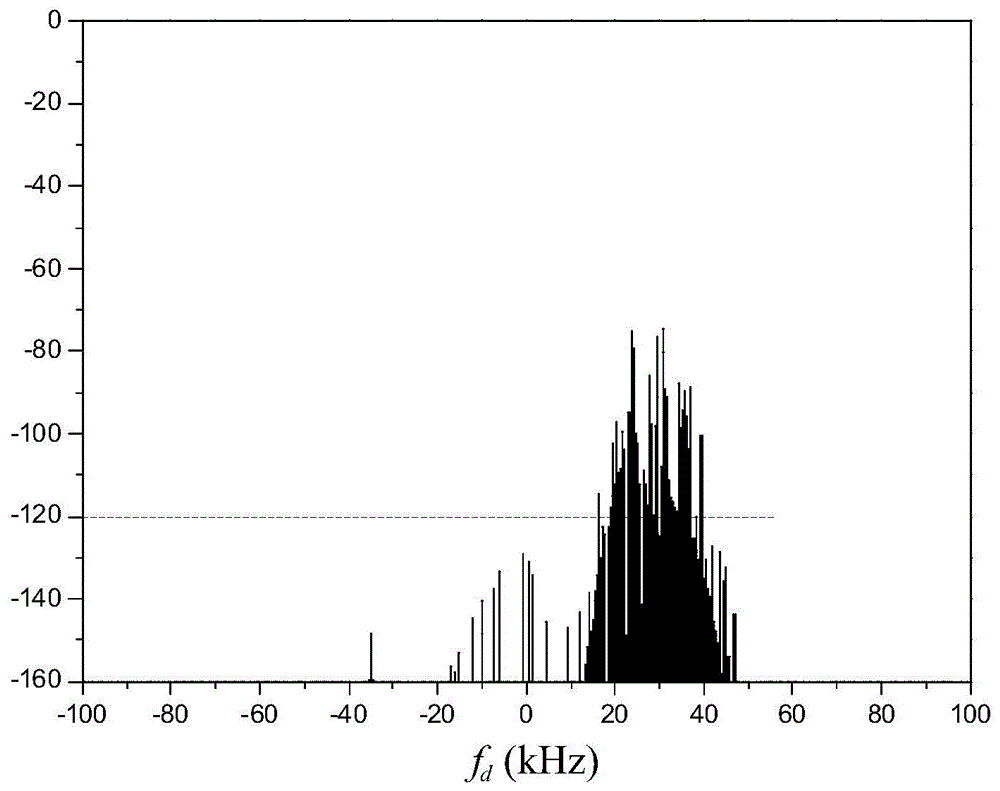

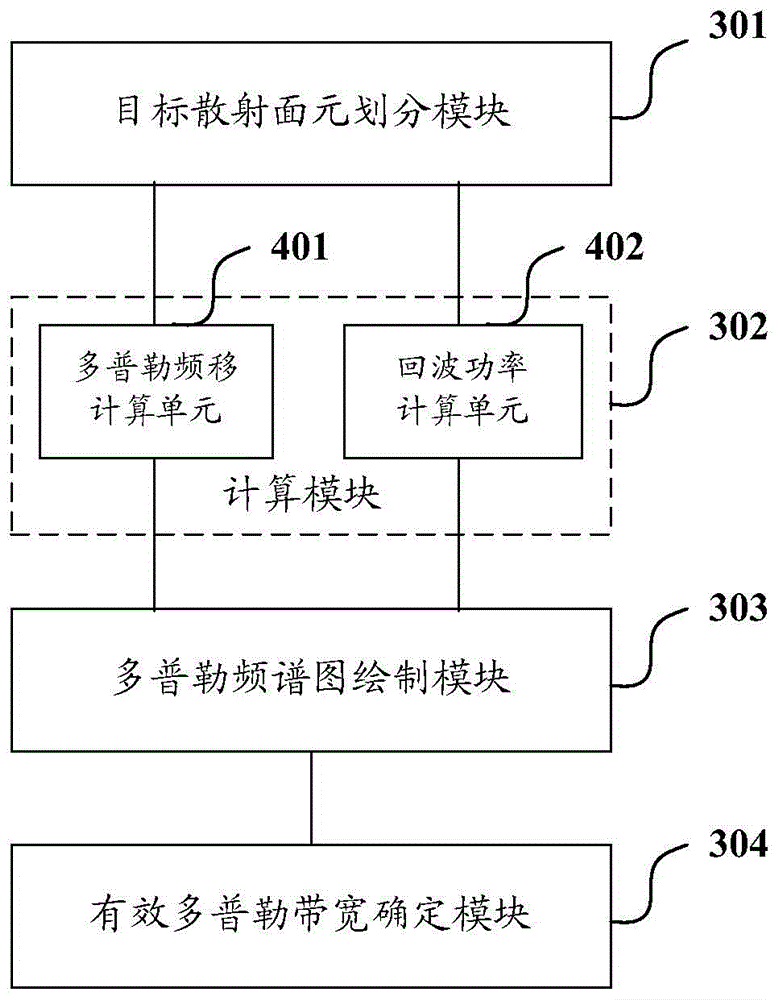

Method and device for determining effective Doppler bandwidth of fuze receiver

ActiveCN104237867AAvoid multiple redesignsAvoid experimentBeacon systems using radio wavesAmmunition fuzesFrequency spectrumGeometric modeling

The invention discloses a method and device for determining the effective Doppler bandwidth of a fuze receiver. The method comprises the steps of dividing a target into multiple target scattering surface elements after geometric modeling is conducted on the target, calculating the Doppler shift of each target scattering surface element and the echo power generated by each target scattering surface element under the missile target encounter condition, drawing a Doppler frequency spectrum diagram of the target according to the calculated Doppler shift and echo power of each target scattering surface element, and cutting out a spectral line range within which echo power is larger than set threshold power from the drawn Doppler frequency spectrum diagram and determining the effective Doppler bandwidth of the fuze receiver according to the cut-out spectral line range. By the adoption of the method and device, estimation of the effective Doppler bandwidth of the fuze receiver can be achieved, so that the fuze receiver can be designed based on the estimated effective Doppler bandwidth of the fuze receiver during fuze slideway testing, and then fuze slideway testing is facilitated.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

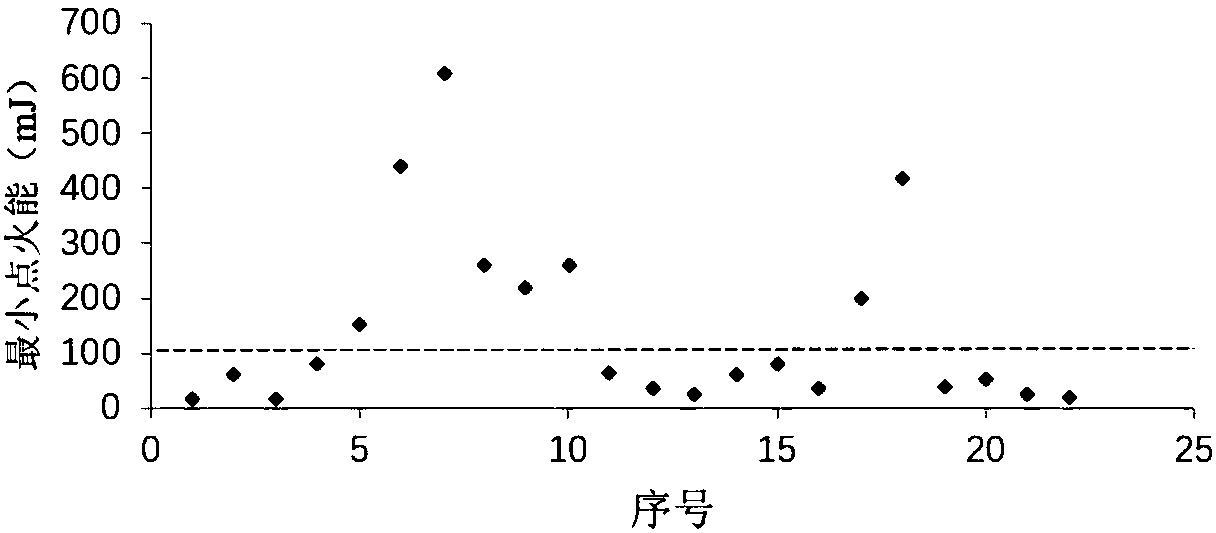

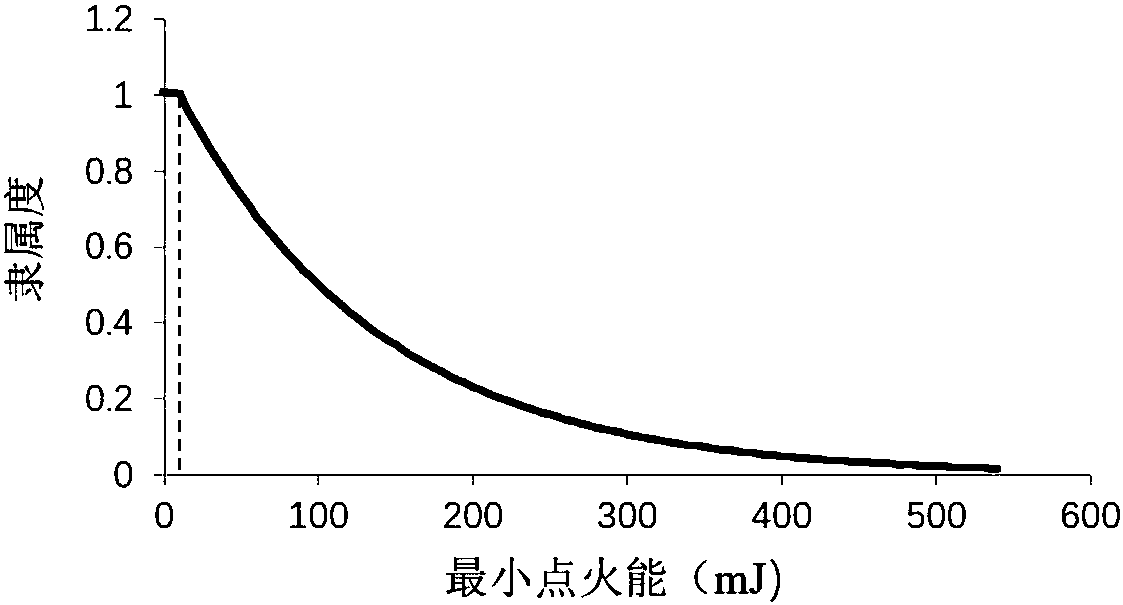

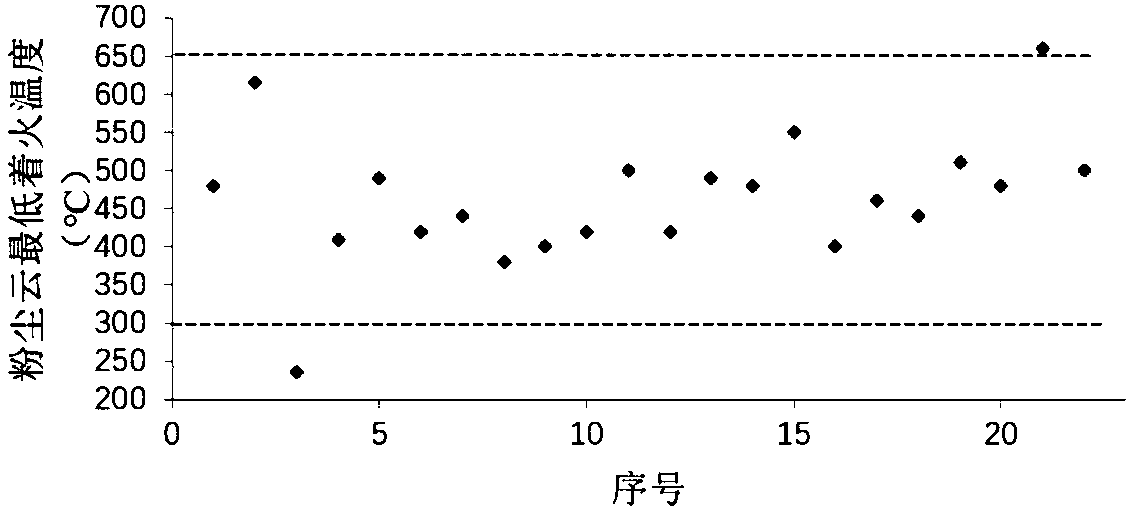

Method for comprehensively evaluating the combustible dust explosion hazard level by utilizing multi-element dust explosion parameters

InactiveCN109389256ARapid identification of explosion hazardsThe evaluation method is simpleResourcesLower limitPressure rise

The invention discloses a method for comprehensively evaluating the combustible dust explosion hazard level by utilizing multi-element dust explosion parameters. The method adopts fuzzy mathematics theory and analytic hierarchy process (AHP) in the system evaluation method, Using representative conventional explosives, According to the minimum ignition energy of dust cloud, the minimum ignition temperature of dust cloud, the minimum ignition temperature of dust layer, the lower limit of explosion, the maximum explosion pressure, the maximum explosion pressure rise rate and the characteristic parameters of explosion index, the membership function is established, and the evaluation model is established to evaluate the explosion hazard of different dust. The comprehensive evaluation method ofthe combustible dust explosion hazard grade established by the invention is simple, Easy to popularize, avoid tedious calculation and test, combine the existing data to obtain the corresponding comprehensive index value, easy to form a common evaluation standard, the result is intuitive, rapid identification of combustible dust dust explosion hazards, can provide guidance for the enterprise design safety production process.

Owner:NANJING UNIV OF SCI & TECH

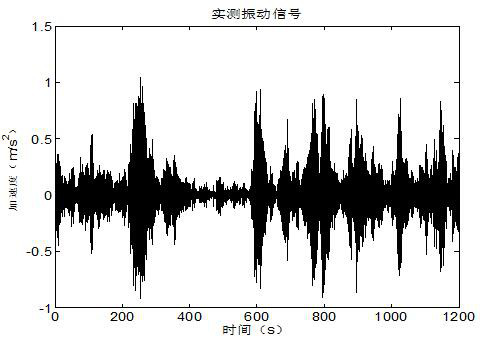

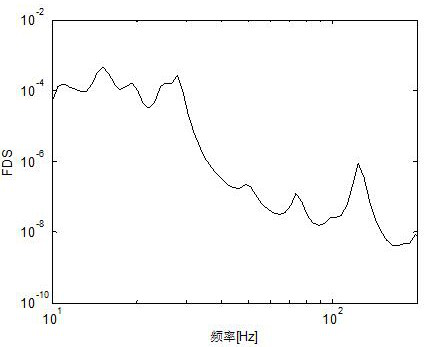

Non-Gaussian load damage equivalent test spectrum optimization method

ActiveCN112199793AImproving the Accuracy of Damage Equivalent Test SpectrumImprove evaluation accuracyGeometric CADDesign optimisation/simulationTime domainEconomic benefits

The invention provides a non-Gaussian load damage equivalent test spectrum optimization method. The method comprises the following operation steps of (1) calculating the FDS of an actually measured signal in a time domain, Q=10, b=4; (2) determining the equivalent test time, and calculating an initial PSD value by utilizing the FDS obtained in the step (1) and a formula (13); (3) calculating FDS in a frequency domain by using the PSD and a frequency domain method, wherein the frequency domain method assumes that a response stress peak value obeys Rayleigh distribution; (4) comparing the FDS calculated in the step (1) with the FDS calculated in the step (3), and if a large error exists, performing iterative optimization on the initial PSD; and (5) calculating the FDS in the frequency domainby using the PSD optimized in the step (4), comparing the FDS with the FDS in the step (1), and obtaining a final damage equivalent test spectrum when the error meets the requirement. According to the method, damage equivalent test spectrum precision of the non-Gaussian load can be effectively improved, over-test and under-test of the product are avoided, and evaluation precision of the reliability and fatigue life of the product is improved, so the economic benefit of a product production enterprise is improved.

Owner:YANCHENG INST OF TECH

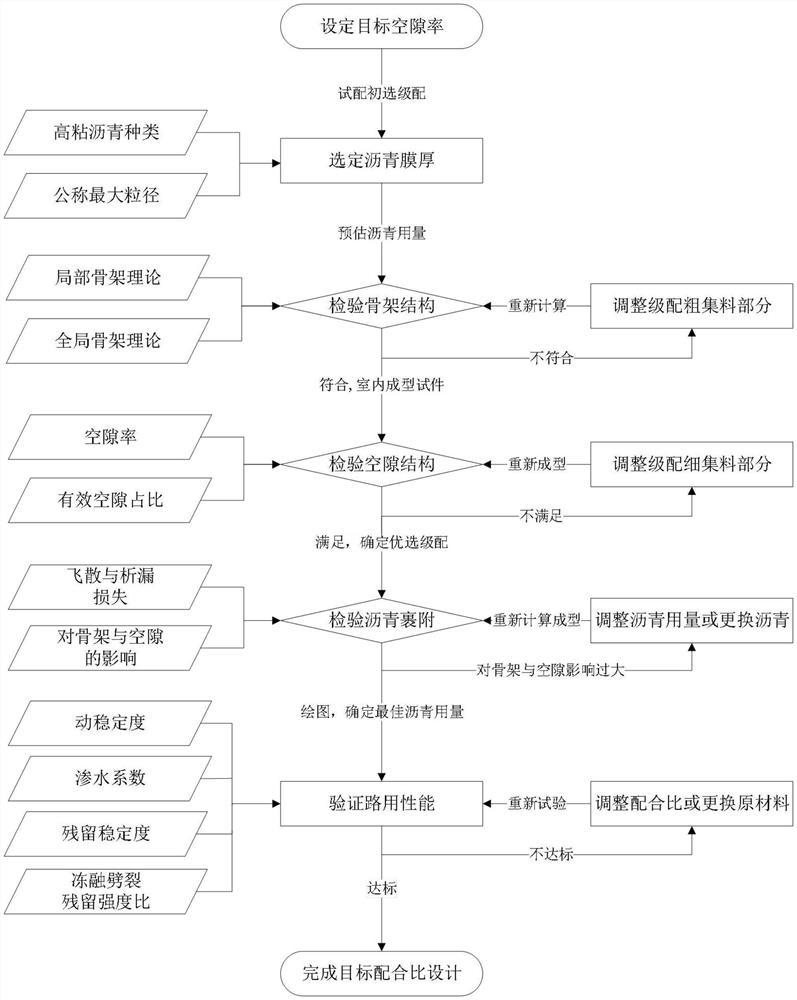

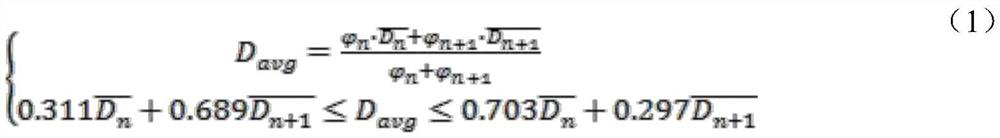

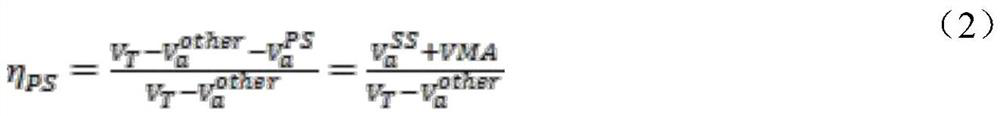

Drainage asphalt mixture optimization design method based on composition mechanism

InactiveCN111892335AGuaranteed design qualityNarrow down the range of available gradesRatio controlStructural engineeringAsphalt

The invention discloses a drainage asphalt mixture optimization design method based on a composition mechanism. The method comprises the following steps: (1) setting a target void ratio, and carryingout grading trial; (2) selecting a corresponding asphalt film thickness according to the type of the used high-viscosity asphalt and the nominal maximum particle size, and estimating the asphalt consumption; (3) checking a skeleton structure, sequentially checking a local skeleton and a global skeleton of each primary gradation according to a gradation skeleton theory suitable for the drainage asphalt mixture, and determining a gradation coarse aggregate part; (4) inspecting the void structure, forming a Marshall test piece, sequentially inspecting the void ratio and the effective void ratio according to the effective void ratio requirements of different nominal maximum particle sizes PAC, and determining optimal gradation; (5) determining the optimal asphalt-aggregate ratio, and inspecting asphalt coating; and (6) performing a performance test, and verifying the pavement performance. According to the method, each design link corresponds to each key performance, optimization and adjustment can be carried out in a targeted manner, and the test time and consumables are saved while the design quality of the drainage asphalt mixture is ensured.

Owner:SOUTHEAST UNIV

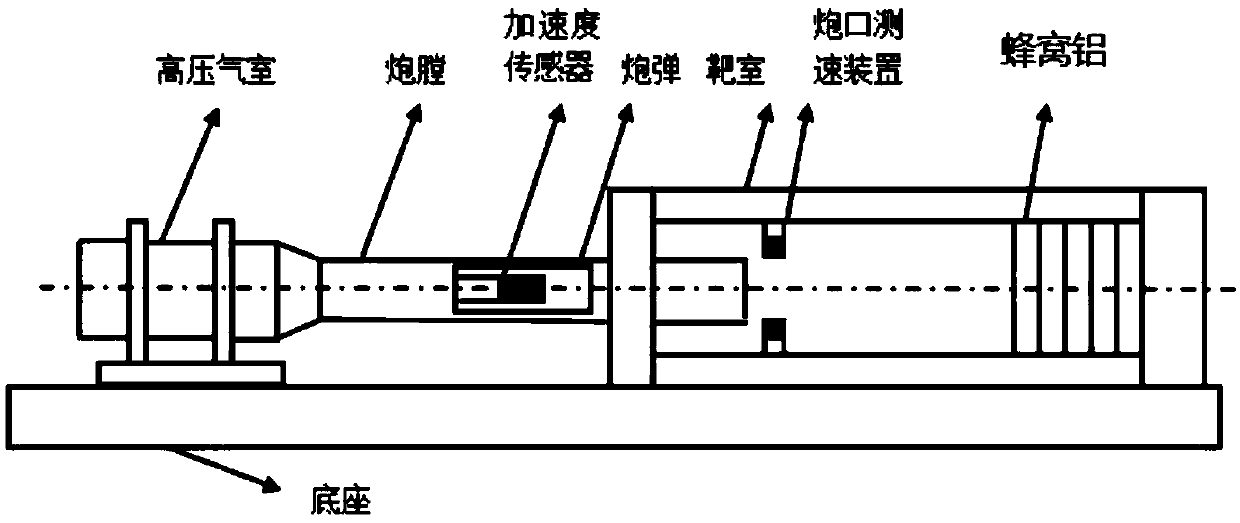

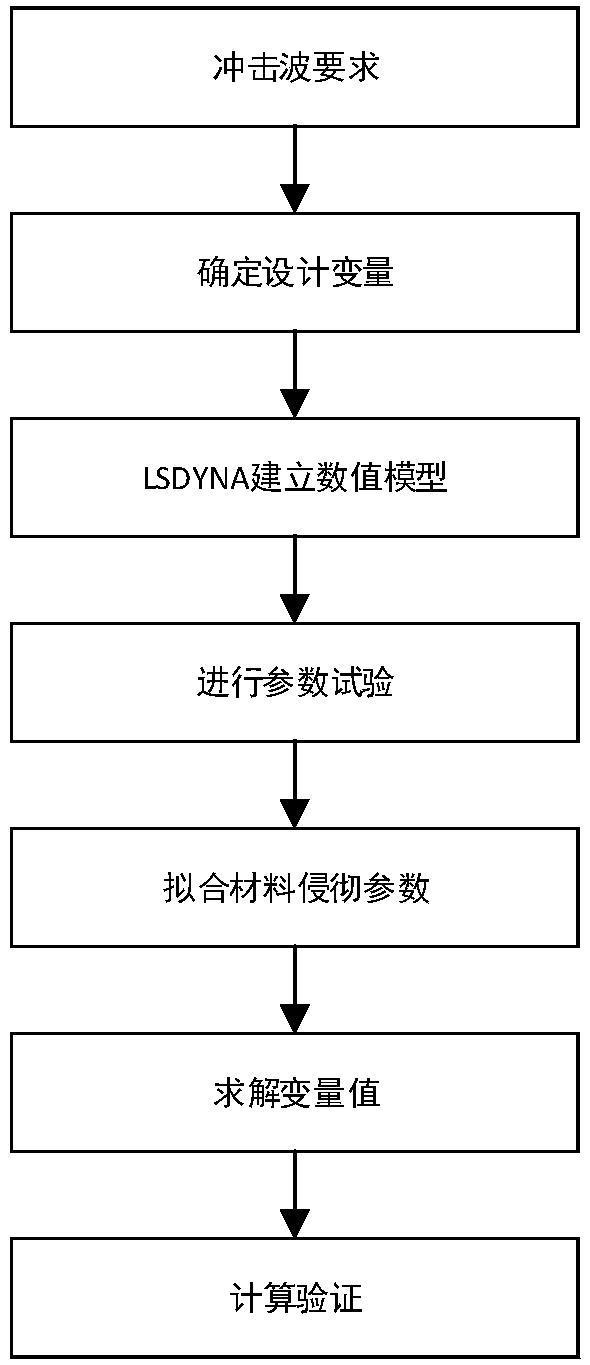

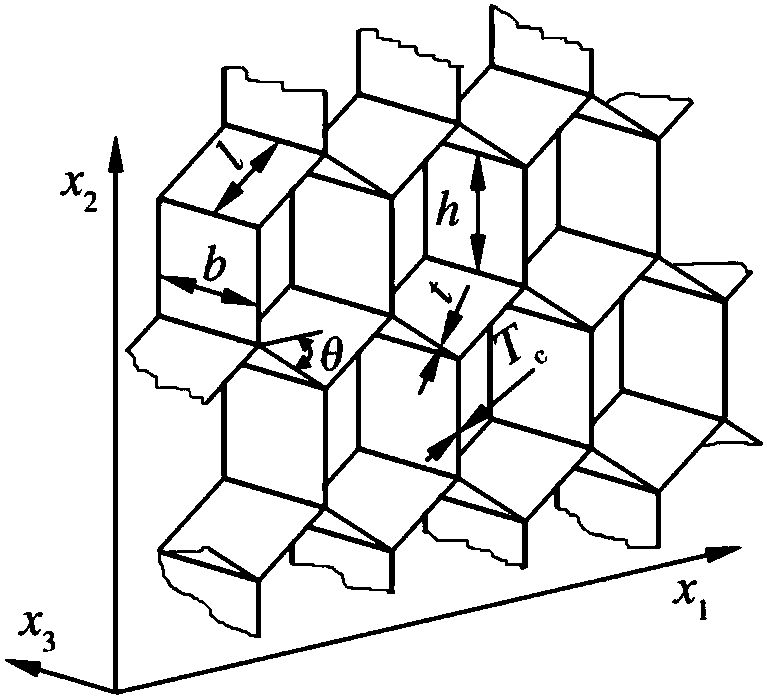

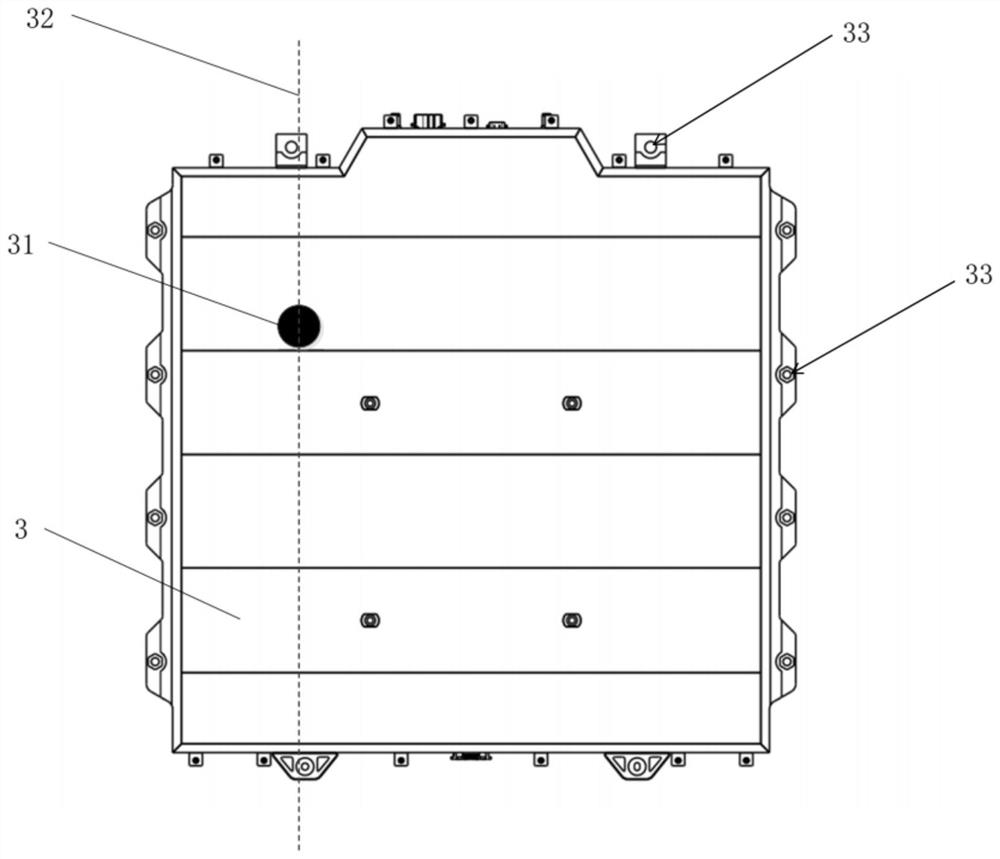

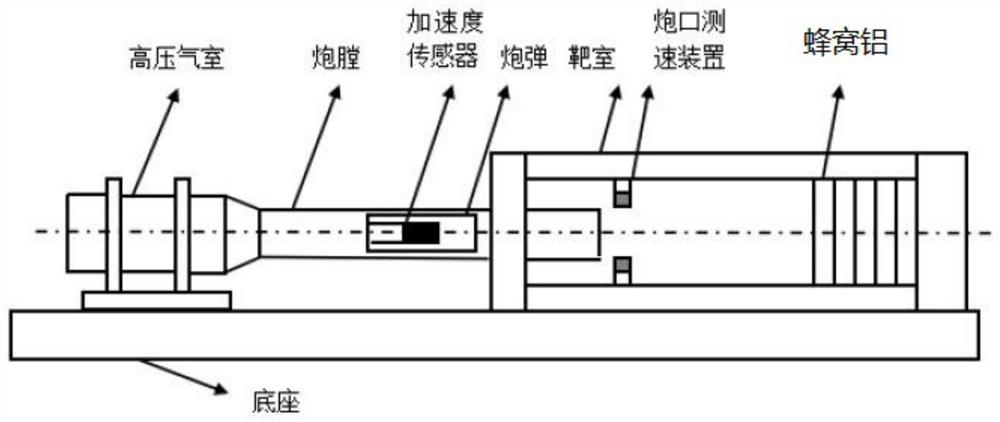

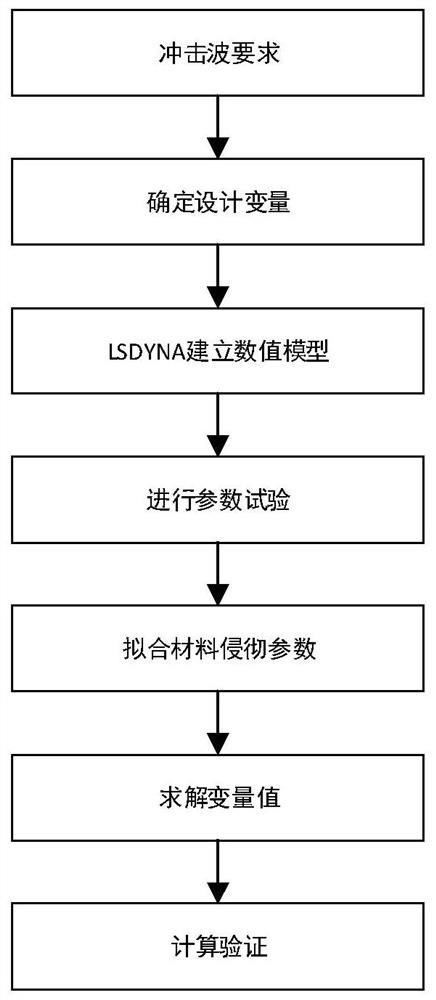

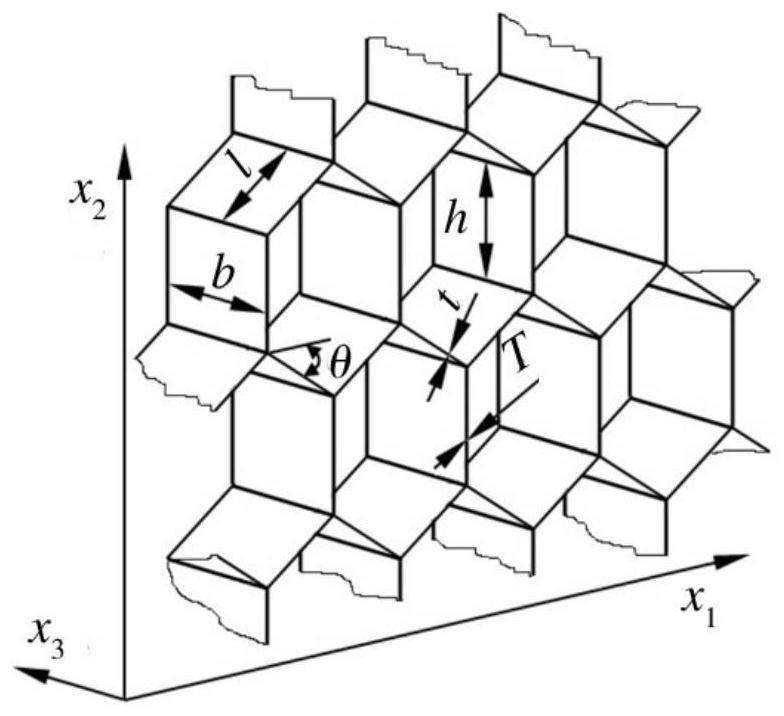

Simulation-based high-G-value broad pulse impact waveform design method

ActiveCN107563106ARapid designShort cycleSpecial data processing applicationsAluminum honeycombSimulation based

The invention discloses a simulation-based high-G-value broad pulse impact waveform design method. The simulation-based high-G-value broad pulse impact waveform design method comprises the following steps: firstly, making impact wave index requirements and design variable to be clear, and calculating relative density of an aluminum honeycomb core in an aluminum honeycomb sandwich plate; secondly,establishing a projectile penetration impact-reduction numerical experimentation model according to the design variable and carrying out parameter experiments to obtain a curve of accelerated speed changed along with speed under aluminum honeycombs with different relative densities; thirdly, fitting penetration coefficients of different buffer materials to obtain cavity expansion model equations of the different materials, then calculating required impact initial speed and the speed and the accelerated speed of projectiles moving to the center point of each aluminum honeycomb sandwich plate, and substituting the speeds and the accelerated speeds into the cavity expansion model equations of the different materials to obtain the relative density value of each aluminum honeycomb core; and finally, inputting the relative density values into projectile penetration impact-reduction numerical experimentation model to obtain high-G-value wide-pulse impact waveform. The simulation-based high-G-value broad pulse impact waveform design method is suitable for impact wave waveform design in various standards; and the design period is short, the design method is speedy, and the efficiency is high.

Owner:NANJING UNIV OF SCI & TECH

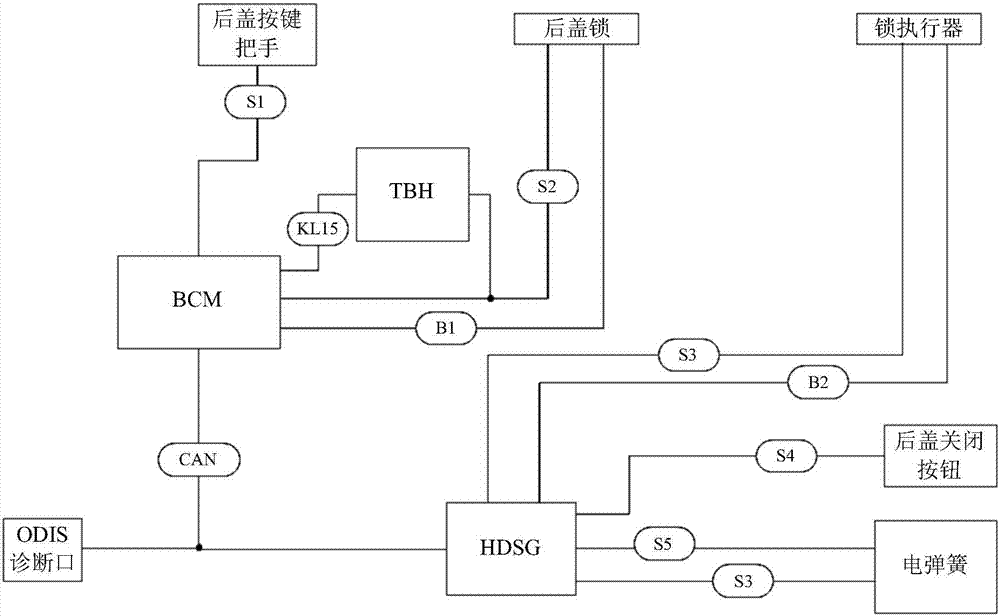

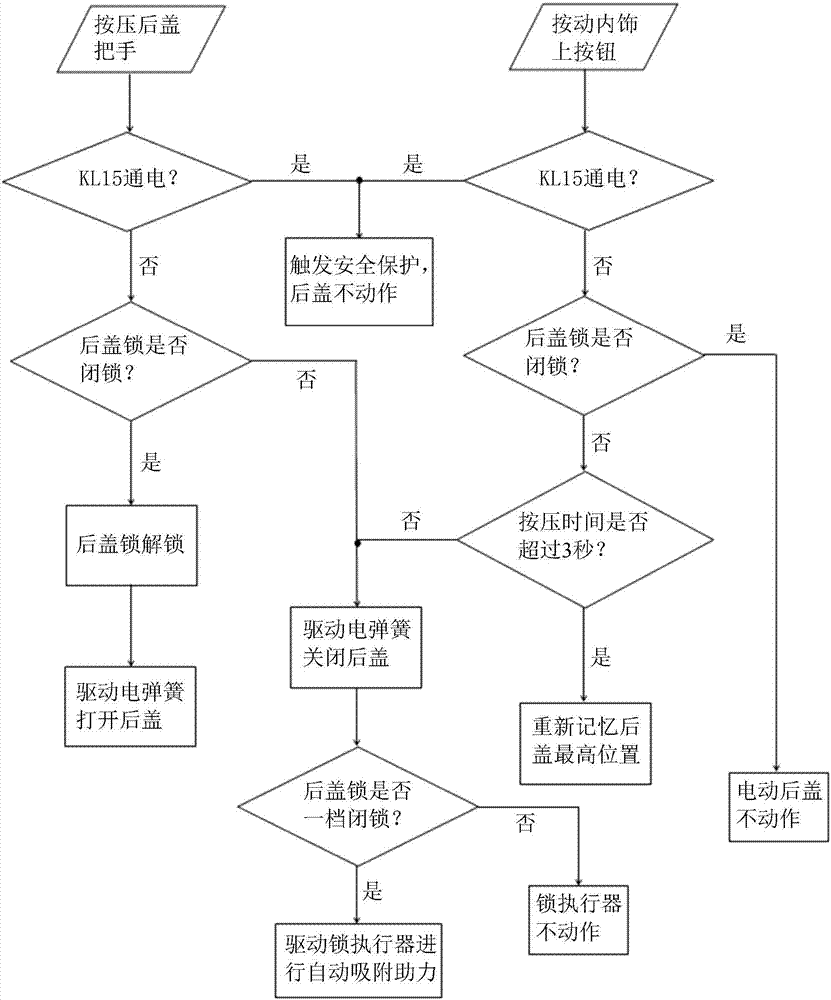

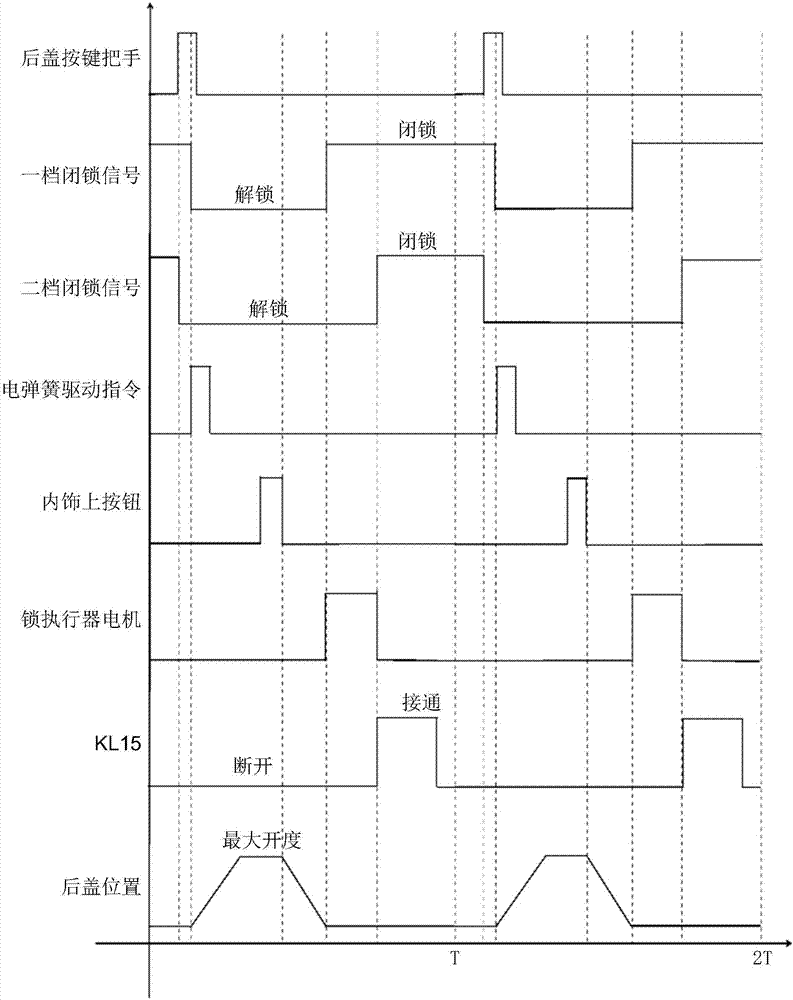

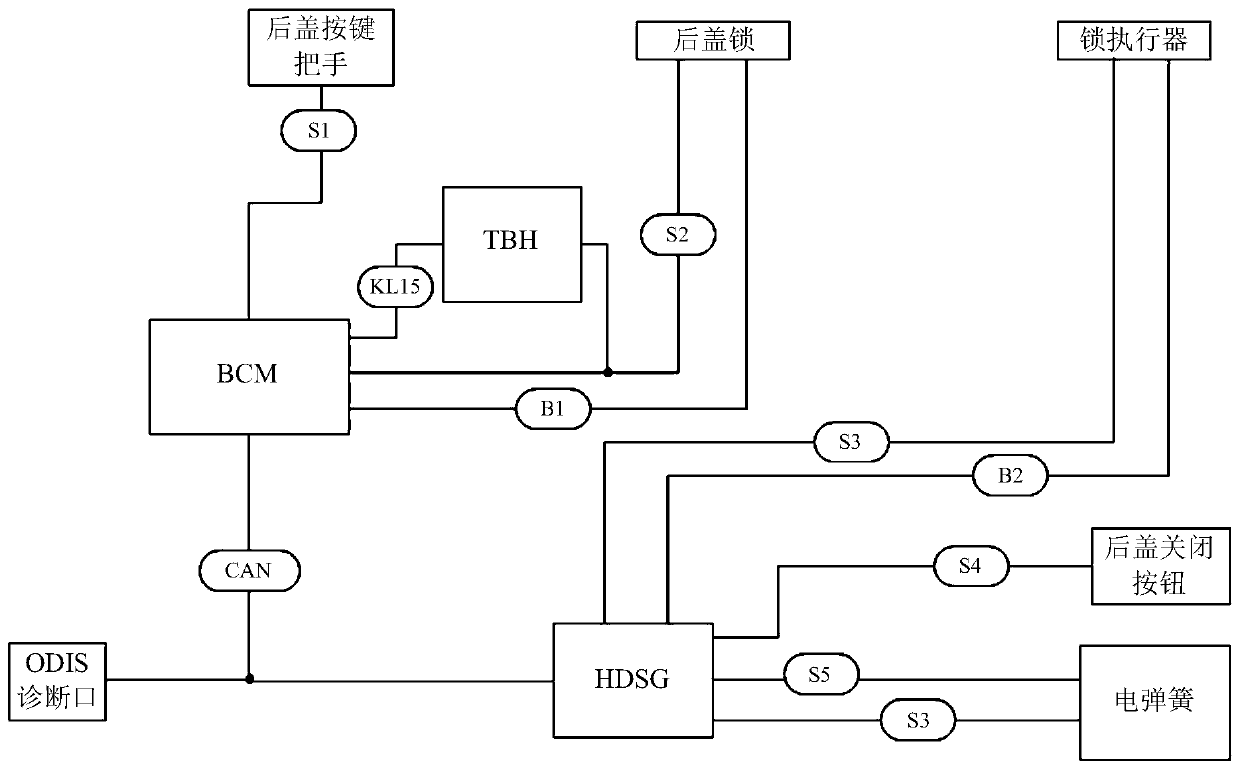

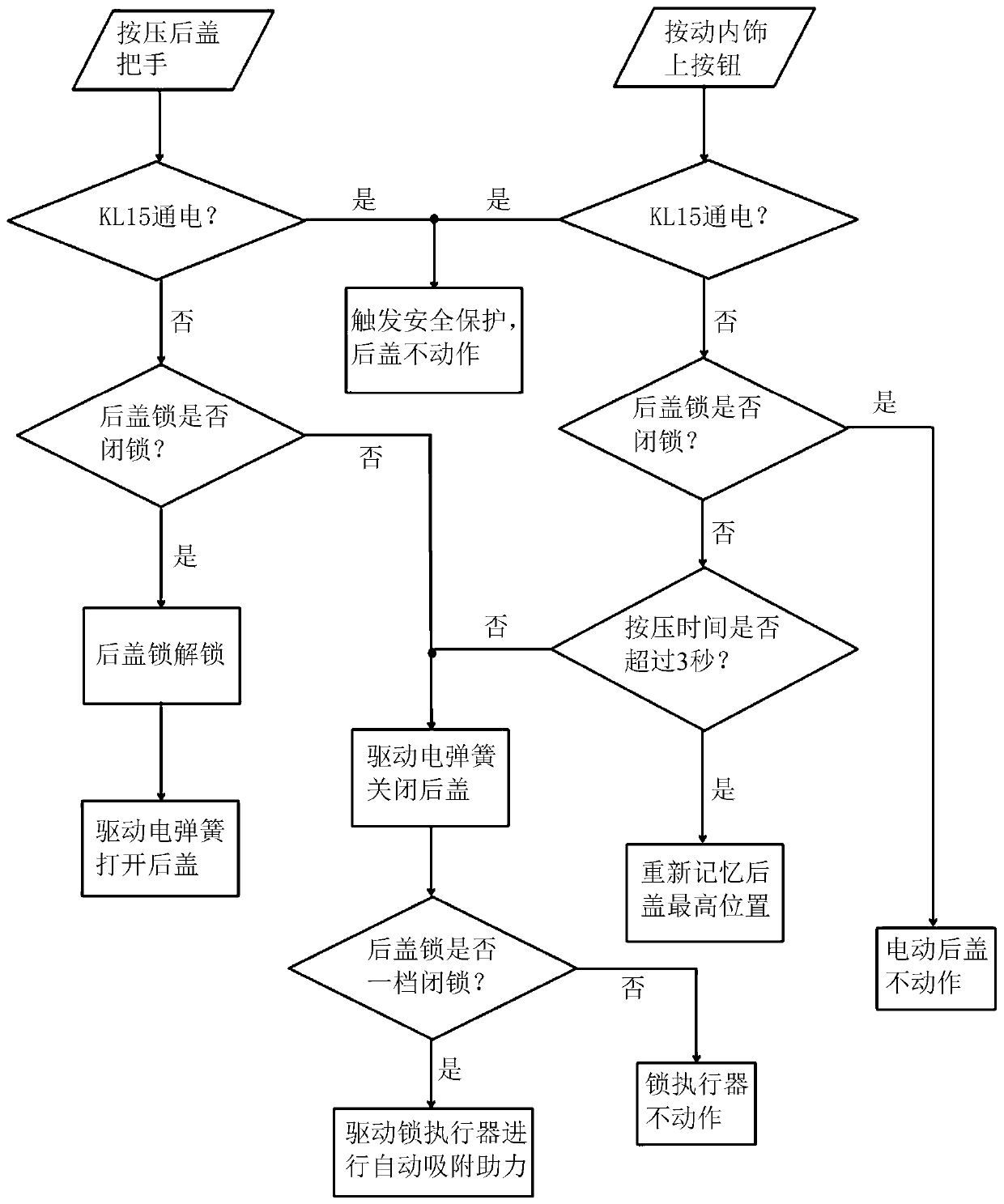

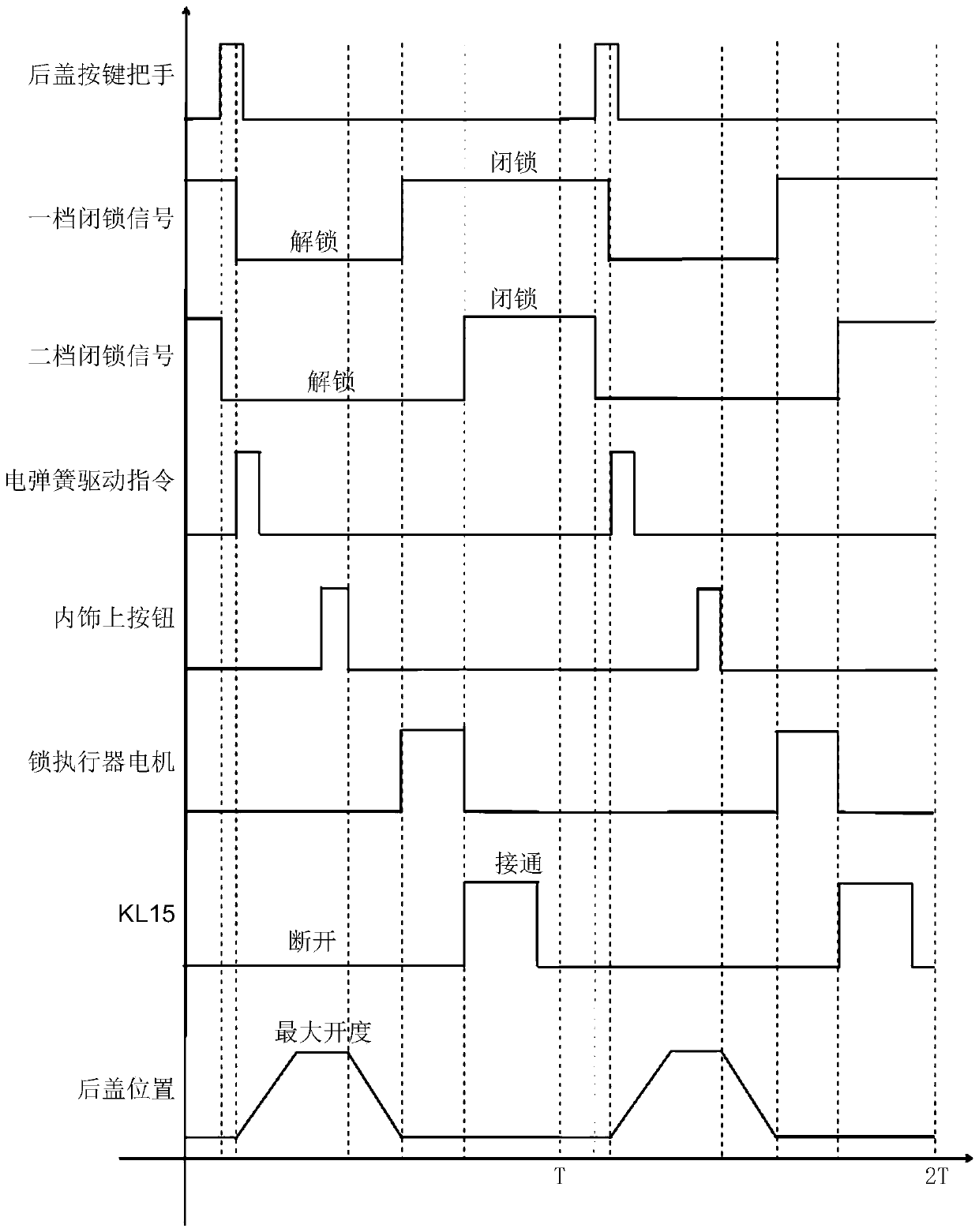

Electric-rear-cover durability test bench

ActiveCN107132059AEasy to implement architectureImprove general performanceVehicle testingOn boardControl system

The invention discloses an electric-rear-cover durability test bench. An electric-rear-cover durability test can be implemented on a body in white, experiment with an entire vehicle is avoided, and test cost is remarkably reduced; the technical scheme includes that a mode that a BCM (body control module) and a HDSG and are combined with a non-on-board controller (TBH) forms a control system of the test bench; only one type of a CAN data bus is related, so that a gateway can be bypassed, and direct access to a vehicle diagnosis port is achieved to perform detection on the running state of an electric rear cover.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Investment casting of hollow components

InactiveCN105792962AShorten cycle timeAvoid experimentAdditive manufacturing apparatusFoundry moulds3d patterningInvestment casting

The invention relates to a method for producing a cast component which has cavity structures, using a 3D pattern of digital geometrical coordinates of the cast component by means of a ceramic mold, said method comprising the following steps: a) producing the core according to the 3D pattern by CNC technology in a first CNC production method; b) positioning the core in a treatment support; c) casting the pattern material around the core in a volume that is larger than the cubature of the cast component which according to the 3D pattern is spatially defined by the position of the core in the treatment support, and allowing the pattern material to solidify; d) producing an outer contour of a disposable pattern of the cast component from the solidified pattern material around the core according to the 3D pattern by CNC technology in a second CNC production method; e) applying a ceramic mold to the outer contour of the disposable pattern and forming a positioning connection of the ceramic mold and the treatment support; f) removing the disposable pattern from the ceramic mold around the core in the treatment support; g) casting metal into the ceramic mold around the core in the treatment support; h) allowing the molten metal to solidify to the solid cast component and i) removing the ceramic mold and the core from the cast component.

Owner:FLC FLOWCASTINGS

Method and device for determining effective Doppler bandwidth of fuze receiver

ActiveCN104237867BAvoid multiple redesignsAvoid experimentBeacon systems using radio wavesAmmunition fuzesFrequency spectrumGeometric modeling

The invention discloses a method and device for determining the effective Doppler bandwidth of a fuze receiver. The method comprises the steps of dividing a target into multiple target scattering surface elements after geometric modeling is conducted on the target, calculating the Doppler shift of each target scattering surface element and the echo power generated by each target scattering surface element under the missile target encounter condition, drawing a Doppler frequency spectrum diagram of the target according to the calculated Doppler shift and echo power of each target scattering surface element, and cutting out a spectral line range within which echo power is larger than set threshold power from the drawn Doppler frequency spectrum diagram and determining the effective Doppler bandwidth of the fuze receiver according to the cut-out spectral line range. By the adoption of the method and device, estimation of the effective Doppler bandwidth of the fuze receiver can be achieved, so that the fuze receiver can be designed based on the estimated effective Doppler bandwidth of the fuze receiver during fuze slideway testing, and then fuze slideway testing is facilitated.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

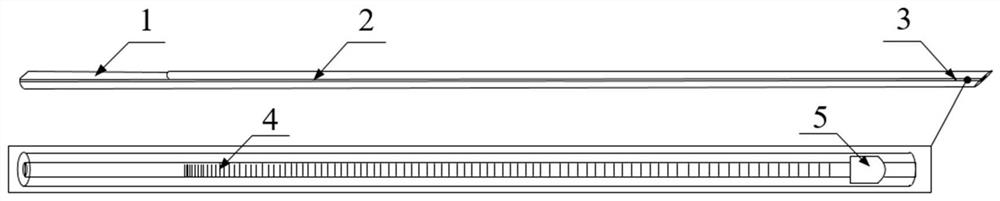

Force-shape self-sensing puncture needle based on light interference and long grating chirp effect

PendingCN114098837AAvoid experimentSurgical needlesVaccination/ovulation diagnosticsAspiration biopsyFiber gratings

The invention discloses a force-shape self-sensing puncture needle based on light interference and long grating chirp effect, which comprises a needle body, a positioning plane is arranged at one end of the needle body far away from a needle tip, Ng U-shaped grooves are uniformly arranged on the side wall of the needle body, first to Ng optical fibers are respectively arranged in the U-shaped grooves, Ng is greater than or equal to 3, and Ng is greater than or equal to 3. Each optical fiber is provided with a segment of chirp fiber grating and an F-P cavity, the chirp fiber grating is arranged at one end far away from the needle tip, the F-P cavity is arranged at one end close to the needle tip, and the chirp fiber grating and the F-P cavity are spaced by a certain distance. According to the invention, the precise monitoring of the whole trace morphological change of the puncture needle and the stress condition of the tip in the needle biopsy operation process is realized.

Owner:WUHAN UNIV OF TECH

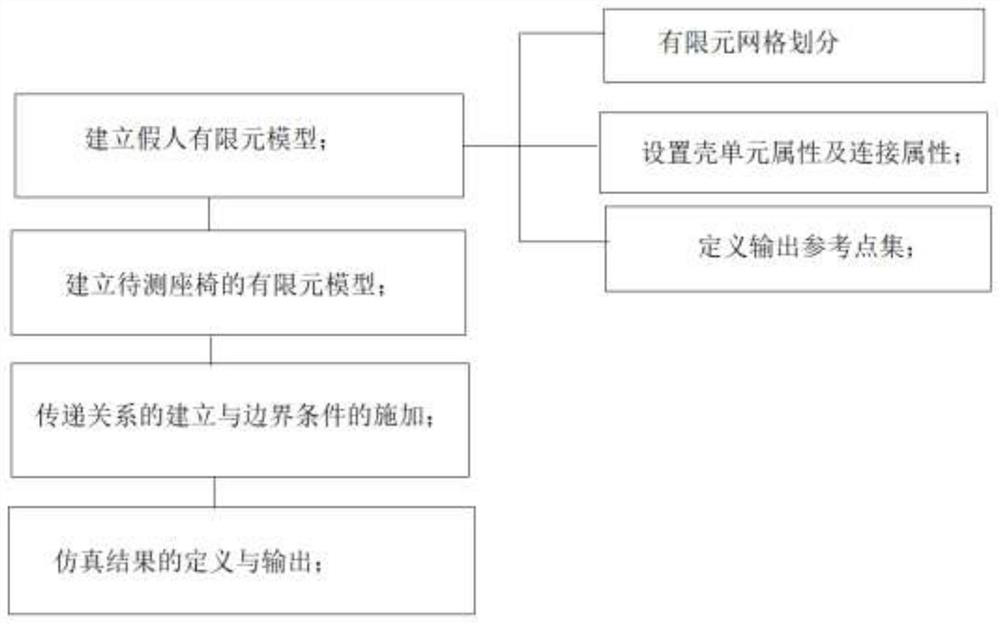

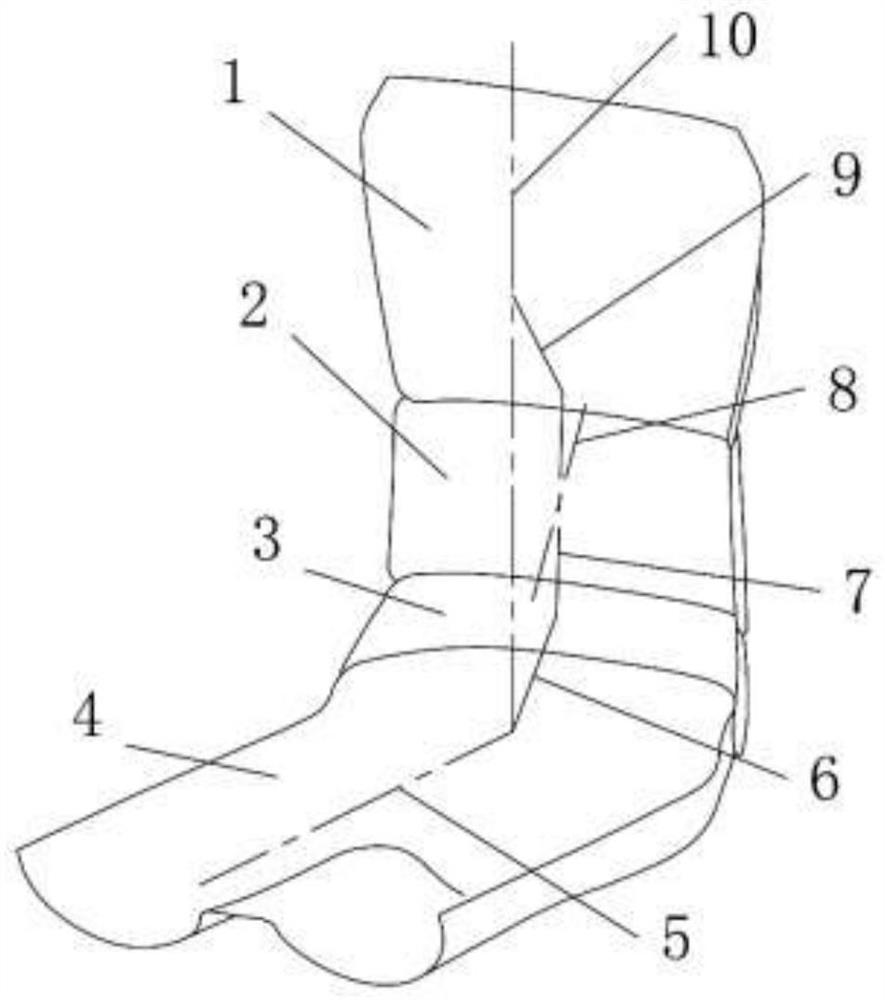

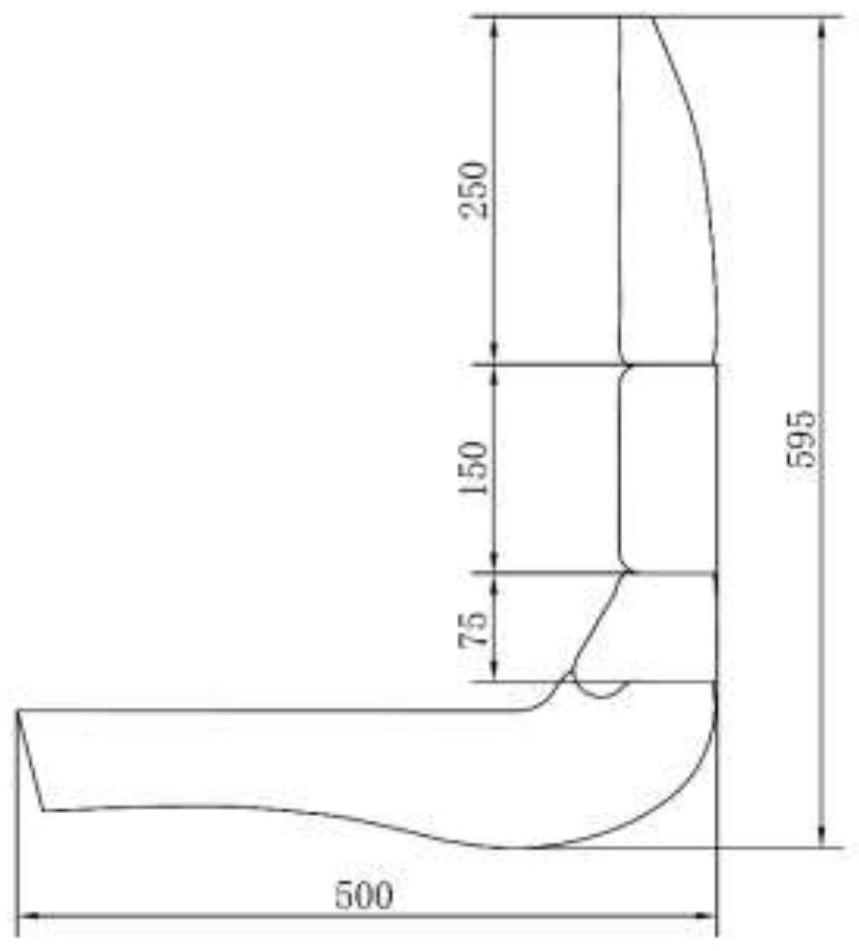

Seat hard point and hard point size rapid simulation calculation method

PendingCN114722684AReduce complexityAvoid trial productionGeometric CADSustainable transportationElement modelMechanical engineering

The invention discloses a seat hard point and hard point size rapid simulation calculation method, and belongs to the technical field of seat development, and the method comprises the steps: building a dummy finite element model, building a finite element model of a to-be-tested seat, building a transmission relation, applying a boundary condition, and defining and outputting a simulation result. According to the method, the finite element simulation technology is used for conducting rapid simulation measurement on the hard point and the size of the hard point, when a simulation result and a design target reach a certain consistency degree, a sample piece is manufactured for physical verification, and evaluation and improvement of a design scheme in the concept stage are facilitated. In addition, the method also has the characteristics of low investment, low cost, convenience, rapidness, accurate and objective result, flexible application and the like. An accurate transmission relation between model input and parameter output is found, the complexity of the model is reduced as much as possible, and the accuracy of a result is improved. The simulation technology is utilized to directly avoid multiple times of sample piece trial-manufacturing and testing, and rapid measurement and verification can be rapidly and conveniently carried out at any time in the design process.

Owner:JILIN UNIV

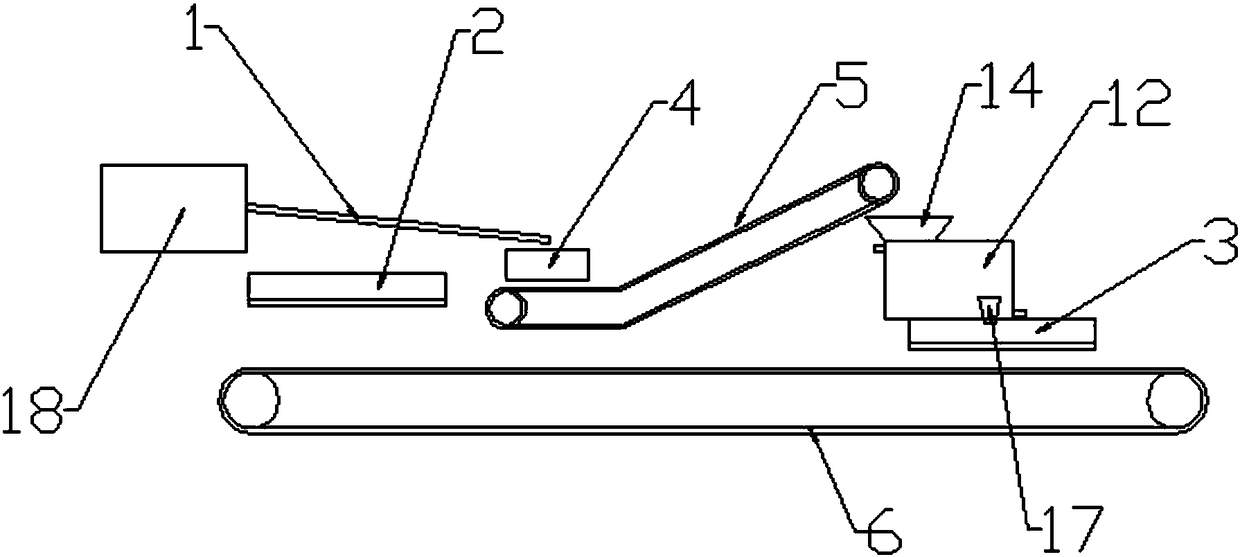

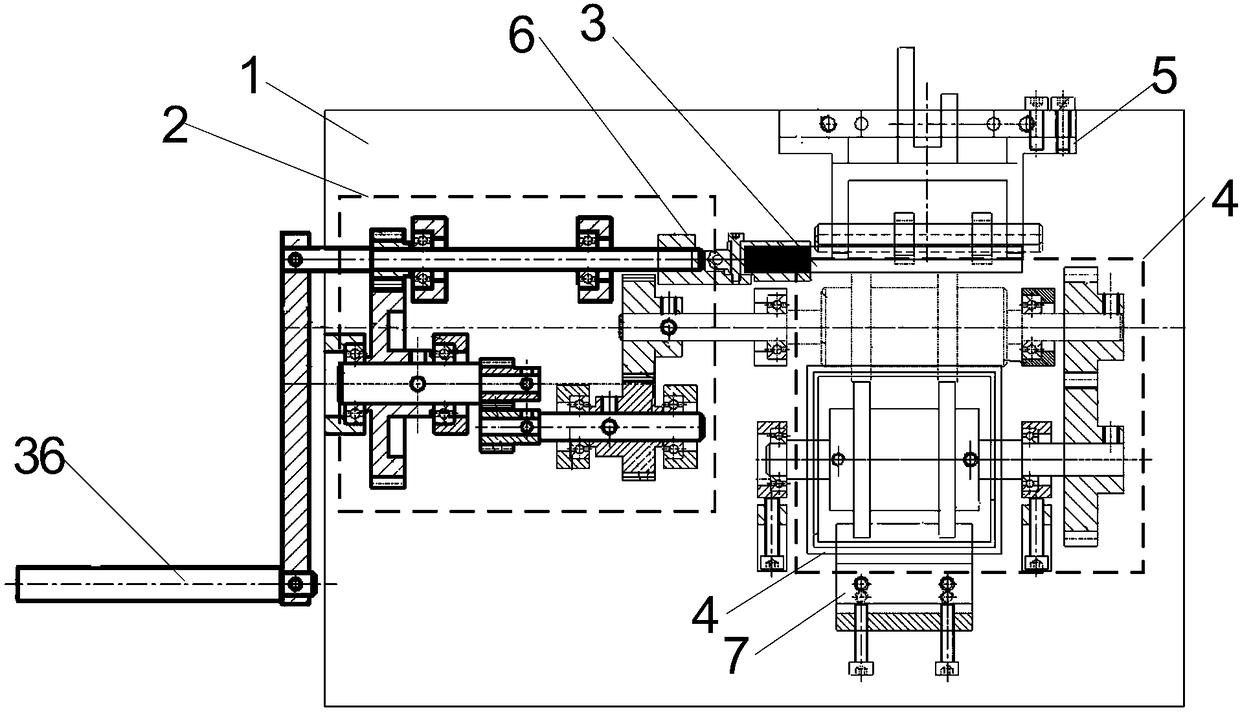

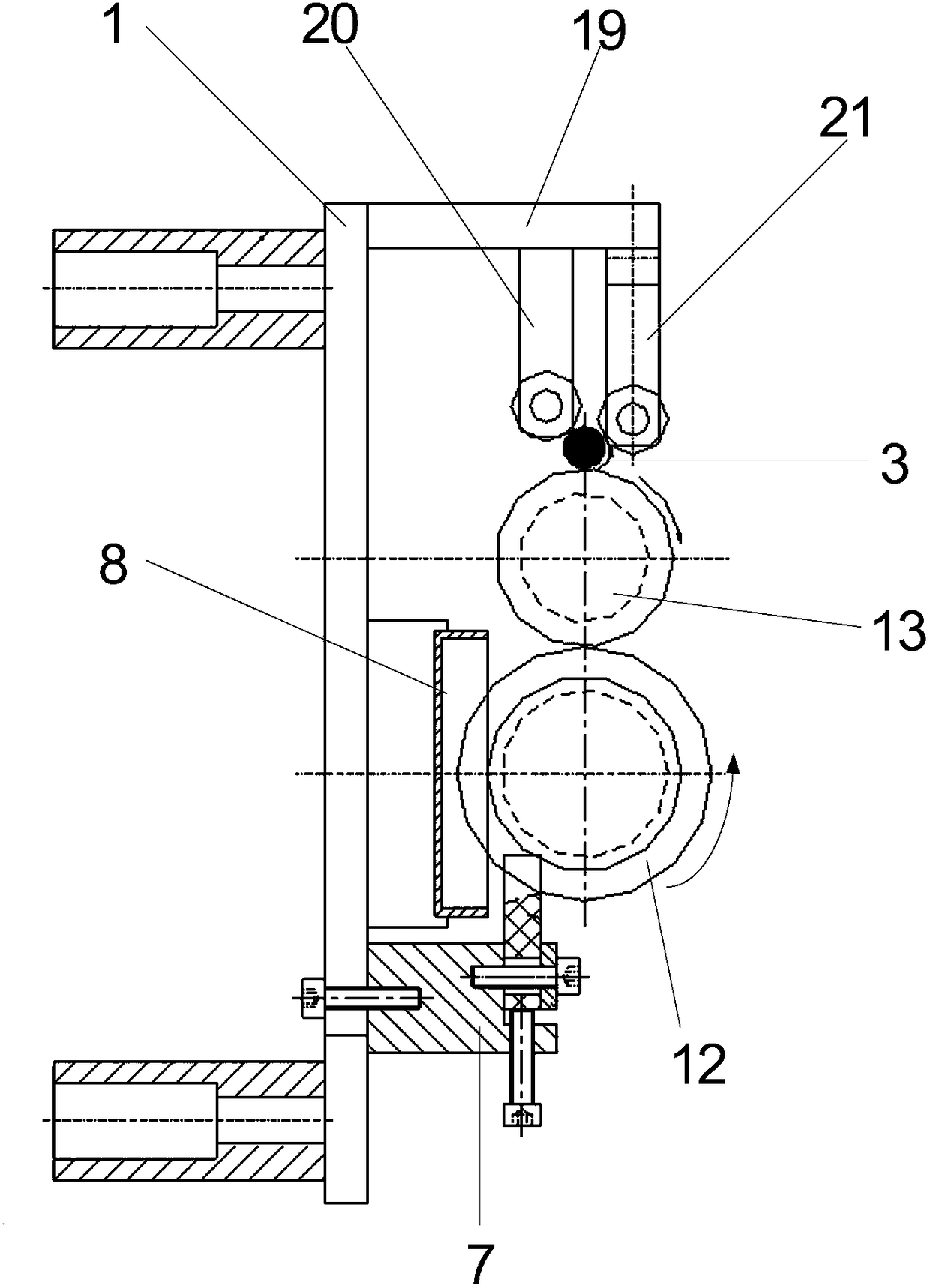

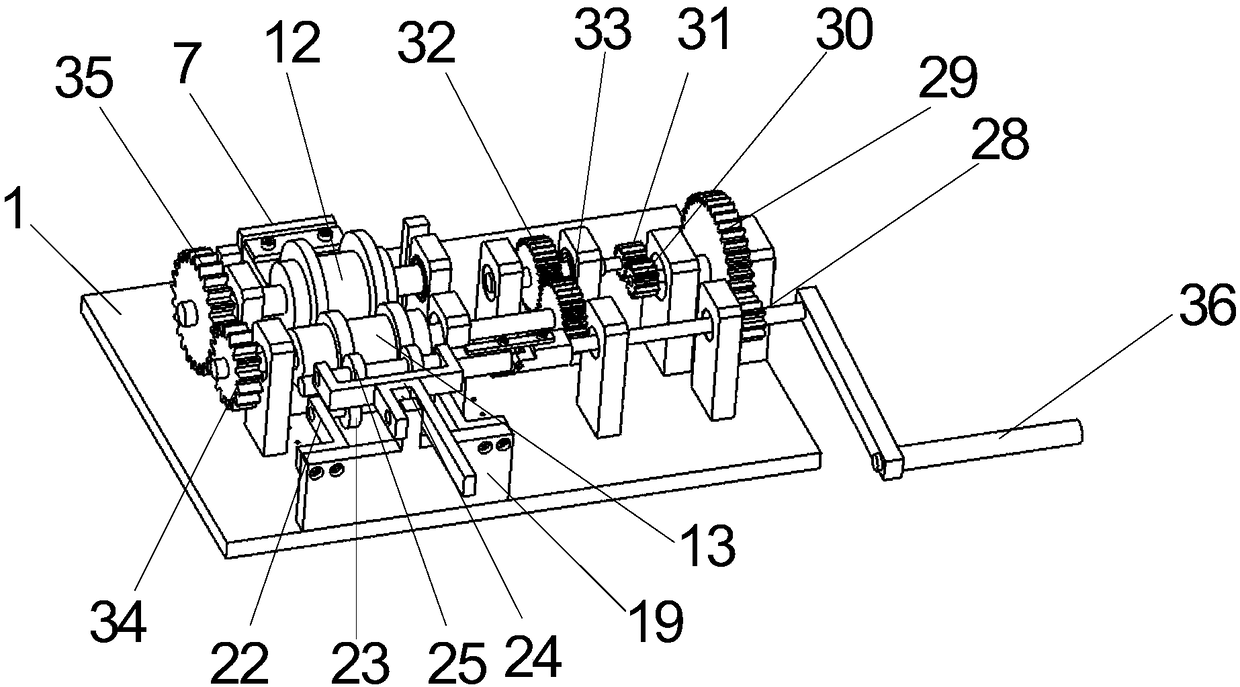

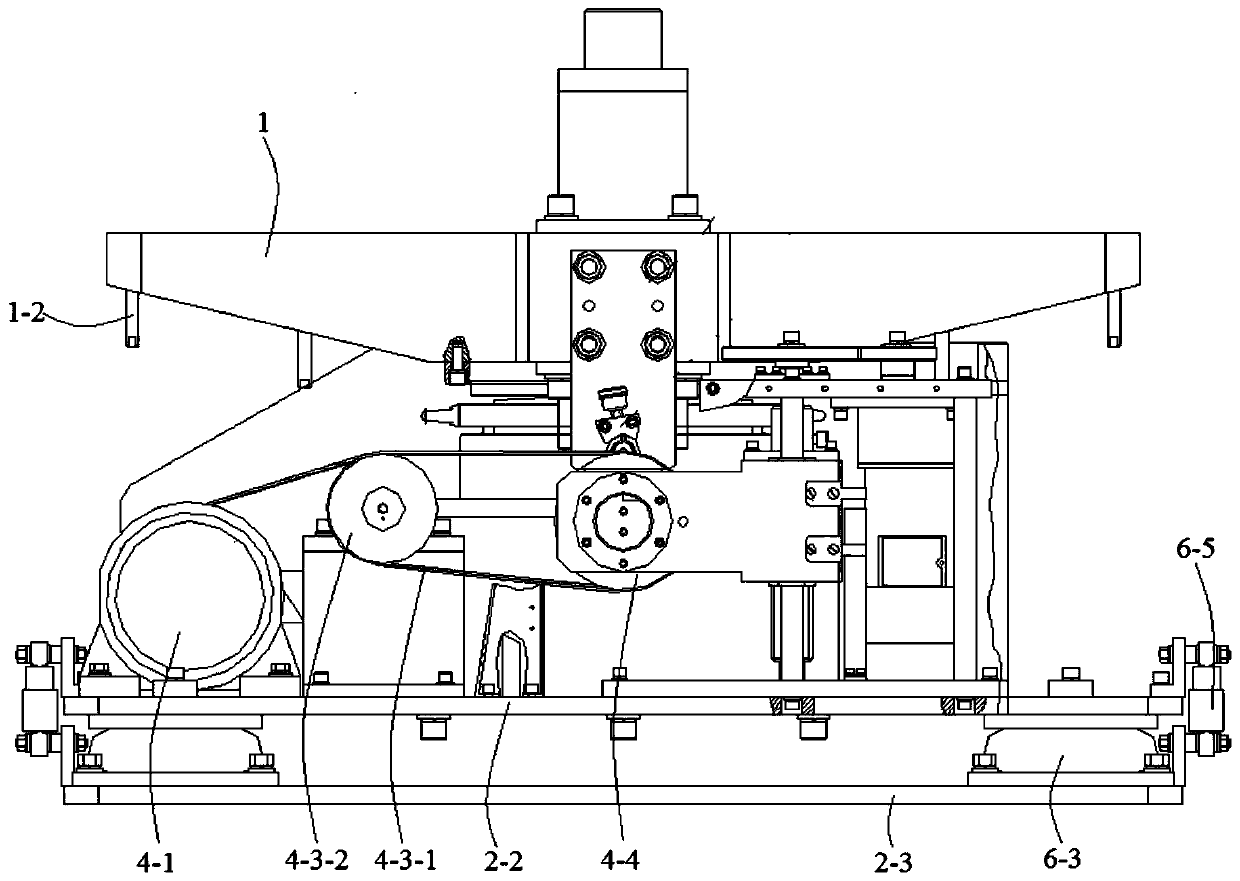

Crushing mechanism of molding device for infant multi-grain nutritional complementary food granules

The present invention discloses a crushing mechanism of a molding device for infant multi-grain nutritional supplementary food granules. The crushing mechanism comprises a main body, a base is arranged at the lower end of the main body, a charging inlet is arranged near one side of the upper end of the main body, the charging inlet is matched with a second conveyor belt, a cooling water outlet isarranged on the upper end of one side of the main body near the charging inlet, a cooling water inlet is arranged at the lower end of the other side of the main body, a discharging outlet is arrangedat the position near the lower end of the main body, and a third vibrating screen is arranged at the lower end of the discharging outlet. The crushing mechanism realizes the control of particle size range of granular surface without the need of preparing corresponding production equipment separately according to production needs, thereby saving occupying space; and the crushing mechanism realizesthe automatic control throughout the whole process, thereby saving production costs.

Owner:郑州琼佩电子技术有限公司

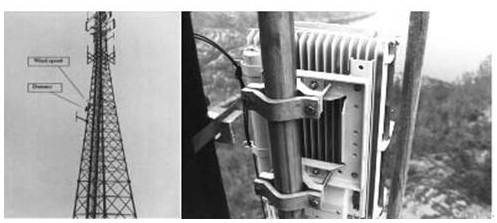

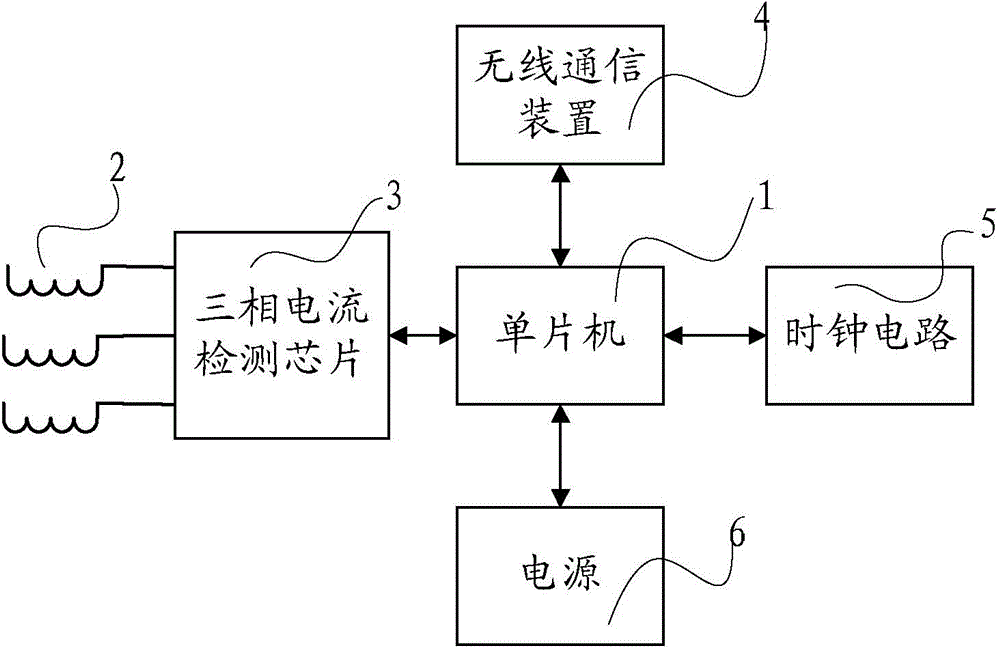

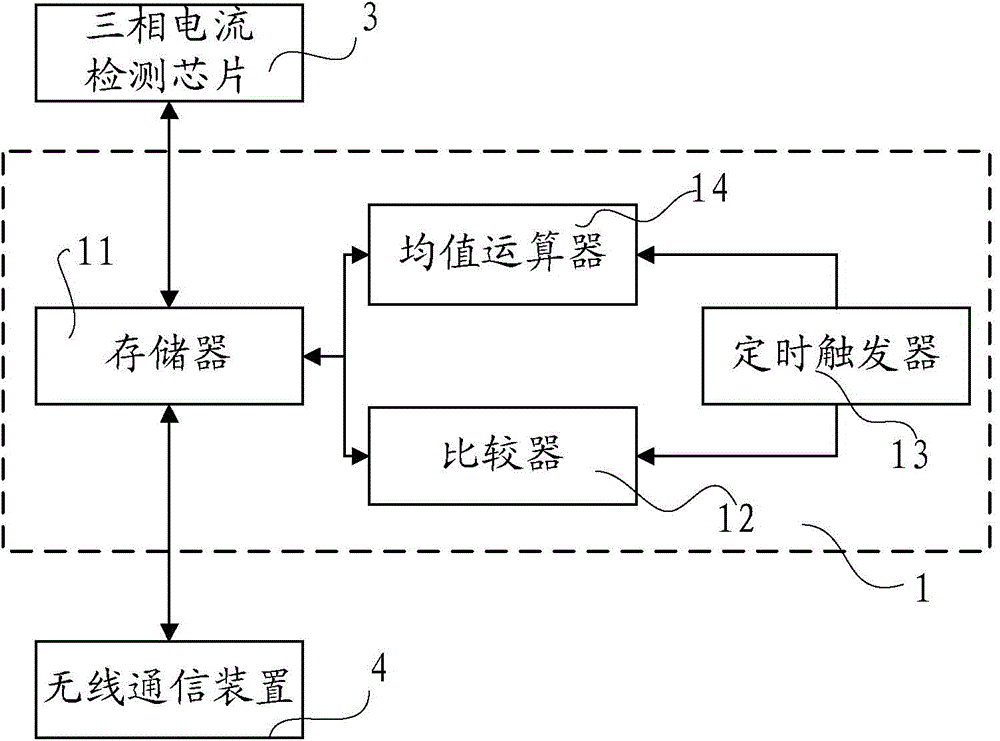

Split acquisition terminal for recognition of low-voltage faulted cables

InactiveCN104808115ARealize real-time monitoringRealize long-distance wireless transmissionTransmission systemsFault locationMicrocontrollerMicrocomputer

The invention discloses a split acquisition terminal for recognition of low-voltage faulted cables. The split acquisition terminal comprises a single-chip microcomputer, three split core type current transformers, a three-phase current detection chip, a wireless communication device, a power source and a clock circuit. The three split core type current transformers are used for acquiring data of three-phase current on a three-phase cable correspondingly; the three-phase current detection chip is connected with the three split core type current transformers and used for reading the data of the three-phase current on the three-phase cable; the wireless communication device is used for sending the data of the three-phase current on the three-phase cable. The three-phase current detection chip, the wireless communication device, the power source and the clock circuit are all connected with the single-chip microcomputer. The split acquisition terminal for recognition of the low-voltage faulted cables has the advantages that real-time monitoring of low-voltage cable equipment can be realized, remote wireless transmission of fault or overload signals of the three-phase cables is realized, and real-time clocking is realized as well; testing the cables one by one is avoided, and accordingly emergency maintenance time is saved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

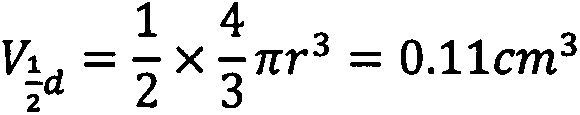

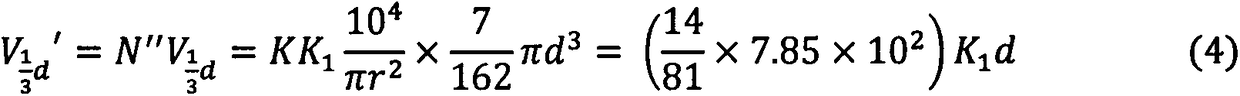

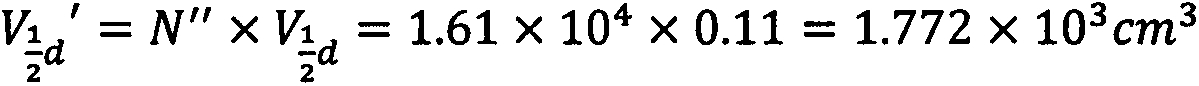

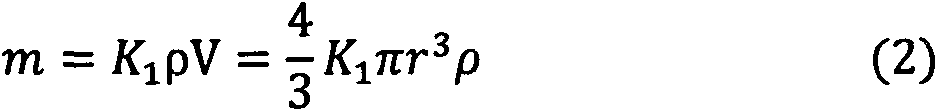

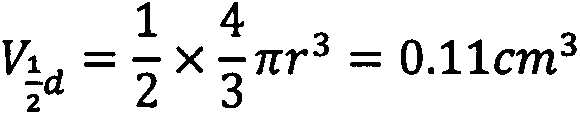

Method for calculating amount of asphalt in crushed stone seal

ActiveCN108875111AAvoid experimentImprove work efficiencyGeometric CADSpecial data processing applicationsCrushed stoneEngineering

A method for calculating the amount of asphalt in a crushed stone seal is disclosed. The method comprise the following steps of approximately treating each crushed stone in the crushed stone seal as asphere, and calculating a total number N of spheres required to cover a unit area according to a maximum cross-sectional area S 'of the approximate sphere; according to the actual situation, correcting the total number N of spheres covering the unit area calculated by a theory, wherein the correction coefficient is K1; filling the gaps among the crushed stones with asphalt, wherein the crushed stones which are approximately spherical are arranged, the asphalt climbing height is between d / 3 ~ d / 2 and the ideal effect can be achieved; then calculating the amount of asphalt in the crushed stoneseal layer according to a theoretical formula. The invention effectively solves the problem of asphalt amount determination in the crushed stone seal, and can accurately and quantitatively calculate the asphalt amounts required in the crushed stone seals with different particle diameters, so the tedious tests are avoided, and the calculation is simple.

Owner:NANJING FORESTRY UNIV

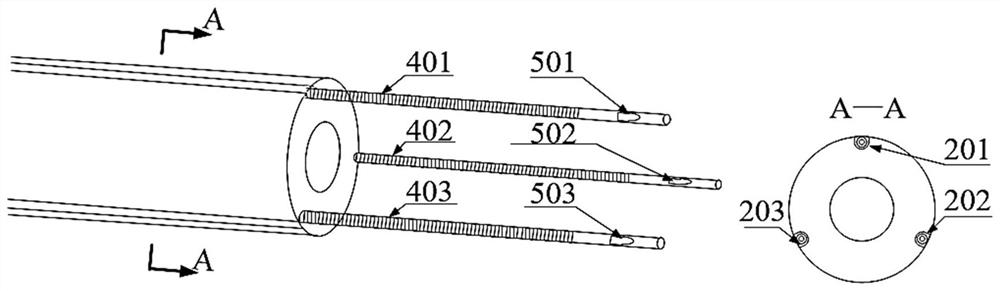

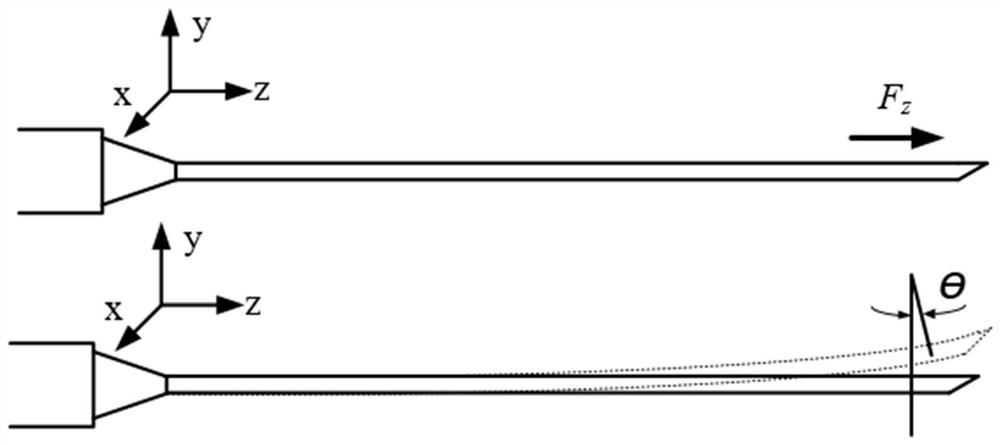

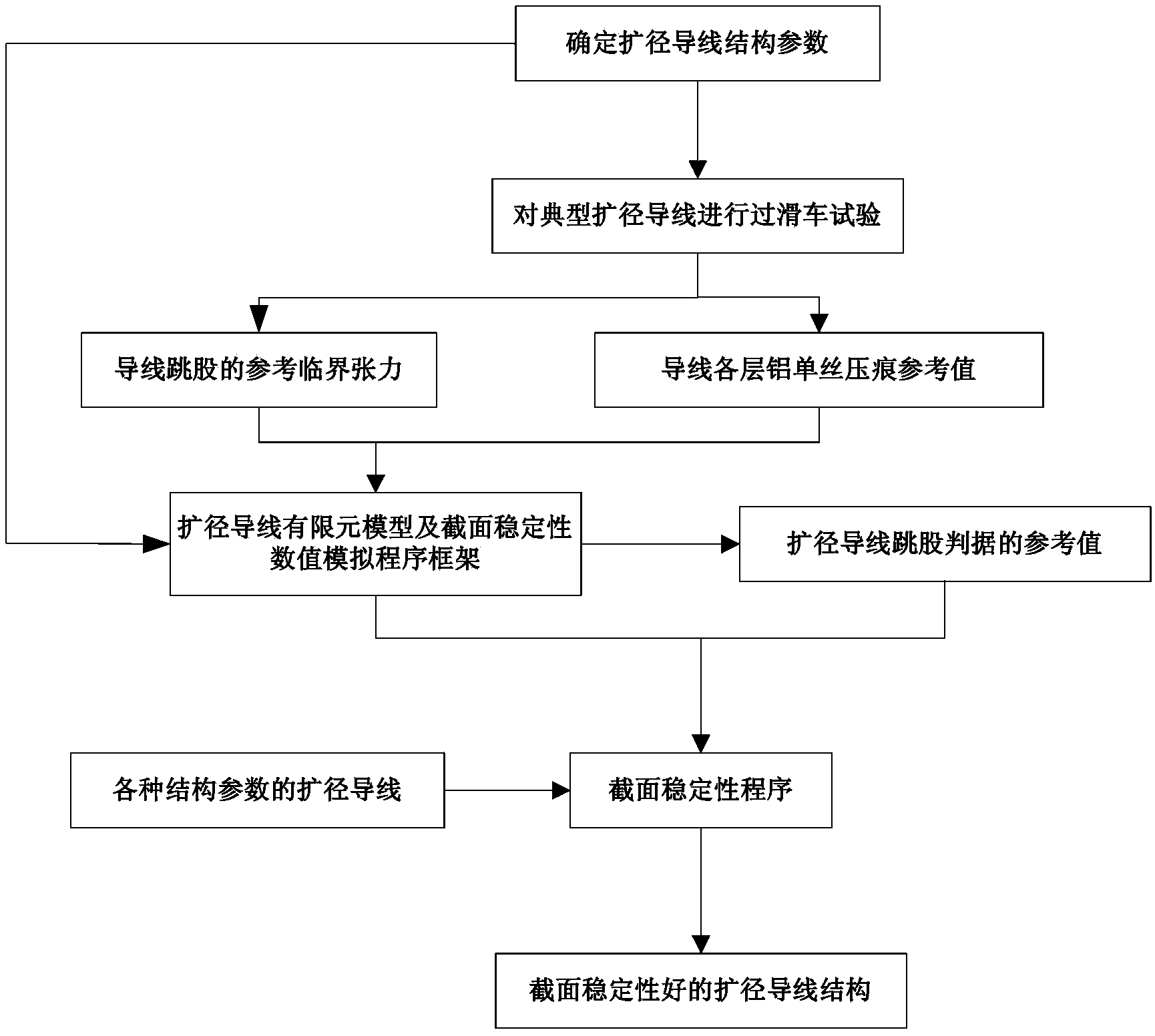

Establishing method of expanded diameter conductor strand jumping criterion

ActiveCN103353417AOptimal structural parametersAvoid experimentMaterial strength using tensile/compressive forcesElement modelEngineering

The invention provides an establishing method of an expanded diameter conductor strand jumping criterion. The method comprises the steps of: determining structure parameters of an expanded diameter conductor, and establishing a corresponding finite element model; subjecting the expanded diameter conductor test piece to a pulley passing test; and establishing the expanded diameter conductor strand jumping criterion. The method provided in the invention solves the problems needing to be solved in expanded diameter conductor application in the prior art, and two section stability expanded diameter conductor structures are provided in the invention according to the method, thus solving the defects that a lot of tests are needed, an optimized conductor structure is likely to be missed, and a section stability expanded diameter conductor cannot be provided in relevant comparative literature. The specific structure parameters of the optimized expanded diameter conductor are provided. The structure parameter optimization process not only considers the influence factors mentioned in the literature "Key technology study on expanded diameter type aluminum cable steel reinforced for 750kV power transmission", and also comprehensively considers indentation, strand jumping critical tension and other factors of an expanded diameter conductor. Thus, the optimized structure is superior to the current local optimized structure acquired only by test, and is more in line with the objective law.

Owner:STATE GRID CORP OF CHINA +1

Cigarette coating test device

ActiveCN108936794AEasy to manufactureAvoid experimentCigar manufactureCigarette manufactureEngineeringPaint roller

The invention discloses a cigarette coating test device. The cigarette coating test device comprises a base, a transmission assembly, a paint roller assembly for coating the cigarette, a cigarette limit assembly, a cigarette loading and unloading clamp for fixing a cigarette holder of the cigarette, a scraper assembly and a paint box arranged on the base. the transmission assembly is configured toat least provide power to the rotation of the paint roller assembly; the cigarette limit assembly is configured to restrict movement of the cigarette away from the paint roller assembly; the scraperassembly is used for removing excess paint on the paint roller assembly; and the paint box is used for supplying a paint to the paint roller assembly. Through the above device, a cigarette sample forthe cigarette coating test can be conveniently produced, and the test on a cigarette unit is avoided, and the influence of the cigarette test on daily production can be prevented.

Owner:CHINA TOBACCO GUIZHOU IND

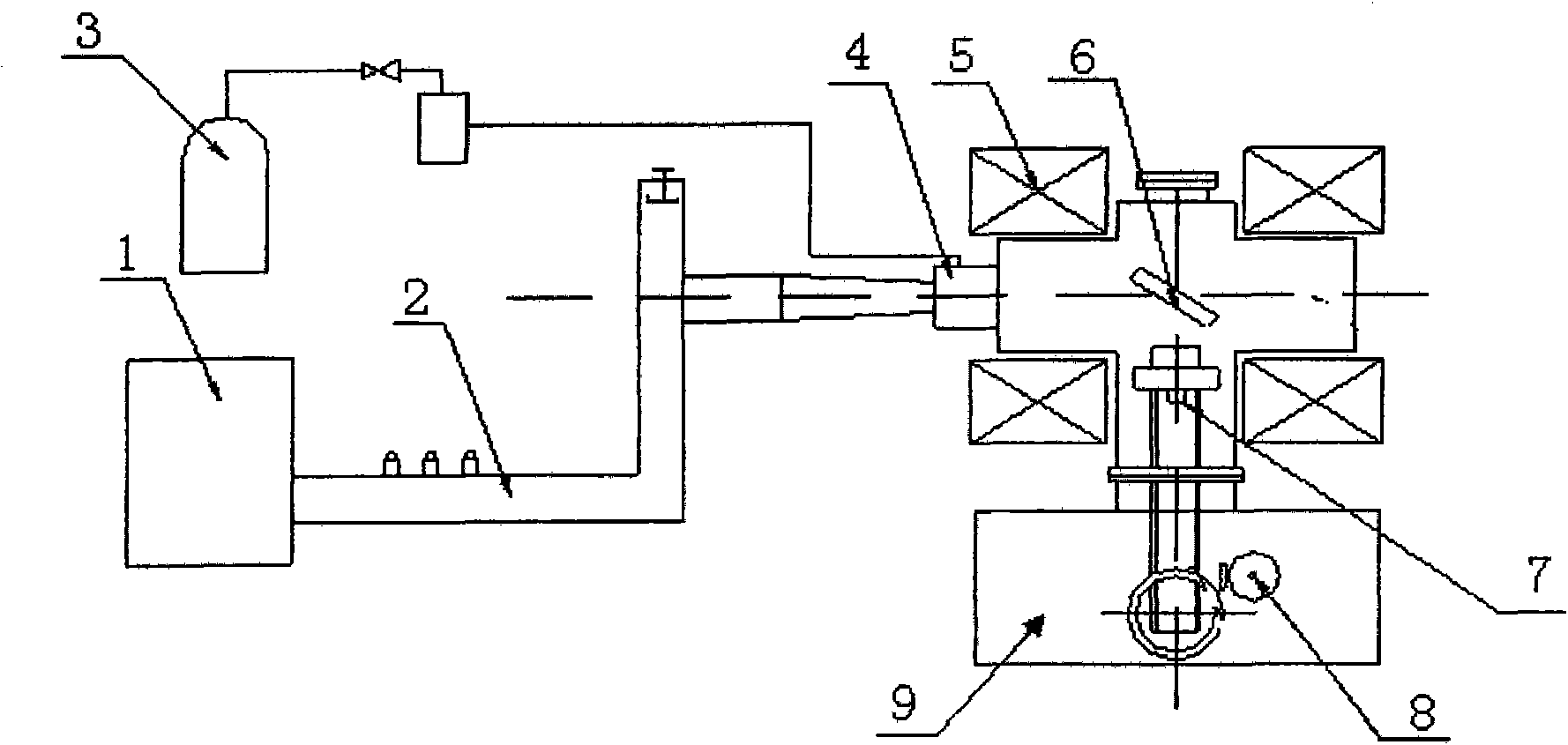

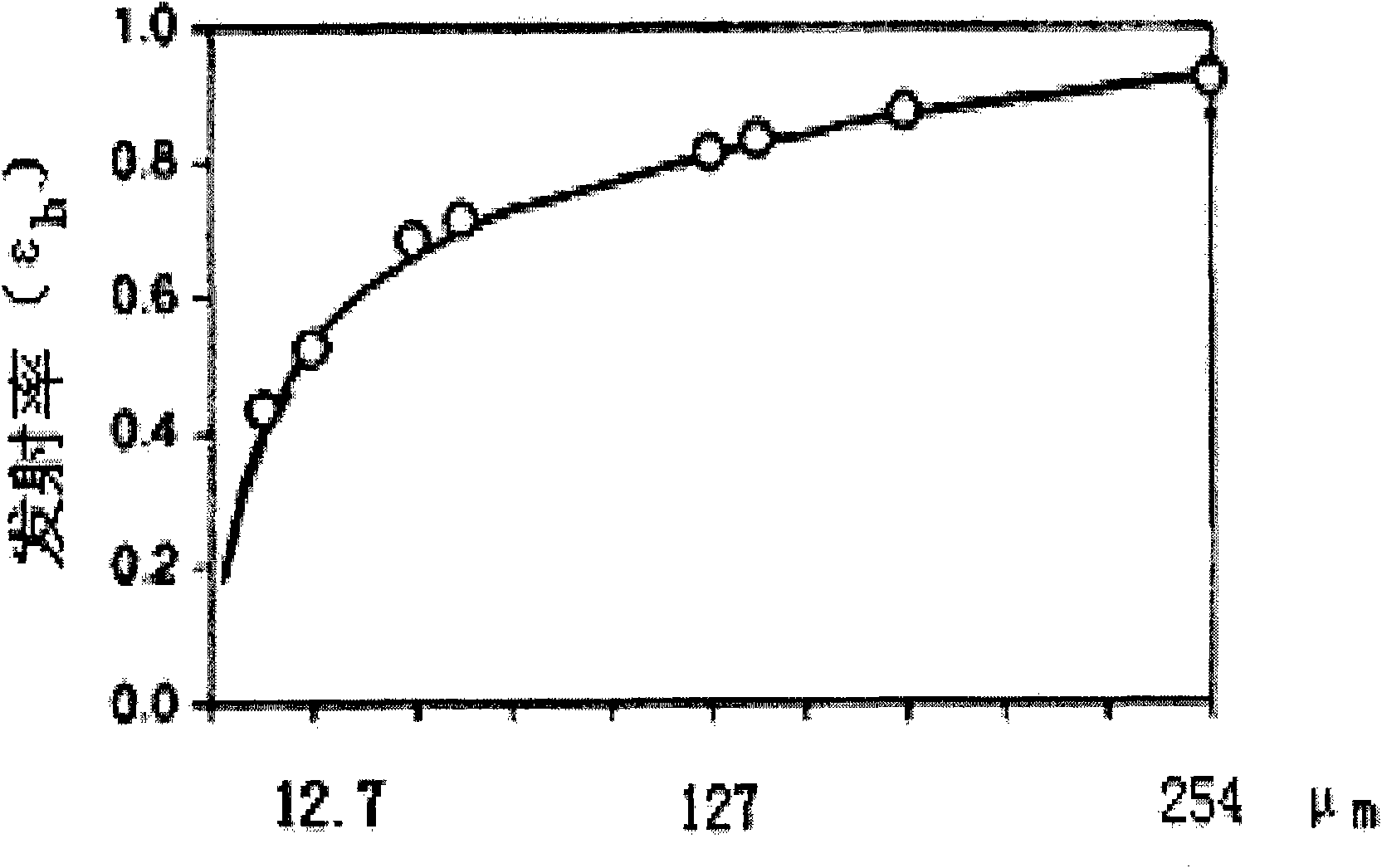

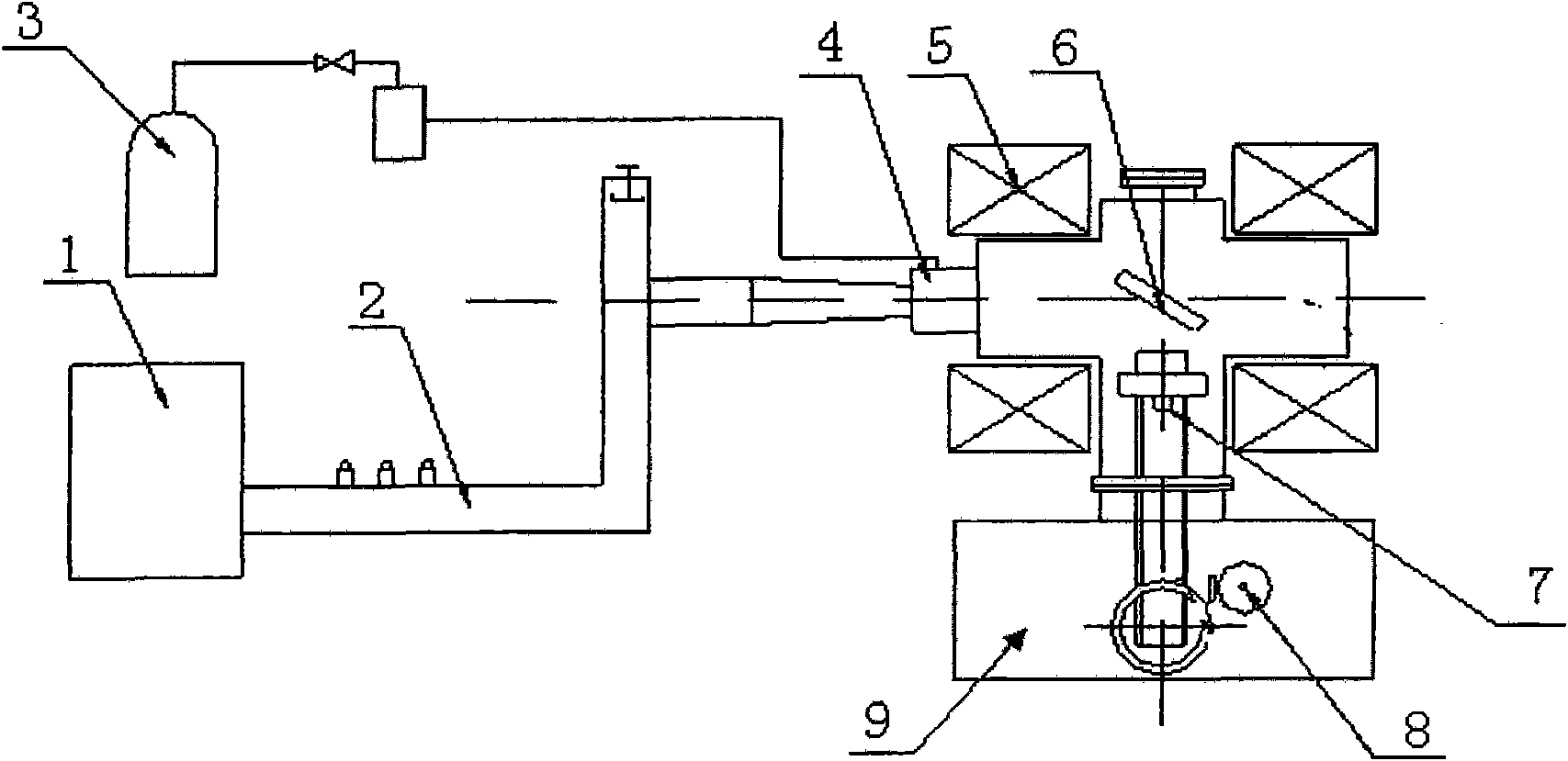

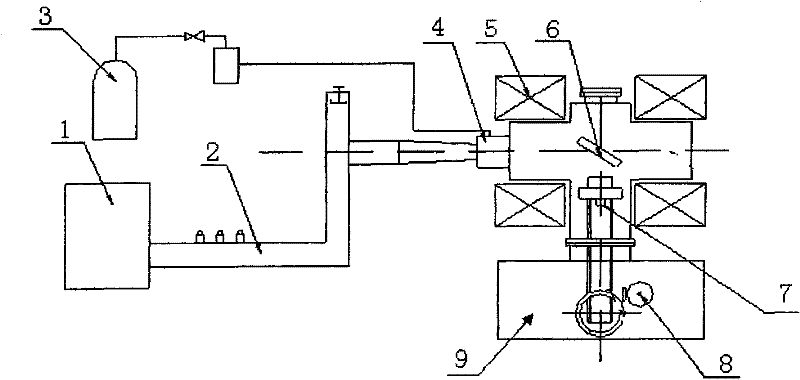

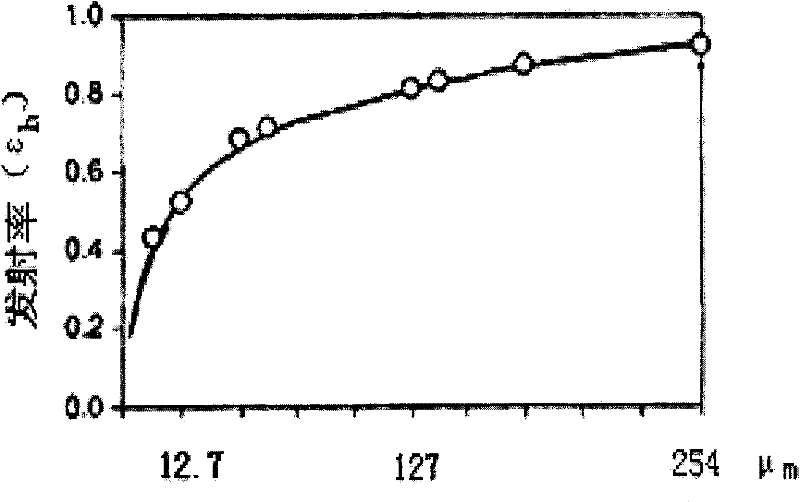

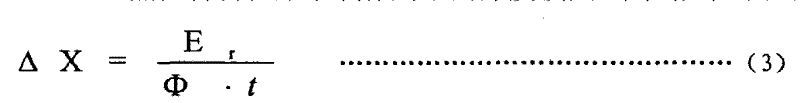

Emissivity extrapolating prediction method under action of F46 thermal control material atomic oxygen

ActiveCN101782534AReduce test intensityImprove efficiencyMaterial analysis using microwave meansPhysicsAtomic oxygen

The invention relates to an emissivity extrapolating prediction method under the action of F46 thermal control material atomic oxygen, belonging to the technical field of aerospace. The method comprises the following steps: placing F46 thermal control material in an atomic oxygen ground test device, using atomic oxygen with a certain energy and density to test; in the testing process, measuring the emissivity (epsilon h) of F46 material to obtain the change data of emissivity under the action of atomic oxygen with a certain flux; after analyzing and fitting data, establishing a mathematical formula of F46 material under the action of atomic oxygen with a certain flux; and finally using the established mathematical formula to extrapolate the change data of emissivity (epsilon h) under the condition that the flux is more than the original flux of atomic oxygen. The method of the invention can be used to fast obtain the emissivity data of F46 material under the action of atomic oxygen with large flux, effectively improve the test efficiency and reduce the test cost.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

A method for calculating the amount of crushed stone in the crushed stone seal

ActiveCN108875110BAvoid experimentImprove work efficiencyData processing applicationsDesign optimisation/simulationCrushed stoneEngineering

Owner:NANJING FORESTRY UNIV

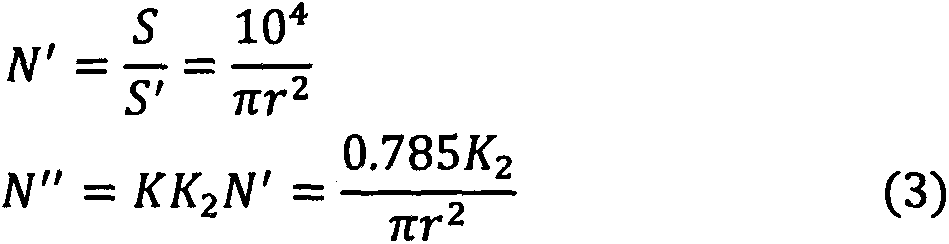

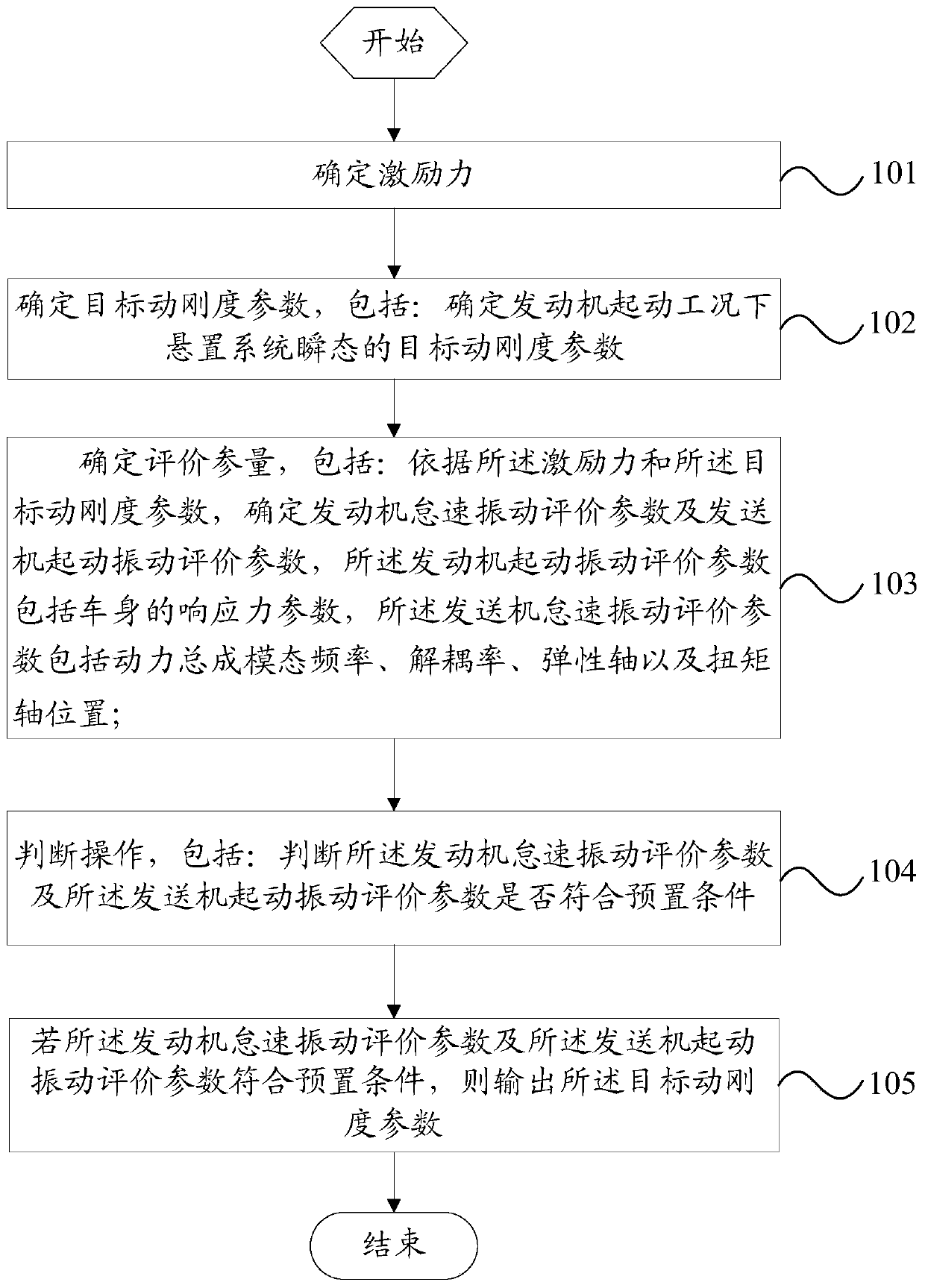

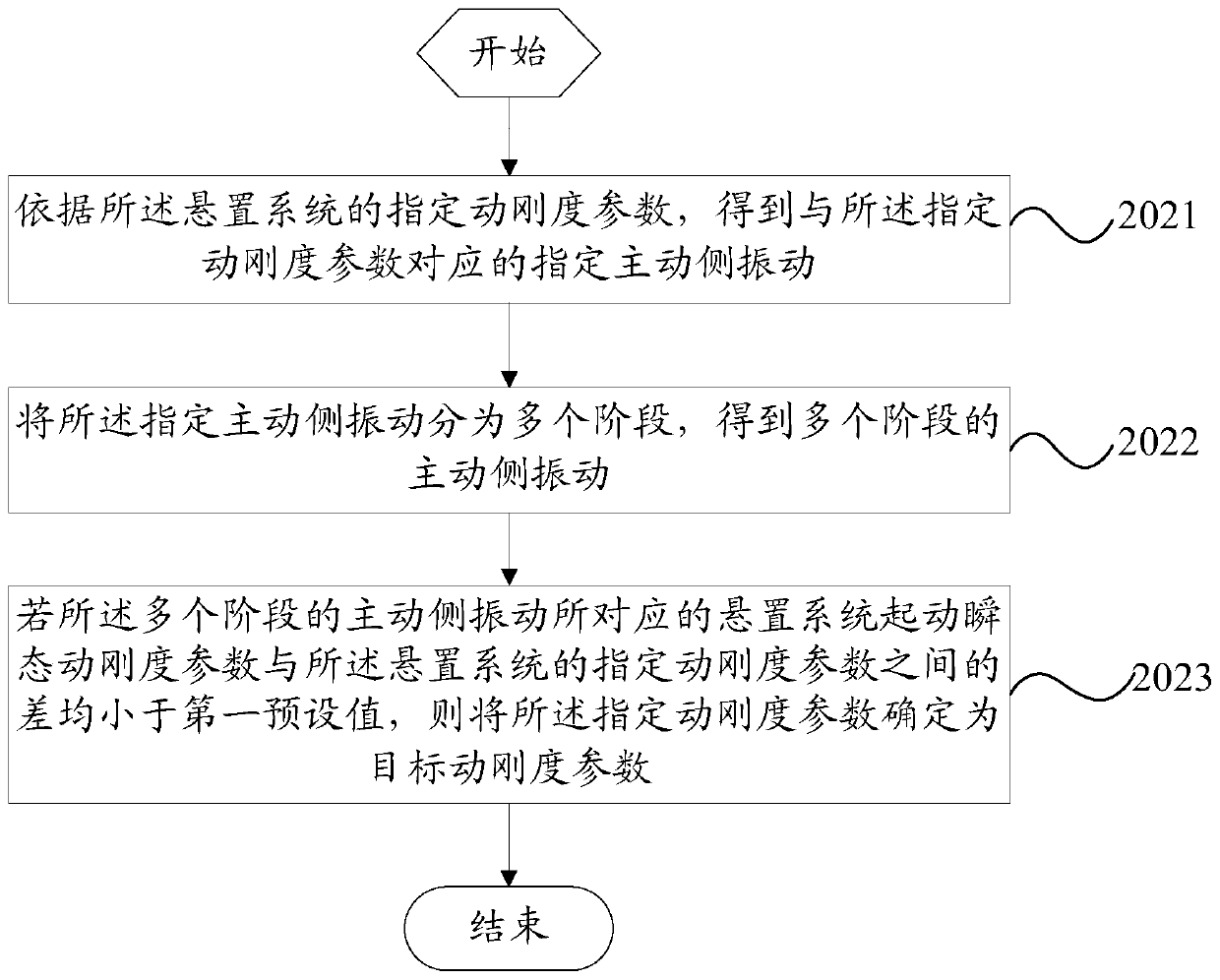

A suspension system optimization method and device

ActiveCN109383261BReduce complexityReduce development costsGeometric CADSustainable transportationIdle speedSuspension (vehicle)

The invention provides a suspension system optimization method and a device. The suspension system optimization method comprises the following steps: determining the excitation force; determining thetarget dynamic rigidity parameters; determining the evaluation parameters comprising an engine idling vibration evaluation parameter and a transmitter starting vibration evaluation parameter accordingto the excitation force and the target dynamic rigidity parameter. To determine the parameters, whether the engine idling vibration evaluation parameter and the transmitter starting vibration evaluation parameter meet preset conditions is considered. Therefore, the system outputs the target dynamic rigidity parameter if the engine idling vibration evaluation parameter and the transmitter startingvibration evaluation parameter meet preset conditions. The suspension system optimization method can simultaneously optimize engine idling speed vibration and the engine starting vibration in the early design phase of a vehicle product, so that the complexity of the suspension system is reduced, the product development period is shortened, and the development cost of the vehicle product is reduced.

Owner:GREAT WALL MOTOR CO LTD

Emissivity extrapolating prediction method under action of F46 thermal control material atomic oxygen

ActiveCN101782534BGround Atomic Oxygen Simulation Tests AvoidAvoid experimentMaterial analysis using microwave meansTest efficiencyEmissivity

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

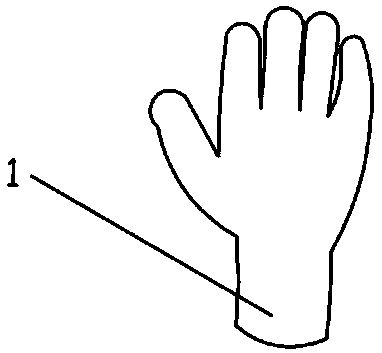

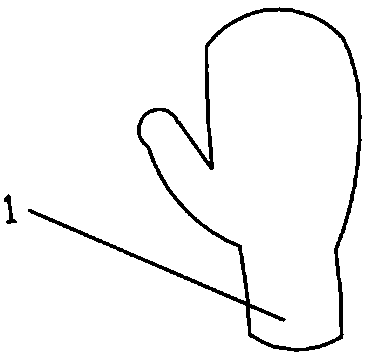

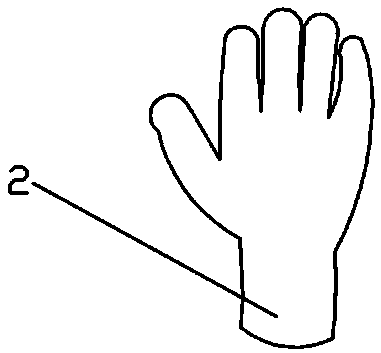

Insulating glove withstand voltage test tool and using method

InactiveCN111025108AAvoid experimentGuaranteed standardTesting vessel constructionPhysical chemistryEngineering

The invention relates to an insulating glove withstand voltage test tool, which comprises an insulating glove, a hand model and a hand concave mold; a conductive glove made of conductive cloth is wornon the surface of the hand model, and a test grounding wire is led out of the conductive glove; the internal of the hand concave mold is fixedly covered with conductive cloth, a pressurizing line fortest is led out of the conductive cloth in the hand concave mold, and the hand model is manufactured according to the insulating glove; and the hand concave mold is manufactured according to the insulating glove, the insulating glove comprises an insulating glove body, and the insulating glove body is a five-finger glove or a connected-finger glove made of rubber. The invention further relates toa using method of the insulating glove withstand voltage test tool, and the using method is simple. The glove is prevented from being immersed in water for testing, the testing speed is increased, and the standard of the withstand voltage of each part of the glove is ensured.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

A method for calculating the amount of asphalt in the gravel seal

ActiveCN108875111BAvoid experimentImprove work efficiencyGeometric CADSpecial data processing applicationsCrushed stoneMechanical engineering

Owner:NANJING FORESTRY UNIV

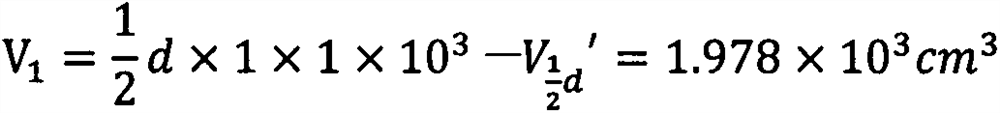

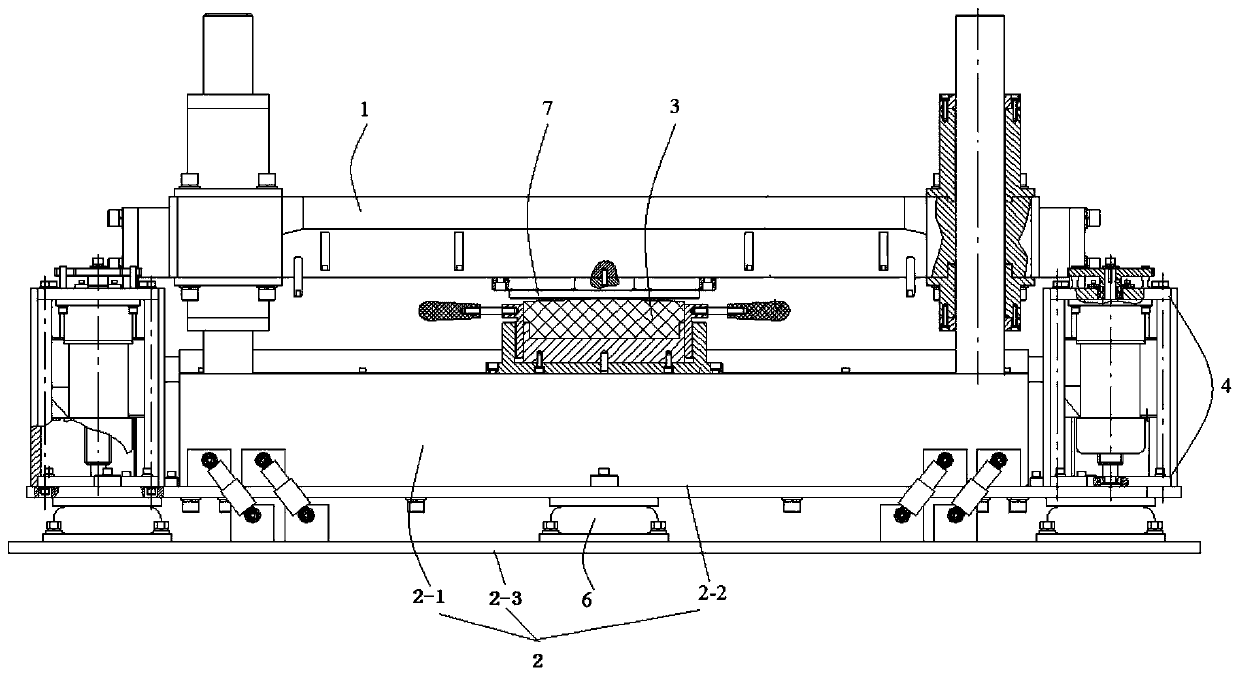

Test method for simulation experiment platform of mechanical structure crash resistance

The invention discloses a test method of a mechanical structure collision resistance performance simulation experiment platform. The method comprises the following steps of setting a collision bench collision parameter, wherein the collision parameter includes a bench surface lifting height, a collision number and a collision frequency; then preparing a collision experiment; measuring a bench surface height and parallelism, and adjusting lifting systems of two sides of a bench surface till that the bench surface height reaches a preset height and a bench surface is in a horizontal state; beginning to simulate the collision experiment; starting a drag system of a collision bench so that an acquired collision waveform is in a corresponding tolerance band; and completing a set collision number so that the experiment is ended. In the invention, an influence factor of a collision process is considered from a plurality of aspects, the influence factor is corrected and finally a waveform required by the experiment is acquired. An accurate reference parameter is provided for the collision process of an actual object so that the object can be effectively prevented from being destroyed during the collision process.

Owner:西安从吾电子科技有限公司

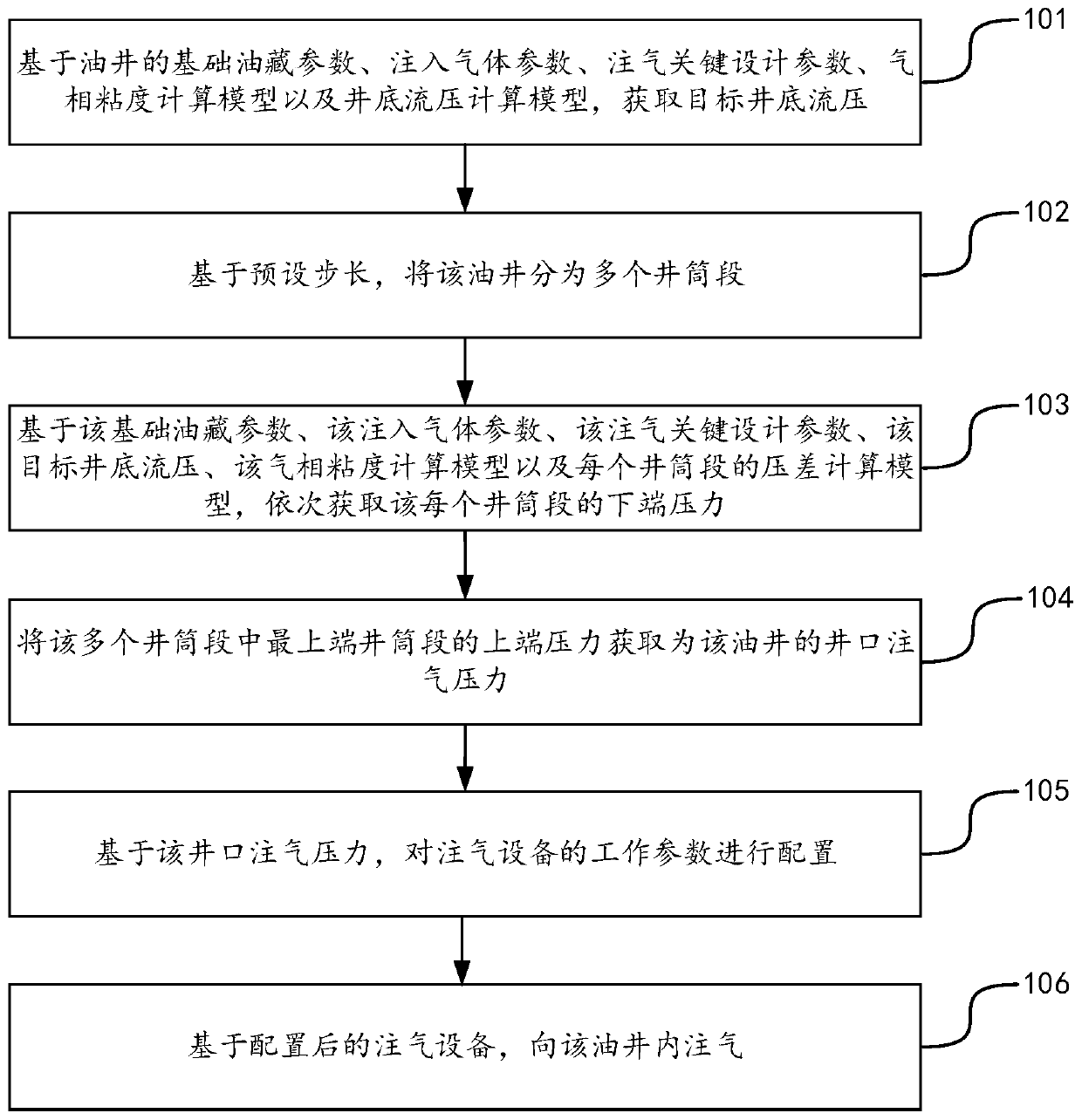

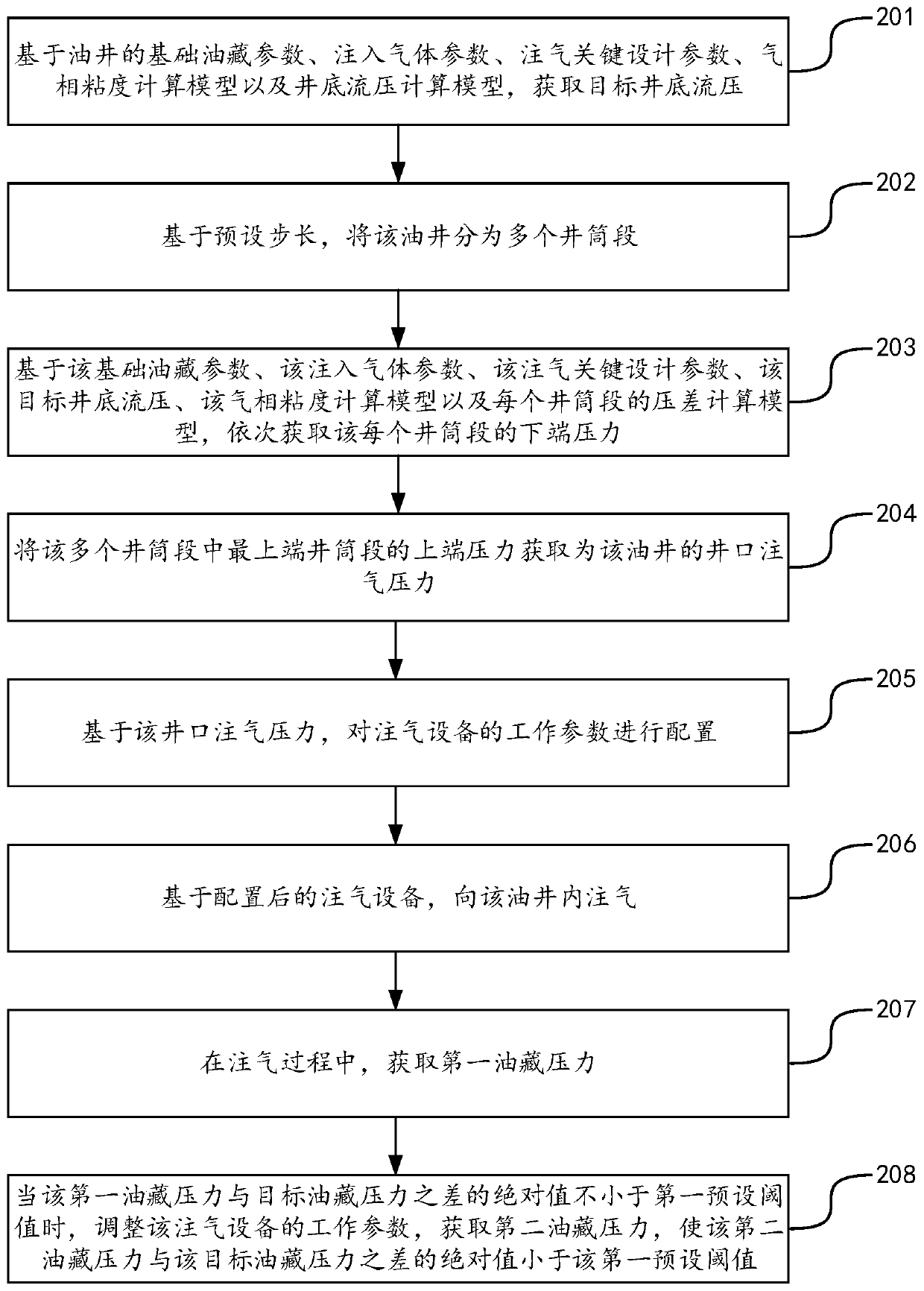

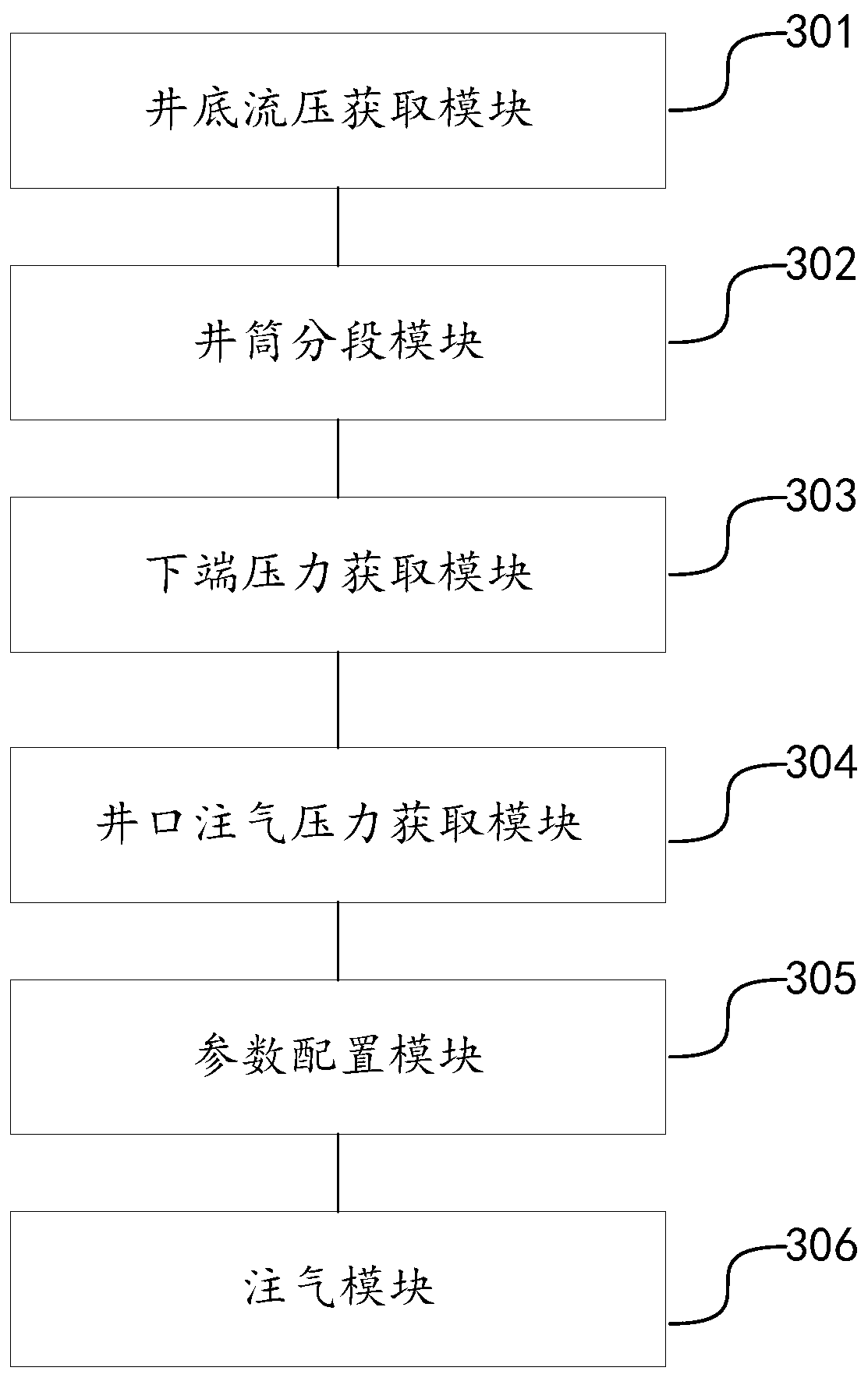

Working parameter configuration method and device for gas injection equipment

ActiveCN111563307AEasy to getQuick configurationFluid removalDesign optimisation/simulationThermodynamicsInjection equipment

The invention discloses a working parameter configuration method and device for gas injection equipment, and belongs to the technical field of gas drive oil extraction. The method comprises the steps:acquiring target bottom hole flowing pressure based on various parameters of an oil well and a bottom hole flowing pressure calculation model; on this basis, based on a pressure difference calculation model of each wellbore section, obtaining the lower end pressure of each wellbore section in sequence, and finally obtaining the wellhead gas injection pressure of the oil well; based on the wellhead gas injection pressure, configuring working parameters of gas injection equipment; and injecting gas into the oil well. In the process, wellhead gas injection pressure is obtained based on preset bottom hole flow pressure and various parameters of an oil well. The method is simple, rapid and convenient, avoids the use of a gas injection compressor and related corollary equipment for testing, also avoids a complex implementation process, can quickly configure the working parameters of the gas injection equipment, improves the efficiency of the gas injection process, and also reduces the costof the gas injection process.

Owner:PETROCHINA CO LTD

An electric back cover durability test bench

ActiveCN107132059BEasy to implement architectureImprove general performanceVehicle testingOn boardControl system

The invention discloses an electric-rear-cover durability test bench. An electric-rear-cover durability test can be implemented on a body in white, experiment with an entire vehicle is avoided, and test cost is remarkably reduced; the technical scheme includes that a mode that a BCM (body control module) and a HDSG and are combined with a non-on-board controller (TBH) forms a control system of the test bench; only one type of a CAN data bus is related, so that a gateway can be bypassed, and direct access to a vehicle diagnosis port is achieved to perform detection on the running state of an electric rear cover.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

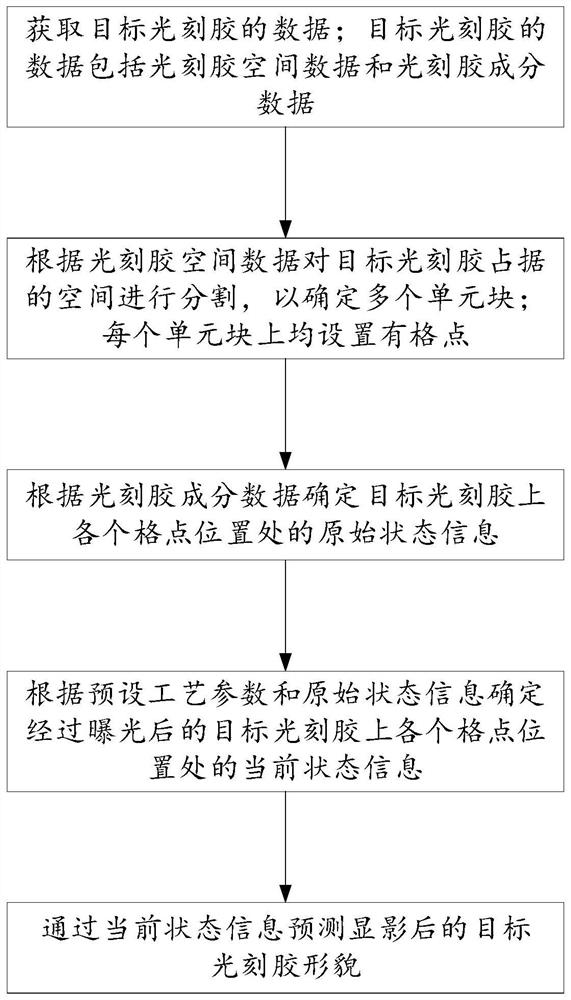

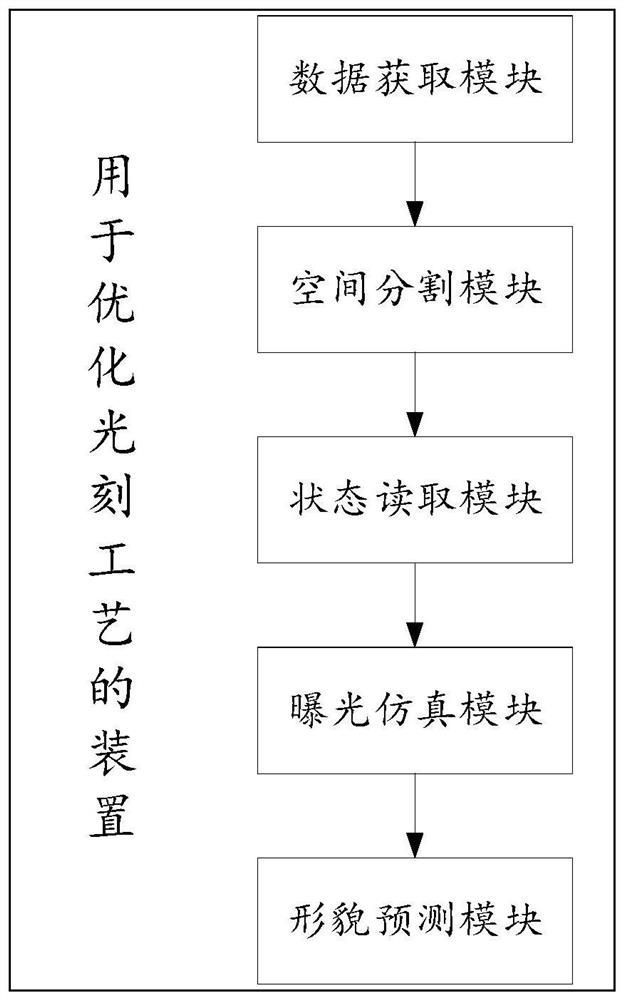

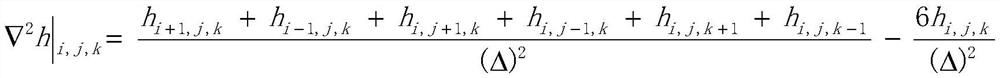

Method and device for optimizing photoetching process, and computer storage medium

PendingCN113589654AContribute to research and developmentPromote research and developmentPhotomechanical exposure apparatusMicrolithography exposure apparatusData packLithography process

The invention can provide a method and a device for optimizing a photoetching process, and a computer storage medium. The method comprises the following steps: acquiring data of a target photoresist, wherein the data of the target photoresist comprises photoresist spatial data and photoresist component data; and segmenting the space occupied by the target photoresist according to the photoresist spatial data to determine a plurality of unit blocks, wherein each unit block is provided with lattice points; determining original state information of each lattice point position on the target photoresist according to the photoresist component data, and determining current state information of each lattice point position on the exposed target photoresist according to preset process parameters and the original state information; and predicting the morphology of the developed target photoresist through the current state information. The morphology of the developed photoresist can be predicted in advance so as to guide and optimize an actual photoetching process, research and development of new varieties or new types of photoresists are facilitated, the research and development progress is promoted, and the research and development cost is reduced.

Owner:GUANGDONG GREATER BAY AREA INST OF INTEGRATED CIRCUIT & SYST

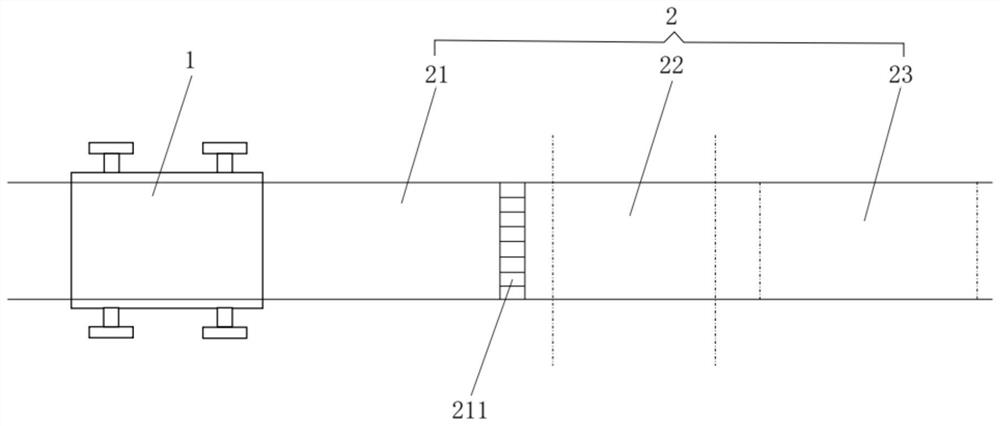

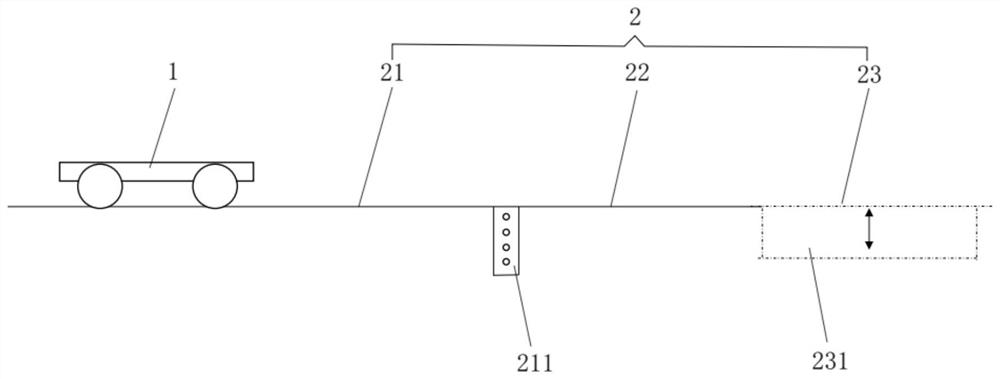

Power battery assembly bottom collision test device and test method

PendingCN113551925AGuaranteed accuracyExpand the scope of the testVehicle shock testingAutomotive engineeringData acquisition module

The invention relates to the technical field of automobile collision tests, and discloses a power battery assembly bottom collision test device and test method. A test sample piece of a power battery assembly is mounted at the bottom of a test trolley, the actual collision working condition can be better fitted, and the accuracy of a test result is ensured. Obstacles are arranged along a collision path, and the maximum collision limit value capable of being borne by the power battery assembly can be obtained. By adjusting the heights of the obstacles and road shoulders, the collision situation when the test trolley passes through the obstacles and the road shoulders with different heights can be simulated, collision data under various collision working conditions can be obtained, and the test range is expanded. After a data processing module receives and processes test parameters, obtained by a data acquisition module, of the test sample piece, the fault level of the test sample piece can be obtained, a display terminal displays the test condition of the test sample piece in real time, and a tester can conveniently observe the test result in real time and evaluate the result. The whole vehicle test is avoided, the test cost is reduced, the operation is simple, and the realization is easy.

Owner:CHINA FIRST AUTOMOBILE

A Simulation-Based Design Method of High-g-value Wide Pulse Shock Waveform

The invention discloses a simulation-based design method for high-G-value wide-pulse shock waveforms. First, the shock wave index requirements and design variables are clarified, and the relative density of the honeycomb aluminum core in the honeycomb aluminum sandwich panel is calculated; The parameter test of the impact numerical test model is carried out to obtain the curves of acceleration versus speed under different relative densities of honeycomb aluminum; then the penetration coefficients of different cushioning materials are fitted to obtain the cavity expansion model equations of different materials, and then the required impact initial velocity is calculated As well as the velocity and acceleration of the projectile moving to the midpoint of each honeycomb aluminum sandwich panel, the relative density value of each honeycomb aluminum core is obtained by substituting the cavity expansion model equation of different materials; finally, the relative density value is input into the projectile penetration reduction The shock numerical test model obtained a high G value wide pulse shock waveform. The invention is applicable to the design of shock wave waveforms of various standards, has short design period, convenient design method and high efficiency.

Owner:NANJING UNIV OF SCI & TECH

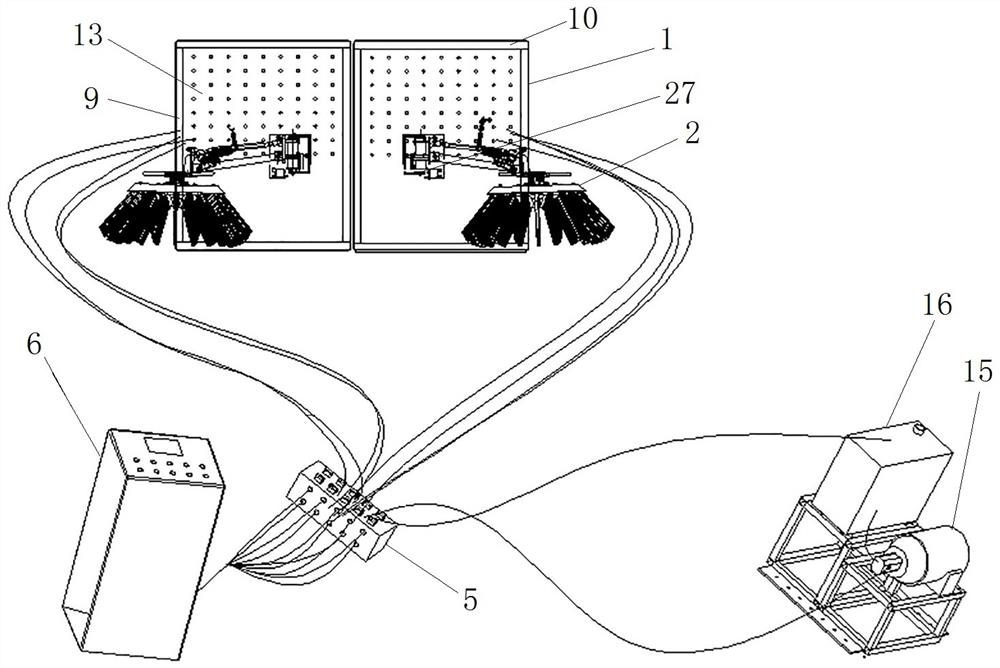

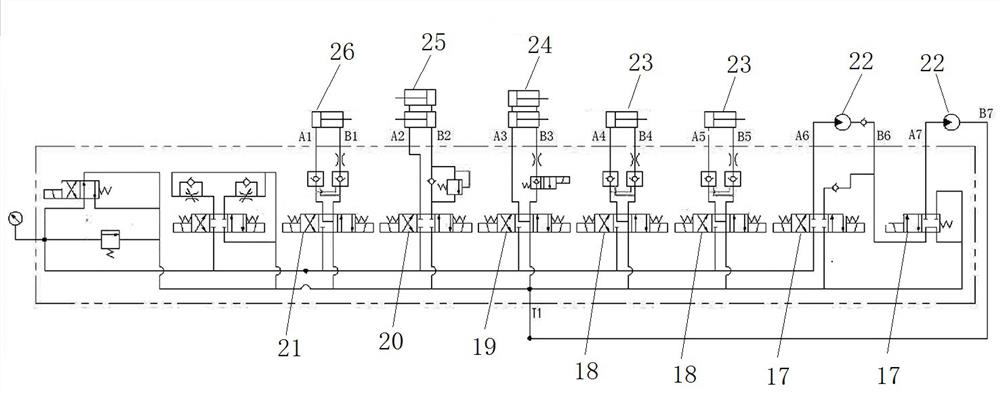

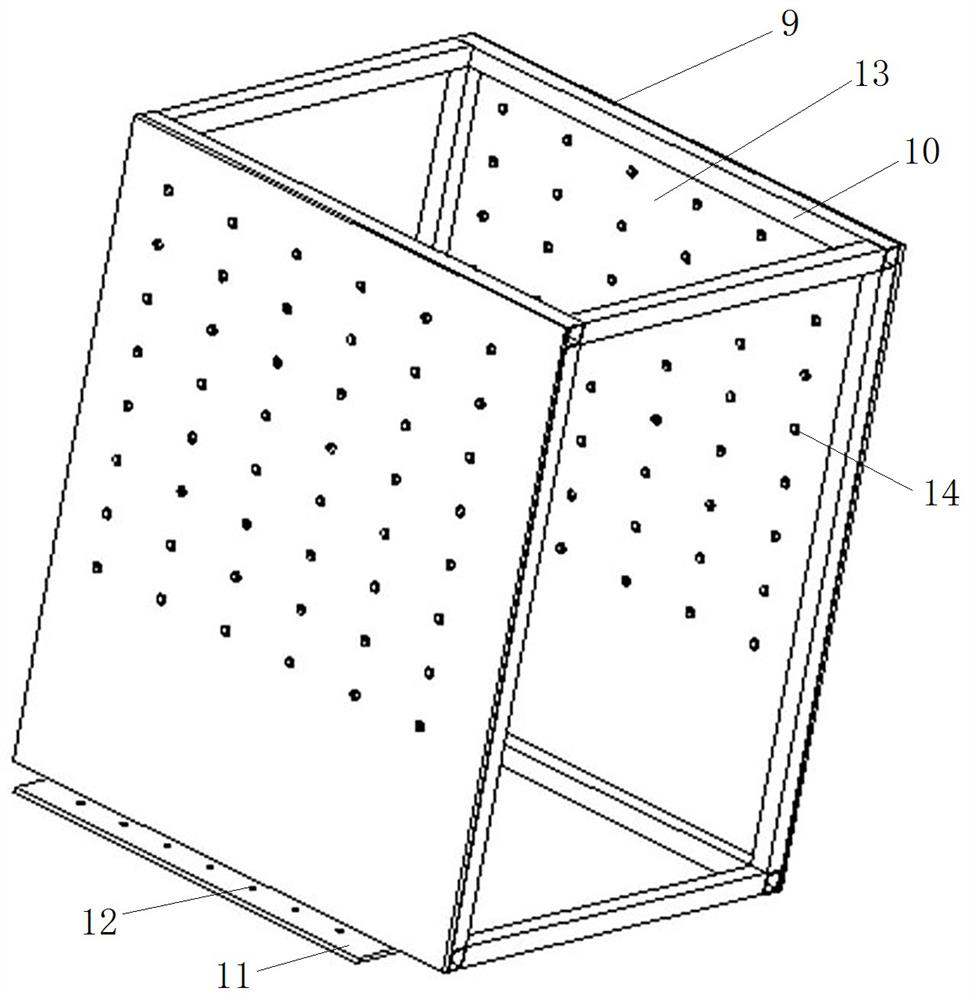

Sanitation vehicle cleaning execution part simulation test device and its support structure

ActiveCN111721540BImprove reliabilityReduce test preparation timeVehicle testingRoad cleaningControl signalControl valves

The invention relates to a simulation test device for cleaning and executing parts of a sanitation vehicle and a supporting structure thereof. The sanitation vehicle cleaning execution part simulation test device includes a support structure for supporting and installing the corresponding cleaning execution parts, and also includes a hydraulic system. The hydraulic system includes a hydraulic power part and a control valve group part. The sanitation vehicle cleaning execution part simulation test device also includes according to the corresponding A console that outputs a control signal to the corresponding control valve in the control valve group section under test conditions. Through the sanitation vehicle cleaning execution part simulation test device, the corresponding cleaning execution parts are installed and supported on the support structure, and the corresponding hydraulic system is configured. During the test, the installation and operation of the cleaning execution parts on the whole vehicle can be effectively simulated. environment, increase the reliability of the test results, and do not need to install the cleaning execution components on the vehicle for simulation tests, which can reduce the test preparation time and shorten the test cycle.

Owner:ZHENGZHOU YUTONG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com