Seat hard point and hard point size rapid simulation calculation method

A simulation calculation, hard point technology, applied in design optimization/simulation, sustainable transportation, geometric CAD, etc., can solve the problems of hard point and hard point size error, waste of time and money, etc., to achieve accurate and objective results and low investment , easy to evaluate and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] In order to clearly and completely describe the technical solution of the present invention and its specific working process, with reference to the accompanying drawings, the specific embodiments of the present invention are as follows:

[0043] In the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected", "fixed" and other terms should be understood in a broad sense, for example, it may be a fixed connection or a detachable connection , or integrated; it can be a mechanical connection or an electrical connection; it can be directly connected or indirectly connected through an intermediate medium, it can be the internal connection of two elements or the interaction relationship between the two elements, unless otherwise specified limit. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood according to specific situations.

[0044] In the...

Embodiment 1

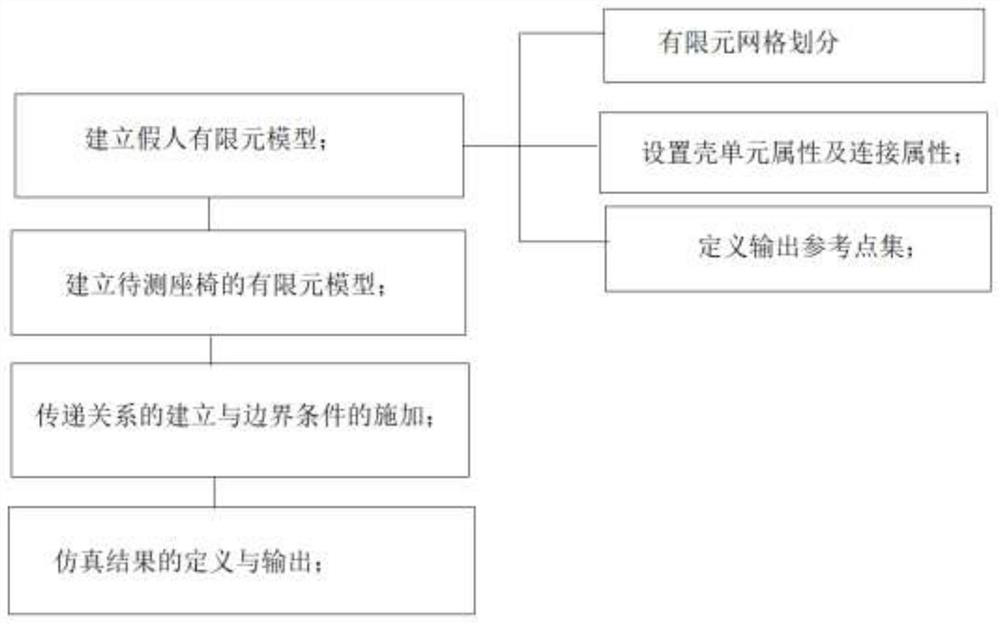

[0046] like figure 1 As shown, this embodiment provides a fast simulation calculation method for seat hard points and hard point sizes, which specifically includes the following steps:

[0047] Step S1: Establish a finite element model of the dummy, including:

[0048]S11: By extracting the contour surface of the standard dummy or the standard human body on the side that is in contact with the seat, as the contour component of the model, and dividing it into finite element meshes by triangular shell elements;

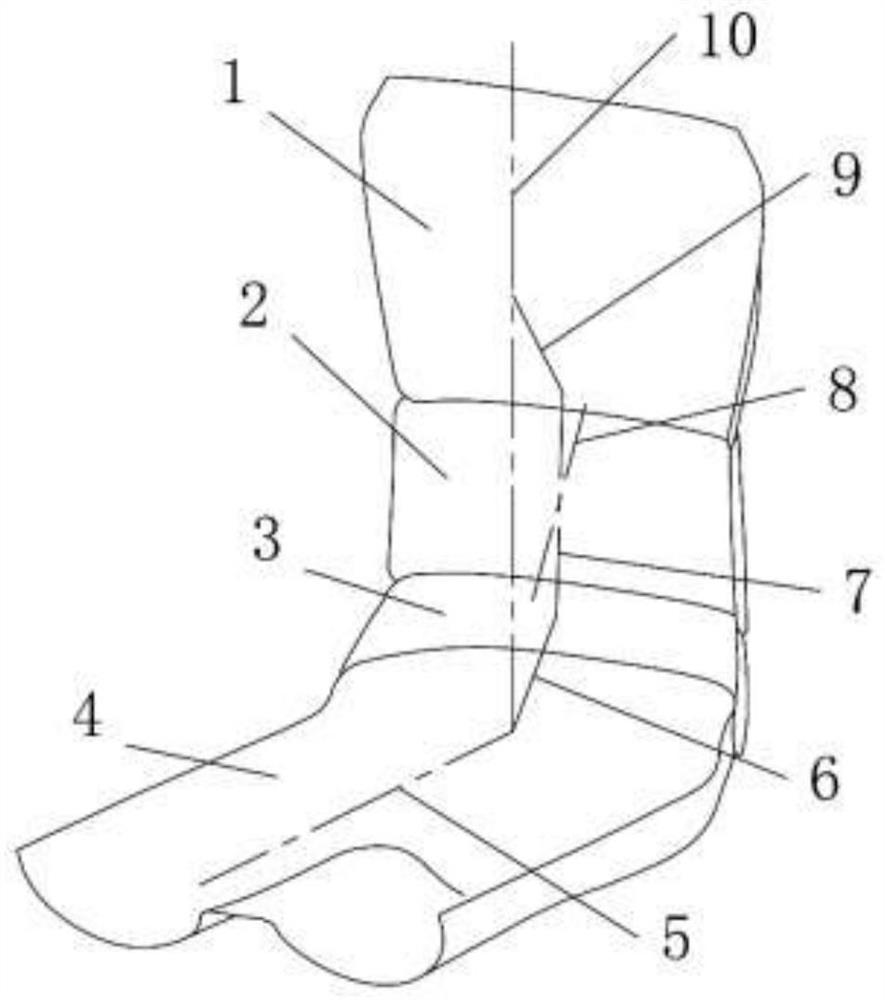

[0049] Among them, the shape of the dummy finite element model is established based on standard dummy tools or standard human body surface. The contour components of the dummy model include shoulder contour, back contour, waist contour and hip contour. The beam components of the dummy model include hip beam, Waist beam, back beam, connecting beam, shoulder beam and trunk beam;

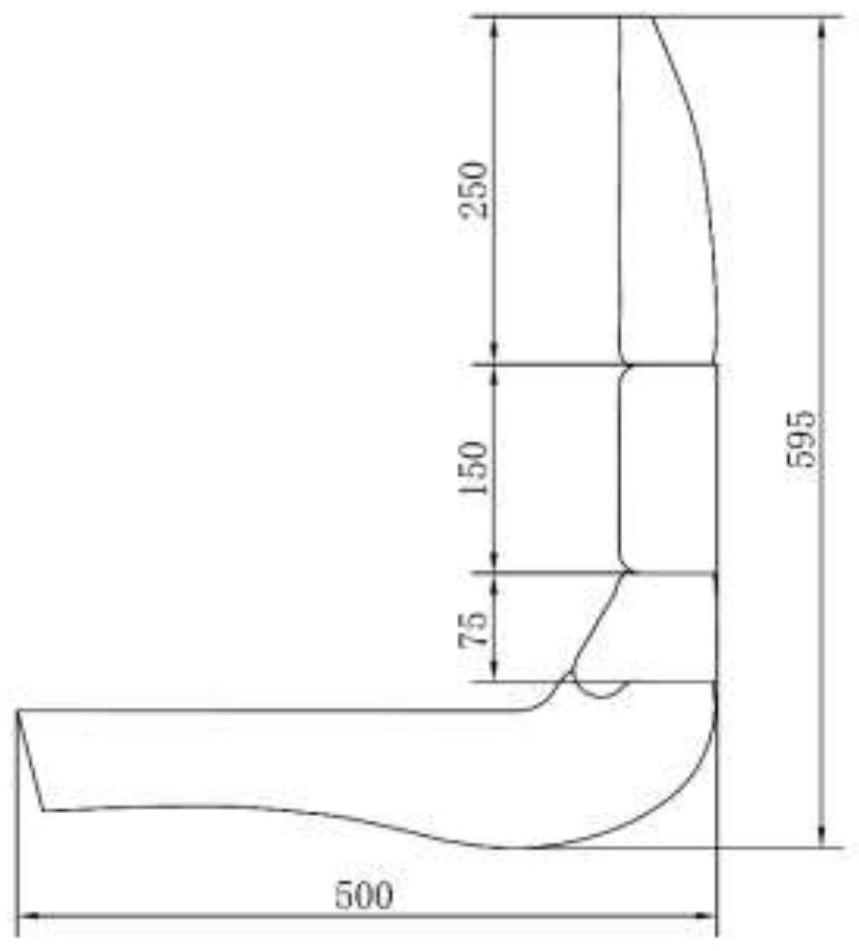

[0050] The size of the shoulder profile is 250mm, the size of the back profile is 150mm, t...

Embodiment 2

[0068] To design and check the seat whose design target population is the 95th percentile of men and has a geometric model, it is necessary to obtain the hard point coordinates and hard point size of the seat.

[0069] The method for fast simulation calculation of seat hard point and hard point size in this embodiment specifically includes the following steps:

[0070] Step S1: Extract the body surface of the 95th percentile man in the sitting posture, including the body surface of the buttocks, waist, back and shoulders; press image 3 and Figure 4 The size of the body surface contour surface is required to be intercepted as each contour component (which is a curved surface rather than a solid body); among them, the shoulder contour height is 250mm, the back contour height is 150mm, the waist contour height is 75mm, the total width is 405mm, and the total length is 500mm. The total height is 595mm; necessary geometric cleaning is performed, and a finite element mesh is draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com