Investment casting of hollow components

A technology of castings and processing methods, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve problems such as errors and achieve the effect of structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

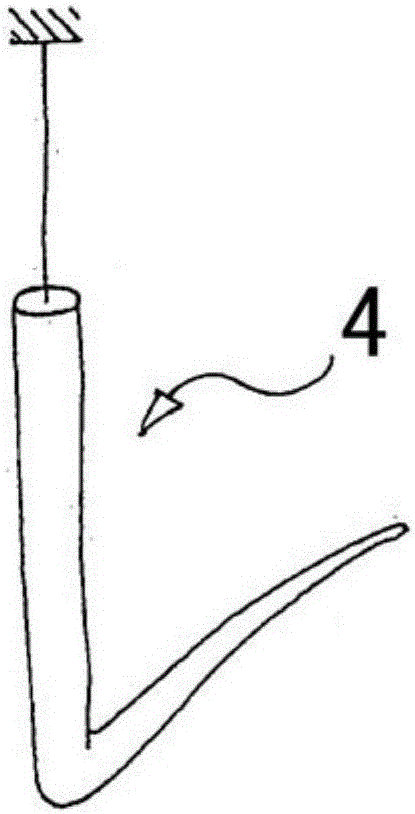

[0068] By using casting parts with 2 ( Figure 7 ) of the digital geometric coordinate system (not shown) of the 3D model, refer to figure 1 , during an initial method step, the core 4 is machined according to the 3D model in the first CNC-machining method, ie by CNC-milling (not shown).

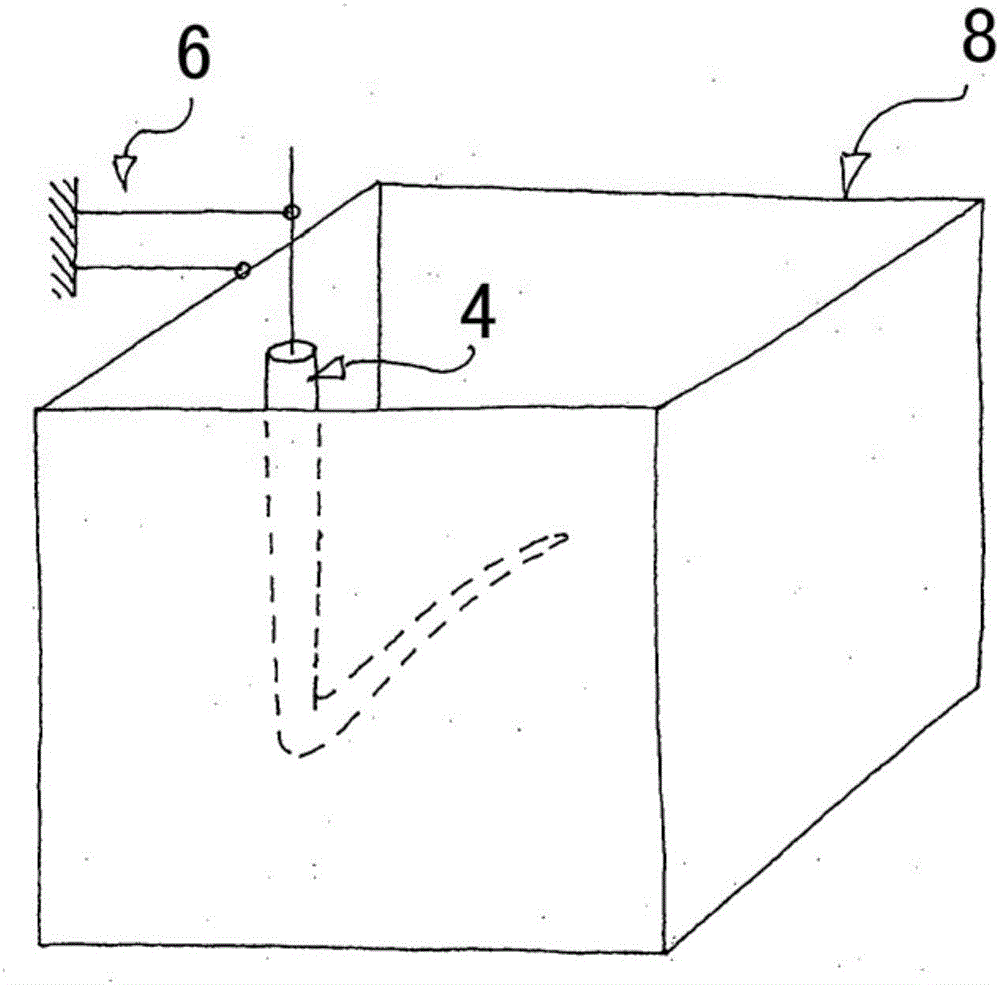

[0069] refer to figure 2 , the core 4 is positioned in the machining fixture 6 when the next process step is performed. The volume 8 is arranged around the mandrel and, at the same time, positioned and fixed in the machining holder 6 .

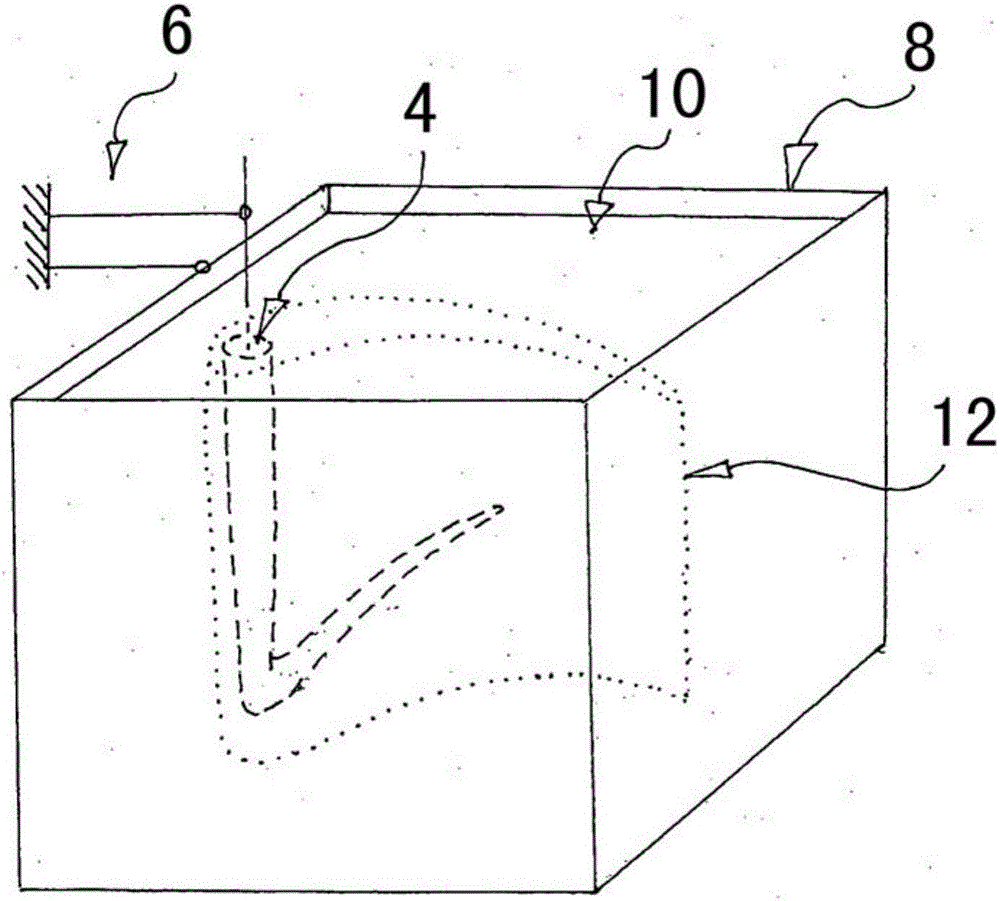

[0070] refer to image 3 , during the next method step, the mold wax 10 is cast around the core 4 into the volume 108 . The volume 8 is larger than the casting volume 12 , and the modeling wax 10 is cast around the core 4 into the volume 8 along the sides of the casting volume 12 . By the position of the core 4 in the machining holder 6, according to the cast part 2 (see Figure 7 ) of the 3D model (not shown) to determine the spatial position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com