A suspension system optimization method and device

A technology of a suspension system and an optimization method, applied in the field of vehicles, can solve problems such as no early design stage of vehicle products, and achieve the effects of shortening the product development cycle, reducing the problem of engine starting vibration, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

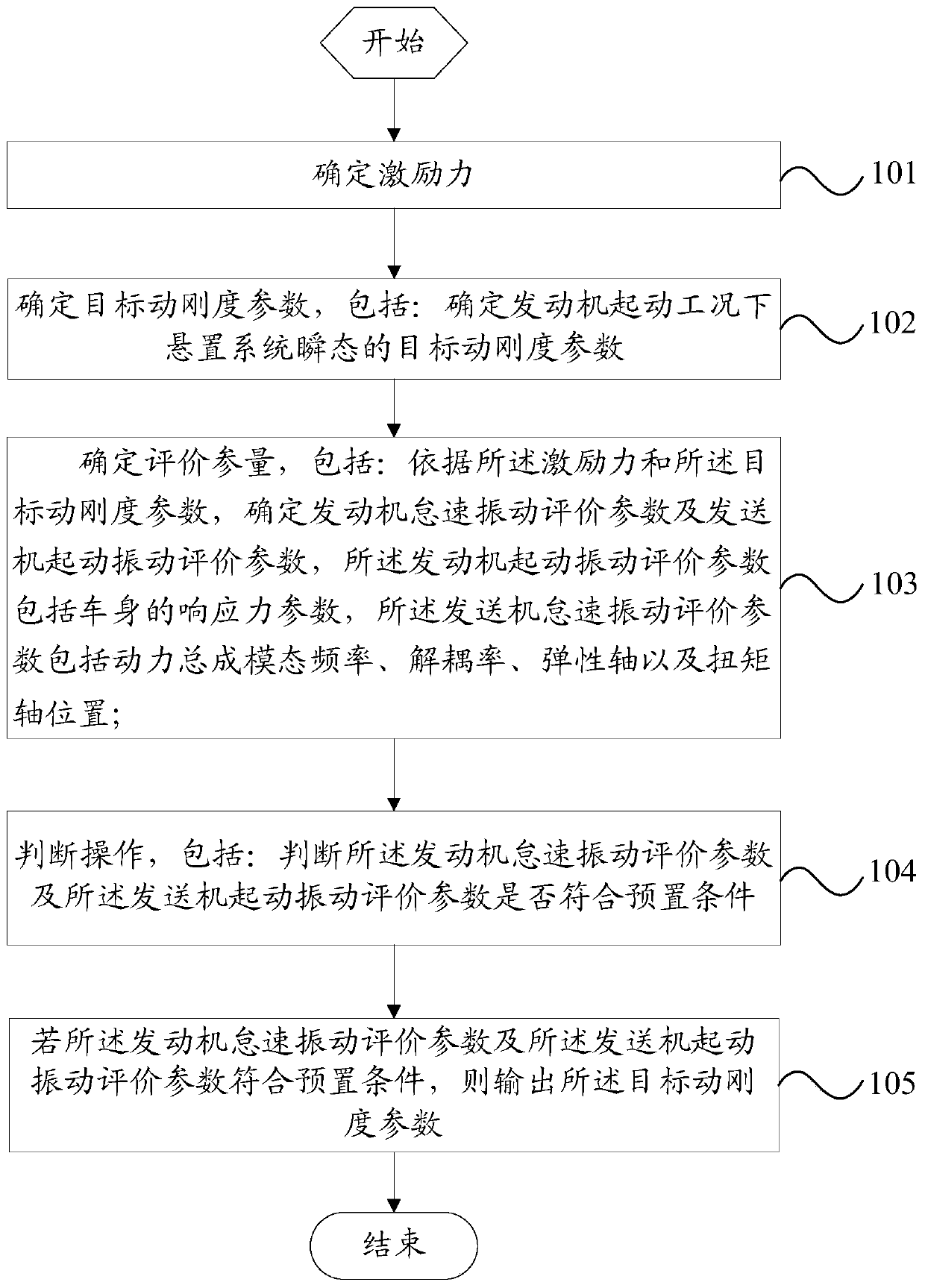

[0070] refer to figure 1 , shows a flow chart of the steps of a suspension system optimization method according to an embodiment of the present invention, which may specifically include the following steps:

[0071] Step 101: Determine the excitation force, including: determining the excitation force required for starting the engine according to the starting cylinder pressure and engine parameters of the engine, the excitation force includes overturning moment and reciprocating inertial force.

[0072] In the embodiment of the present invention, a powertrain model can be established. According to the starting cylinder pressure of the engine parameters of the engine, the powertrain model is used to determine the excitation force required for starting the engine. The excitation force includes overturning moment and reciprocating inertial force.

[0073] Step 102: Determine the target dynamic stiffness parameters, including: determining the transient target dynamic stiffness par...

Embodiment 2

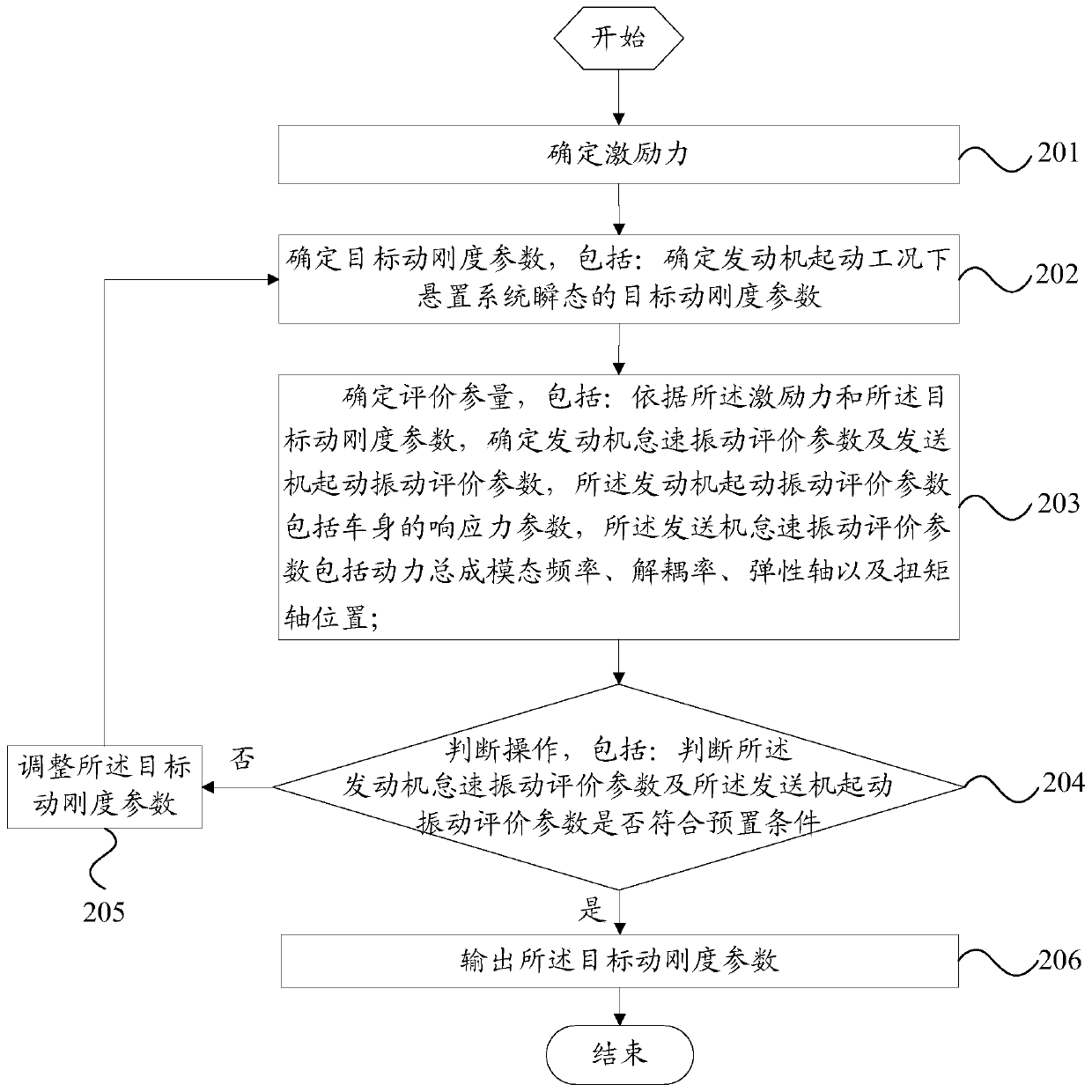

[0087] refer to figure 2 , shows a flow chart of steps of another suspension system optimization method according to an embodiment of the present invention, which may specifically include the following steps:

[0088] Step 201: Determine the excitation force, including: determining the excitation force required for starting the engine according to the starting cylinder pressure and engine parameters of the engine, the excitation force includes overturning moment and reciprocating inertial force.

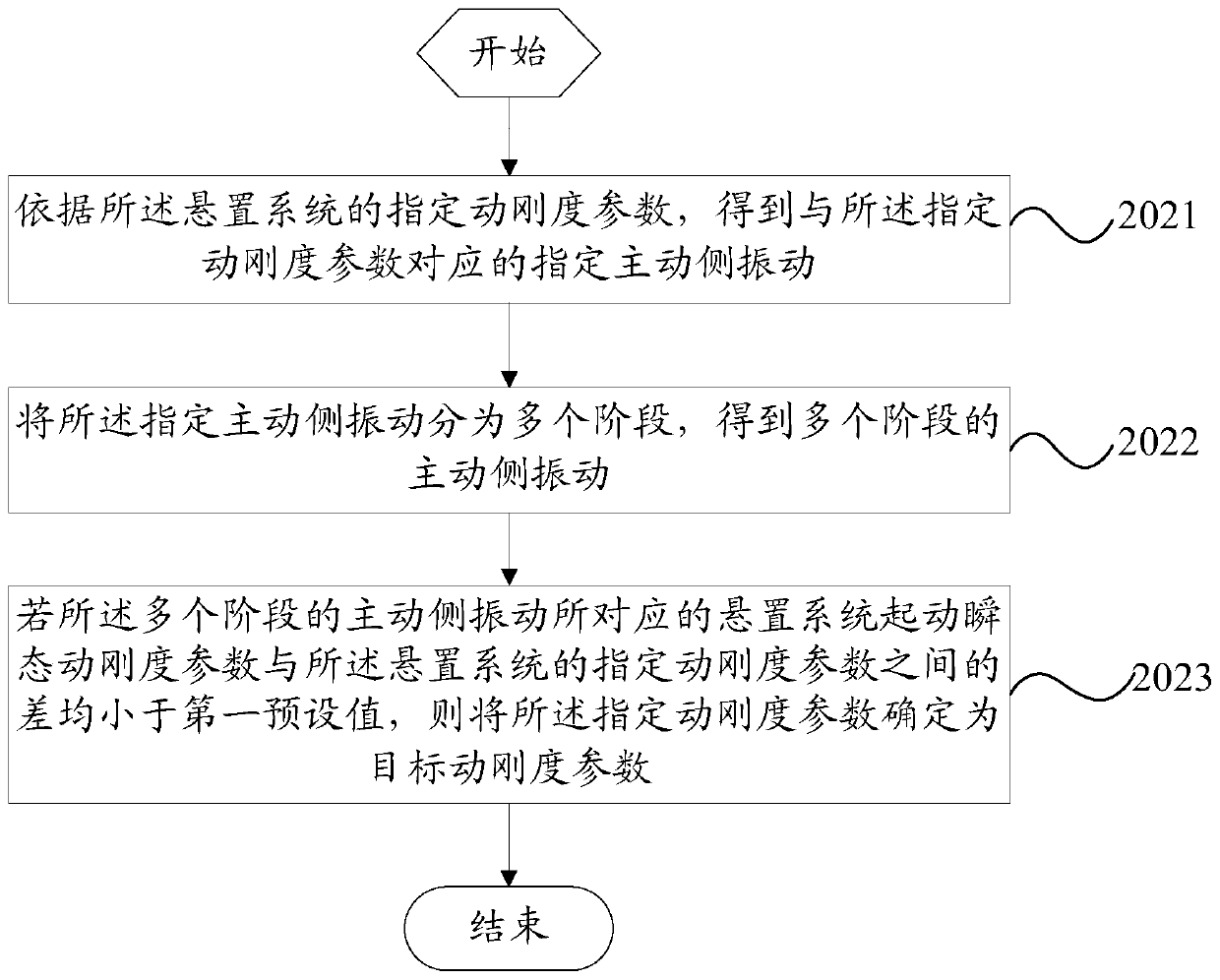

[0089] Step 202: Determine the target dynamic stiffness parameters, including: determining the transient target dynamic stiffness parameters of the suspension system under the engine starting condition.

[0090] In practical applications, the dynamic stiffness parameters of the mount system vary at different amplitudes and frequencies. The general dynamic stiffness parameters refer to the dynamic stiffness of the mount system at ±0.1mm amplitude and 25Hz frequency parameter, howeve...

Embodiment 3

[0132] refer to Figure 5 , which shows a structural block diagram of a suspension system optimization device according to an embodiment of the present invention, which may specifically include:

[0133] The excitation force determination module 501 is used to determine the excitation force, including: determining the excitation force required for starting the engine according to the starting cylinder pressure and engine parameters of the engine, the excitation force includes overturning moment and reciprocating inertial force;

[0134] A target dynamic stiffness parameter determining module 502, configured to determine a target dynamic stiffness parameter, including: determining a target dynamic stiffness parameter of the suspension system transient under engine starting conditions;

[0135] The evaluation parameter determination module 503 is used to determine the evaluation parameters, including: according to the excitation force and the target dynamic stiffness parameter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com