Method for determining rationality of thermal cycling test condition cutting of spacecraft electronic equipment

A technology of electronic equipment and test conditions, applied in the fields of electrical digital data processing, instruments, special data processing applications, etc., can solve the problems of under-testing or over-testing of a single spacecraft, and the tailoring formula cannot cover the types of spacecraft subsystems, etc. Avoid the effects of over-testing and under-testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: applied to thermal control subsystem TCS

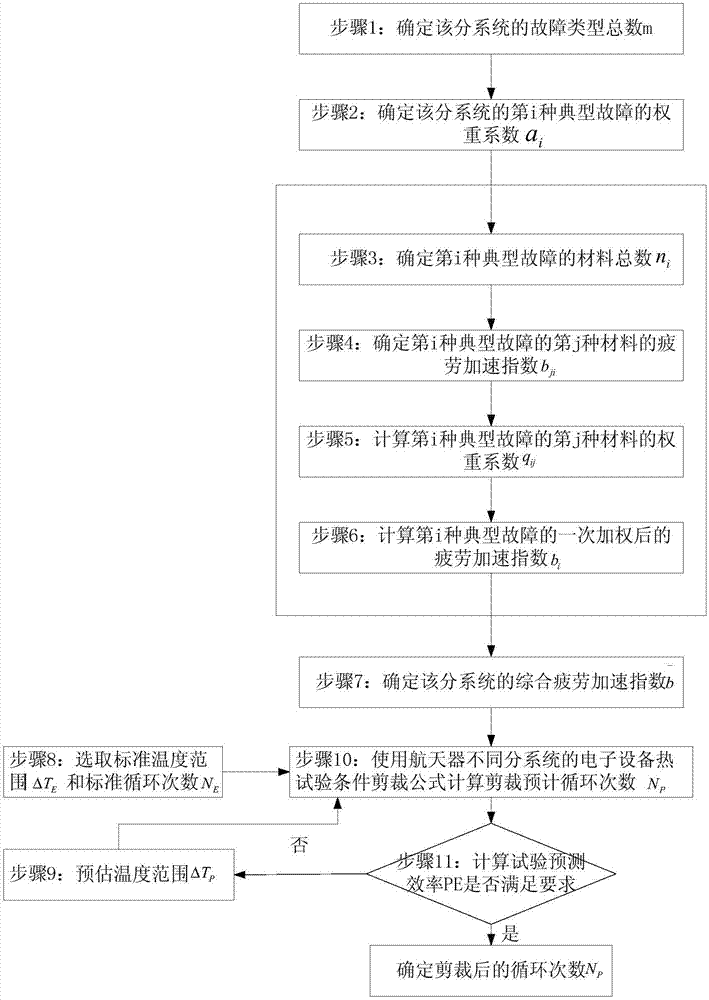

[0054] according to figure 1 The specific steps of the method are as follows:

[0055] Step 1: Determine the total number of failure types of the subsystem m = 5, including five types of failures: solder joint failure, coating failure, component failure, wire failure, and circuit board thermal deformation.

[0056] Step 2: According to the historical fault distribution statistics of spacecraft subsystems, determine the fault weight coefficient a of TCS i , the values are shown in Table 3.

[0057] Table 3 Weight coefficients of thermal failure types of TTC subsystems

[0058] weight factor

a 1

a 2

a 3

a 4

a 5

Fault type

Solder joint failure

coating failure

Component failure

wire fault

Thermal deformation of the circuit board

value

0.5

0.12

0.04

0.2

0.14

[0059] Step 3: Count the material types of TCS electronic equipment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com