Working parameter configuration method and device for gas injection equipment

A technology of working parameters and parameters, which is applied in the fields of earthwork drilling, design optimization/simulation, electrical digital data processing, etc., and can solve the problems of complex implementation process and inability to configure gas injection equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

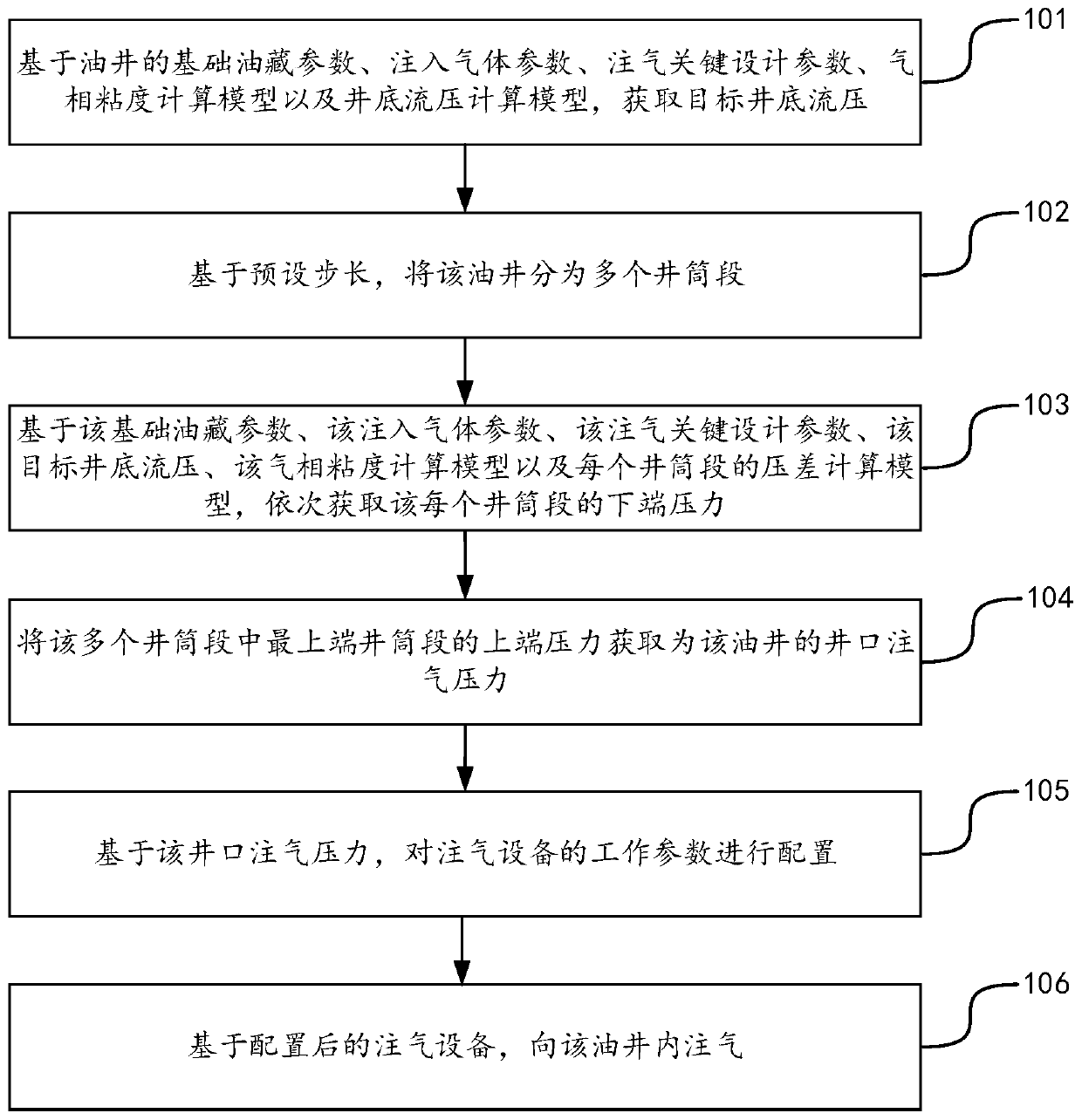

[0103] figure 1 It is a flow chart of a method for configuring working parameters of an infusion device provided by an embodiment of the present invention. The method may be applied to computer equipment, the method comprising:

[0104] 101. Based on the basic reservoir parameters, injection gas parameters, key design parameters of gas injection, gas phase viscosity calculation model and bottom hole flow pressure calculation model of the oil well, the target bottom hole flow pressure is obtained.

[0105] Among them, the basic reservoir parameters include formation temperature, oil layer depth, oil layer thickness and permeability, and the injected gas parameters include gas relative density, average gas compressibility factor, gas av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com