Machine shell fixing connection structure of dish washing machine

A technology for dishwashers and cabinets, which is applied in the field of fixed connection structures of cabinets, can solve problems such as not meeting user experience, not meeting production needs, increasing production costs, etc., to achieve cleaning, strong practicability, and The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

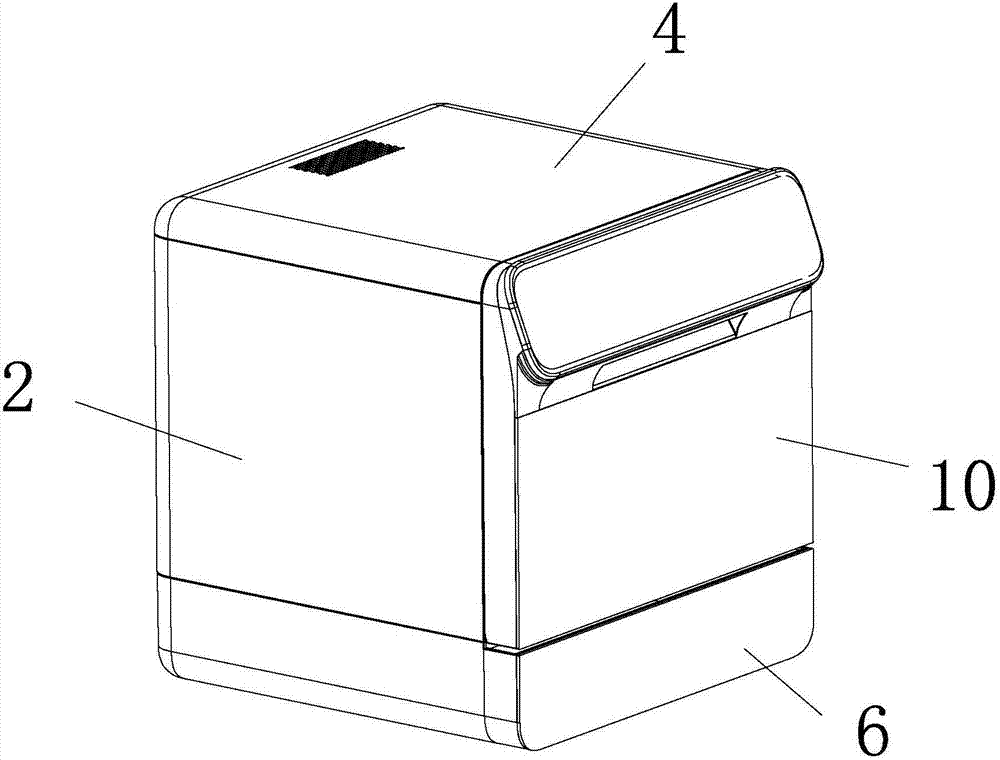

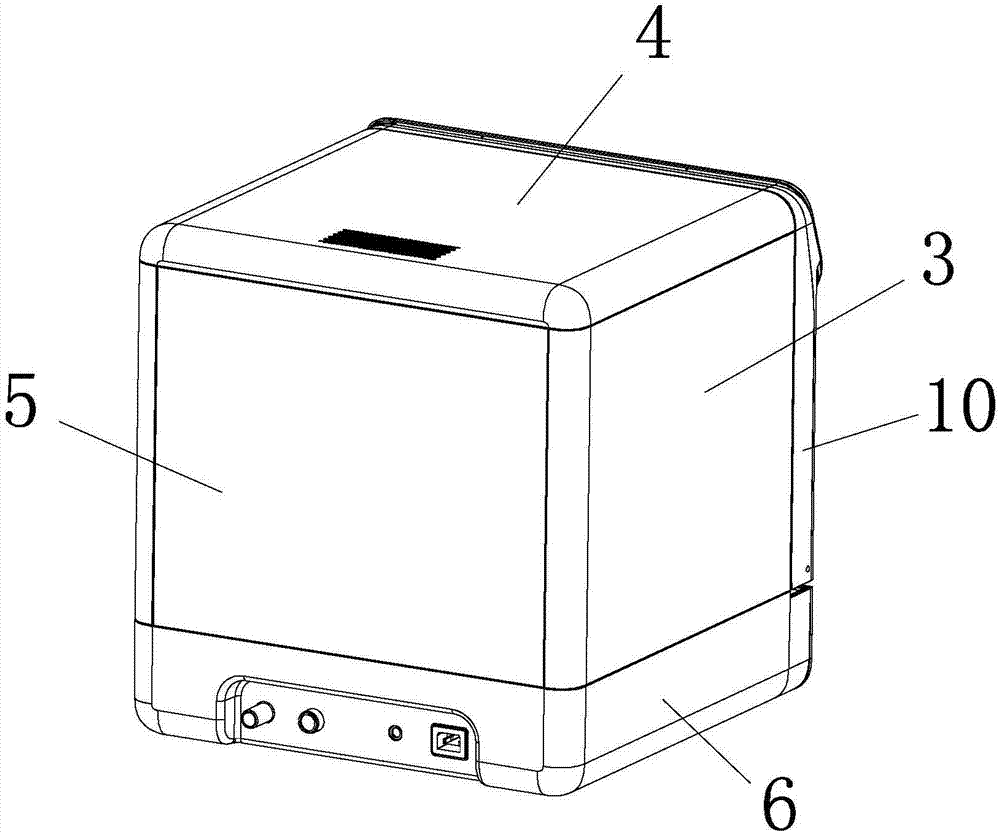

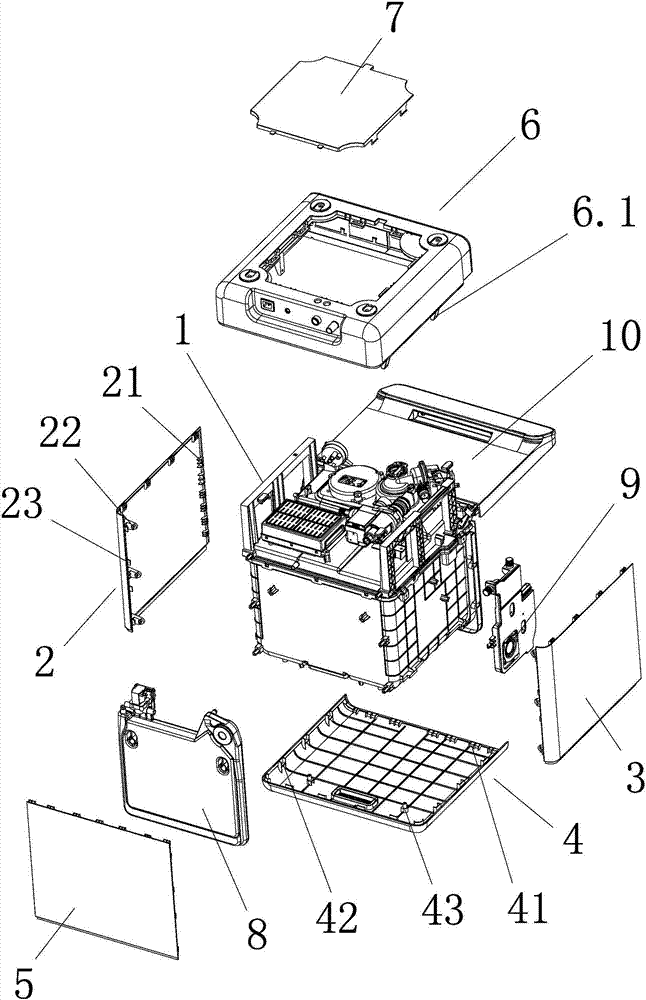

[0024] see Figure 1-Figure 11 , the fixed connection structure of the dishwasher, including an inner tank assembly 1, a left side panel 2, a right side panel 3, an upper cover 4, a rear cover 5, a bottom shell 6 and a door assembly 10, and the inner tank assembly 1 Including the inner tank base 11, the inner tank 12 and the front support bar 13 of the inner tank, the front support bar 13 of the inner tank is fixed to the front end of the inner tank 12 by screws, the inner tank base 11 and the inner tank 12 are engaged with each other, and the two are locked After being connected, they are fixed to each other by screws, and the inner tank base 11 is supported on the top of the bottom shell 6, and the two are fixed to each other by screws; On the top, the left side plate 2 and the right side plate 3 are respectively fixed to the inner tank 12 by screws,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com