Powder coating processing device

A technology of processing equipment and powder coating, applied in the field of powder coating processing equipment, can solve the problems of inconvenient maintenance, difficult maintenance, difficult manufacturing, etc., and achieve the effect of convenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

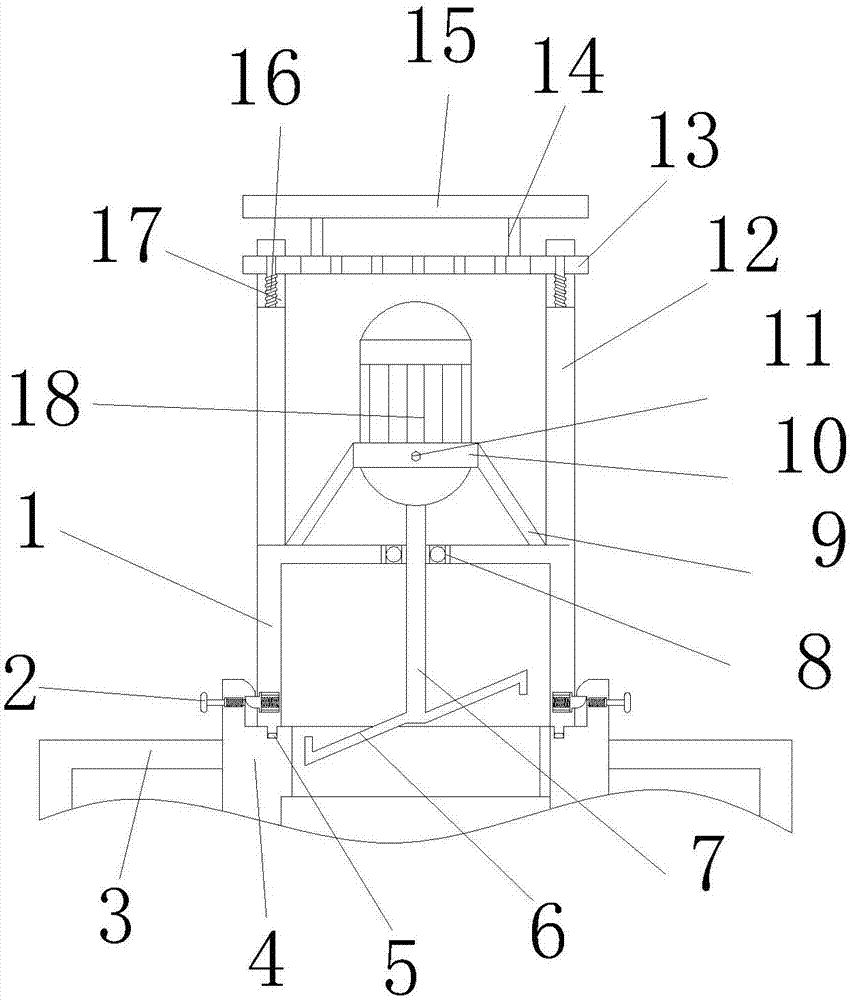

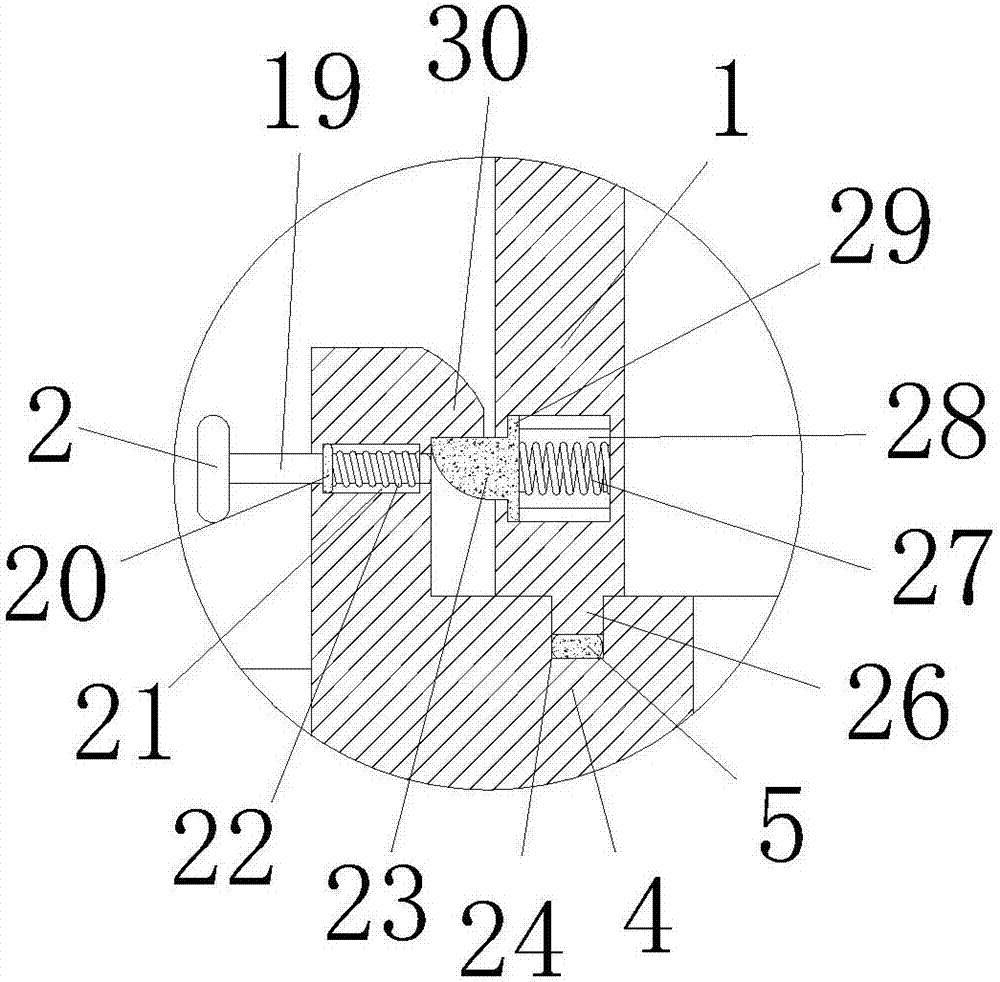

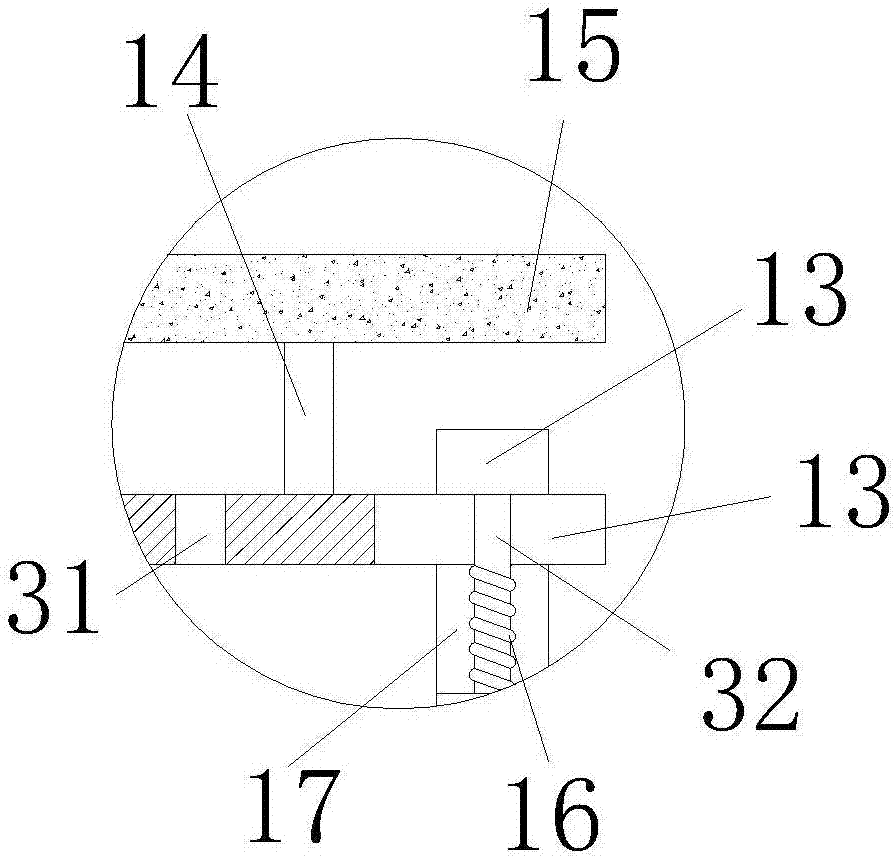

[0014] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0015] see Figure 1-3 , the present invention provides a technical solution: a powder coating processing equipment, including a base 4 and a housing 1, the housing 1 is installed above the base 4, feet 3 are provided on the left and right sides of the base 4, and the upper surface of the housing 1 is provided with There is a cylinder 12, an empty slot 17 is arranged above the cylinder 12, a first cover plate 13 is provided inside the empty slot 17, and a plurality of vents 31 are arranged on the surface of the first cover plate 13, through which vents 31 can keep For the normal flow of air inside the cylinder 12, a metal connecting rod 25 is provided inside the cavity 17, and the metal connecting rod 25 runs through the first cover plate 13 and connects with the cavity, and the first cover plate 13 can move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com