A kind of production process and production device of fiber composite airgel felt

An aerogel felt and fiber composite technology, used in ceramic products, other household appliances, household appliances, etc., can solve the problem of re-rolling, cumbersome winding process, difficult to control solvent volatilization and dripping, complicated and unsafe rolling /winding and other issues, to achieve the effect of realizing large-scale automated production, reducing organic material handling operations, and maintaining quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

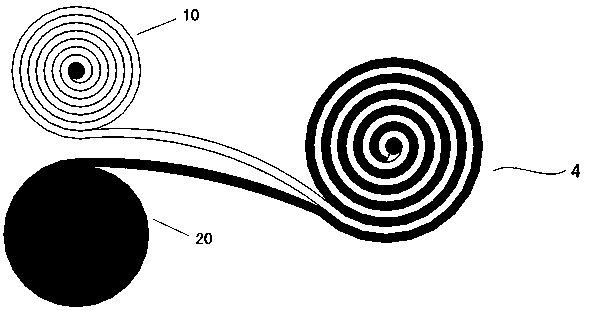

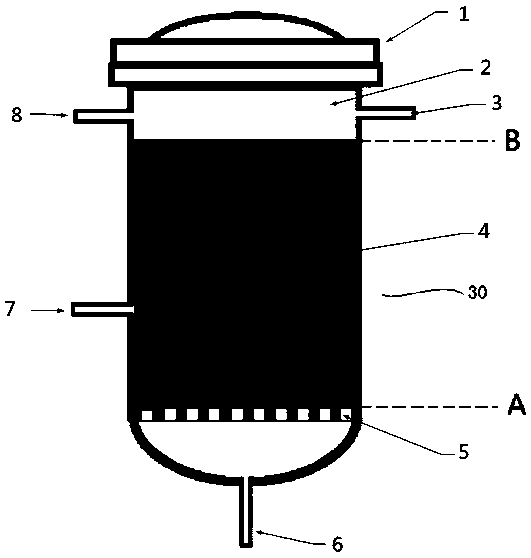

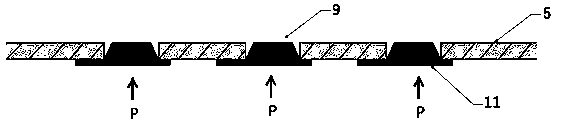

[0078] Press the fiberglass mat with the flexible interlayer of polyamide figure 2 Roll into a roll, hang it into the drying kettle, seal the drying kettle, and inflate and pressurize the bottom of the drying kettle, so that the small holes of the pallet are sealed. The alumina alcohol sol liquid is prepared in advance, mixed with sodium hydroxide aqueous solution in a certain proportion, and then added to the drying kettle through the liquid inlet on the upper part of the drying kettle until the glass fiber mat is fully saturated, and then the liquid inlet is closed. After standing for 30 minutes, the hydrolyzed liquid gels, and then standing for 50 minutes for aging. Open the bottom valve of the kettle, remove the gas to reduce pressure, and introduce carbon dioxide gas from the upper air inlet. The small holes of the support plate are open and gradually pressurized. to 12Mpa, and heated to 45°C, then through the carbon dioxide supercritical cycle drying process to remove t...

Embodiment 2

[0080] Press the PET fiber mat and the flexible interlayer made of polyacrylate figure 2 Roll into a roll, hang it into the drying kettle, seal the drying kettle, and inflate and pressurize the bottom of the drying kettle, so that the small holes of the pallet are sealed. The pre-prepared resorcinol-formaldehyde sol liquid was added to the drying kettle through the liquid inlet on the upper part of the drying kettle until the PET fiber felt was fully saturated, and then the liquid inlet was closed. After standing for 20 minutes, the hydrolyzate gelled, and then left standing for aging for 2 hours. The mixed fluid of carbon dioxide and acetone was introduced from the upper air inlet, gradually pressurized to 10Mpa, and heated to 50°C, and then through the carbon dioxide supercritical cycle drying process, the solvent in the gel was removed, and finally the isothermal pressure reduction process was carried out to reduce the temperature. After reaching normal pressure, open the...

Embodiment 3

[0082] Press the fiberglass mat with the flexible interlayer of polysiloxane figure 2 Roll into a roll, hang it into the drying kettle, seal the drying kettle, and inflate and pressurize the bottom of the drying kettle, so that the small holes of the pallet are sealed. Using ethyl orthosilicate and methyltriethoxysilane in a mass ratio of 4:6 as a mixed silicon source, ethanol as a solvent, and an aqueous sulfuric acid solution as a catalyst, a hydrolyzed solution is pre-prepared, and mixed with an aqueous sodium carbonate solution in a certain proportion, Through the liquid inlet on the upper part of the drying kettle, add it into the drying kettle until the glass fiber mat is fully saturated, and then close the liquid inlet. After standing for 15 minutes, the hydrolyzed liquid gelled, and then left standing for aging for 1 hour. Carbon dioxide gas was introduced from the upper air inlet, gradually pressurized to 15Mpa, and heated to 50 °C, and then the supercritical carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com