Cashmere carding machine

A technology of flat carding machine and cashmere, applied in the field of cashmere flat carding machine, can solve the problems of poor quality and insufficient uniformity of fiber web.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the drawings.

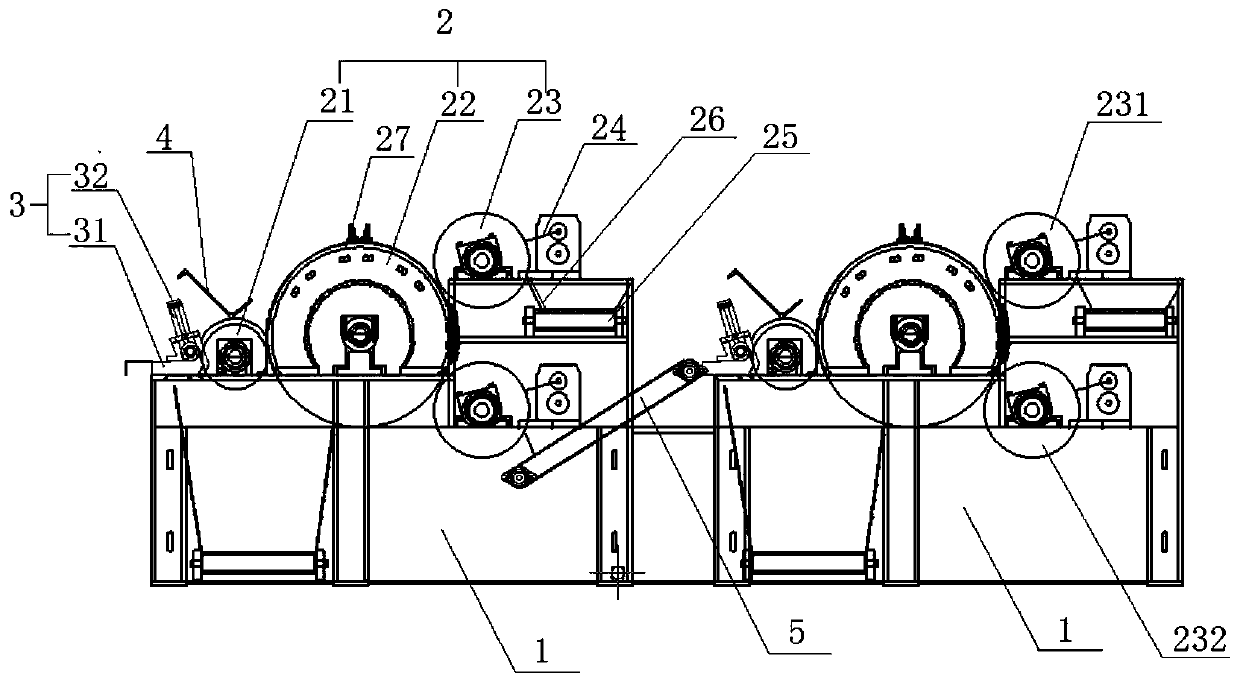

[0032] figure 1 It is a schematic structural diagram of a cashmere flat combing machine in the embodiment of the present invention; it includes a flat combing mechanism 1, the number of flat combing mechanisms 1 is at least two, and the flat combing mechanisms 1 are connected in series.

[0033] For example, two flat combing mechanisms 1 are set, and a conveying flat curtain 5 is arranged between the two flat combing mechanisms 1 connected in series. After the current flat combing mechanism 1 completes the combing work, the wool is conveyed through the conveying flat curtain 5 and the next flat comb The combing work is repeated again in the mechanism 1, so after repeated combing, rough removal, combing and agglomeration, most of the coarse hair and impurities can be removed, and the generation of waste can be greatly reduced, and the extraction rate of fluff-free can be improved.

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com