Method for resin hole plugging after patterning

A resin plug hole and pattern technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve problems such as high cost and complex process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

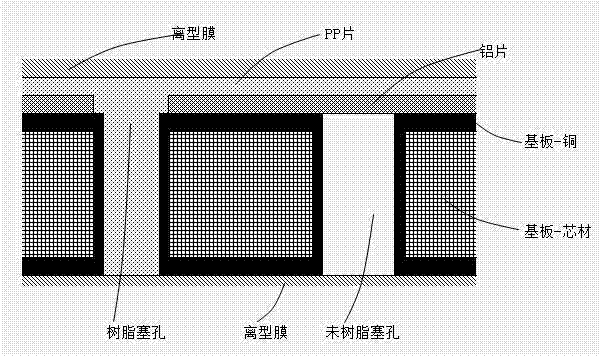

[0024] For setting forth the concrete implementation method of the present invention, below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] A. The substrate that needs to be plugged after the graphics are prepared. The size of the substrate is 610mm*510mm, the thickness of the substrate is 1.6mm, the hole diameter that needs to be plugged is 0.45mm, the number of holes is 9846, the graphics area accounts for 56% of the substrate area, and the copper thickness is 51um. The transparent PET film to be torn off after the dry film is applied, the thickness of the film is 10um, and the size is 615mm*515mm.

[0026] B. Put the PET film on both sides of the board, apply alcohol rosin on the four corners of the substrate to have a slight adhesion with the PET film, put 5 pieces of kraft paper on each side for normal vacuum lamination, the pressure is 30kgf / cm2, and the temperature is 180°C. The lamination time is 30 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com