Wood product deburring equipment

A technology for wood products and deburring, used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as hidden installation hazards, low work efficiency, easy damage to wood products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

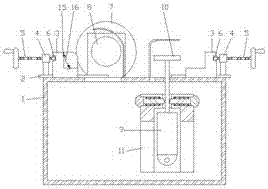

[0015] Example: see figure 1 , 2 As shown, the wood product deburring equipment includes a box body 1, a guide rail 2 is fixed on the box body 1, an L-shaped slider 3 is inserted and sleeved on the guide rail 2, a nut 4 is fixed on the box body 1, and a hand screw 5 and The nuts 4 are screwed together, the outer ring of the bearing 6 is fixed on the slider 3, and the inner ring of the bearing 6 is fixed with the hand screw 5;

[0016] The first motor 7 is fixed on the box body 1, and an elastic friction roller 8 is fixed on the rotating shaft of the first motor 7;

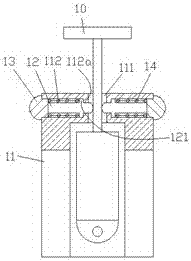

[0017] A grinding wheel 10 is fixed on the rotating shaft of the second motor 9, and the motor seat of the second motor 9 is hinged on the floating seat 11, and the floating seat 11 is fixed in the casing 1, and the upper part of the floating seat 11 is cylindrical and formed with a floating seat The center hole 111, the rotating shaft of the second motor 9 is inserted in the center hole 111 of the floating seat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com