Installation vehicle for overhead power line supporting frame

A technology for high-voltage wires and support frames, applied in workshop equipment, overhead line/cable equipment, manufacturing tools, etc., can solve problems such as unstable support frames and potential safety hazards, improve installation efficiency and quality, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

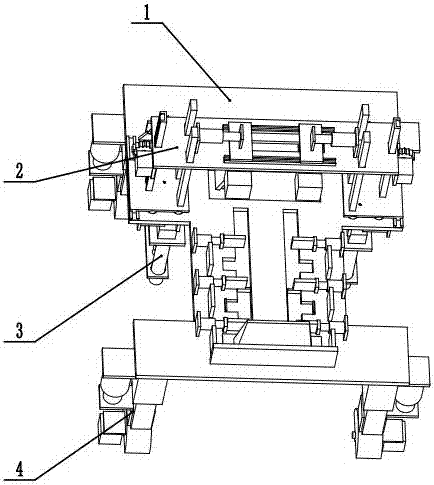

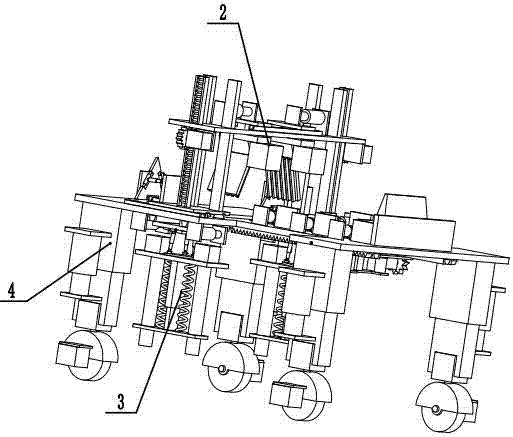

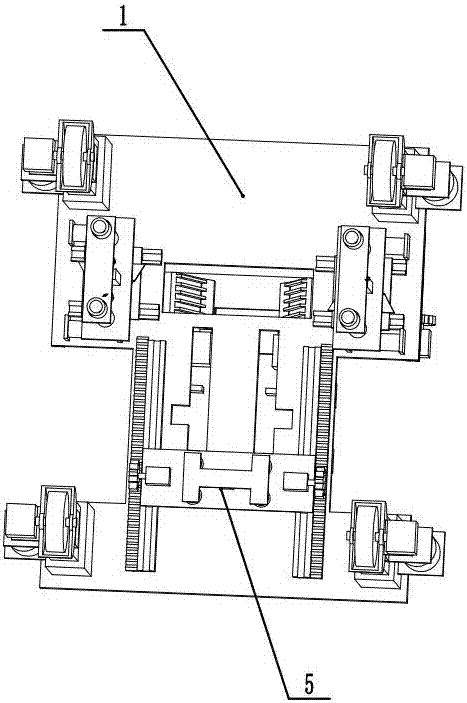

[0019] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a high-voltage wire support frame installation vehicle includes a base 1, a support frame fixing part 2, two screw parts 3, four walking parts 4, and a support frame transport part 5. It is characterized in that: the support frame The two first sliders 201 of the fixed part 2 are respectively slidably installed in the two first dovetail grooves 103 above the base 1, and the outer sides of the two second parallel mechanism bottom plates 218 are respectively fixedly installed on the two first support plates 102 inner side; the four second sliders 304 of the two screwing parts 3 are respectively slidably installed in the four second dovetail grooves 114 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com