Foam cutting machine

A cutting machine and foam technology, applied in metal processing and other directions, can solve problems such as low safety factor, poor mold applicability, delay time, etc., and achieve the effect of ensuring no need to repair, control production speed, and facilitate cutting control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

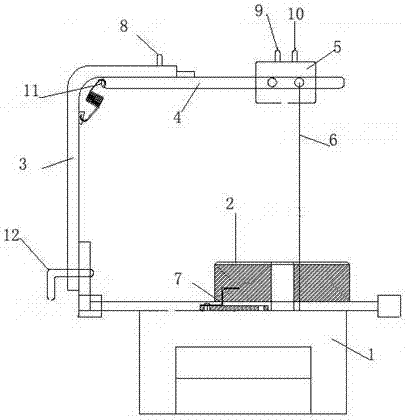

[0013] Combine below figure 1 Specific description embodiment:

[0014] The foam cutting machine includes a workbench 1, the workbench 1 is provided with a rotary adjustment disc 2, one side of the workbench 1 is provided with a single gantry Y-axis 3, and the upper end of the single gantry Y-axis 3 is provided with a single gantry X axis 4, one end of single gantry X axis 4 is connected with a heating wire adjustment device 5, and the heating wire adjustment device 5 is connected with a heating wire 6, and one end of the heating wire 6 is set on the heating wire adjustment device, and the other end of the heating wire 6 Set on the sliding assembly 7 of the workbench 1, the position of the heating wire 6 on the workbench can be adjusted through the heating wire adjusting device and the sliding assembly.

[0015] Preferably, a heating wire tightness adjusting device 8 is provided between the single gantry Y-axis 3 and the single gantry X-axis 4, and a heating wire fastening de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com