Bearing roller orderly-arrangement mechanism and bearing production equipment

A technology of bearing rollers and rollers is applied in the fields of bearing roller straightening mechanisms and bearing production equipment, which can solve problems such as low production efficiency and achieve the effect of solving the low production efficiency of manual material sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

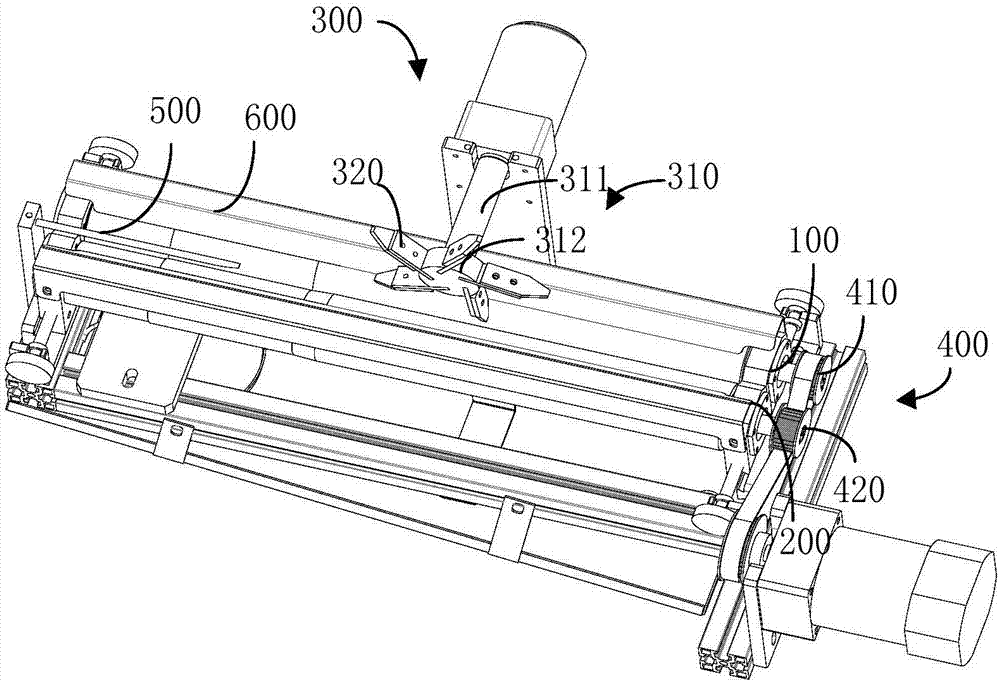

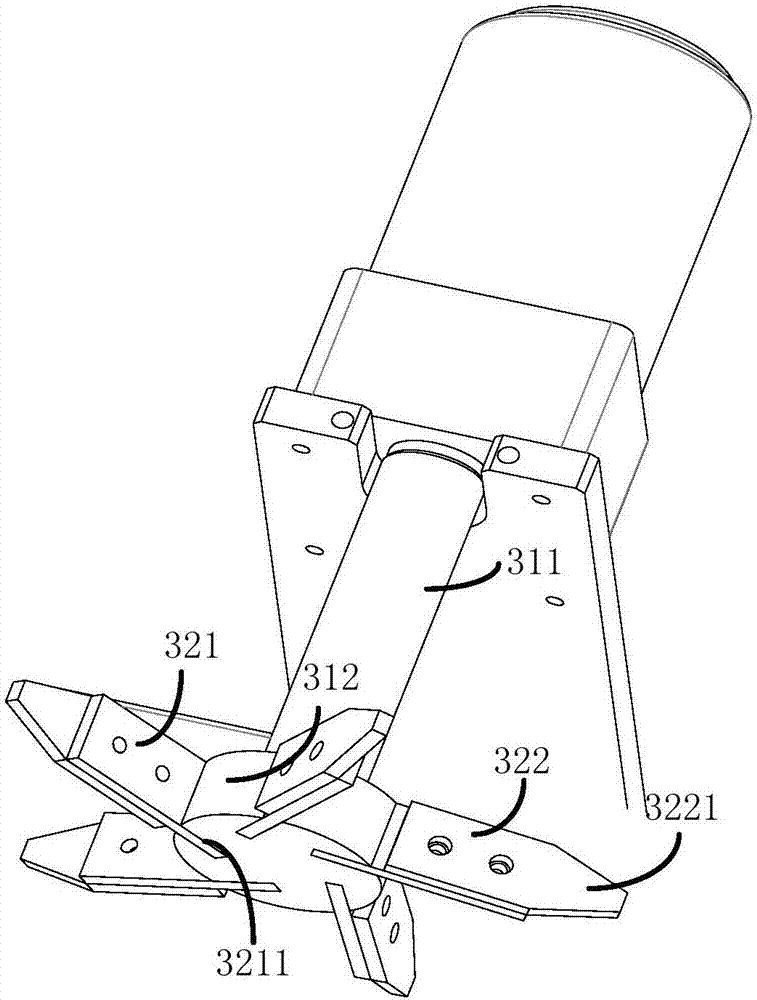

[0053] This embodiment provides a bearing roller straightening mechanism, please refer to Figure 1 to Figure 5 , including a first drum 100 , a second drum 200 and a distributor 300 .

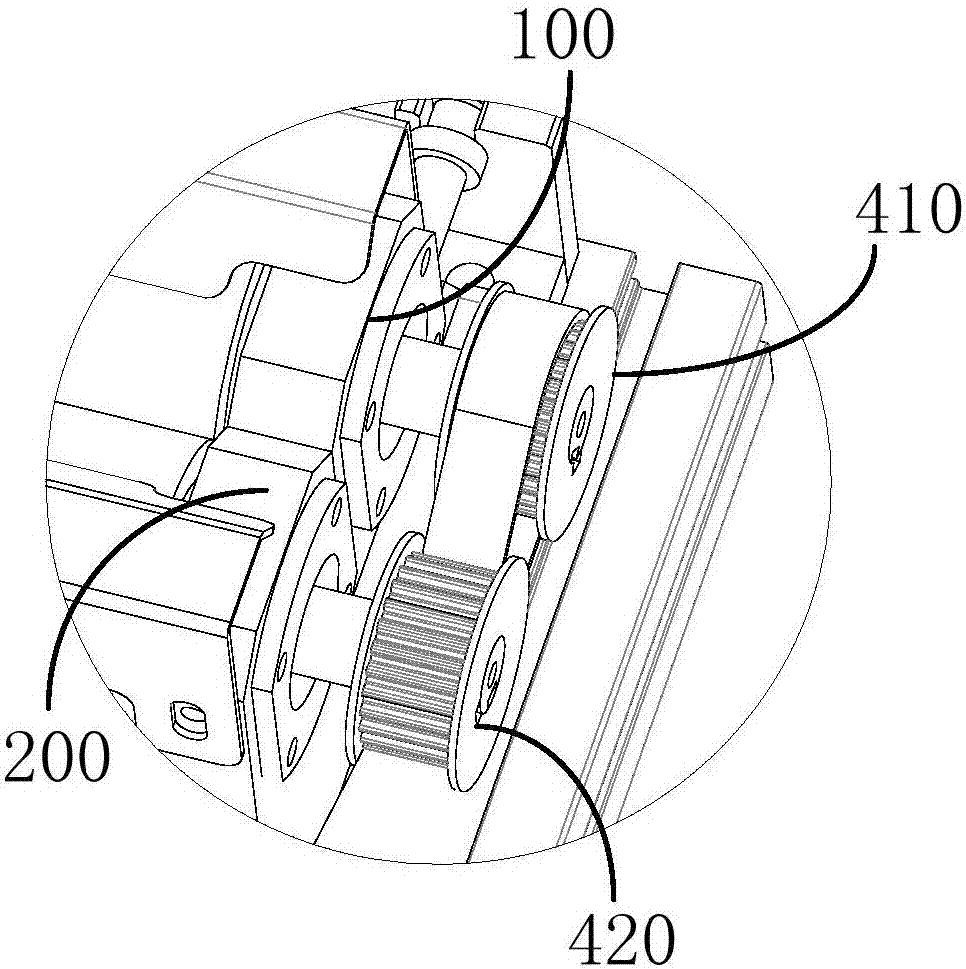

[0054] The first roller 100 and the second roller 200 can rotate oppositely around their own axes, and a transportation channel for bearing rollers is formed between the first roller 100 and the second roller 200,

[0055] The distributor 300 is located above the transport channel, and can rotate around its own axis and move the bearing rollers to adjust the attitude of the bearing rollers.

[0056] In the specific work process:

[0057] The first roller 100 and the second roller 200 rotate oppositely around their own axes, and the bearing roller enters the transport channel formed between the first roller 100 and the second roller 200 from the feed port end of the bearing roller straightening mechanism, and passes through the first The rotating force of the roller 100 and the second roller 20...

Embodiment 2

[0077] This embodiment provides a bearing production equipment, including the bearing roller straightening mechanism in Embodiment 1.

[0078] In the specific work process:

[0079] The first roller 100 and the second roller 200 rotate oppositely around their own axes, and the bearing roller enters the transport channel formed between the first roller 100 and the second roller 200 from the feed port end of the bearing roller straightening mechanism, and passes through the first The rotating force of the roller 100 and the second roller 200 is gradually conveyed to the outlet end of the bearing roller straightening mechanism, and changes from a disordered state to a neat state during the conveying process, and because the distributor 300 can rotate and move the bearing Therefore, the posture of the bearing rollers can be further adjusted, and the straightening operation of the bearing rollers is realized, which effectively solves the technical problem of low production efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com