Three-phase separator used for internal circulation anaerobic reactor

A technology of three-phase separator and anaerobic reactor, applied in the field of three-phase separator, can solve problems such as blockage of gas collecting holes, and achieve the effect of uniform liquid and less entrained fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

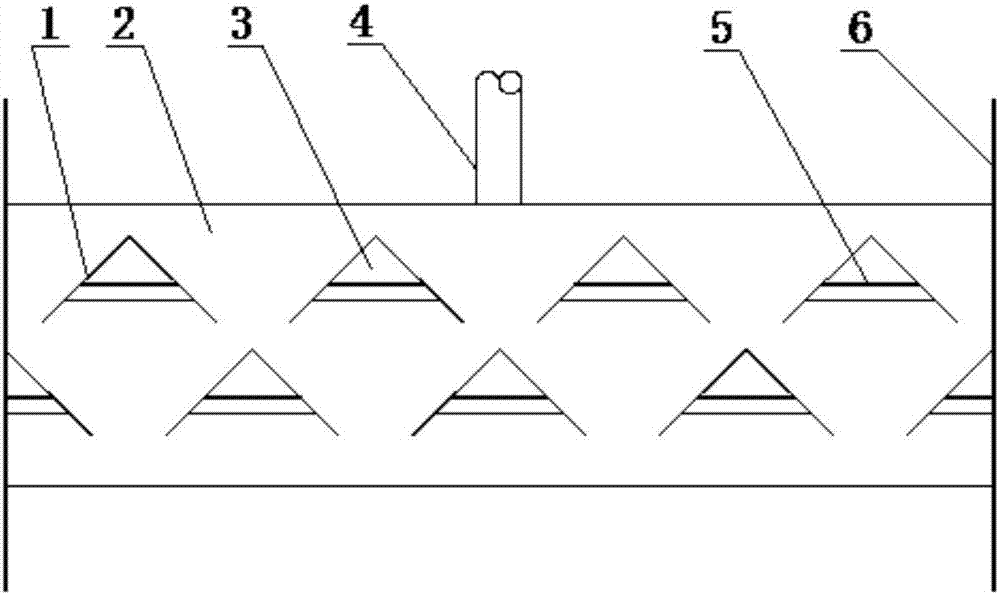

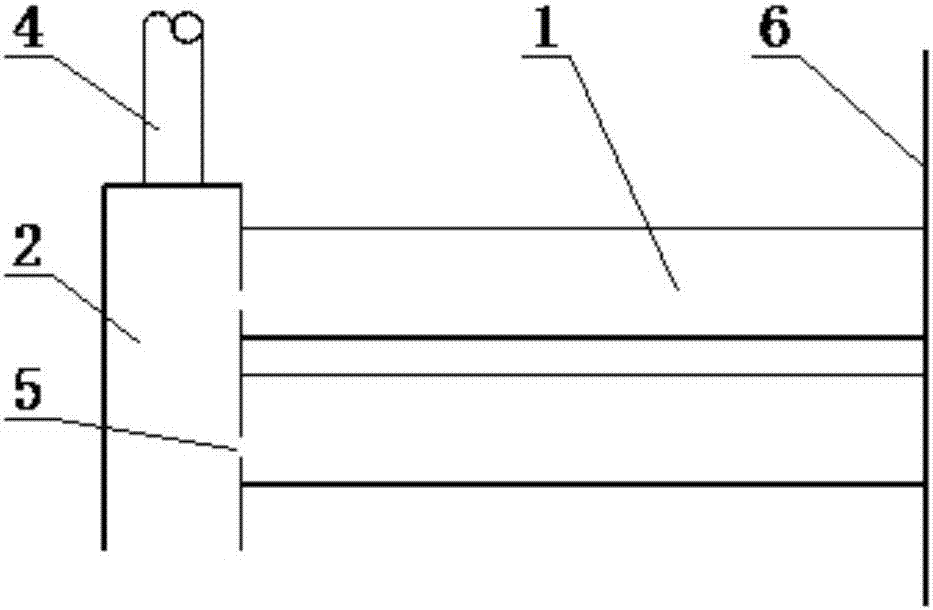

[0033] Such as Figure 7-9 As shown, the present invention is used for the three-phase separator of the internal circulation anaerobic reactor, including: gas collection hood 50, gas collection chamber 70 and draft tube (not shown in the figure); Wherein,

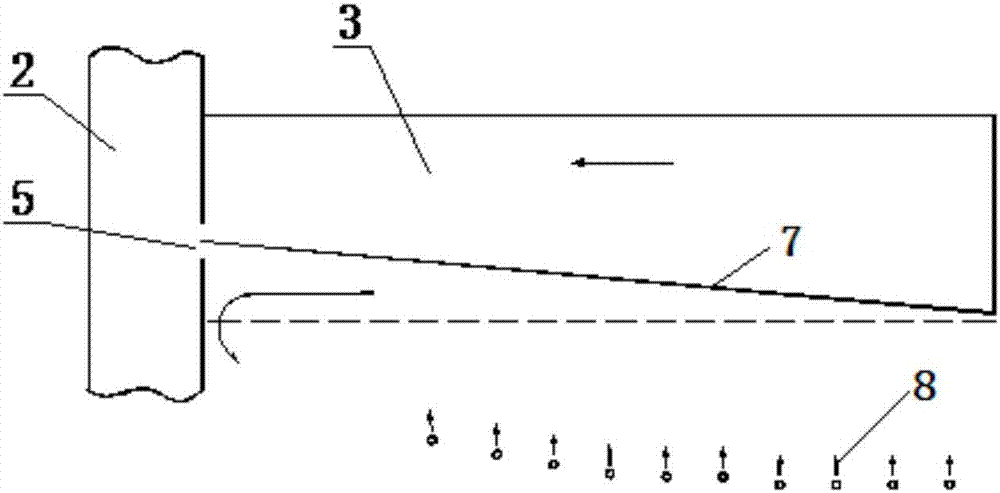

[0034] The gas collecting hood 50 is an inverted V-shaped structure, and the two ends of the gas collecting hood 50 along its length direction are vertically arranged on the side wall 60 of the reactor;

[0035] The air collecting chamber 70 is a closed cylindrical cavity, and its upper surface 72 and lower surface 76 both protrude upwards, and the lower surface 76 is provided with an air collecting hole 74 along the alignment direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com