A kind of slope support construction method

A construction method and slope technology, applied in excavation, artificial islands, water conservancy projects, etc., to achieve the effects of low cost, enhanced water erosion resistance, and enhanced construction mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

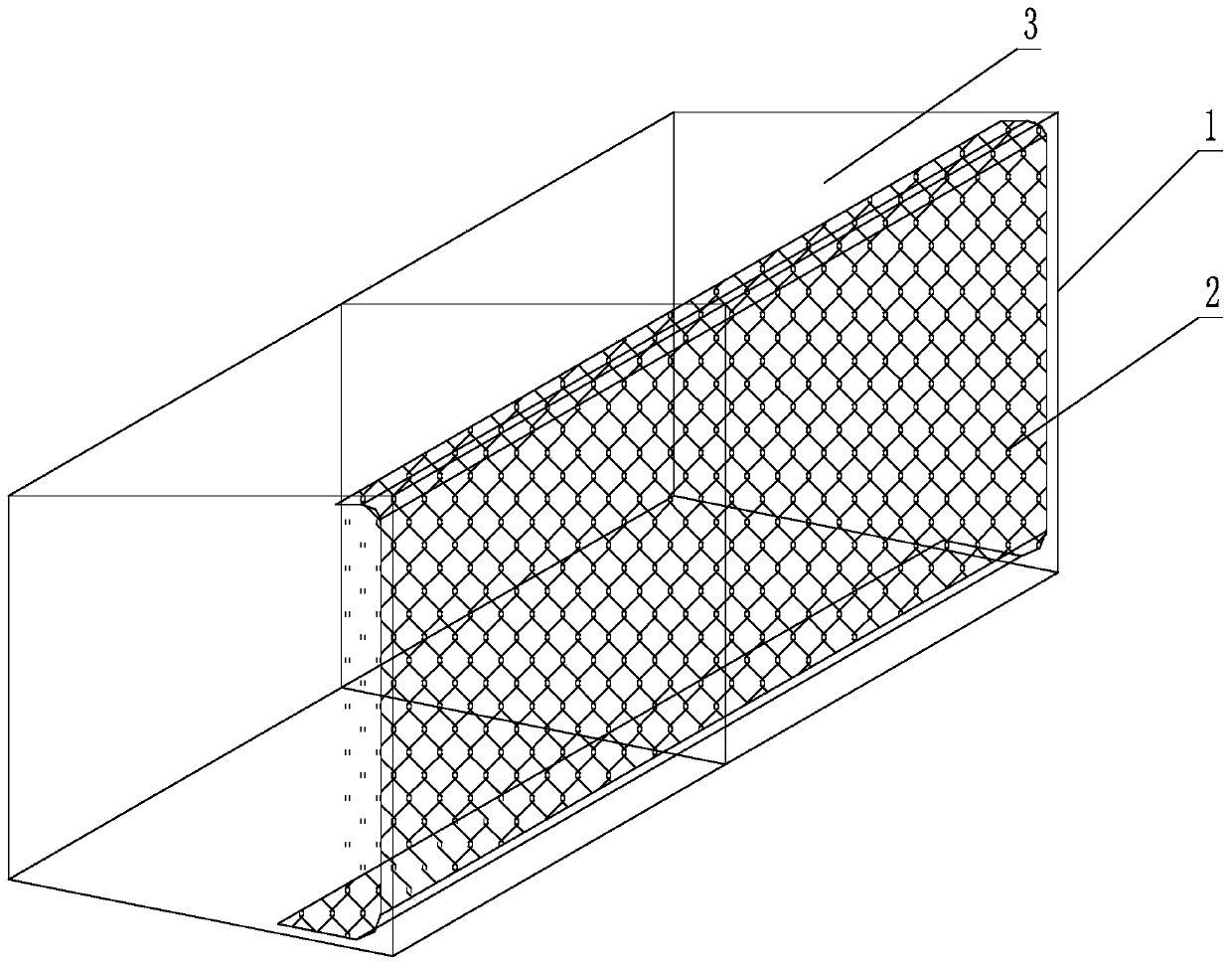

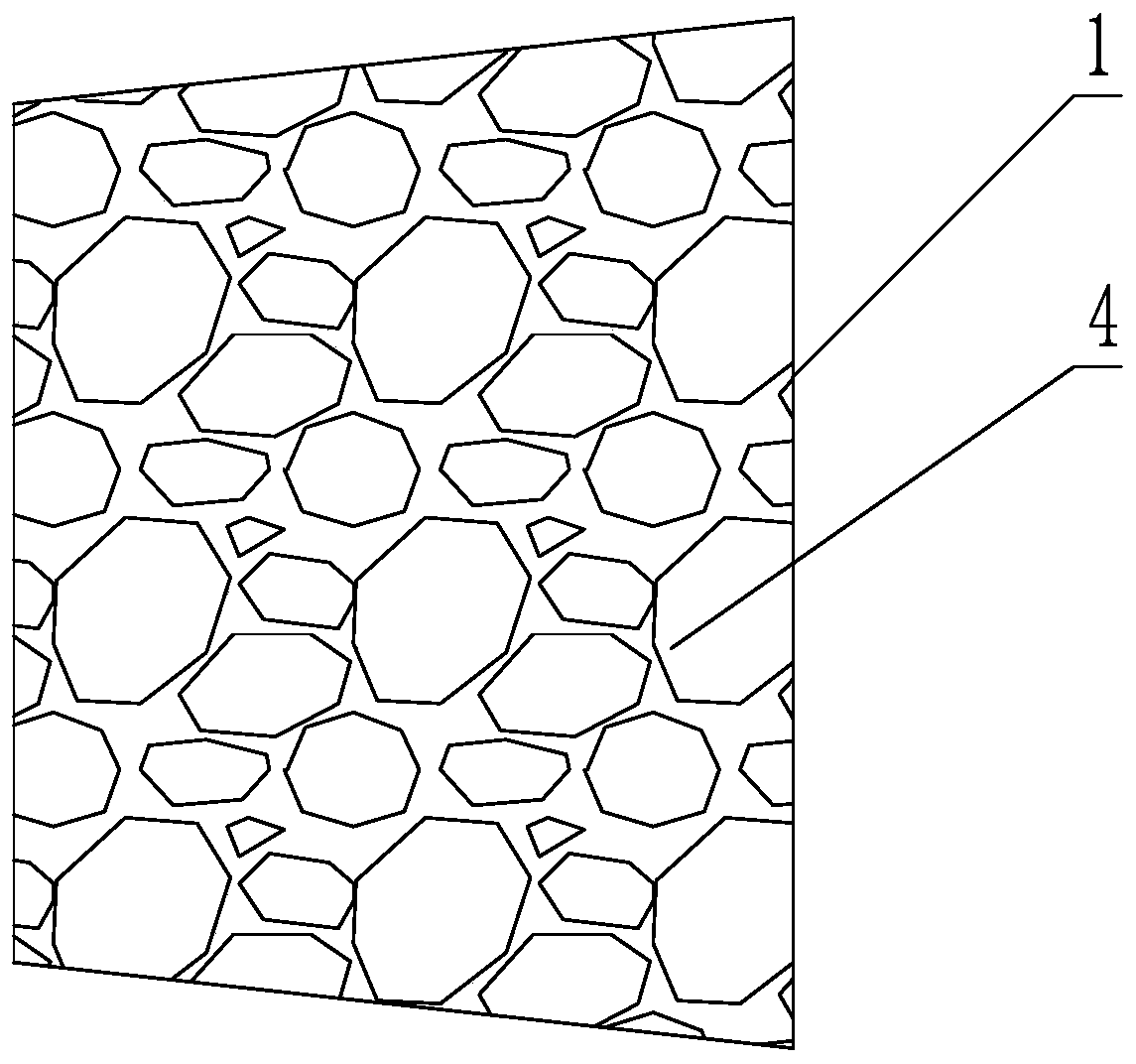

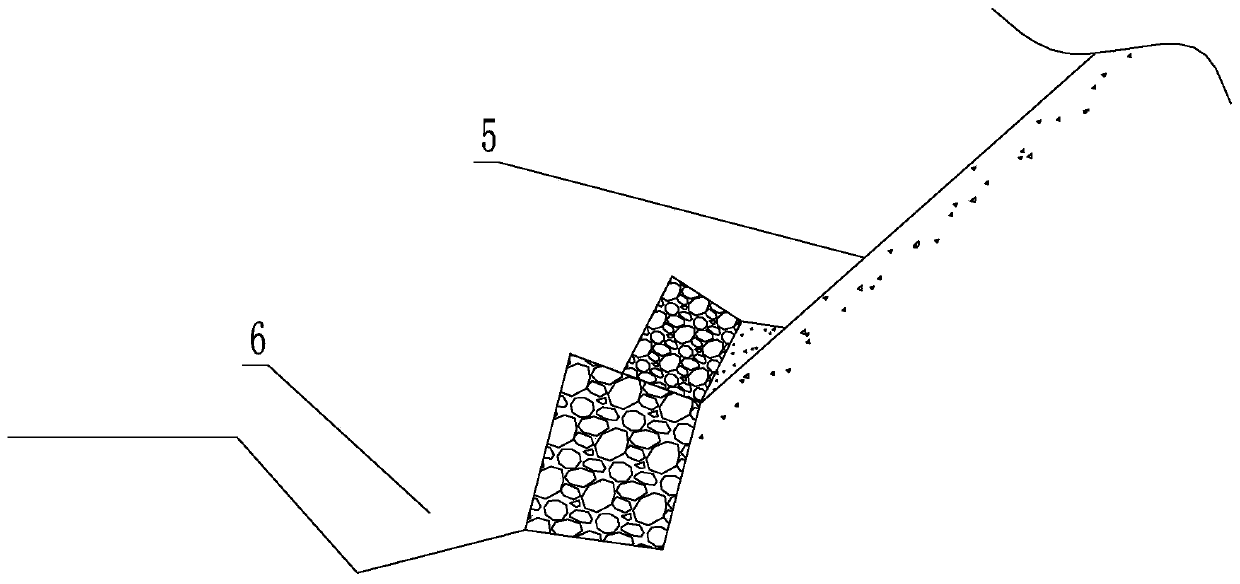

[0031] Such as Figure 1 to Figure 3 Shown as shown, a kind of slope support construction method, this method comprises that concrete spray surface 5 is set on the slope and retaining wall is set at the bottom of the slope, described retaining wall is a reinforced gabion, and the reinforcing bar The gabion includes a bar-shaped gabion basket 1, inside the gabion basket 1 is a filling space 3 filled with a filling layer 4, and the filling layer 4 is formed by stacking crushed stones, and the gabion basket 1 has at least one There is also a pocket net 2 fixed on the side;

[0032] The installation method of the steel gabion is as follows:

[0033] S1, install the gabion basket 1 provided with the net 2 on the slope bottom of the slope, and make the outer side of the gabion basket 1 away from the slope be the side of the gabion basket 1 fixed with the net 2;

[0034]S2 , filling gravel into the filling space 3 of the gabion basket 1 to obtain a filling layer 4 .

[0035] Speci...

Embodiment 2

[0038] Such as Figure 1 to Figure 3 As shown, this embodiment is further limited on the basis of Embodiment 1: as mentioned above, the reinforced gabion can be used as a gravity retaining wall in the supporting structure, so that the reinforced gabion can be installed in the foundation pit , the center of gravity of the reinforced gabion can be shifted to one side of the edge of the foundation pit so that the reinforced gabion can better compress the slope, and the section of the gabion basket 1 is trapezoidal. In the step S1, The reinforced gabion surface where the bottom edge of the section is located faces the slope and is installed, and the reinforced gabion surface where the upper bottom edge is located faces the center of the foundation pit. As those skilled in the art, the trapezoidal structure includes two bases and two sides, wherein the longer base is the lower base, and the shorter base is the upper base, so that the center of gravity of the steel bar can be used t...

Embodiment 3

[0049] This embodiment further limits this case on the basis of any one of the technical solutions provided by any one of the above embodiments. As a kind of foundation pit backfill, the steel gabion needs to be buried in the backfill soil, and the net 2 has good resistance. Corrosion ability, with the realization of ideal structural strength, the net 2 is a stainless steel wire mesh bound on the gabion basket 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com