Vane

A kind of technology of blade and blade body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

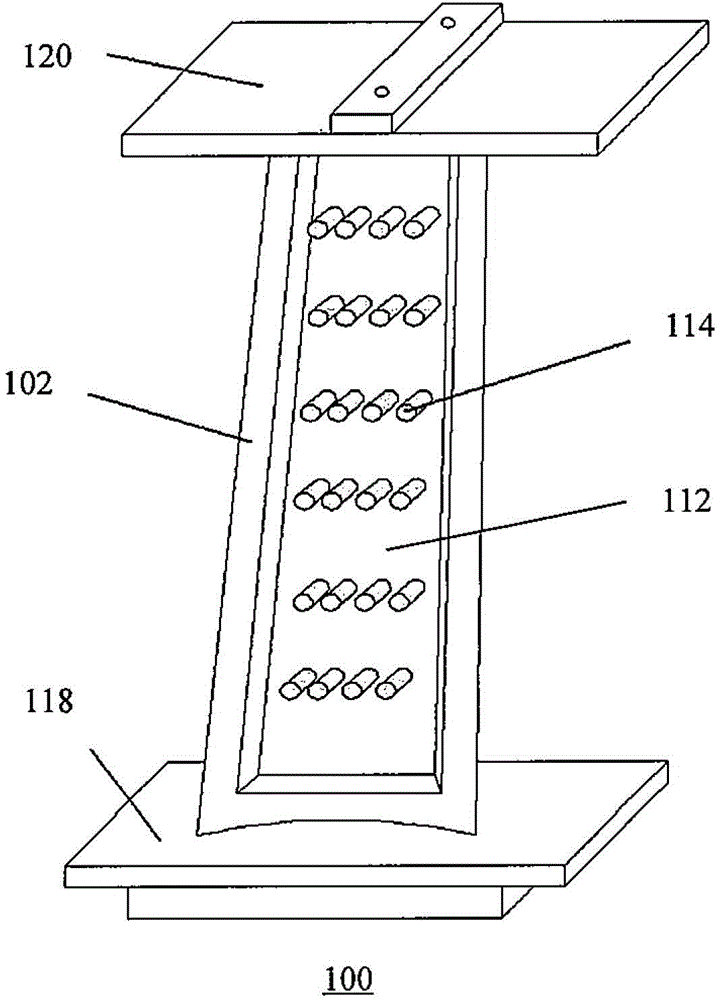

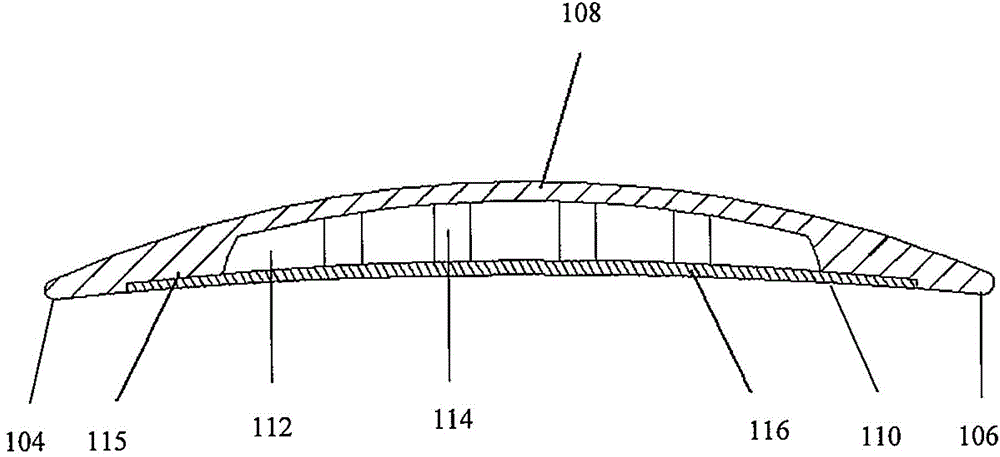

[0026] see Figure 1a , Figure 1b , Figure 1a Schematically shows a perspective view of a blade 100 according to an embodiment of the invention, with the cover removed; Figure 1b show Figure 1a A cross-sectional view of the blade 100.

[0027] Specifically, the blade 100 includes a blade body 102 having a leading edge 104 , a trailing edge 106 , and a suction surface 108 and a pressure surface 110 formed extending from the leading edge 104 to the trailing edge 106 . The blade body 102 is also provided with a recessed portion 112 recessed inwardly from one side of the suction surface 108 , and a plurality of reinforcing columns 114 are evenly arranged and fixed in the recessed portion 112 . The blade body 102 forms a joint area 115 around the recessed portion 112. A cover 116 is positioned to the joint area 115 and closes the recessed portion 112. The inner surface of the cover 116 is fixed to a plurality of reinforcing columns 114. The cover 116 The outer surface of 116 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com