Glass protective handrail

A technology for protecting railings and glass, which is applied in building structures, stepped structures, buildings, etc., can solve the problems of insufficient protection of tempered glass at the bottom, affecting the quality of glass protective railings, and easy to wear tempered glass, and achieves good application prospects and structure. Simple, secure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

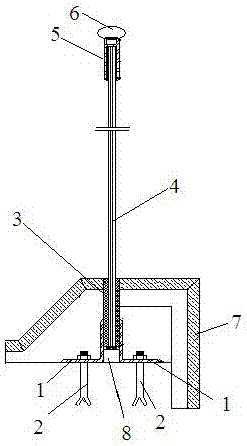

[0017] Such as figure 1 As shown, a glass protective railing includes angle steel 1 arranged symmetrically on the left and right. The angle steel 1 is fixed on the base by expansion bolts 2. The two pieces of angle steel 1 are L-shaped, and the lateral sides are symmetrically distributed outwards. The fixing stability of the angle steel 1, a U-shaped rubber protective sleeve 3 is embedded between two pieces of angle steel 1, and a vertically upward toughened glass 4 is embedded in the rubber protective sleeve 3, and the bottom of the toughened glass 4 passes through the sealant and the rubber protective sleeve 3-phase bonding, the bend of the rubber sheath 3 is a right-angle transition, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com