Impact-resistant high-capacity oil tank

A large-capacity, impact-resistant technology, applied to the fuel tank, substructure, coating, etc. of the power unit, can solve the problems of impact resistance and poor corrosion resistance, achieve excellent compression and wear resistance, protect the fuel tank, and prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

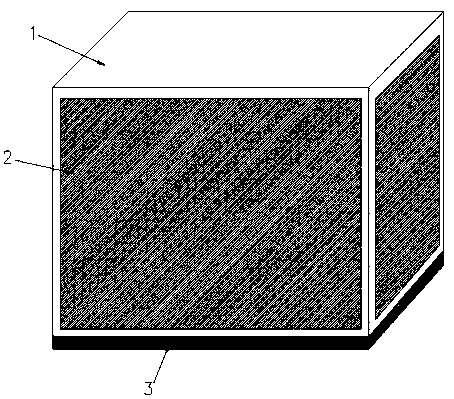

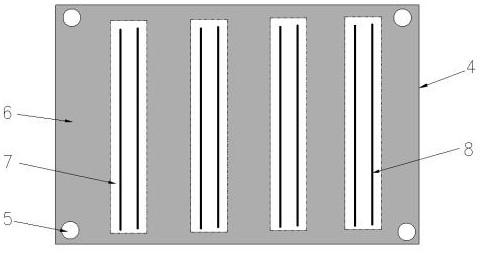

[0018] see Figure 1-2 , the present invention provides a technical solution: an impact-resistant large-capacity fuel tank, including a fuel tank body 1, the fuel tank body 1 adopts a cuboid structure, the length of the fuel tank body 1 is 40cm-50cm, the height is 50cm-60cm, and the width is 30cm-60cm. 40cm. A guard plate 2 is installed on the outer wall of the fuel tank body 1, and a wear-resistant steel plate 3 is welded on the bottom of the fuel tank body 1. The guard plate 2 includes a guard plate body 4, and the thickness of the guard plate 2 is 4mm-6mm; The plate body 4 adopts a rectangular structure. Bolt holes 5 are opened on the four corners of the plate body 4. The plate body 4 is made of steel. The front and back of the plate body 4 are coated with wear-resistant The material layer 6, the surface of the guard plate body 4 is provided with reinforcing rib grooves 7, and two reinforcing ribs 8 are welded in each reinforcing rib groove 7.

[0019] In the present inve...

Embodiment 2

[0022] An impact-resistant large-capacity fuel tank includes a fuel tank body 1, the fuel tank body 1 adopts a cuboid structure, the fuel tank body 1 has a length of 40cm-50cm, a height of 50cm-60cm, and a width of 30cm-40cm. A guard plate 2 is installed on the outer wall of the fuel tank body 1, and a wear-resistant steel plate 3 is welded on the bottom of the fuel tank body 1. The guard plate 2 includes a guard plate body 4, and the thickness of the guard plate 2 is 4mm-6mm; The plate body 4 adopts a rectangular structure. Bolt holes 5 are opened on the four corners of the plate body 4. The plate body 4 is made of steel. The front and back of the plate body 4 are coated with wear-resistant The material layer 6, the surface of the guard plate body 4 is provided with reinforcing rib grooves 7, and two reinforcing ribs 8 are welded in each reinforcing rib groove 7.

[0023] In the present invention, the wear-resistant steel plate 3 includes a steel plate body, and the bottom of...

Embodiment 3

[0026] An impact-resistant large-capacity fuel tank includes a fuel tank body 1, the fuel tank body 1 adopts a cuboid structure, the fuel tank body 1 has a length of 40cm-50cm, a height of 50cm-60cm, and a width of 30cm-40cm. A guard plate 2 is installed on the outer wall of the fuel tank body 1, and a wear-resistant steel plate 3 is welded on the bottom of the fuel tank body 1. The guard plate 2 includes a guard plate body 4, and the thickness of the guard plate 2 is 4mm-6mm; The plate body 4 adopts a rectangular structure. Bolt holes 5 are opened on the four corners of the plate body 4. The plate body 4 is made of steel. The front and back of the plate body 4 are coated with wear-resistant The material layer 6, the surface of the guard plate body 4 is provided with reinforcing rib grooves 7, and two reinforcing ribs 8 are welded in each reinforcing rib groove 7.

[0027] In the present invention, the wear-resistant steel plate 3 includes a steel plate body, and the bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com