Soft decoration wall module and assembly method

An assembly method and wall technology, which can be used in covering/lining, construction, floor, etc., can solve the problems of inconvenient assembly, troublesome disassembly, difficult moving, etc., and achieve the advantages of saving decoration costs, simple house decoration, and lowering the technical threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

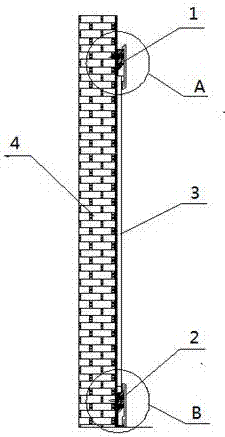

[0041] Such as Figure 1-3 As shown, the present embodiment is a kind of soft-fitting wall module, and the soft-fitting wall module includes an upper card slot 1 arranged on the mirror line of the wall 4, and a lower card slot 1 arranged on the baseboard of the wall 4 The slot 2 and the wall board 3 whose two ends are adapted to the upper card slot 1 and the lower card slot 2 respectively;

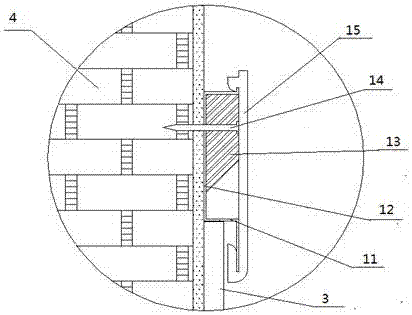

[0042] The upper card slot 1 at least includes an upper horizontal panel 11 arranged horizontally and an upper vertical panel vertically arranged; one end of the upper horizontal panel 11 is fixedly connected with the upper vertical panel; the upper horizontal The free end of the wall 11 is detachably connected to the wall 4, and the upper horizontal wall 11, the upper vertical wall and the wall 4 at least form a slot with an opening downward;

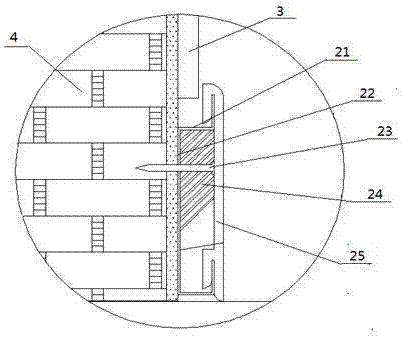

[0043] The lower slot 2 at least includes a horizontally arranged lower horizontal panel 21 and a vertically arranged lower vertical panel; one e...

Embodiment 2

[0047] Such as Figure 2-3As shown, based on the above-mentioned embodiment, the upper card slot in this embodiment also includes an upper slot body 12, an upper skid 13, a fixing nail 14 and an upper decorative strip 15, and the side wall of the upper slot body 12 is connected with the upper slot body. The upper end surface of the horizontal coaming plate 11 is fixedly connected; the opening of the upper tank body 12 is set opposite to the wall body 4, and the groove depth of the upper tank body 12 is the same as the distance between the upper vertical coaming plate and the body of wall 4 The distances are equal, the upper skid 13 is arranged in the upper tank body 12, the thickness of the upper skid 13 is not greater than the groove depth of the upper tank body 12, the upper skid 13 and the upper tank body 12 The fixing nail 14 is fixedly connected with the body of wall 4, and the upper decorative strip 15 is covered on the outer wall of the upper vertical enclosure and abov...

Embodiment 3

[0055] Such as Figure 4 As shown, based on the above-mentioned embodiment, the wallboard 3 in this embodiment includes a wallboard main body 5 and several wallboard linings 6, and the side of the wallboard body 5 opposite to the wall 4 is provided with a number of embeddings arranged at intervals. Groove, the wall panel lining 6 is fixedly arranged in the embedding groove;

[0056] The section of the wallboard lining 6 is a corrugated lining board with triangular crests and troughs or a corrugated lining board with arc-shaped crests and troughs. The wallboard lining 6 The two ends are respectively fixedly connected to the bottom ends of the two side walls of the embedding groove, and the distance between the surface where the crest of the corrugated liner is located and the surface where the wave trough is located is equal to the depth of the embedding groove, and the corrugated lining is The crests or troughs of the board are used to place wires, or the crests or troughs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com