A manufacturing method of wooden heat storage and heat preservation floor with built-in heating layer

A built-in heating and flooring technology, applied in the field of flooring, can solve the problems of slow heat transfer, low thermal efficiency, non-functionality, etc., and achieve fast heating effect, good heat preservation effect, and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

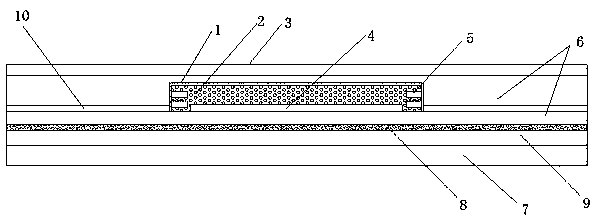

[0020] like figure 1 As shown, the present invention proposes a manufacturing method of wooden heat storage and heat preservation floor with built-in heating layer, comprising the following steps:

[0021] Step 1. Cut out the size of the required 6051 polyimide film 6 according to the size of the floor, and stick the copper sheet 4 on the 6051 polyimide film 6 manually; the 6051 polyimide film 6 is high temperature resistant 280 ℃, insulation products with high voltage resistance above 6000V, the copper sheet 4 is wrapped by the frame wire structure 1 and the honeycomb structure 2 to form a heating element;

[0022] Step 2. Prepare the conductive carbon paste according to the required resistance, and stir well; on the high temperature and high pressure resistant 6051 polyimide film 6, screen print the conductive carbon paste layer 10, and remove it by baking at 200°C For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com