Rock porosity measuring device

A measuring device and porosity technology, which is applied in the fields of oil and gas layer evaluation and geological petrophysical property measurement, can solve the problems of large results, low work efficiency, and difficult to guarantee measurement accuracy, and achieve the effect of reducing detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

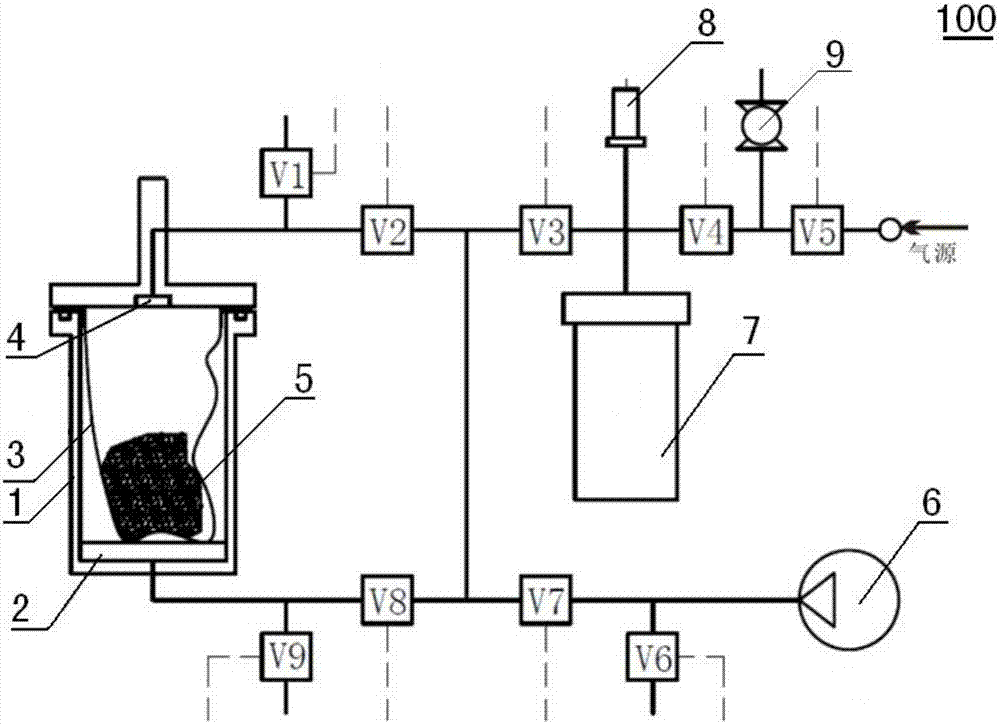

[0024] Such as figure 1 As shown, a rock porosity measurement device 100 includes: a sample cup 1 , a sample cover 3 disposed inside the sample cup for wrapping the sample, and a gas pipeline connected to the bottom 2 and the cover 4 of the sample cup. A plurality of valves V1 to V9 are connected to the gas pipeline. A vacuum pump 6, a standard chamber 7 and a pressure sensor 8 are also connected to the gas pipeline. By controlling the switches between different valves, the vacuum pump 6 can evacuate the bottom or upper part of the sample cup; the standard chamber 7 and the pressure sensor 8 cooperate to measure the pressure value in the sample cup 1 under different states, and then calculate the pores of the rock 5 Rate.

[0025] In a specific embodiment of the present invention, V1 to V9 are all high-precision valves, wherein V1, V6 and V9 are vent valves. The vent va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com