Needle holder for minimally invasive surgery

A technology of minimally invasive surgery and needle holders, applied in the field of medical equipment, can solve the problems of not using surgery, difficult inside the human body, large movements, etc., and achieve the effects of wide application prospects, improved oxidation resistance, and excellent electrical conductivity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

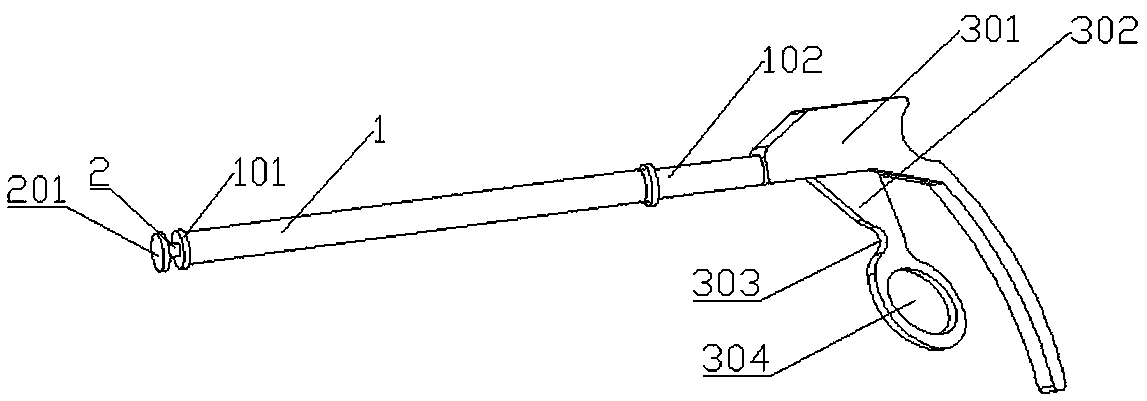

[0021] Specific embodiment 1: A needle holder for minimally invasive surgery, including:

[0022] The gun handle, the gun handle is located at the proximal end of the needle holder for operating the needle holder, and the gun handle includes a trigger 302;

[0023] Needle holder needle, the needle holder needle is used to hold the surgical needle, the needle holder needle includes a first clamping part 101 and a second clamping part 201;

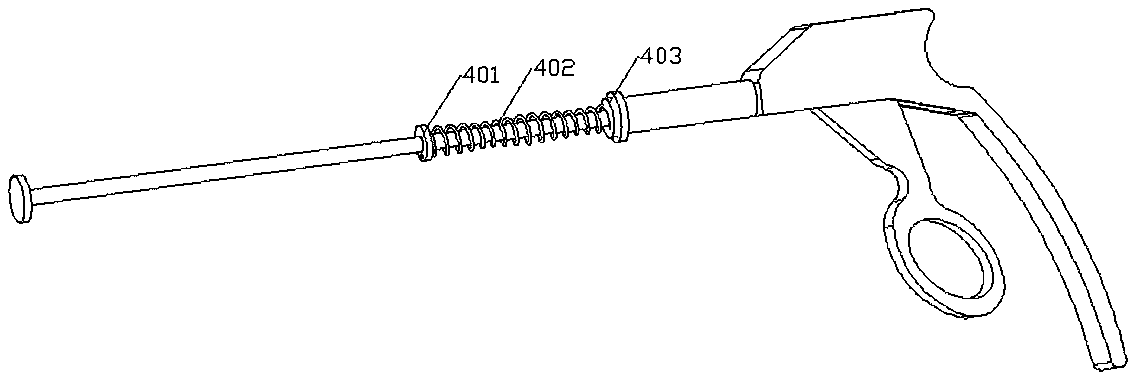

[0024] The connecting shaft is located between the gun handle and the needle of the needle holder, and is used for the gun handle to control the needle of the needle holder. The connecting shaft includes a hollow outer tube 1 and a pull rod 2, through which the pull rod 2 passes In the hollow position of the outer tube, the outer tube and the handle are fixedly connected, the trigger control pull rod moves along the axial direction of the outer tube, the first clamping part is connected with the pull rod, and the second clamping part is connected w...

specific Embodiment 2

[0027] Specific embodiment 2: The present invention discloses a preparation method of titanium alloy material: preparation according to the following steps:

[0028] Step 1. Select titanium raw materials and put them in the furnace;

[0029] Step two, turn on the power supply, pass in argon gas, maintain a vacuum of 15Kpa-40Kpa, preferably 20Kpa, heat to 1700°C-1800°C for melting, adjust the power appropriately according to the melt change to make the bubbles stable;

[0030] Step 3. When no bubbles are formed, blow in argon gas and maintain a vacuum of 50 Kpa -100 Kpa. At this time, add alloying elements, which are 100 parts titanium, 0.04 parts lithium, 0.03 parts zinc, and 0.04 parts chromium. , 0.02 parts of lanthanum and 0.02 parts of cerium.

[0031] Step 4: After melting for 10min-50min, cool down. When cooling, use ultrasonic irradiation to crystallize. Ultrasonic power is M*40W. M is the mass of molten alloy, and the unit is KG. Ultrasonic irradiation can increase the titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com