Selective wave crest welding spray nozzle structure and spray nozzle disc composed of same

A wave soldering and selective technology, applied in the direction of welding equipment, tin feeding device, metal processing equipment, etc., can solve the problems of poor tin connection, reduce interference, reduce overflow range, reduce poor cleaning and PCB The effect of overall board size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

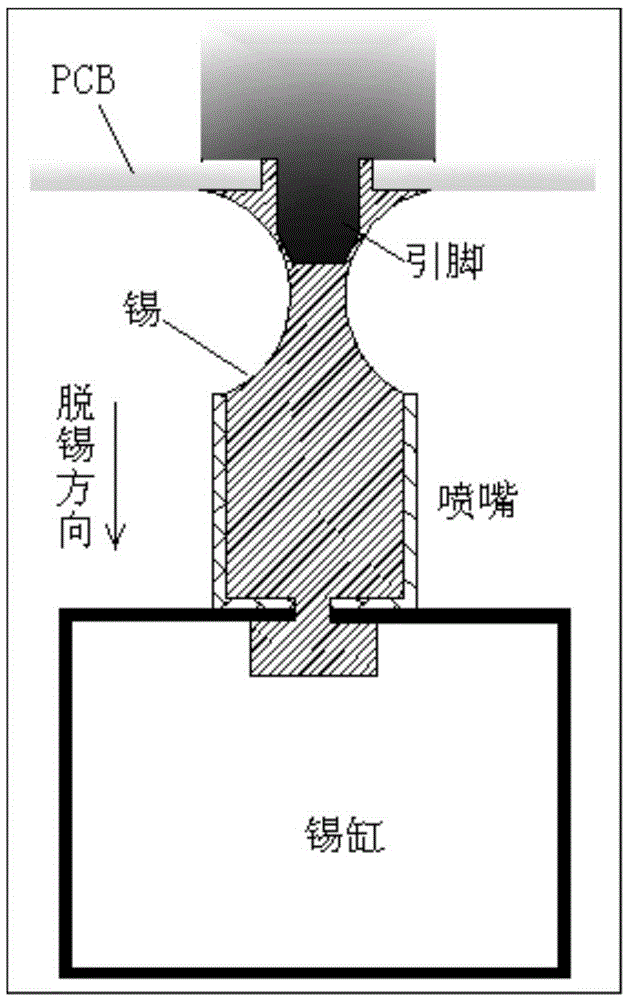

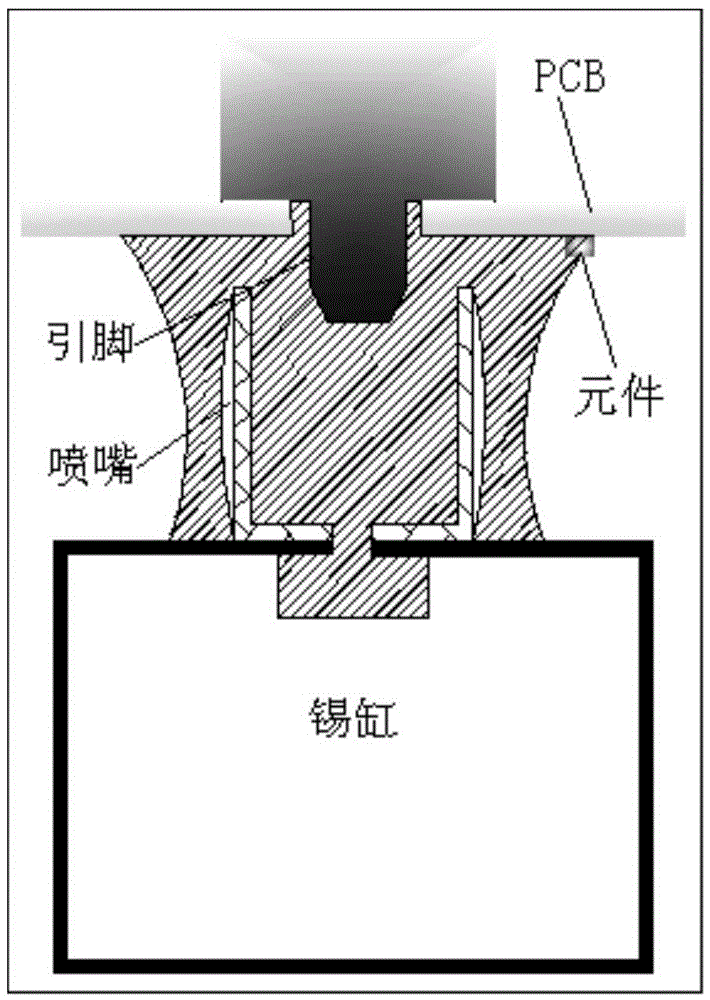

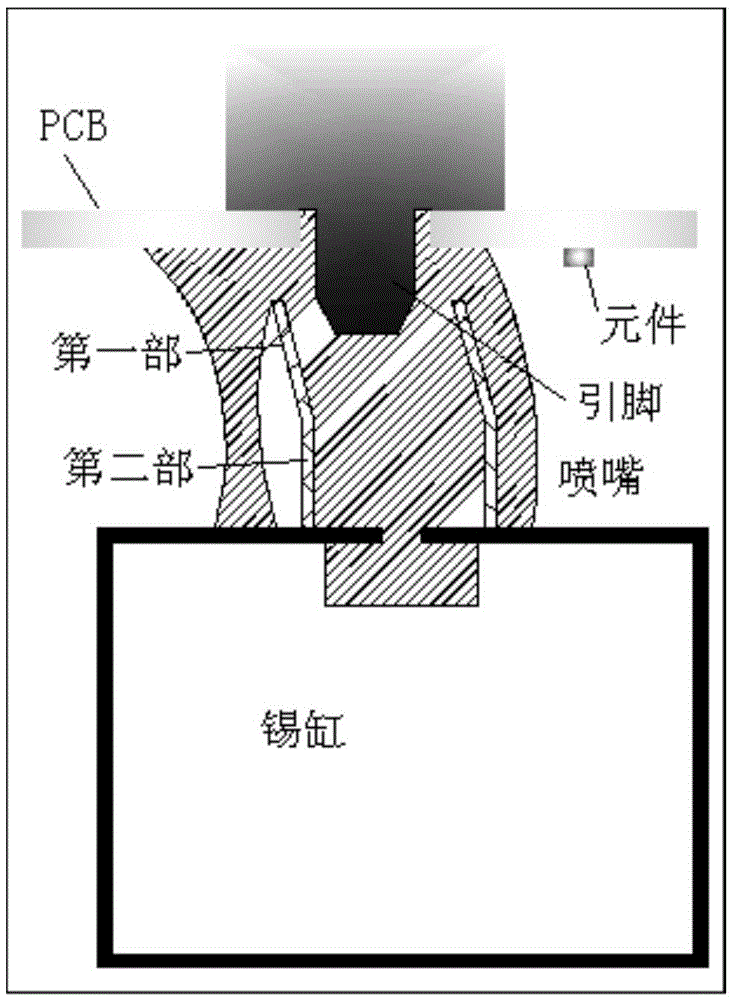

[0023] Such as image 3 , Figure 4 As shown, the selective wave soldering nozzle structure provided by the present invention, wherein: the nozzle structure is divided into a first part vertically arranged on the tin cylinder; For the second part of the inclination angle A, the inclination angle A is 12 degrees to 22 degrees, and the inclination angle A is preferably 14 degrees, 15 degrees or 16 degrees.

[0024] Wherein, the relationship between the length a of the first part of the nozzle structure and the length b of the second part satisfies the following conditions;

[0025] 8mm≤COSA×b+a≤25mm. Preferably, 12mm≤COSA×b+a≤18mm.

[0026] The present invention provides a nozzle plate composed of any one of the above nozzle structures, wherein: the second part of the nozzle structure is inclined in a direction away from the component closest to the corresponding pin of the nozzle.

[0027] The present invention has been described in detail through specific implementations a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com