Wire repairing mechanism installed on live working robot and robot

A technology of live work and robots, which is applied in the direction of manipulators, overhead line/cable equipment, manufacturing tools, etc., and can solve problems such as large workload and manual repair of wire broken strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

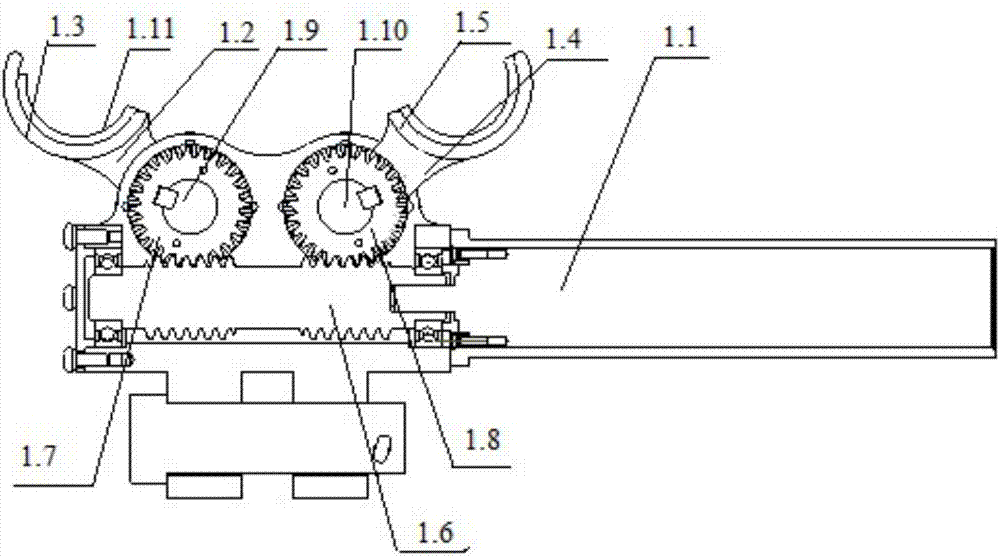

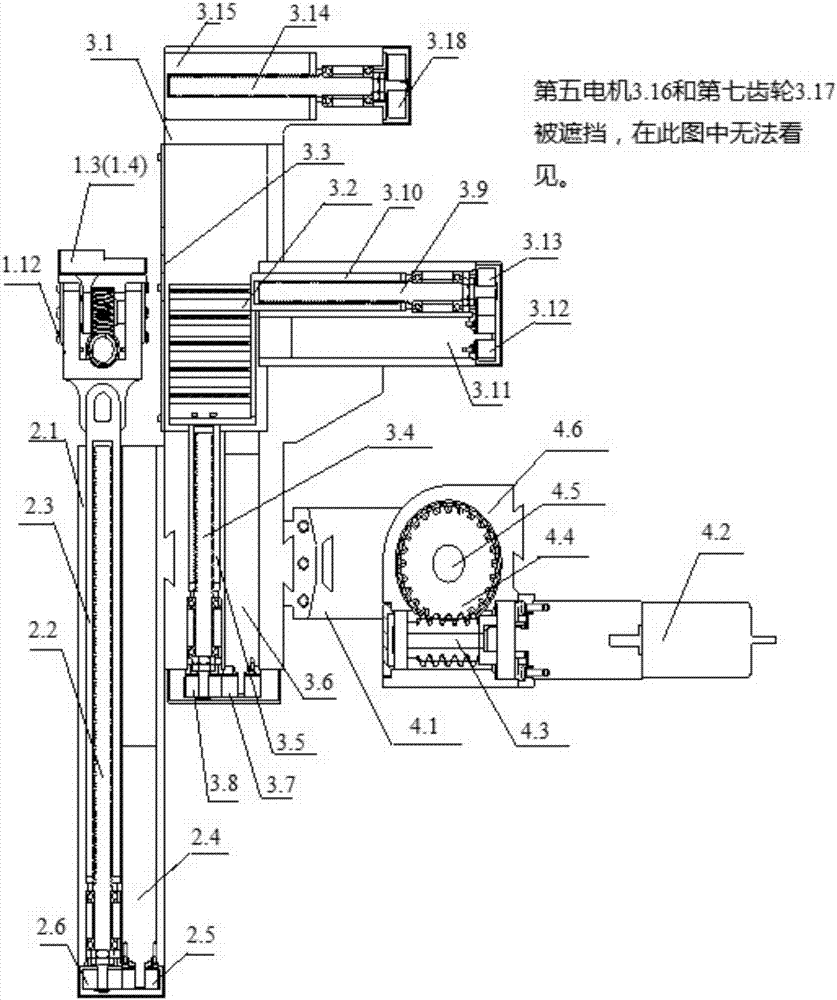

[0082] see figure 1 , an embodiment of the present invention provides a wire repair mechanism installed on a live working robot.

[0083] An embodiment of the present invention provides a wire repair mechanism installed on a live working robot, including: a first motor 1.1, a first worm gear mechanism, a first clamping arm, a second clamping arm, a first transmission shaft 1.9 and a second Two drive shafts 1.10;

[0084] The first clamping arm includes a first wire clamping portion 1.3 and a first fixing portion 1.2 for fixing the first wire clamping portion to the first transmission shaft, and the second clamping arm includes a second wire clamping portion 1.5 and The second fixing part 1.4 for fixing the second wire clamping part to the second transmission shaft;

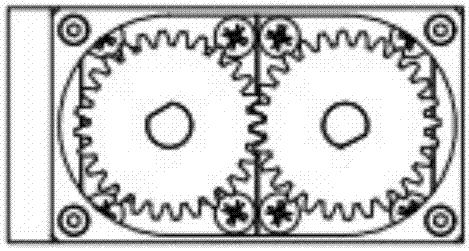

[0085] The first worm gear mechanism includes a first worm 1.6, a first worm wheel 1.7 and a second worm wheel 1.8;

[0086] The driving end of the first motor 1.1 is coaxially connected with the first worm 1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com