An anti-condensation heating device for refrigerators

A heating device and anti-condensation technology, which is applied to household refrigeration devices, lighting and heating equipment, applications, etc., can solve the problems of troublesome operation process, high temperature, poor safety, etc., and achieve simple heater wiring process and shorten heating time , the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

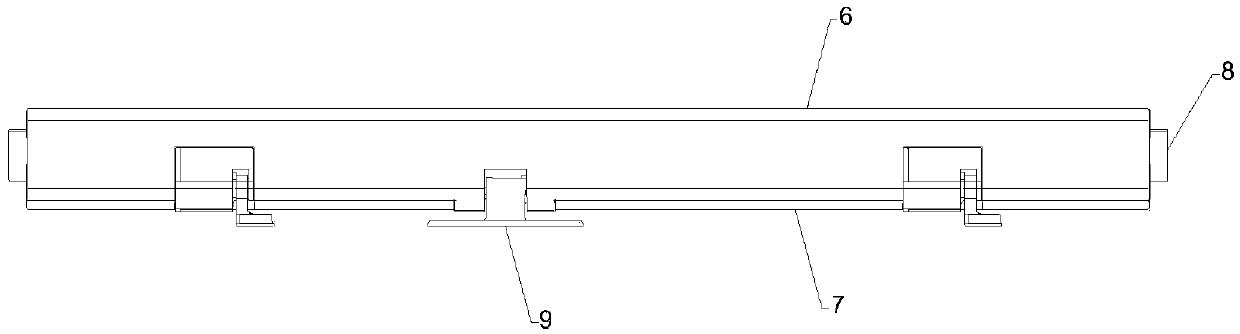

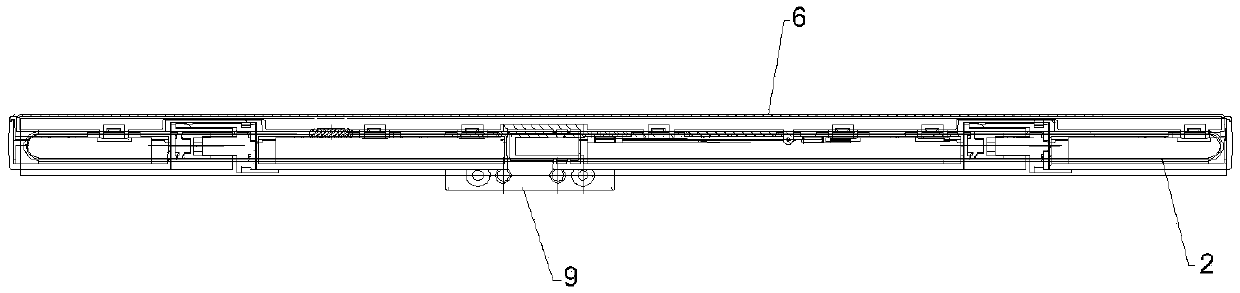

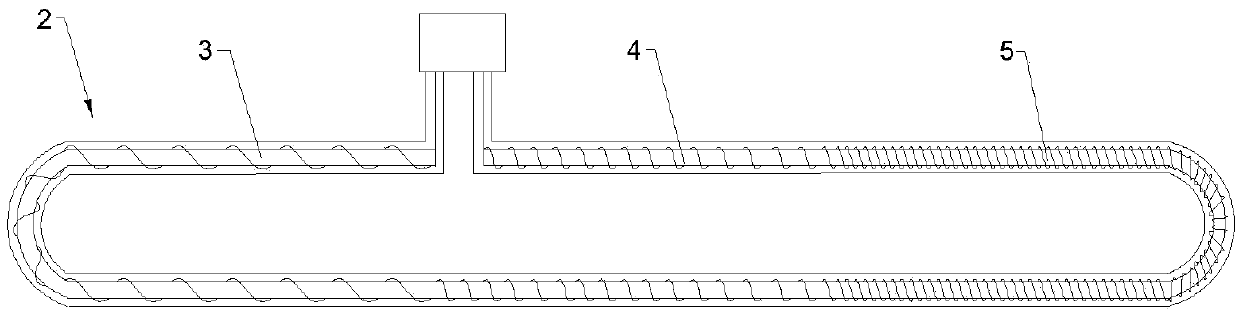

[0016] see figure 1 , figure 2 , the anti-condensation heating device for refrigerators in this embodiment, wherein the refrigerator includes a box body and a door body 1 rotatably connected with the box body, the heating device includes a door swivel beam assembly vertically placed on the door body 1, and the door swivel The interior of the beam assembly is a cavity with a built-in heater 2. The heater 2 is provided with an upper heater 3, a middle heater 4 and a lower heater 5 with increasing power from top to bottom, such as image 3 shown.

[0017] In this embodiment, the winding density of the heating wire inside the upper heater 3, the middle heater 4, and the lower heater 5 increases progressively to realize the incremental increase in power. Specifically, the power of the upper heater 3 is 2W, and the power of the middle heater 4 The power is 3W, and the power of the lower heater 5 is 5W.

[0018] Specifically, the door swivel beam assembly is composed of the door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com