Punch die suitable for cold forging and reverse extruding of joint yoke

A joint fork and cold forging technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of wasting manpower and material resources, affecting efficiency, affecting product quality, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

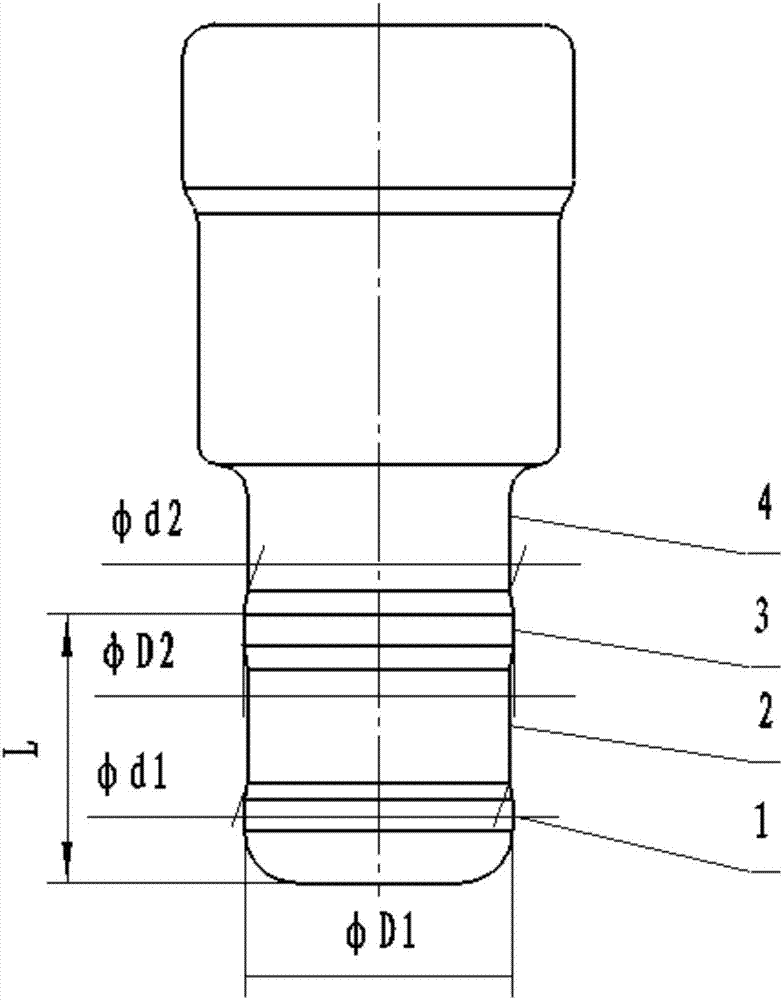

[0018] Such as figure 1 As shown, the present invention discloses a punch die suitable for cold forging and reverse extrusion of the fork, including a working ligament, which adds an auxiliary ligament behind the working ligament, and the length L of the auxiliary ligament from the bottom end is less than the effective segment length of the reverse extrusion fork. The secondary extrusion is performed on the upper mouth of the fork through the auxiliary ligament, which enlarges the size. Under the action of the auxiliary ligament, the punch die suitable for cold forging and reverse extrusion of the fork disclosed by the present invention performs secondary extrusion on the fork to enlarge the size, thereby effectively solving the problem of undersized size caused by stress release. The length L of the auxiliary lig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap