Construction elevator

A construction elevator and modular technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as troublesome elevator installation and disassembly, small openings of elevator shaft doors, and inability of hanging cages to enter and exit. The cage size is too small and the effect of increasing the layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

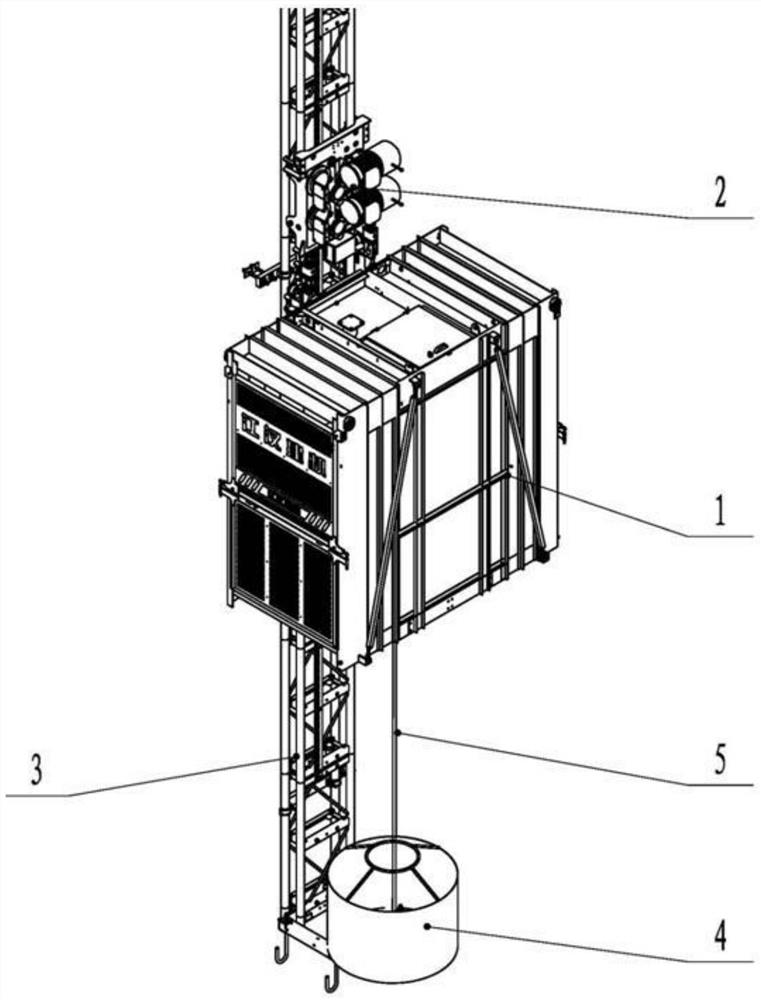

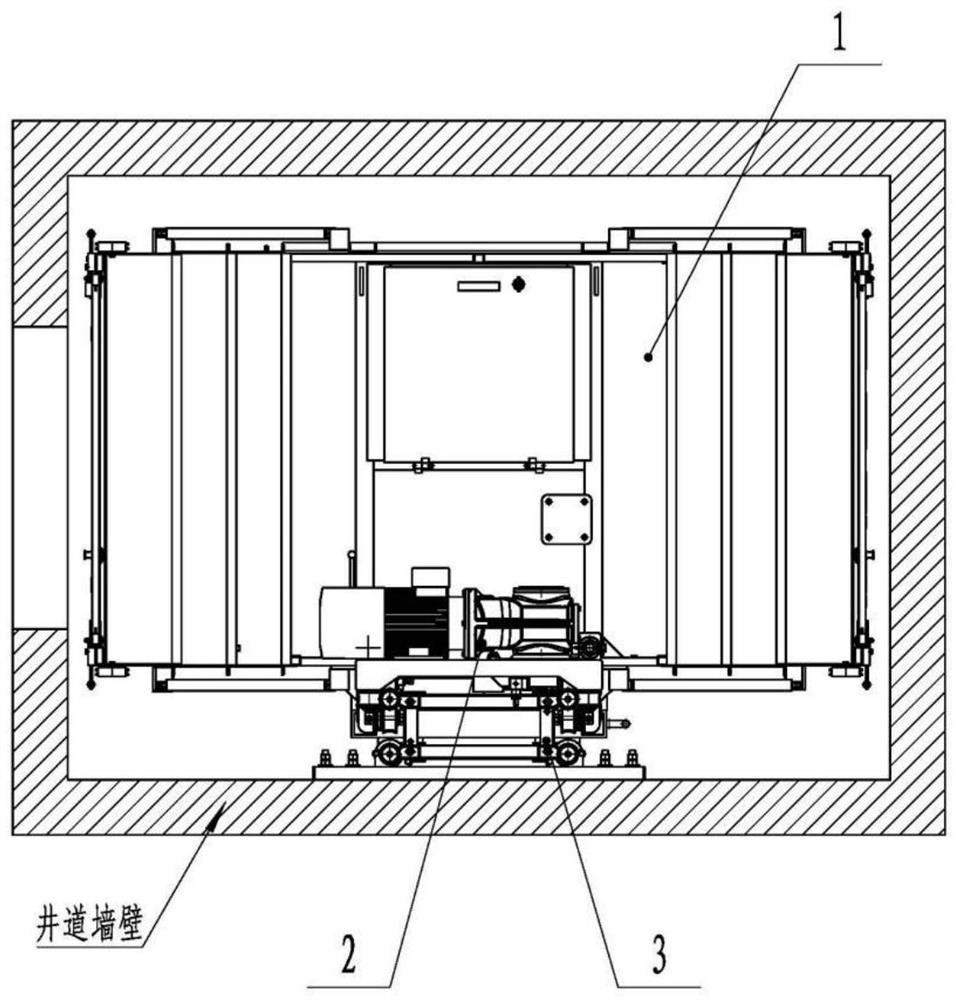

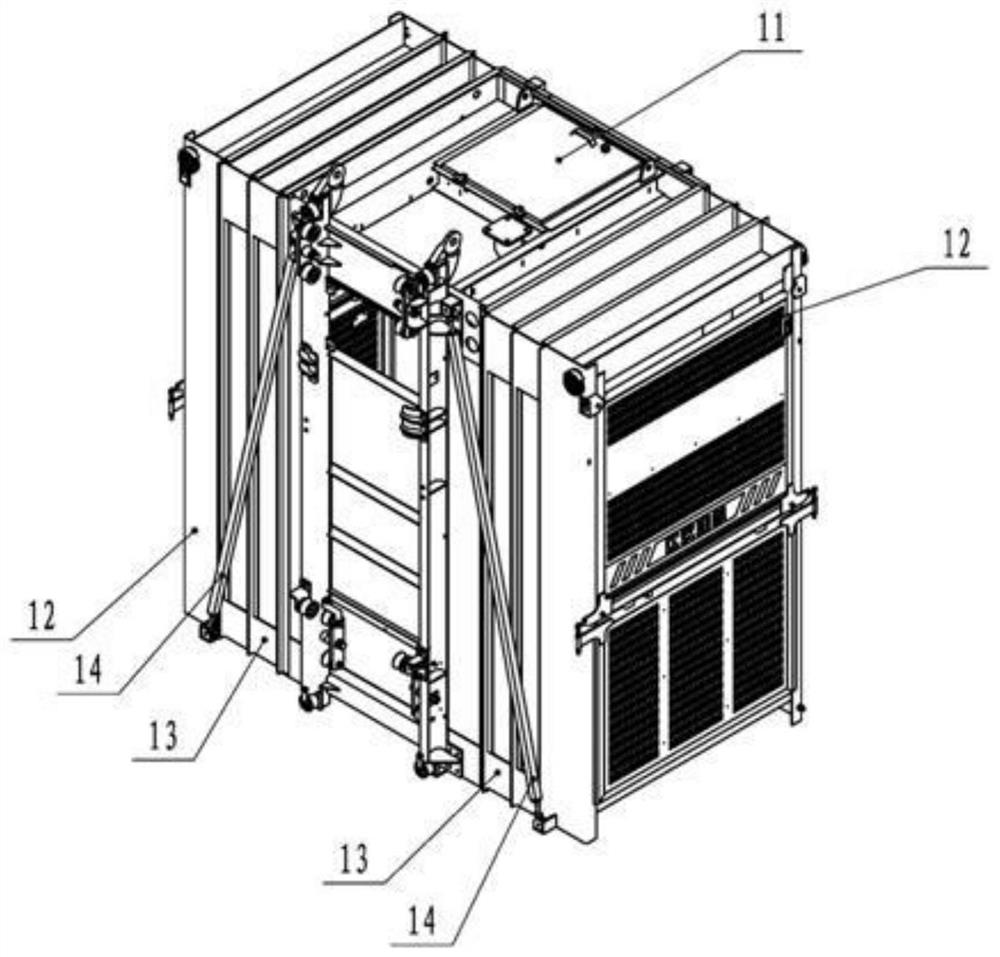

[0028] like figure 1 , image 3 , Figure 4 A construction hoist shown includes a modular hanging cage 1, a trolley frame 2, a standard section 3, a cable drum 4, a cable 5 and an electric control system, and the multi-section standard sections 3 are connected up and down in sequence to form a guide rail frame, The guide rail frame is fixed on the ground of the shaft foundation pit and installed against the wall. The trolley frame 2 and the modular cage 1 are installed on the rail frame, and the trolley frame 2 is set above the modular cage 1, and the cable barrel 4 is arranged on the On the ground of the foundation pit directly below the modular hanging cage 1, the cable 5 coils are placed in the cable barrel 4, and one end is fixed upward on the center of the bottom plate of the modular hanging cage 1, and connected to the electric control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap