Device and method for preparing homogeneous alloy continuous casting billet through high-intensity magnetic field composite electromagnetic oscillation

A composite electromagnetic and homogeneous alloy technology, applied in the field of preparation of homogeneous non-segregation alloy materials, can solve the problems of large grain size, low yield, increased production costs, etc., to achieve dispersion of alloy elements, solution to composition segregation, The effect of increasing supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

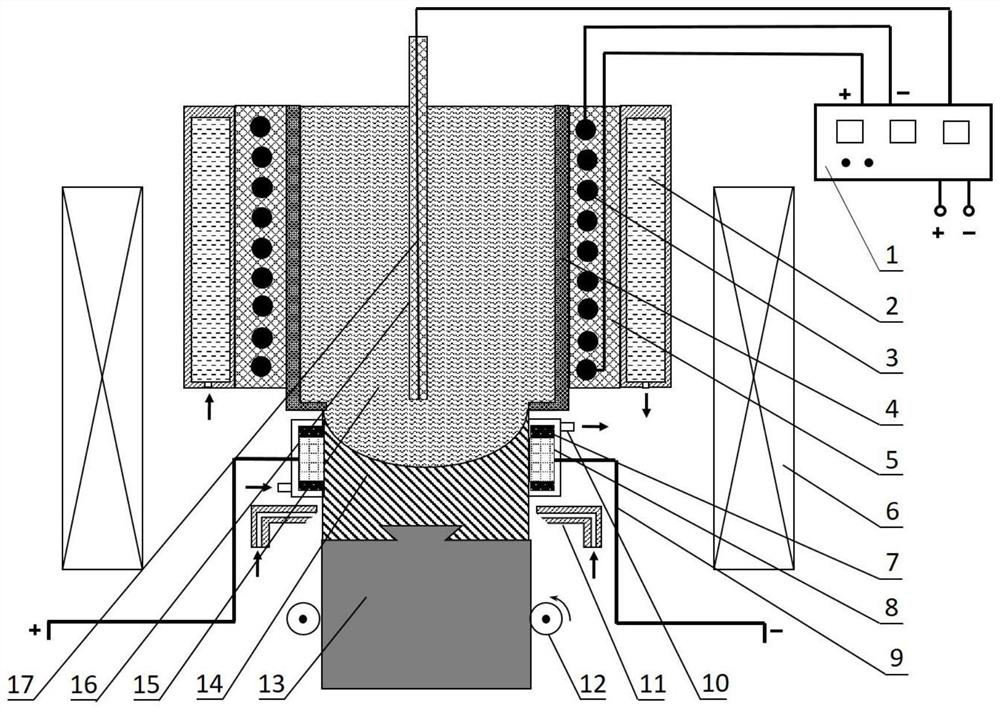

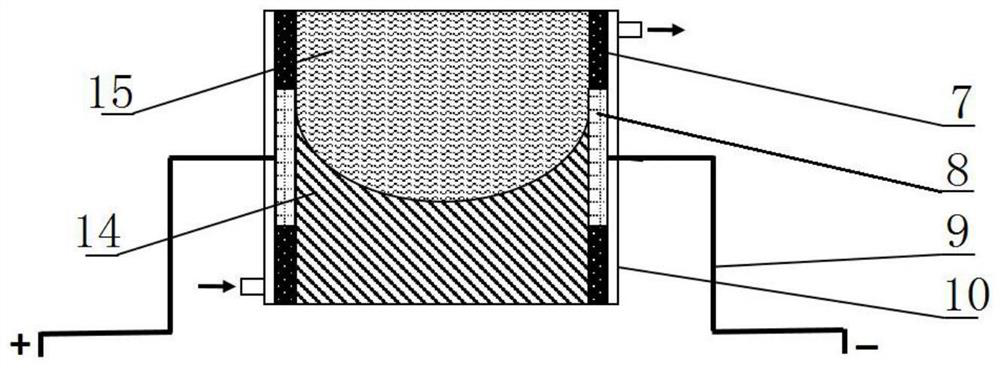

[0032] In this example, see figure 1 and figure 2, a device for preparing homogeneous alloy continuous casting slabs with strong magnetic field combined with electromagnetic oscillation, comprising a heating furnace device and a crystallizer device, characterized in that: the heating furnace device includes a melt memory 4, a heating controller 1, and a heating device 3 , heating furnace water cooling jacket 2 and refractory insulation layer 5, the periphery of refractory insulation layer 5 is protected by heating furnace water cooling jacket 2, melt storage 4 is used to load metal melt 15, and the periphery of melt storage 4 is provided with heating device 3 , the outside of the heating device 3 is provided with a refractory insulation layer 5 and a heating furnace water cooling jacket 2 in sequence, and the thermocouple 17 wrapped in the refractory ceramic tube 16 is inserted into the metal melt 15 inside the melt storage 4, and the melt is fed back The real-time temperatu...

Embodiment 2

[0037] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0038] In this embodiment, the inner casing of the crystallizer 7 is made of graphite, stainless steel, copper or other high temperature resistant / weak magnetic alloys. The conductive ceramic 8 in the electromagnetic oscillator adopts conductive high temperature anti / weak magnetic metal sheet and graphite sheet. The current and the frequency of the connected power supply 9 are adjustable, and the current is alternating and pulse current. Strong magnet 6 adopts the strong magnet that superconducting coil, Bitter resistance copper sheet or other magnets are made. It is applicable to the down-draw continuous casting process of metals, and the casting slab 14 is a round billet, a square billet, a slab or a special-shaped billet. The cooling medium sprayed by the cooling nozzle 11 is water, an inert low-temperature gas or a water-gas composite medium. This embodiment a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap