Efficient and simple material dividing mechanism

A material-distributing mechanism and high-efficiency technology, which can be applied to conveyor objects, transportation and packaging, etc., and can solve problems such as high cost, complex structure, and product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

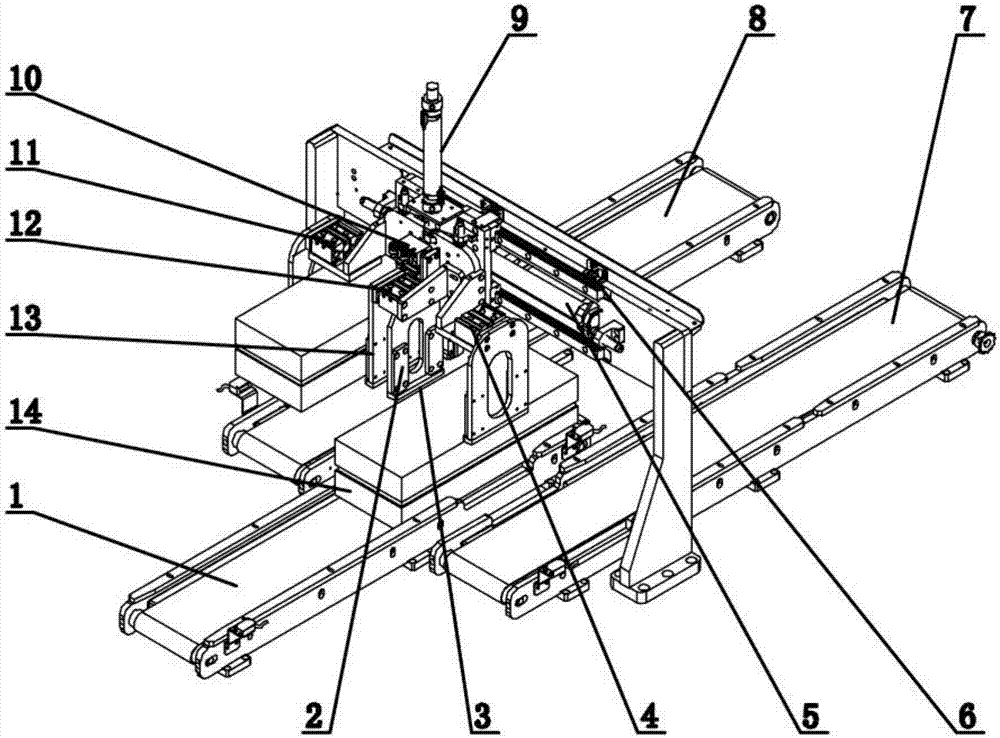

[0023] Such as figure 1 As shown, a high-efficiency simple material distribution mechanism includes a main flow line, a line A, a line B, a vertical sliding assembly and a horizontal sliding assembly, and the main flow, the assembly line A, and the assembly B are all set as conveyor belts. A and pipeline B are arranged in parallel on both sides of the end of the main waterline, and the horizontal sliding components are arranged across the two sides of the pipeline A and pipeline B directly above the end of the main waterline. The direction is provided with a translation cylinder and a linear track. The vertical sliding assembly is slidably set on the mounting plate through the upper and lower cylinders. The mounting plate is installed on the linear rail through the translation cylinder. Two sets of clamping mechanisms composed of jaws; the upper and lower cylinders move up and down along the mounting plate by controlling the clamping mechanism, and the translation cylinder dri...

Embodiment 2

[0035] On the basis of Example 1, different from Example 1, the splint is vertically suspended and arranged as a rectangular plate with an arch-shaped arc at the top, and a weight-reducing through hole is provided in the middle of the splint along the central axis. The top of the splint is set in a smooth arc shape, with strong smooth transition, and the weight-reducing through hole is set in a similar ellipsoidal structure, which greatly reduces the gravity of the splint itself, and maintains the stability of the vertically suspended support while maintaining strong operational stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com