Patents

Literature

36results about How to "Double the efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

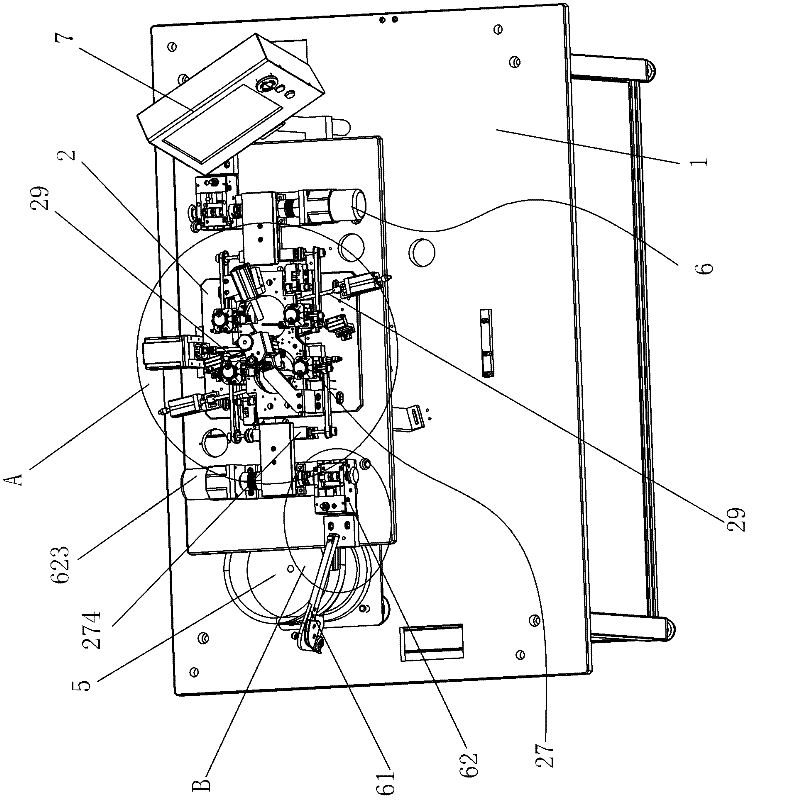

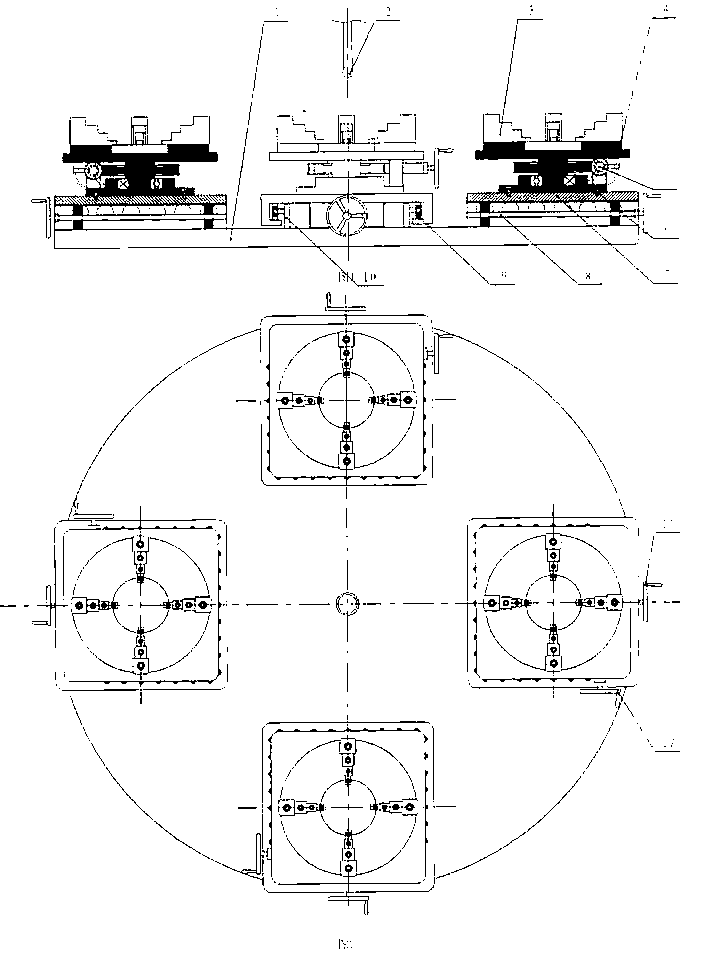

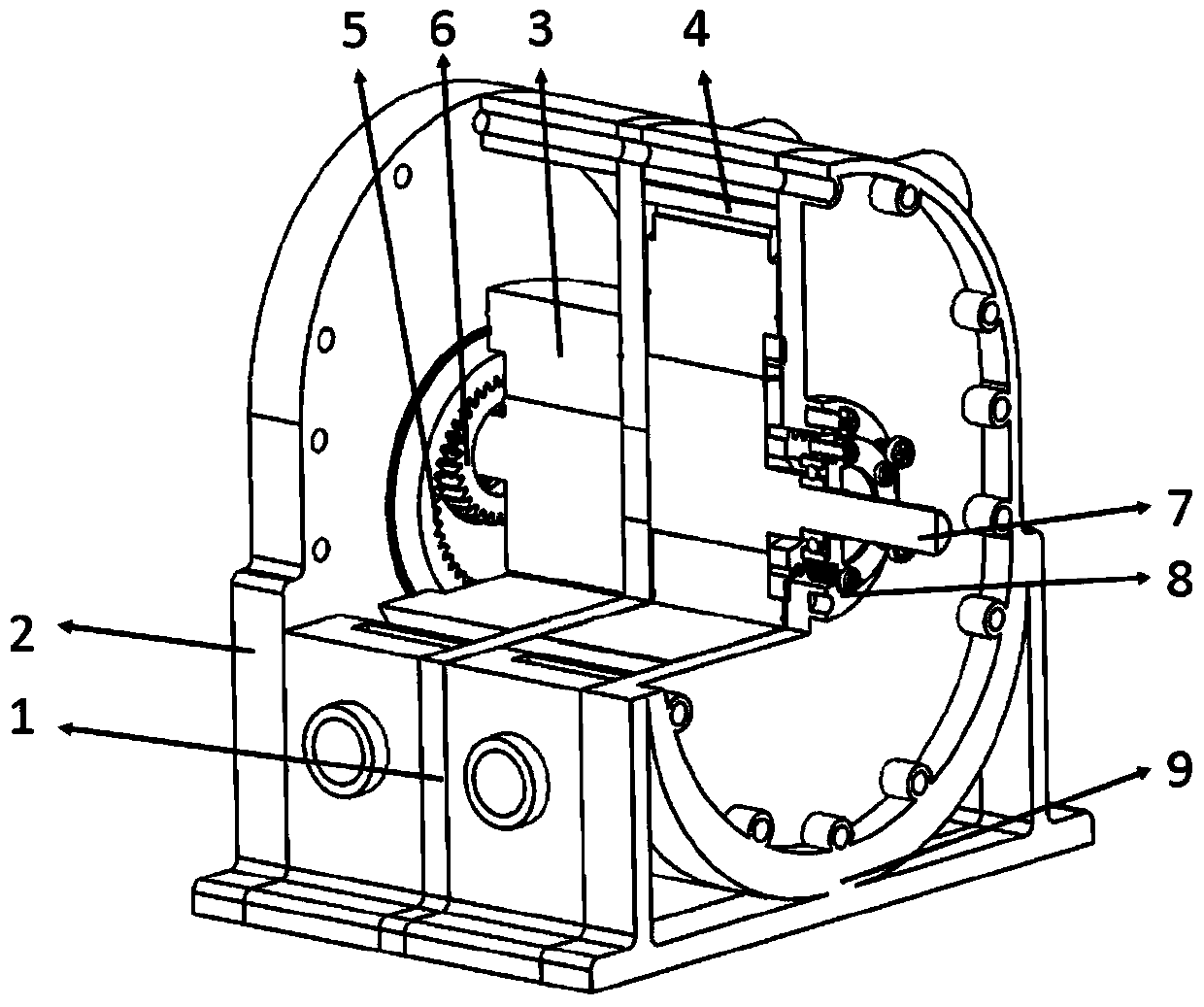

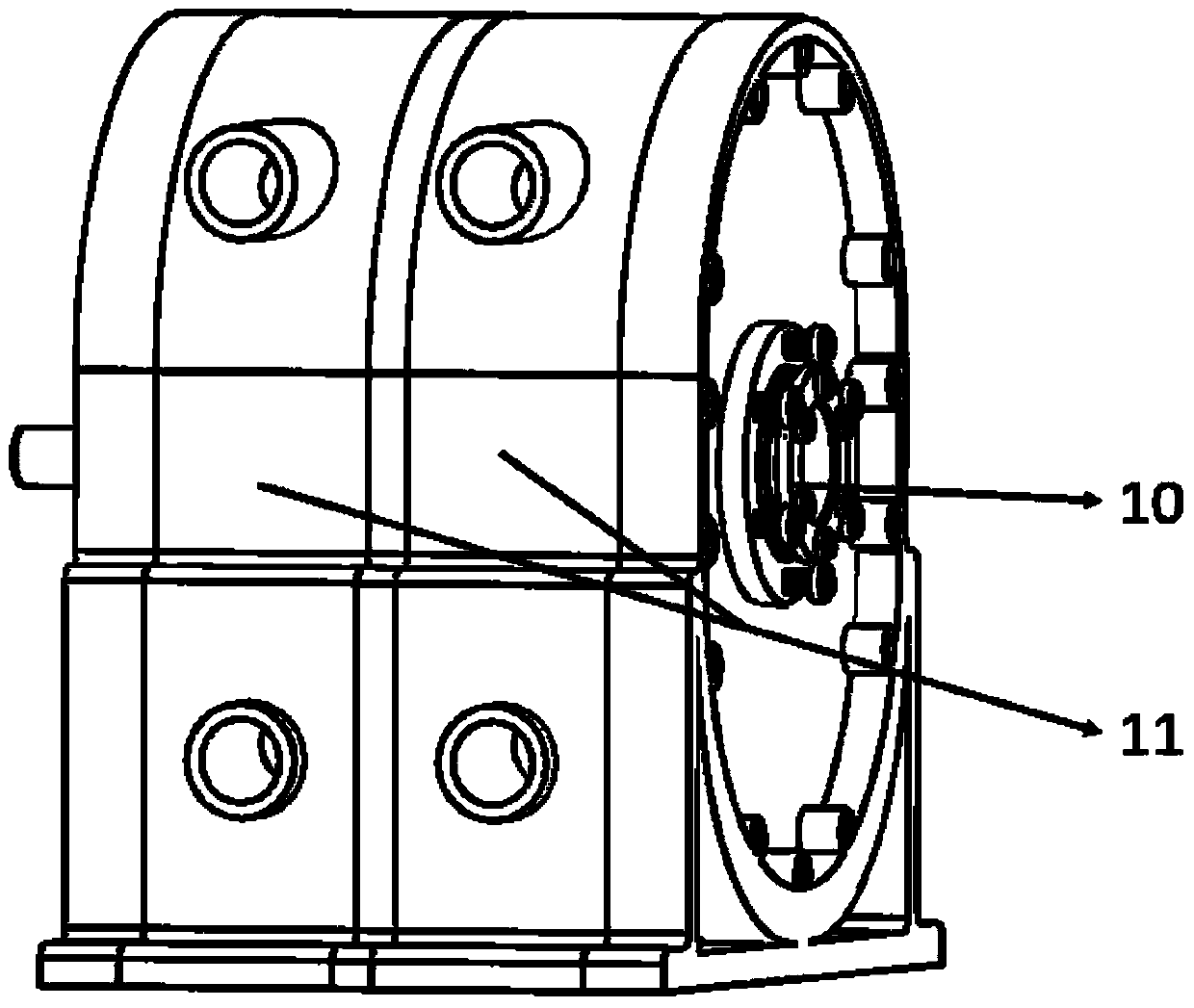

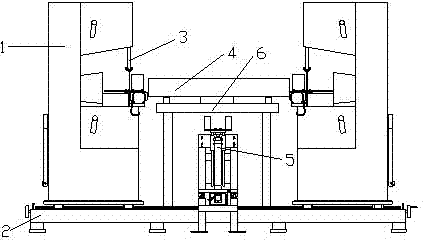

Equipment and method for precise positioning drilling at wall of subway tunnel via automatic benchmark leveling

PendingCN108915587AAccurately determine the location of the drill holeDouble the efficiencyDrilling rodsConstructionsVehicle frameData entry

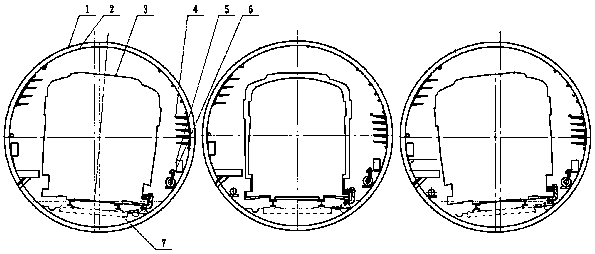

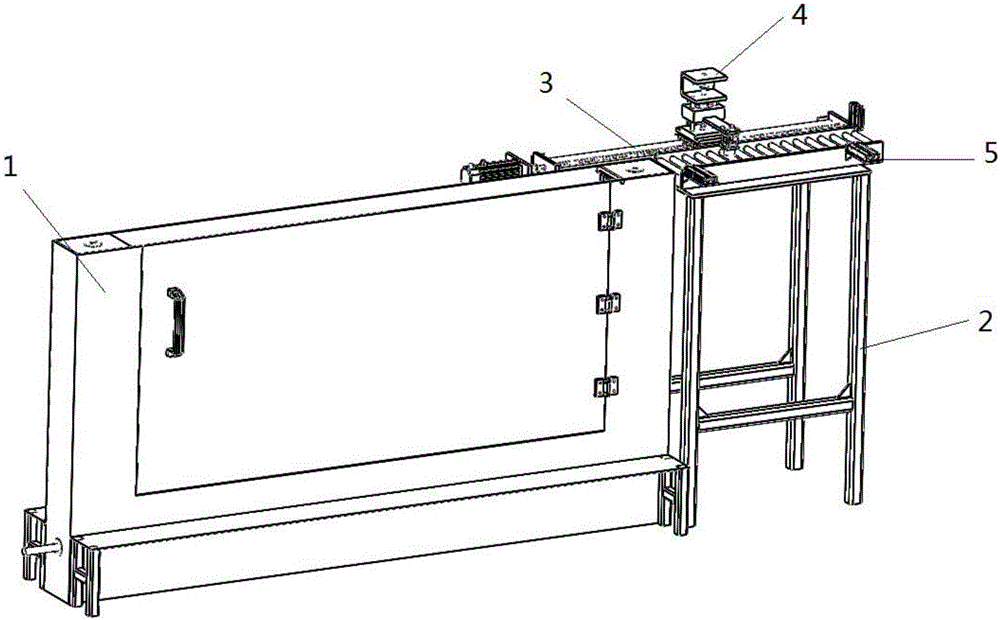

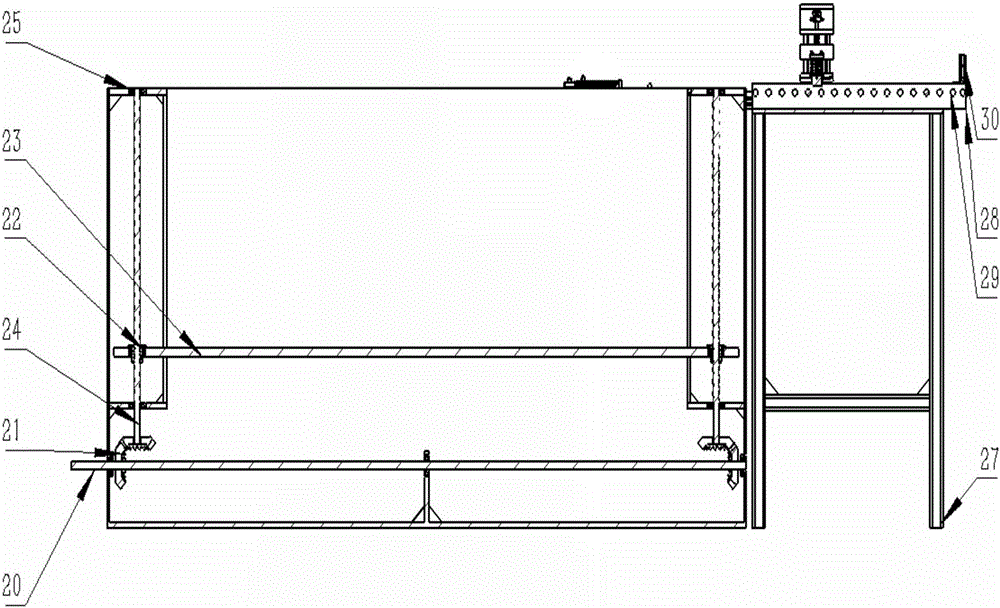

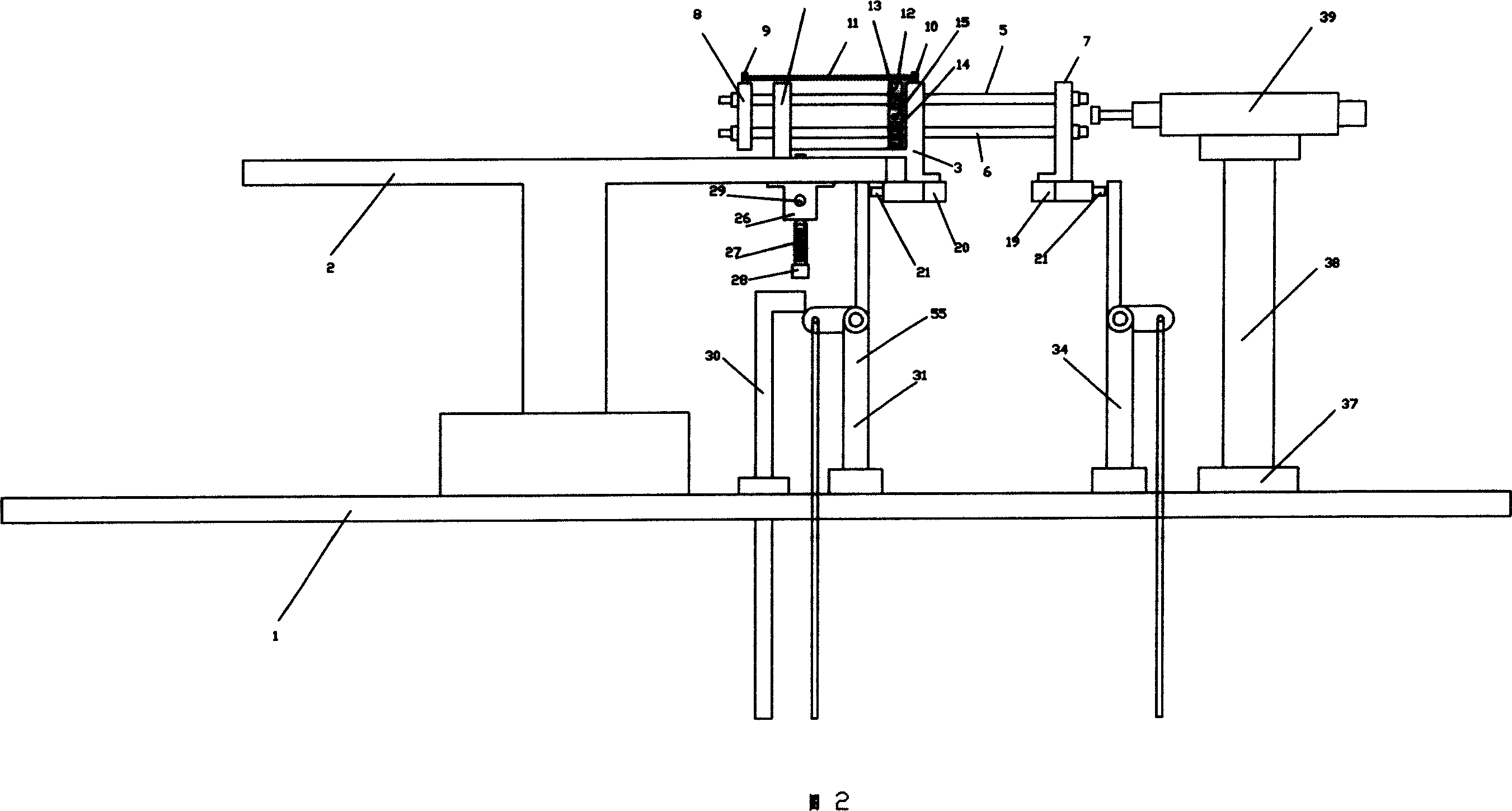

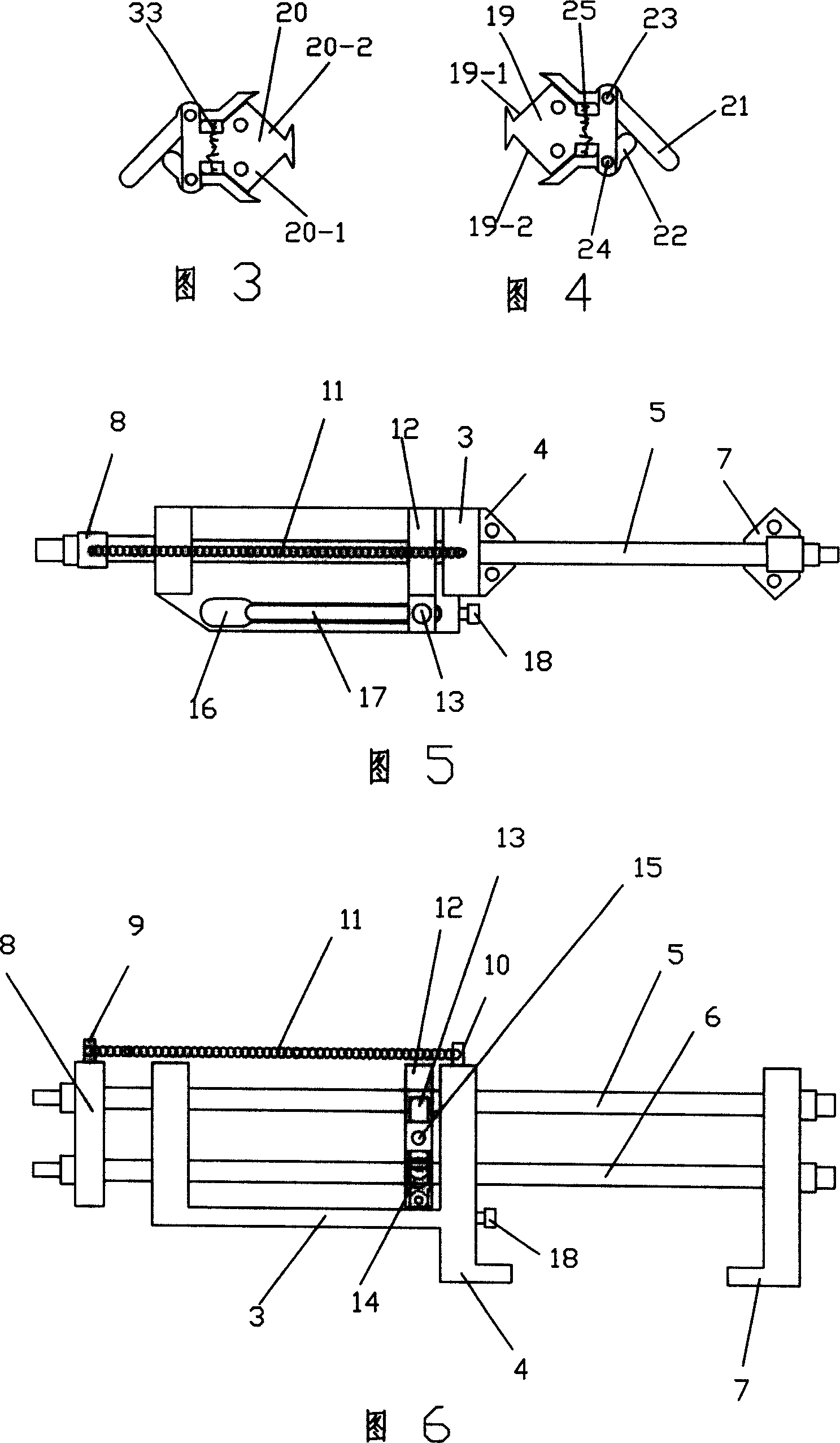

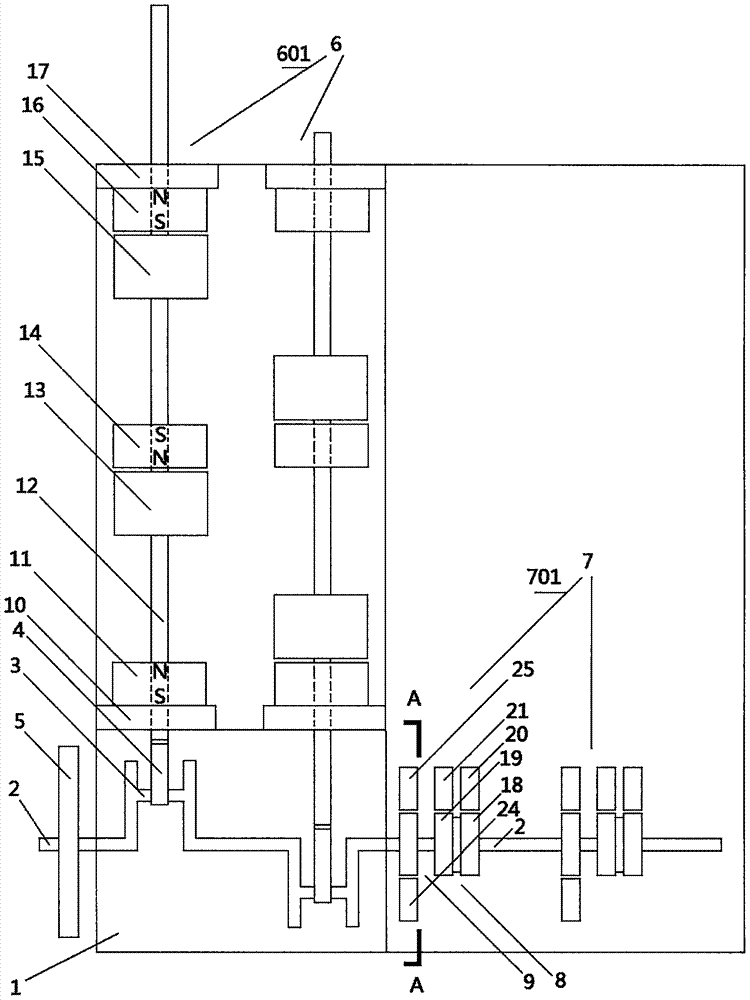

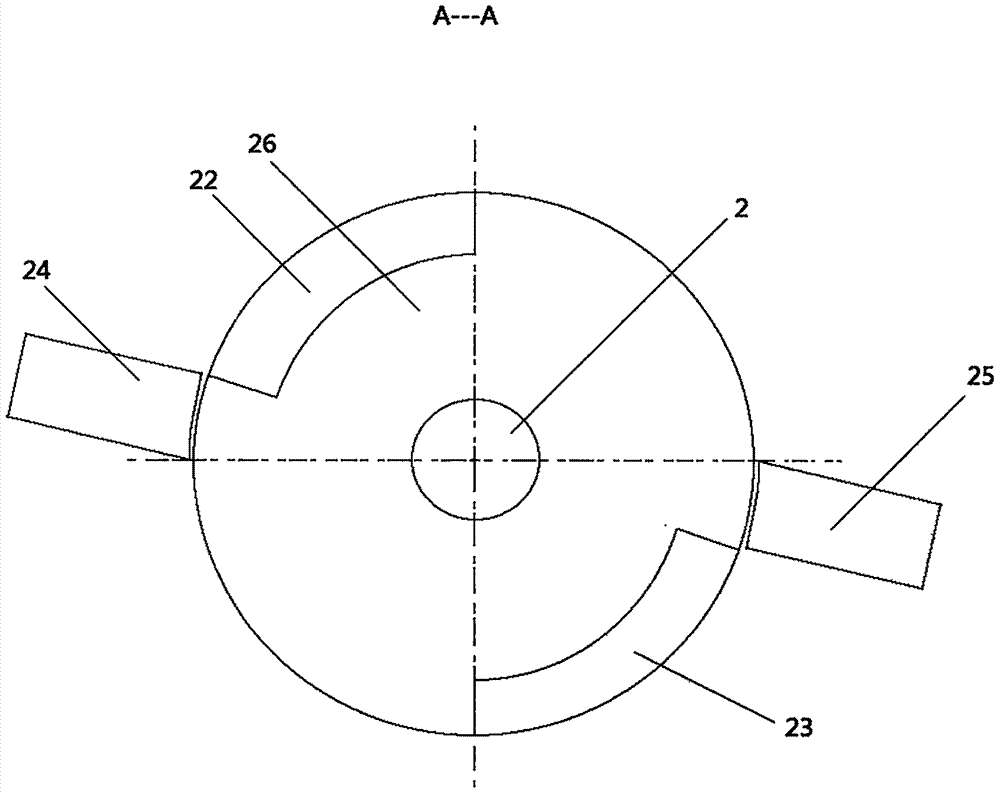

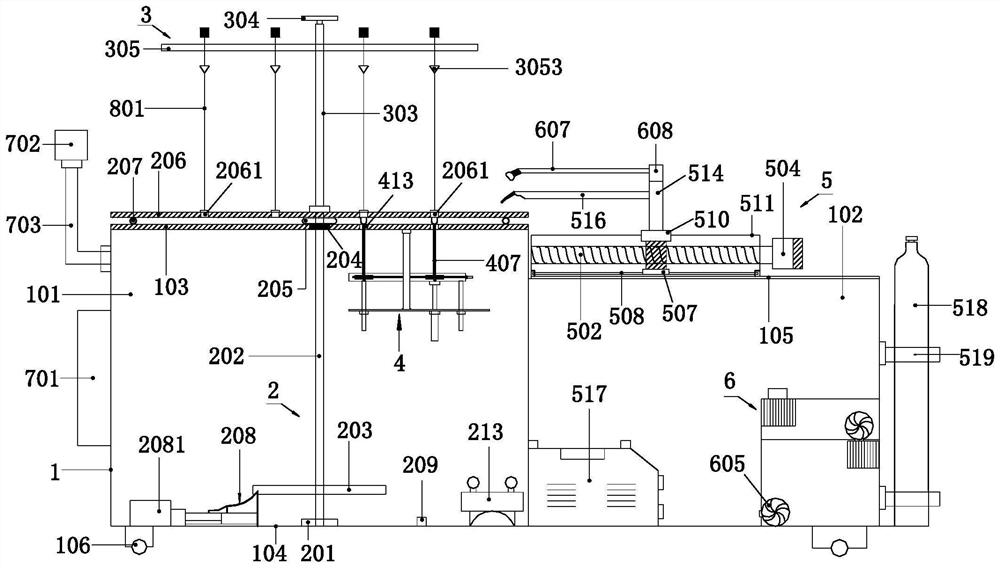

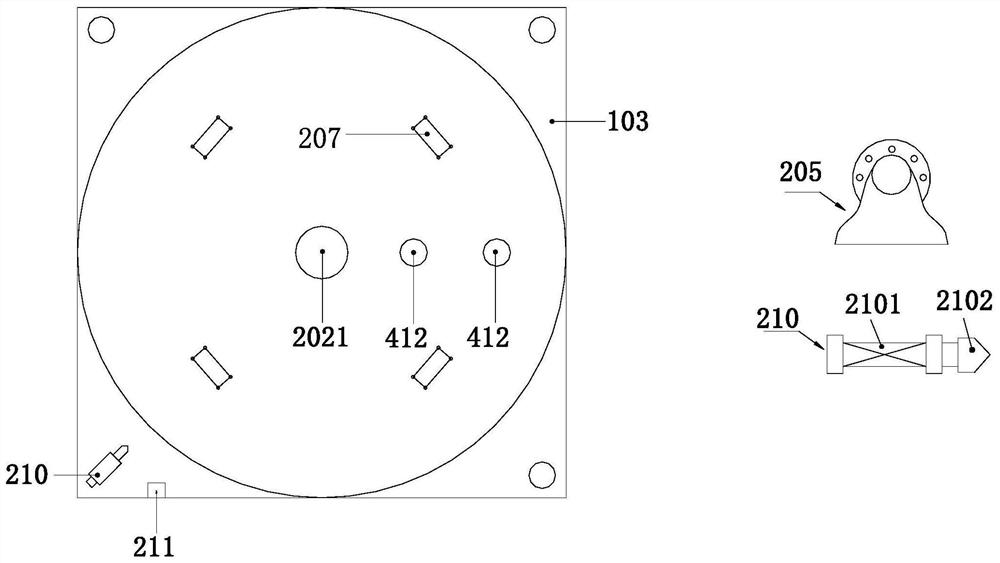

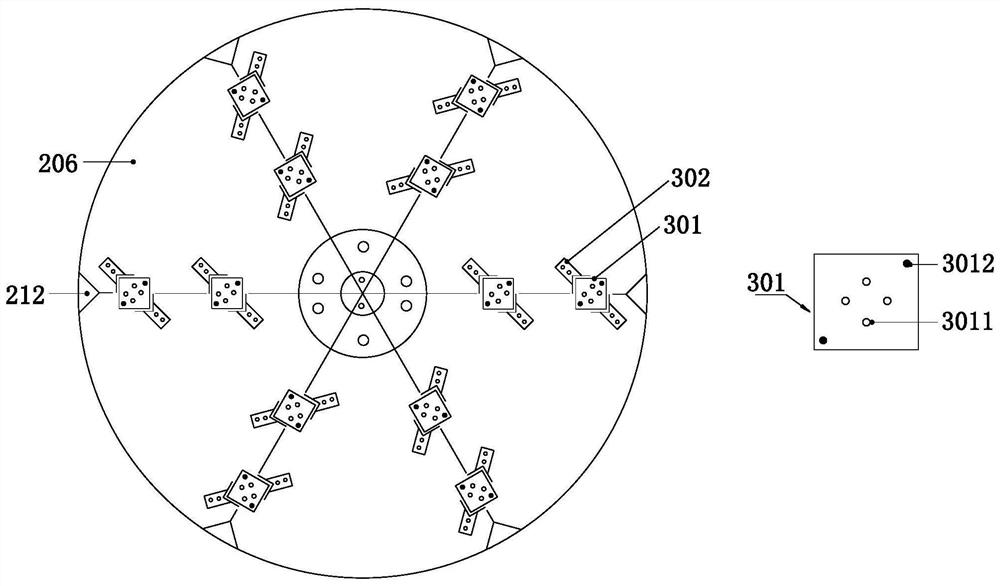

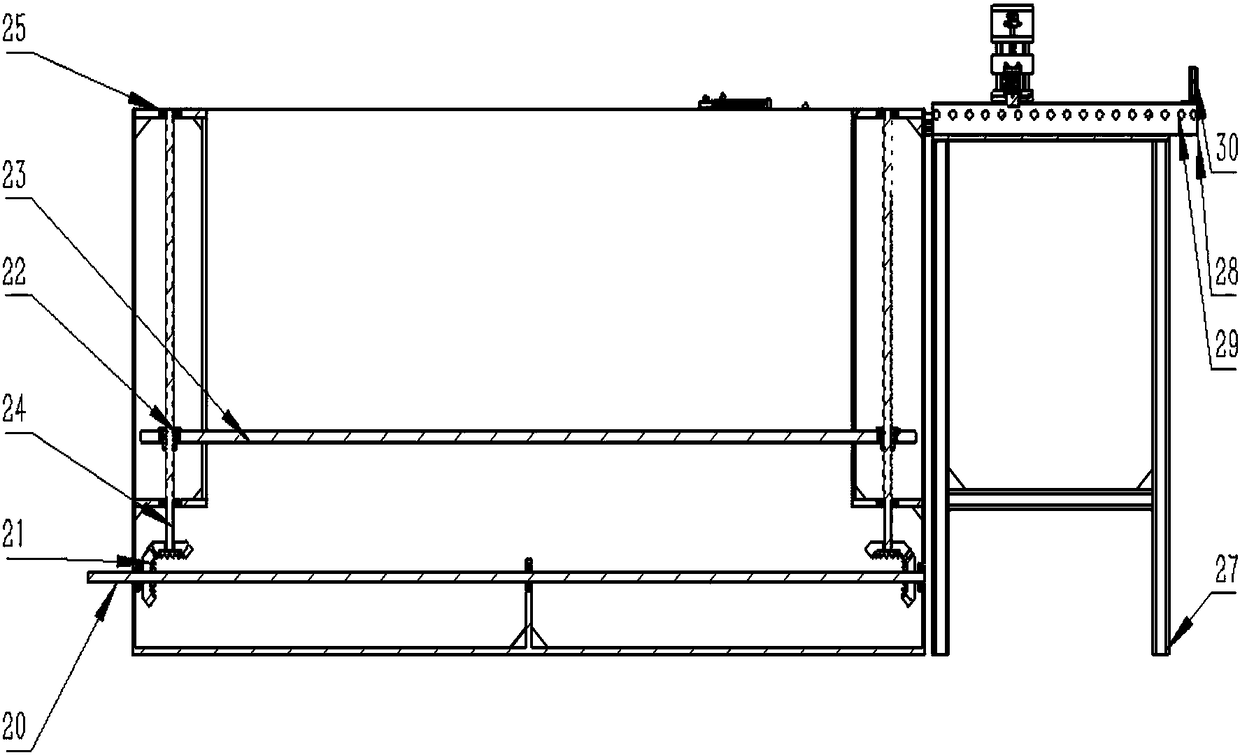

The invention provides equipment and a method for precise positioning drilling at the wall of a subway tunnel via automatic benchmark leveling. The equipment is characterized in that an electric PLC (programmable logic controller) control system is used for collecting an inputted displacement sensor signal and an inputted inclination sensor signal, then a hydraulic pump station is controlled to supply oil for different support oil cylinders, and a whole track frame is arranged at the horizontal position of the cross section of the subway tunnel; by inputting the data of a height laser distancemeasuring instrument and a horizontal direction laser distance measuring instrument, the height of the whole track frame can be adjusted; by establishing a horizontal benchmark, a height benchmark and a center benchmark, the working benchmark is provided for a machine frame at the upper part of the track frame and preselected porous formworks which are manufactured according to positioning of tunnel holes; the multiple groups of porous formworks can be moved along slide rails, so that the multiple times of drilling can be continuously performed after one-time positioning of the vehicle frame;because the positioning is automatically completed, the multiple batches of drilling can be continuously performed along the whole length of the track frame after positioning, and the multiple groupsof machine frames are arranged to simultaneously work according to the workload and project progress, the efficiency is doubled after multiple batches of operation.

Owner:山西伟捷瑞铁路工程有限公司

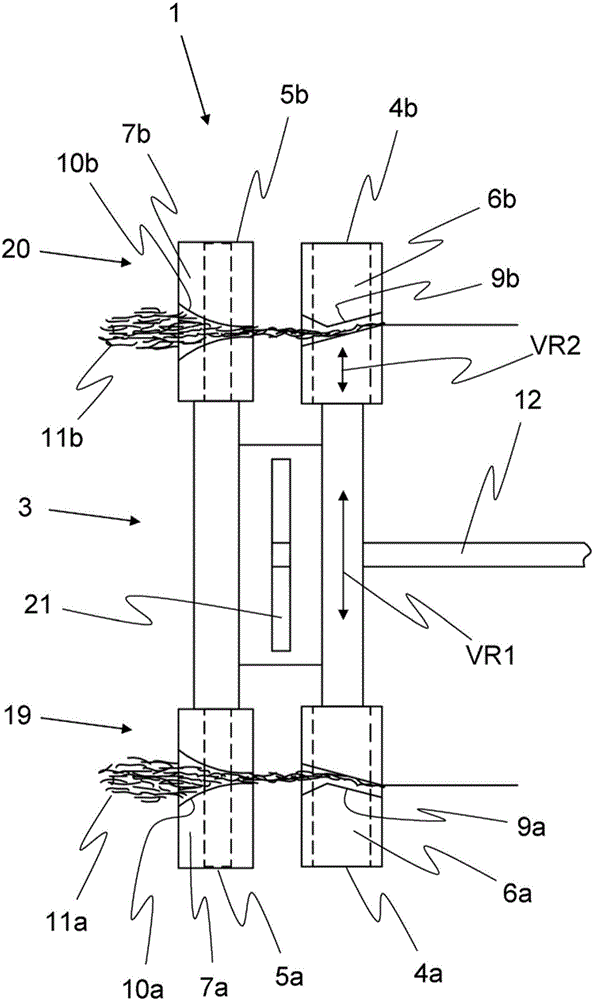

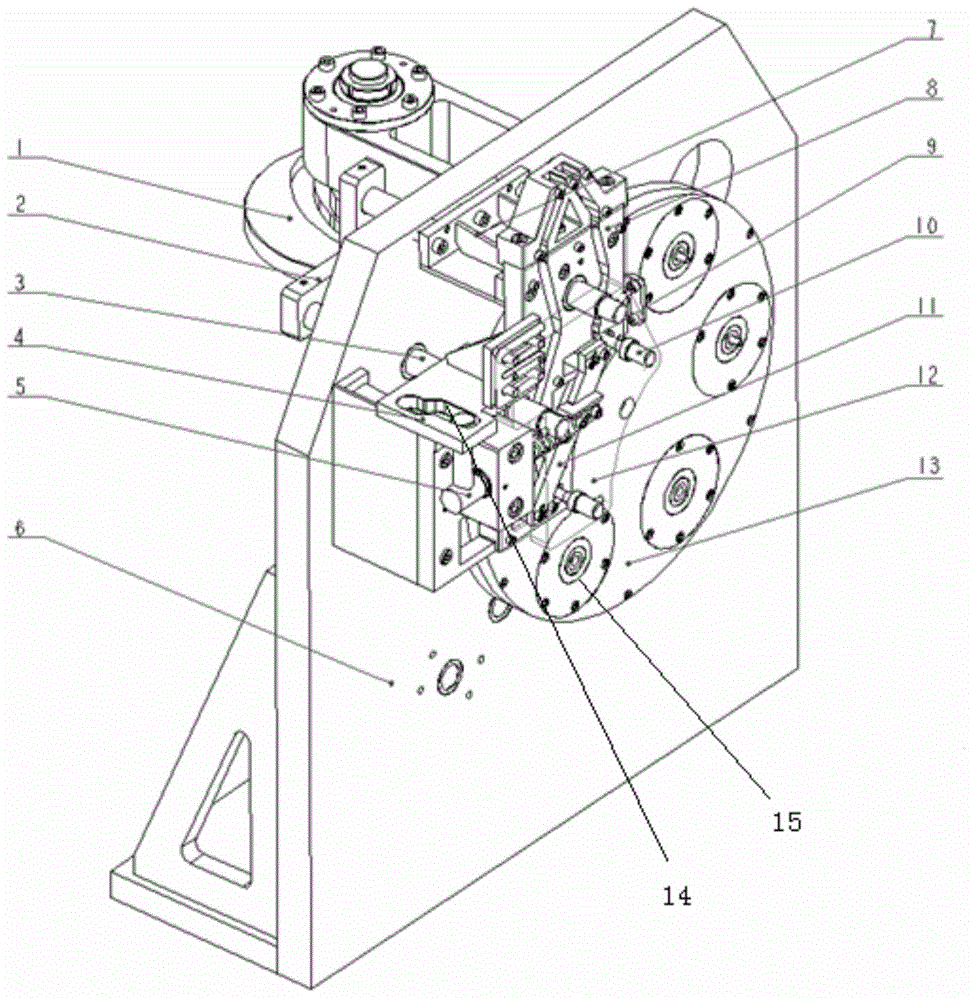

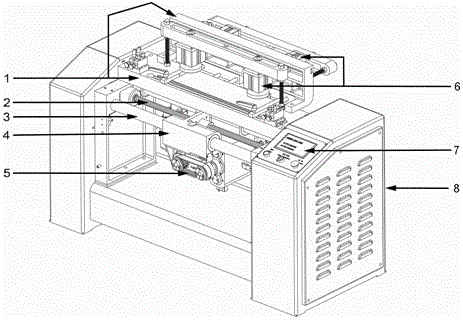

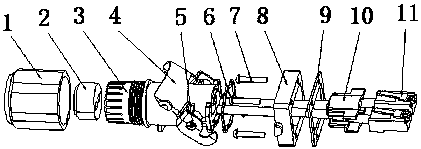

Full-automatic double-reel combined winding machine

InactiveCN102412062AIncreased effective clamping contact surfaceWiring turns smoothlyCoils manufactureWinding machineEngineering

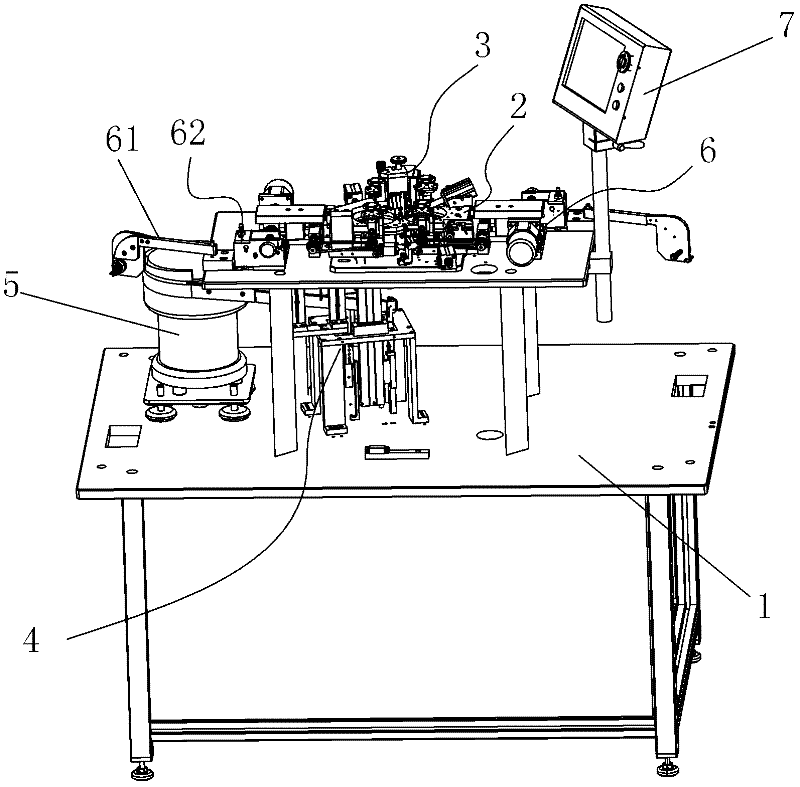

The invention discloses a full-automatic double-reel combined winding machine, which comprises a base, and is characterized in that the base is provided with a double-reel combined winding reel, a magnetic ring clamping device is arranged at the middle position of the double-reel combined winding reel, for containing a magnetic ring, a vertical feeding mechanism which can feed the magnetic ring into the magnetic ring clamping device is arranged under the double-reel combined winding reel, the vertical feeding mechanism is connected with a vibration feeder arranged on the base, the two ends of the double-reel combined winding reel are respectively connected with a wire feeding mechanism which can feed varnished wires into the double-reel combined winding reel, and a controller which is used for controlling the parts to work is arranged at the base. The invention aims to overcome the defects in the prior art, and provides the full-automatic double-reel combined winding machine which has a simple structure, can simultaneously wind wires with different wire diameters, or simultaneously wind two groups of symmetric windings.

Owner:迪斯曼戴克

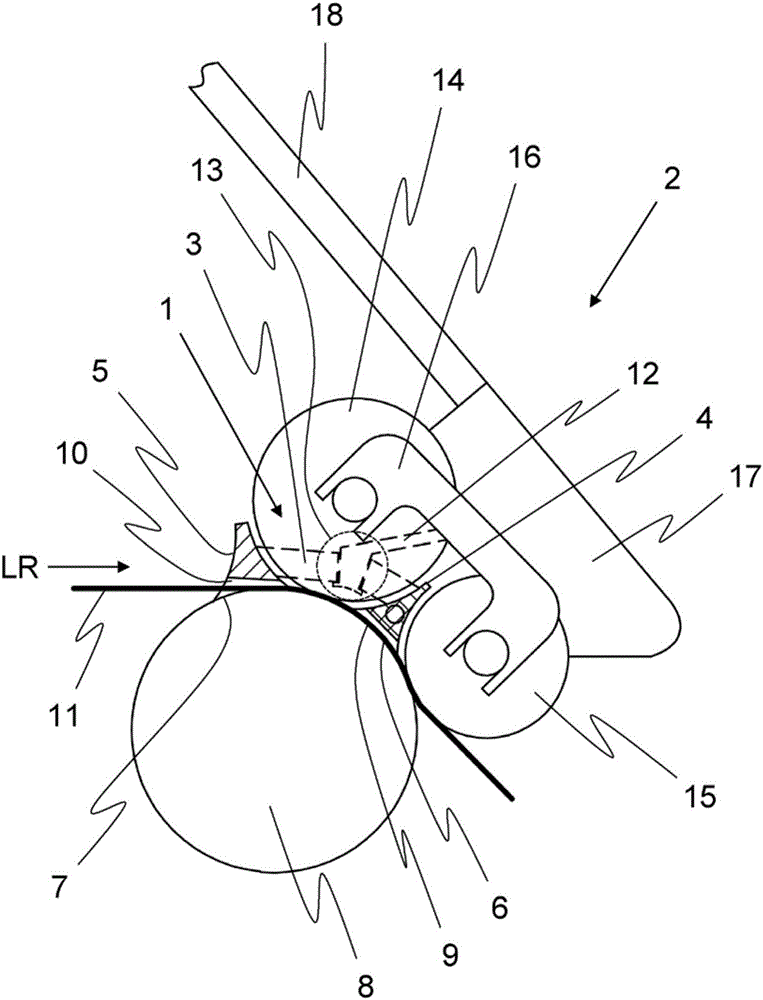

Compressor unit for a stretcher of a textile machine

ActiveCN106400219AChange positionPrevent slipping outDrafting machinesEngineeringMechanical engineering

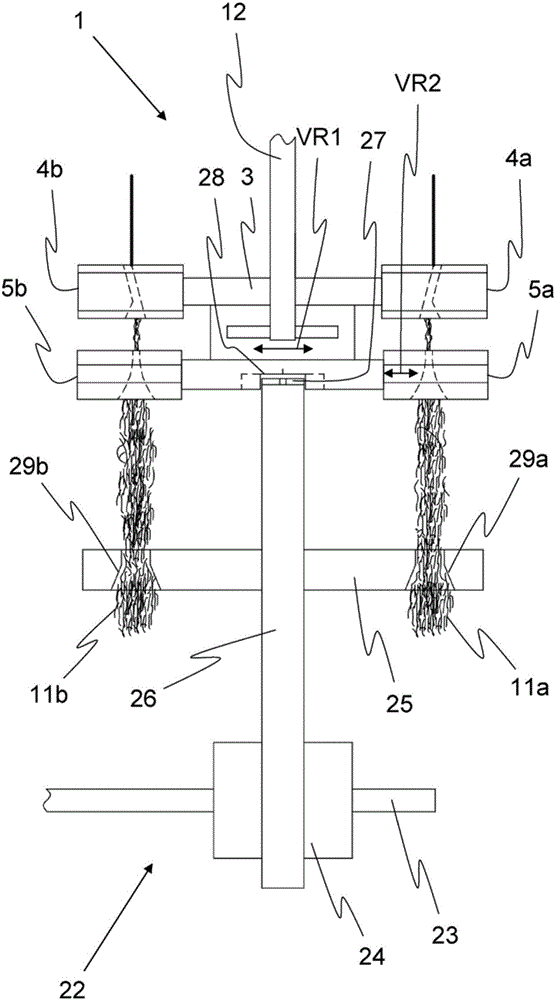

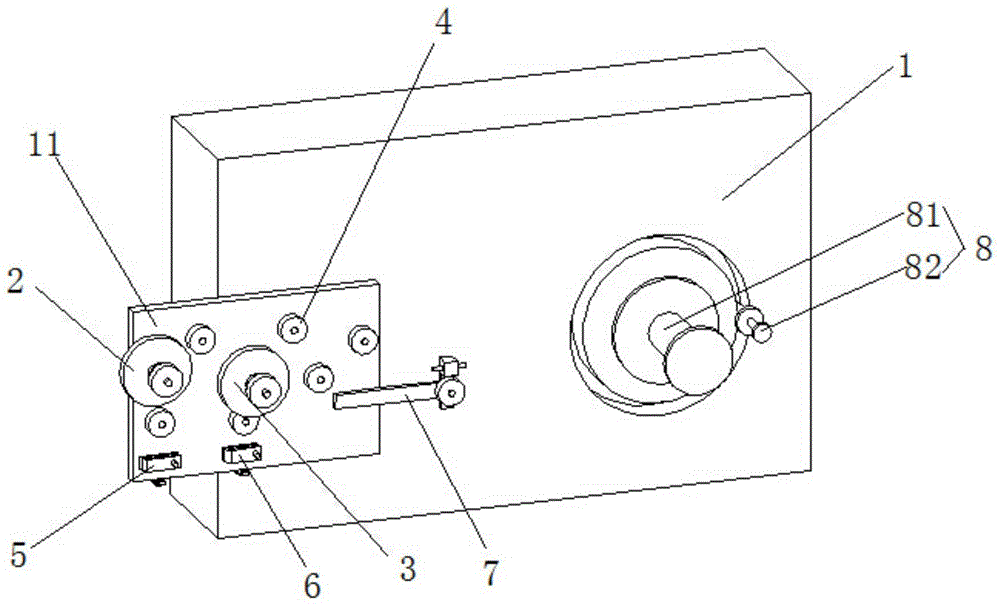

The invention relates to a compressor unit for a drafting machine (2) of a textile machine, comprising at least one guide (4a, 5a, 4b, 5b) and a support (3), wherein the at least one guide (4a, 5a, 4b, 5b) (6a, 7a, 6b, 7b) which rests against a drafting roller (8) during operation of the drafting unit (2), the holding device (3) Wherein a compaction area (9a, 10a, 9b, 10b) is arranged in and / or on the at least one guide (4a, 5a, 4b, 5b), in particular in and / or on the bearing surface (6a, 7a, 6b, 7b) (11a, 11b) guided by the compression region (9a, 10a, 9b, 10b), and having a receiving element (12) which has a connection (13) with the support (3), and Wherein the compressor unit (1) can be accommodated in the drafting unit (2) by means of the receiving element (12). According to the invention, the guide (4a, 5a, 4b, 5b) and / or the holder (3) and / or the receiving element (12) or the complete compressor unit (1) are displaceable in the axial direction of the drafting roller (8). In addition, the compressor unit (1) has an alignment area (28) in order to be able to align the compressor unit (1) on a traverse device.

Owner:MASCHINENFABRIK RIETER AG

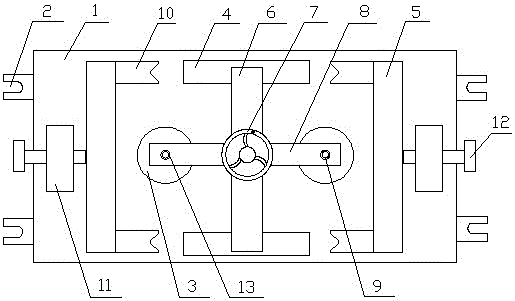

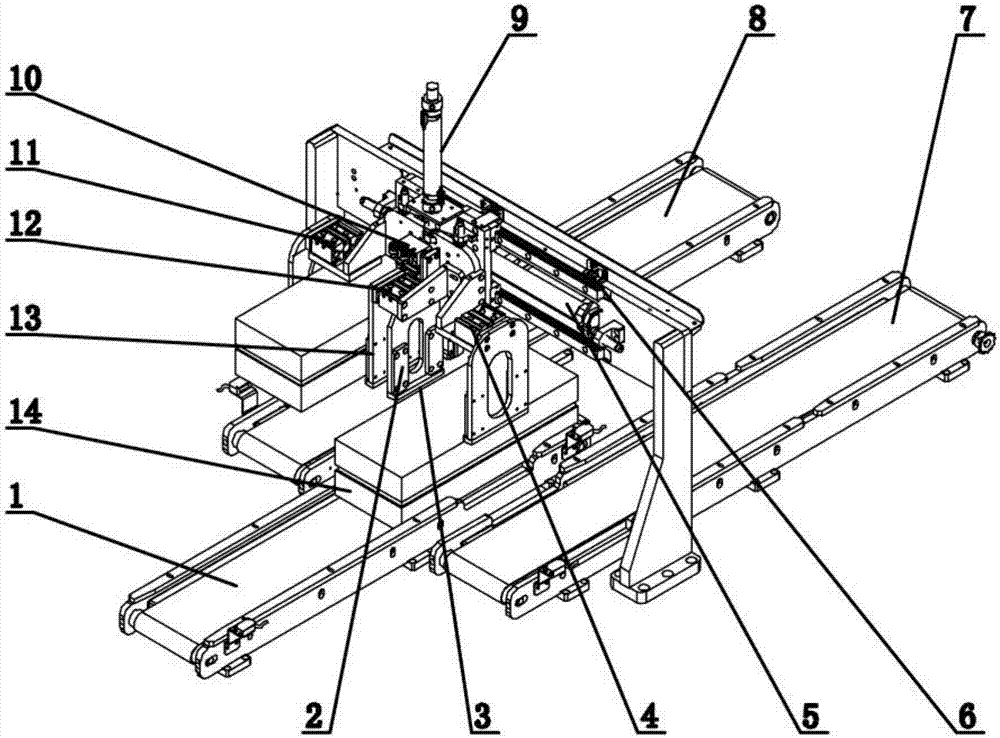

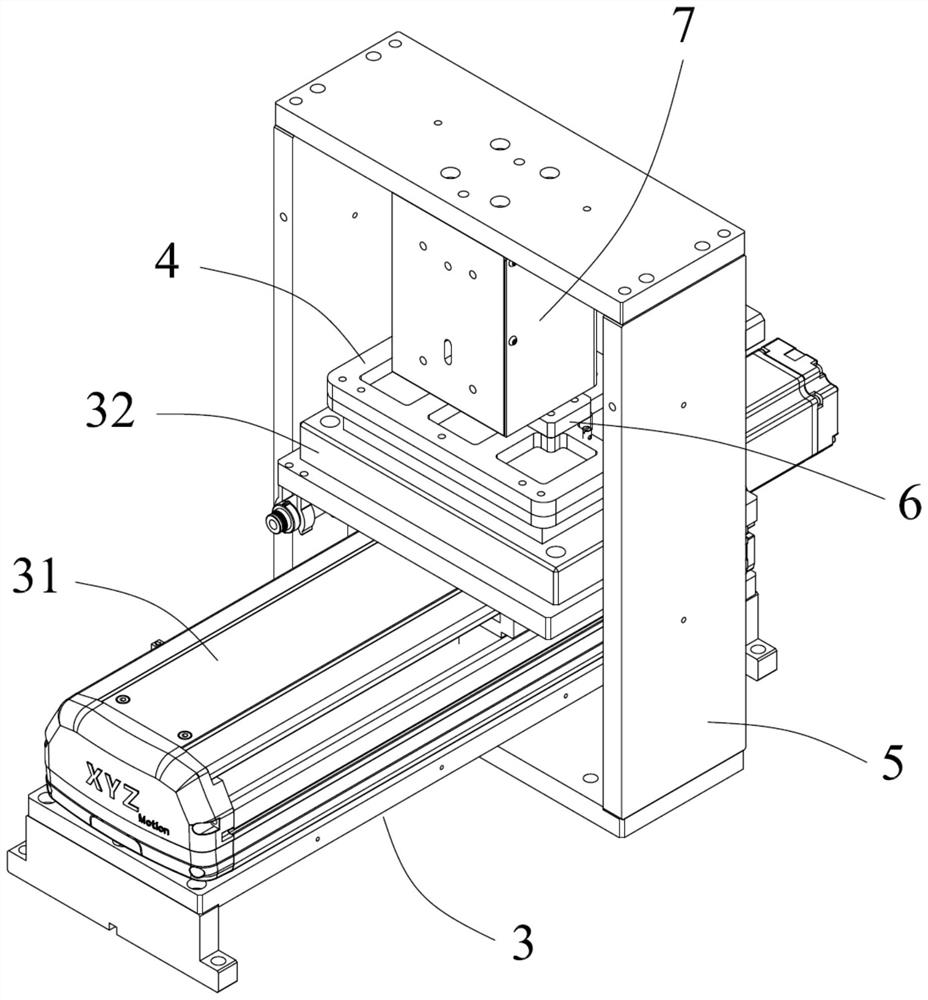

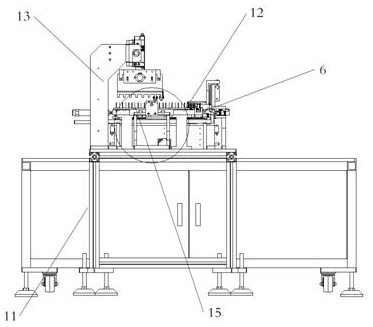

Adjustable intelligent charging and discharging mechanism of punch press

ActiveCN106001305AHigh precisionQuick RetrievalMetal-working feeding devicesPositioning devicesPunch pressEngineering

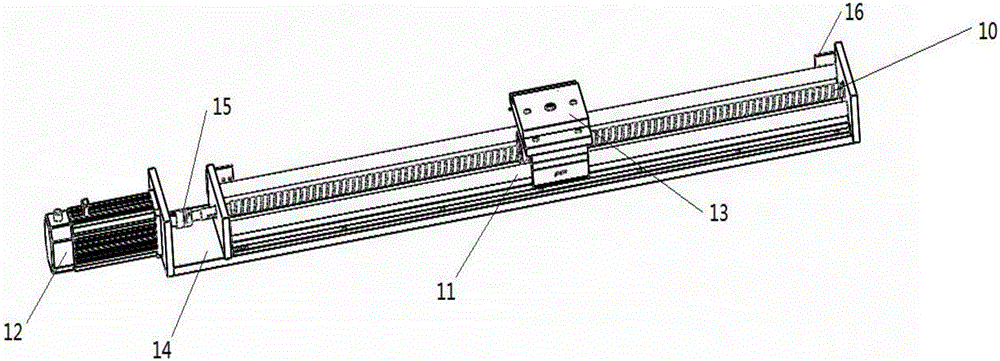

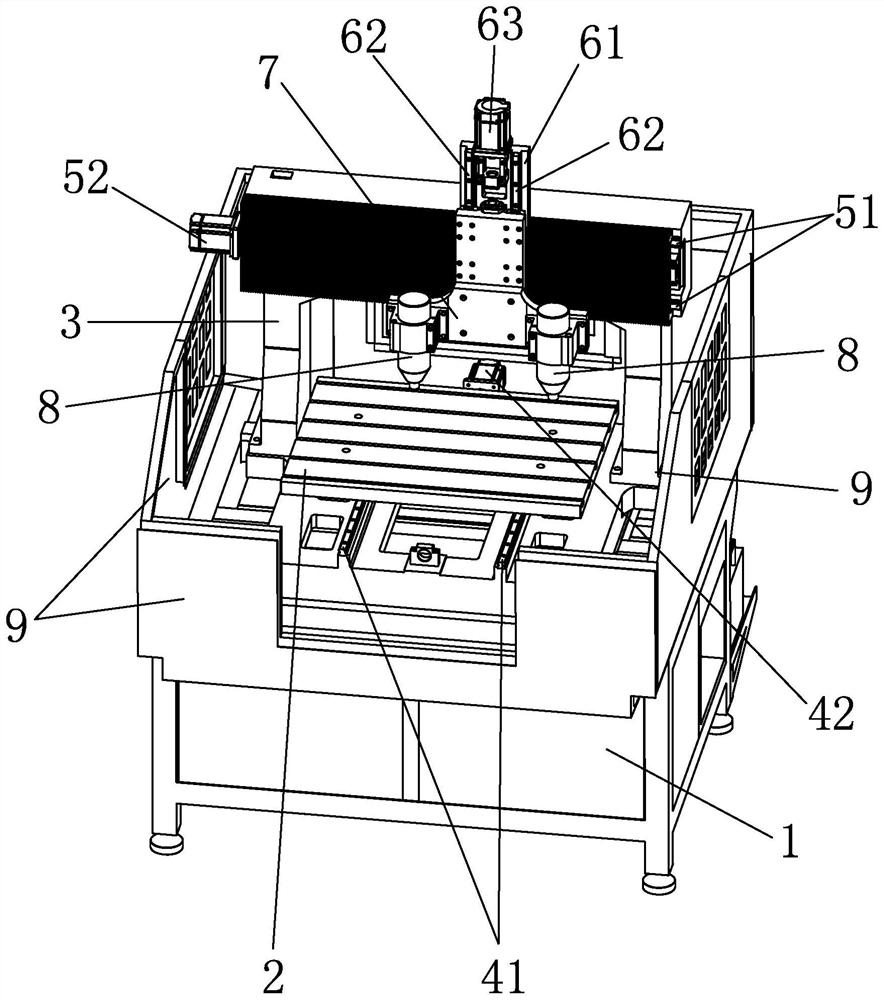

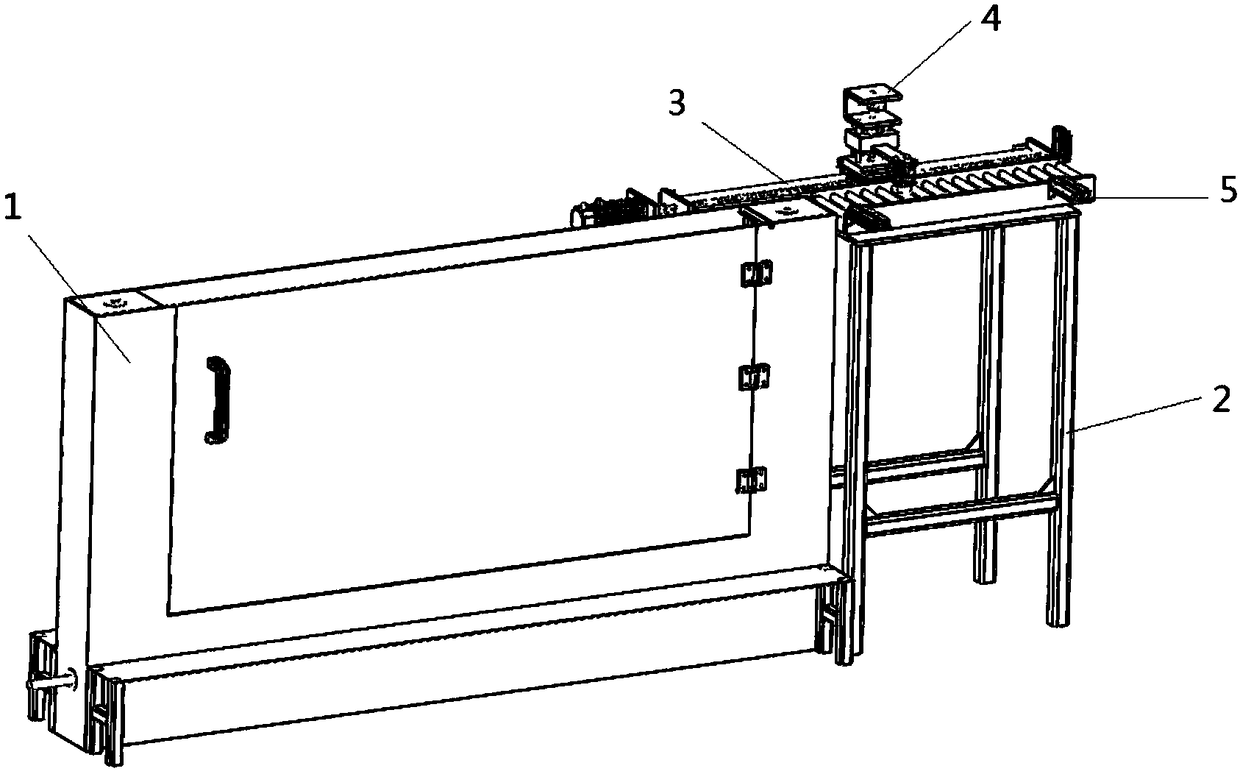

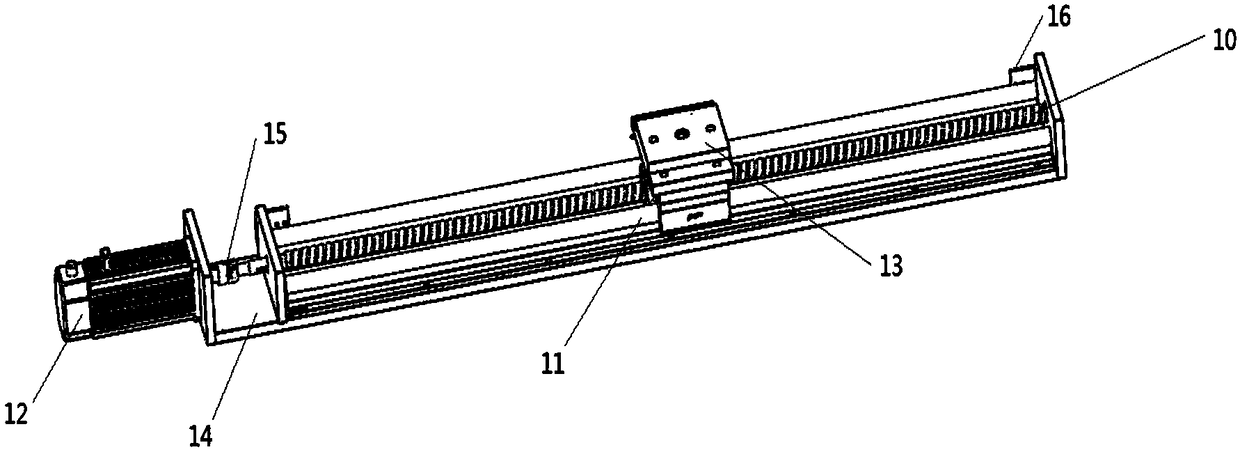

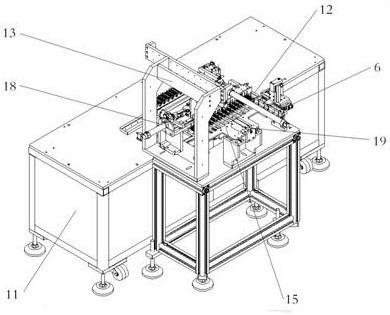

The invention provides an adjustable intelligent charging and discharging mechanism of a punch press. The adjustable intelligent charging and discharging mechanism is mounted at a charging position of a machine tool, and comprises a charging mechanism, a feeding mechanism, an X-axis left-and-right movement liner die set, and a Z-axis up-and-down movement liner die set, wherein the charging mechanism is mounted on one side of the machine tool; the feeding mechanism is erected on the charging mechanism, and the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set are mounted on the feeding mechanism. The adjustable intelligent charging and discharging mechanism of the punch press comprises the charging mechanism, the feeding mechanism, the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set, and through the X-axis left-and-right two-dimensional movement liner die set, and the Z-axis up-and-down two-dimensional movement liner die set, rapid and intelligent material taking can be realized. The adjustable intelligent charging and discharging mechanism is simple in structure and high in operating stability, the precision of a manipulator is high, and the consistency of products is notably improved; besides, normal time for charging and discharging needs to be four hours or above, and the normal processing time of the adjustable intelligent charging and discharging mechanism disclosed by the invention is within 2 hours, so that the efficiency is doubled.

Owner:江苏迈步智能装备科技有限公司

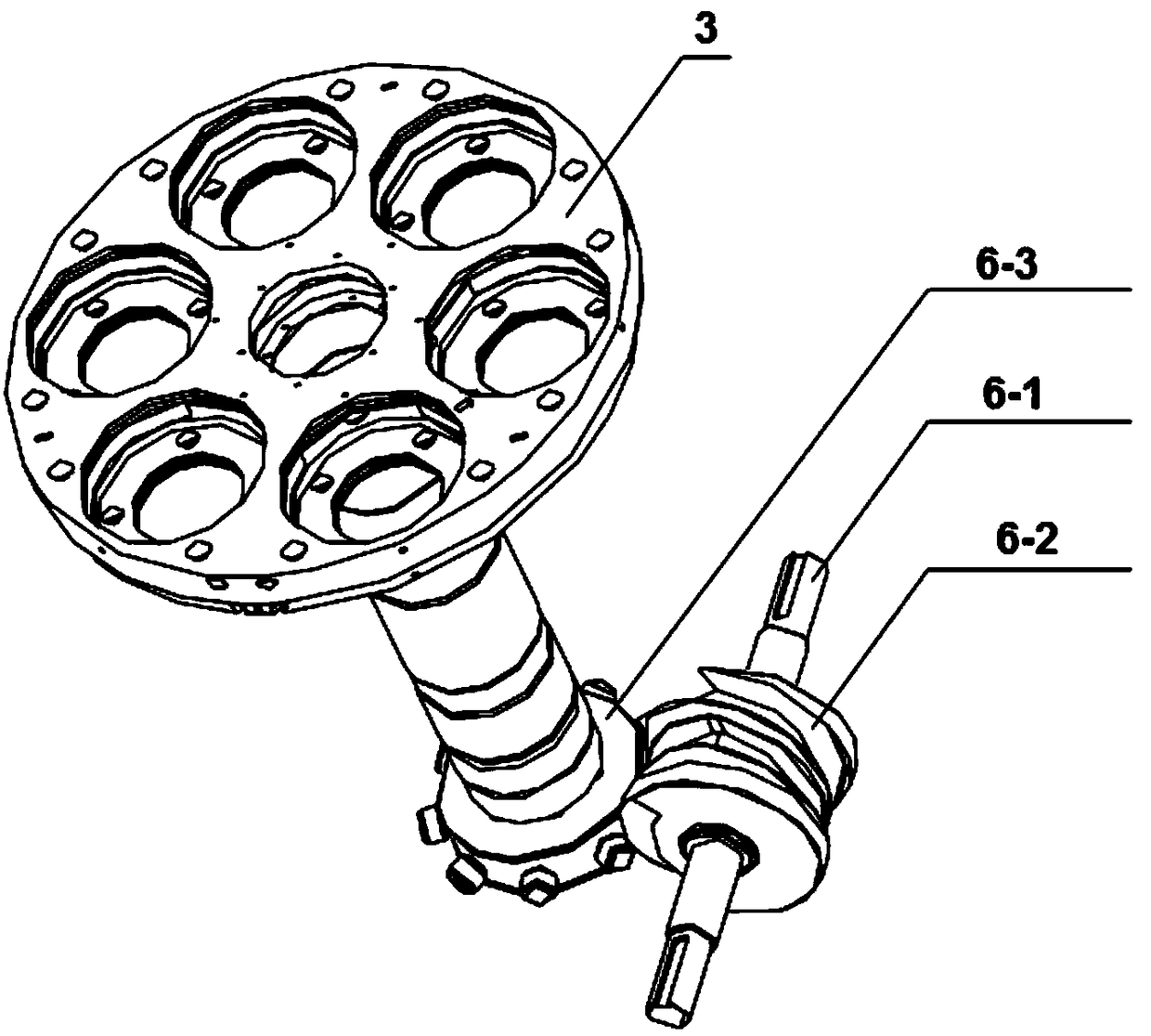

Loading jacking device for cartridge cases

InactiveCN103551905ASimple structureEasy to manufacture and installMetal working apparatusEngineeringCam

The invention discloses a loading jacking device for cartridge cases. The loading jacking device for the cartridge cases comprises a cam, a connecting rod, a shaft, a guide support, a push rod, a support board, a support, a chute board, a clamping jaw, a pressure rod, a connecting board, a board and a rotary wheel disc. The connecting rod is connected with the cam; one end of the shaft is connected with the connecting rod; the other end of the shaft is connected with the board; the guide support is fixedly arranged on the board; the guide support is provided with a guide slot; the guide slot is divided into a loading stroke and a knockout stroke; one end of the push rod is clamped in the guide slot of the guide support; the other end of the push rod is connected with the connecting board; the pressure rod is fixedly arranged on the board; the clamping jaw is fixedly arranged on the connecting board; the connecting board is arranged below the board; the chute board is arranged below the connecting board; the chute board is fixedly arranged on the support board through the support; the rotary wheel disc is provided with multiple stations; the shaft and the board are driven by the cam to realize a feeding process and a loading process. Through the use of the loading jacking device for the cartridge cases disclosed by the invention, by using a mode of cam drive, the structure is simple, and manufacturing and installation are simple and convenient. Loading is performed simultaneously at two stations, so that the efficiency is improved by two times. By adopting a rotary wheel disc-type main shaft, the loading, processing and blanking can be performed simultaneously.

Owner:SANY GRP

Automatic and efficient production line for chains

PendingCN110711838AHigh shaping precisionExtended service lifeMetal chainsProcess engineeringOil and grease

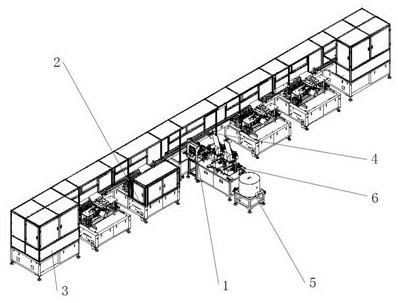

The invention discloses an automatic and efficient production line for chains in the field of chain production. The automatic and efficient production line comprises a feeding assembly mechanism, an assembly machine, a riveting machine, a double-static-load pre-pulling joint disassembling machine and an oil lubricating machine, wherein the feeding assembly mechanism is connected with the rivetingmachine; the double-static-load pre-pulling joint disassembling machine is mainly composed of a pre-tightening running-in area and a joint disassembling area; the riveting machine is connected with the pre-tightening running-in area; the pre-tightening running-in area is connected with the oil lubricating machine; and the oil lubricating machine is connected with the joint disassembling area. According to the automatic and efficient production line, automatic piece discharging of chain workpieces is achieved, the operation difficulty is lowered, the chain assembly precision is improved, and the service life of the chains is prolonged. The double pre-pulling efficiency is high, the service life of chain wheels is prolonged, and the quality of the chains is guaranteed. The constant temperature is controlled through the oil lubricating machine, grease does not age, oil gas is collected and treated, and the automatic and efficient production line is more environmentally friendly. The automatic and efficient production line is formed, the working efficiency is improved, and the production cost is reduced.

Owner:JIANGSHAN JINLIAN PRECISION TECH

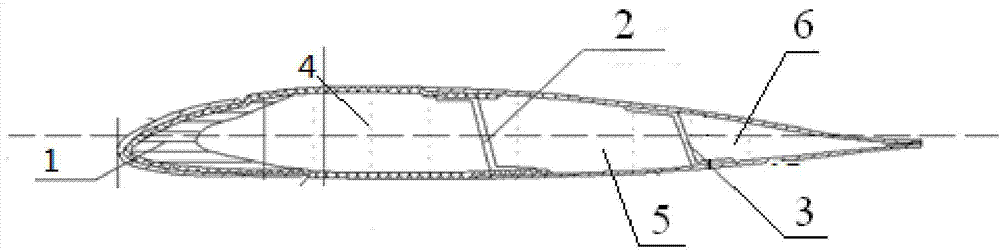

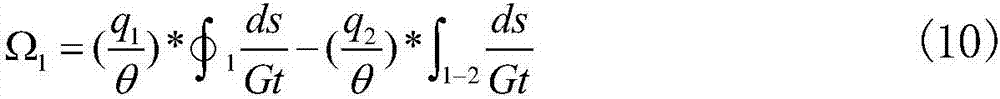

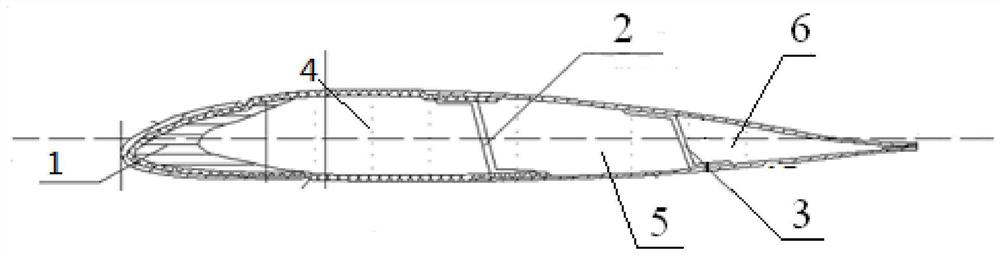

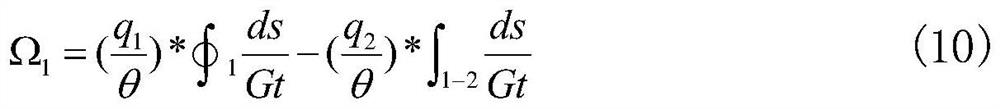

Composite blade section property calculation method

ActiveCN107220458AHigh precisionDouble the efficiencyGeometric CADDesign optimisation/simulationData fileEngineering

The invention belongs to the field of helicopter design, and particularly relates to a composite blade section property calculation method. Blade section properties are the most basic original parameters for helicopter rotor dynamic calculation. Accuracy of the blade section properties is a premise for judging helicopter rotor dynamic properties and vital to rotor dynamic design. According to the composite blade section property calculation method, data files of sections of blades are built according to blade structures, wing profile theory contour data and material data, rigidity is calculated by a modulus weighting method according to anisotropic performances of composites, and mass is calculated by a finite element concept. Accurate basic data are provided for blade dynamic analysis and design, the blade section properties can be rapidly and accurately calculated, optimal design of the blades can be rapidly finished, and rotor system dynamic design technology is broken through.

Owner:哈尔滨哈飞航空工业有限责任公司

Double-cylinder eccentric rotary pump

ActiveCN106014974AHigh liftEasy maintenanceRotary piston pumpsRotary/oscillating piston combinationsRotary pumpEngineering

The invention discloses a double-cylinder eccentric rotary pump. The double-cylinder eccentric rotary pump comprises a first cylinder body and a second cylinder body. The first cylinder body and the second cylinder body are each internally provided with a cavity. The outer end surface of the first cylinder body and the outer end surface of the second cylinder body are each provided with inlets and outlets. The cavity of the first cylinder body and the cavity of the second cylinder body are internally provided with a first rotor and a second rotor correspondingly. Working cavities are formed between the side surface of the first rotor and the cavity of the first cylinder body as well as between the side surface of the second rotor and the cavity of the second cylinder body correspondingly. The first rotor and the second rotor are installed on a first eccentric part and a second eccentric part of the same crankshaft in a sleeving mode correspondingly so that the working cavities can be increased or decreased and the inlets can communicate with the outlets. The first rotor is in clearance fit with the crankshaft, and the second rotor is in clearance fit with the crankshaft. Fixed gears are fixed to the first cylinder body and the second cylinder body. Teeth or gear rings matched with the fixed gears are arranged in the middle of the first rotor and the middle of the second rotor. The double-cylinder eccentric rotary pump is high in efficiency, user-friendly, convenient to transport, easy to maintain and capable of achieving real-time monitoring and stepless speed adjusting.

Owner:SHANDONG UNIV

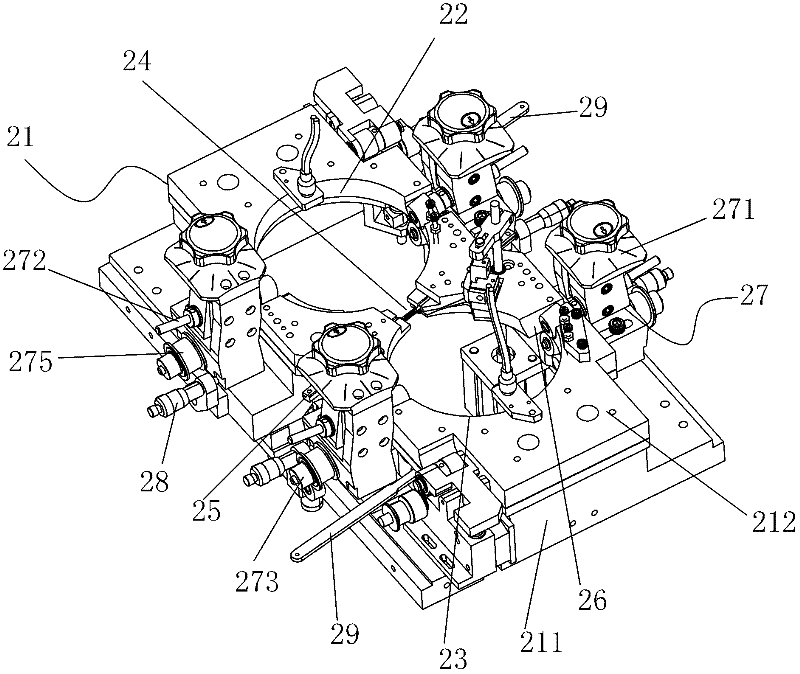

Punching clamp for cam shaft housing

ActiveCN106378648AEasy to installCompact and reasonable structurePositioning apparatusMetal-working holdersPunchingEngineering

The invention discloses a punching clamp for a cam shaft housing. The punching clamp comprises a base. Two working tables, two spacing blocks and two stop blocks are arranged on the upper pane of the base. The two spacing blocks are arranged at the front end and the rear end of the upper plane of the base. Cross beams connected with each other are arranged on the spacing blocks. A first rotary pressing part is arranged between the cross beams. A pressing plate is arranged below the first rotary pressing part. Through holes are formed in two sides of the pressing plate. The two stop blocks are arranged on two sides of the upper pane of the base. V-shaped blocks are arranged at the front part and the rear part of the inner side of each stop block. Fixed blocks are arranged at the outer sides of the stop blocks. A second rotary pressing part is arranged on each fixed block, and is opposite to the middle of each corresponding stop block. Each working table is arranged between the corresponding V-shaped blocks. Positioning rods are arranged on the working tables, and are arranged in the through holes. The punching clamp is reasonable and compact in structure, and convenient to operate, and realizes all-directional clamping. After being punched, the cam shaft housing is accurate in size and position. A cam shaft is conveniently mounted. Two cam shaft housings can be processed at one step, so that the efficiency is doubled.

Owner:上海伟奕传动轴配件有限公司

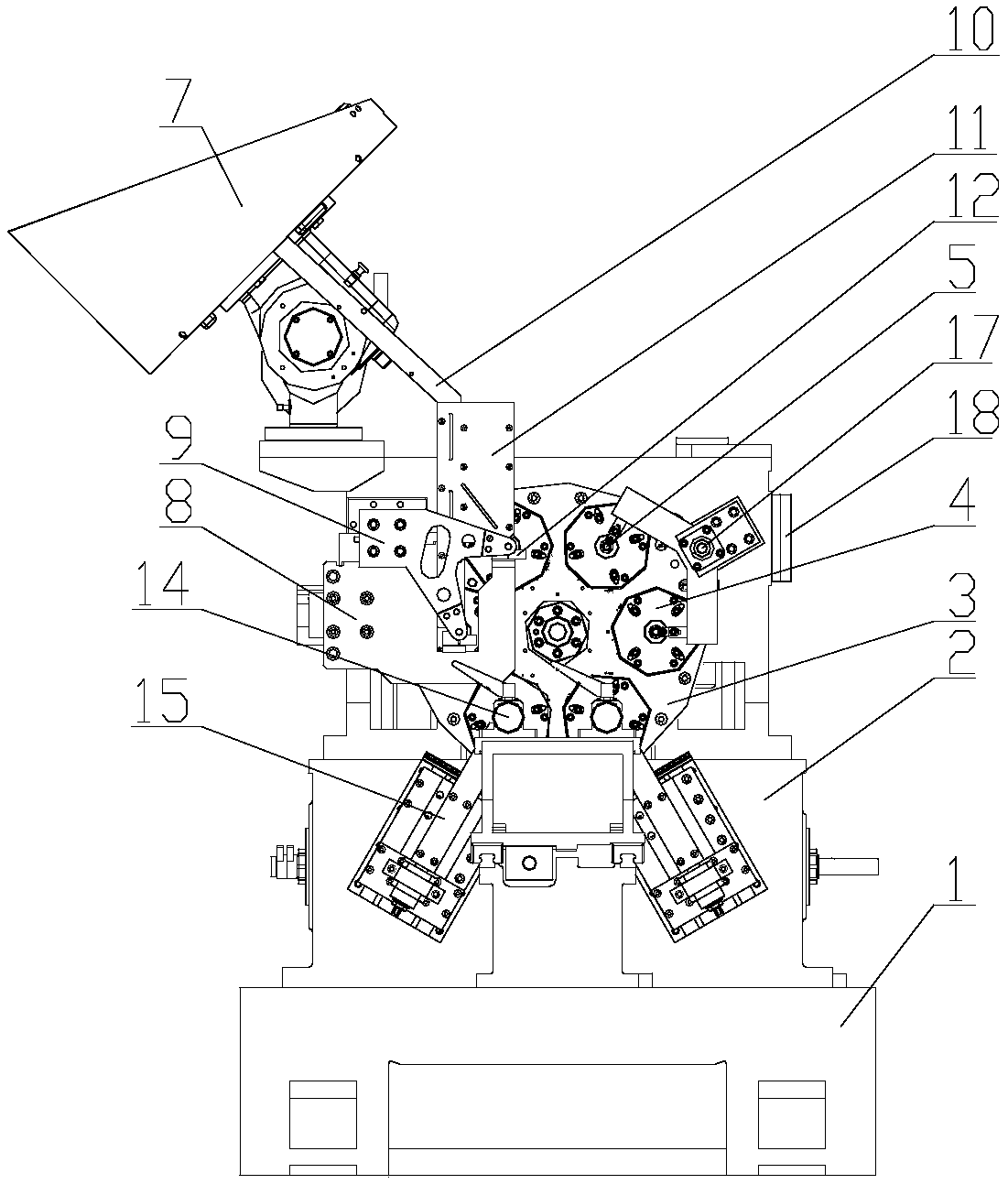

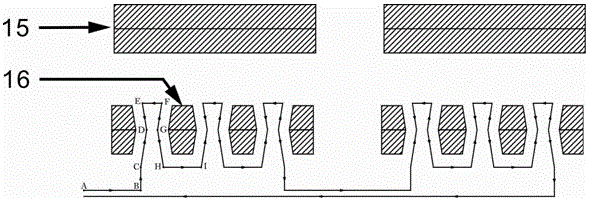

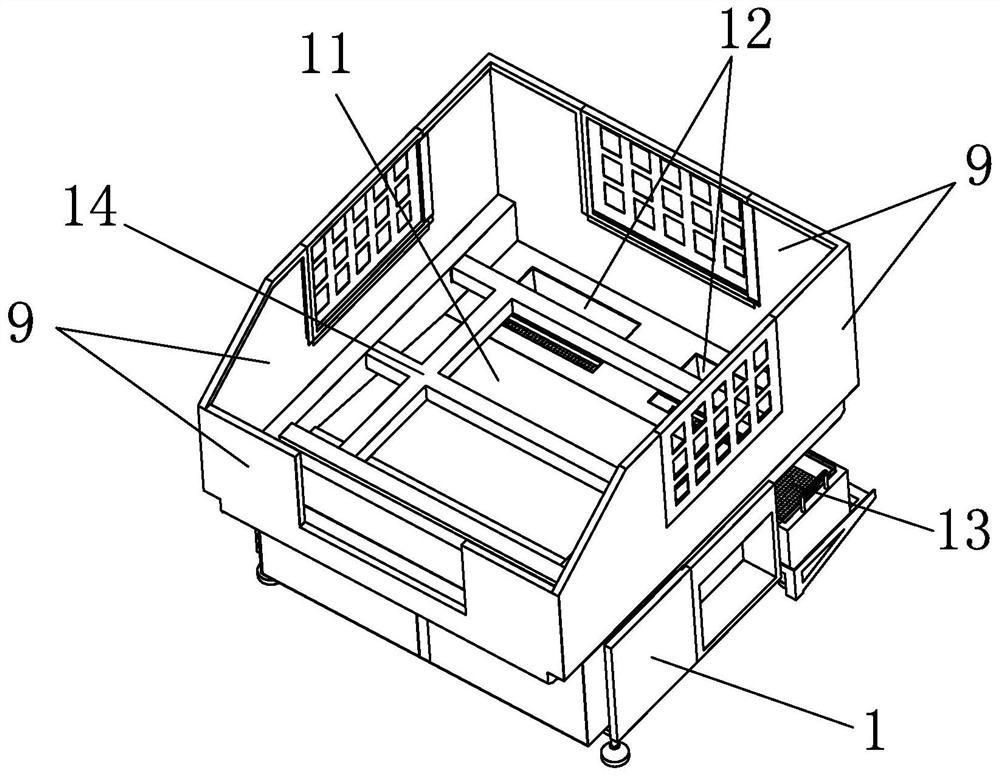

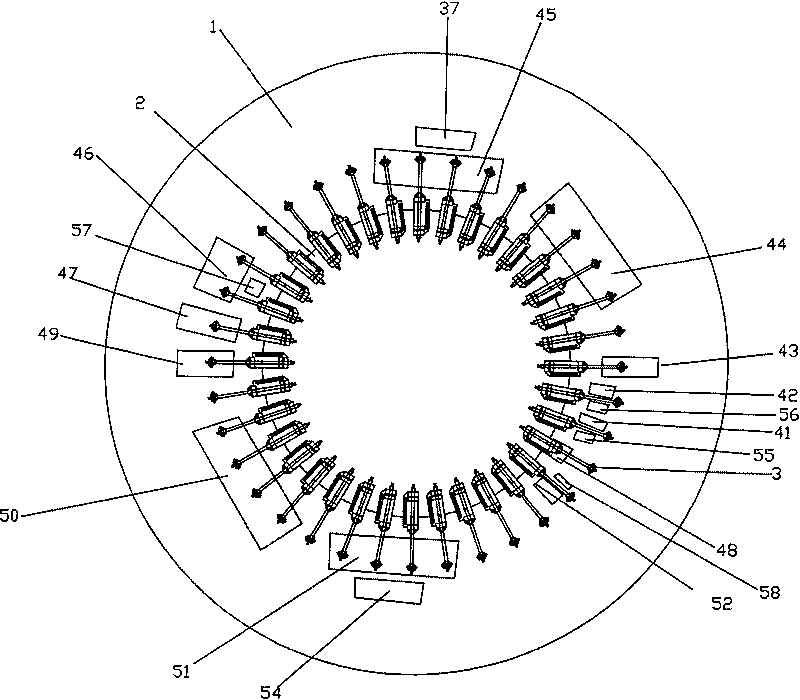

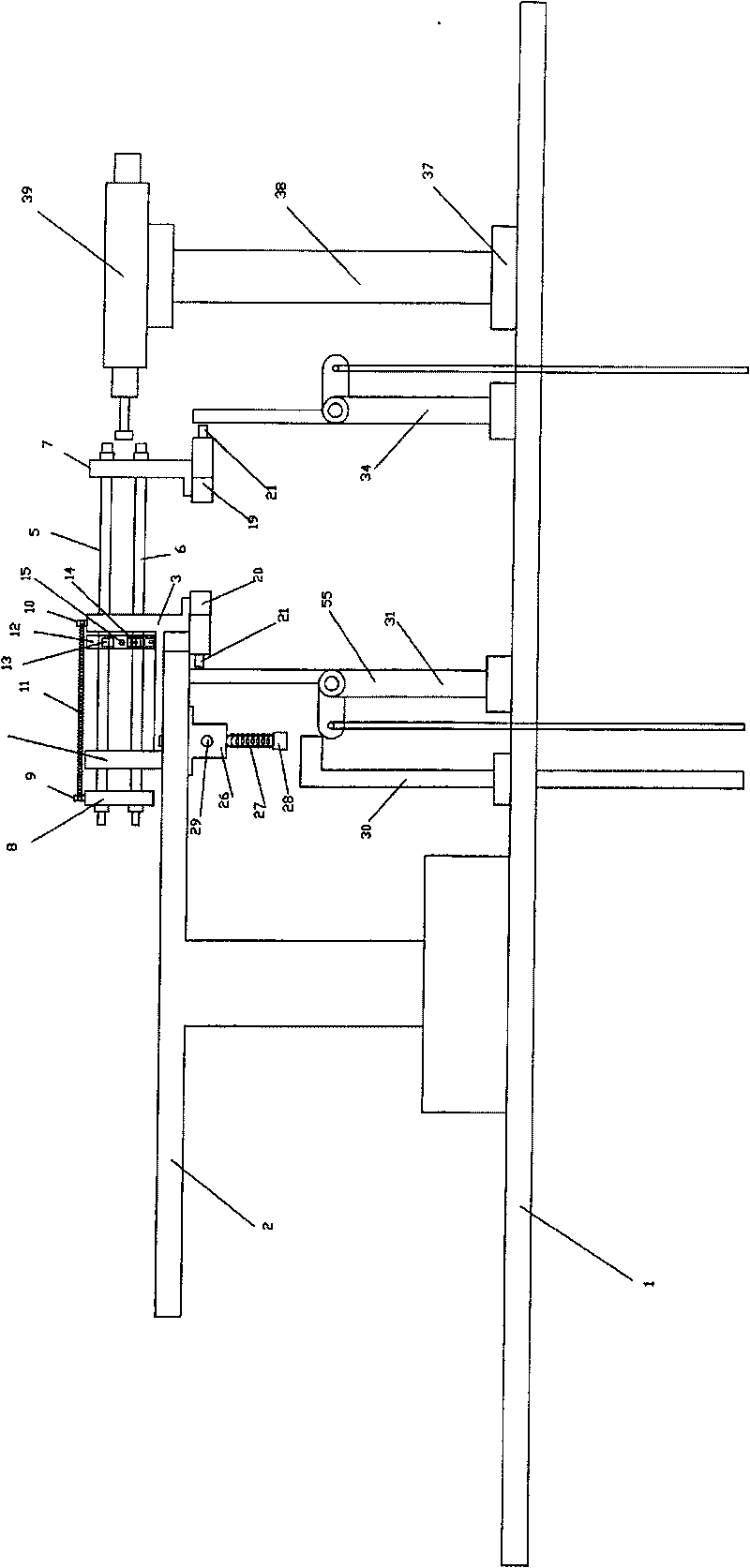

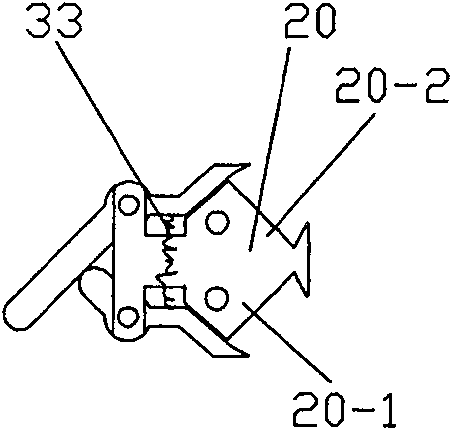

Full-automatic 4U lamp tube bridging apparatus and its process

InactiveCN101007701AIncrease profitActions are reasonably preciseVessels or leading-in conductors manufactureGlass reforming apparatusStructural engineeringMechanical engineering

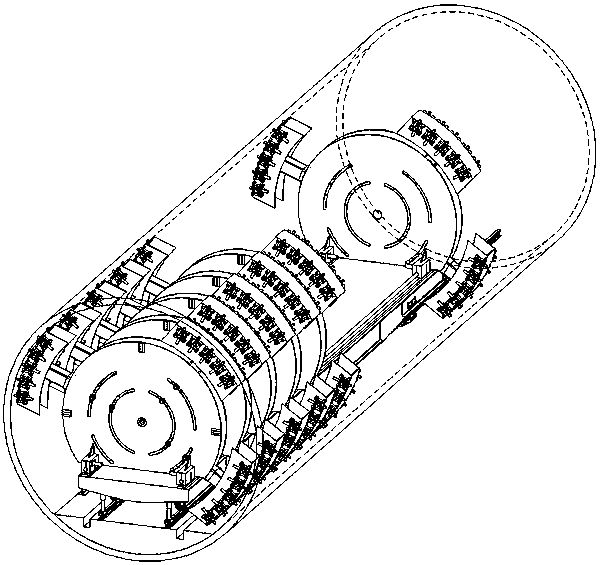

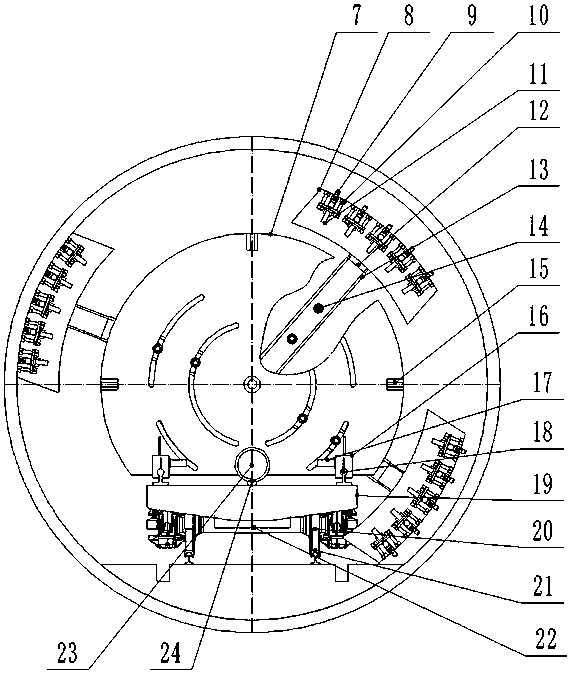

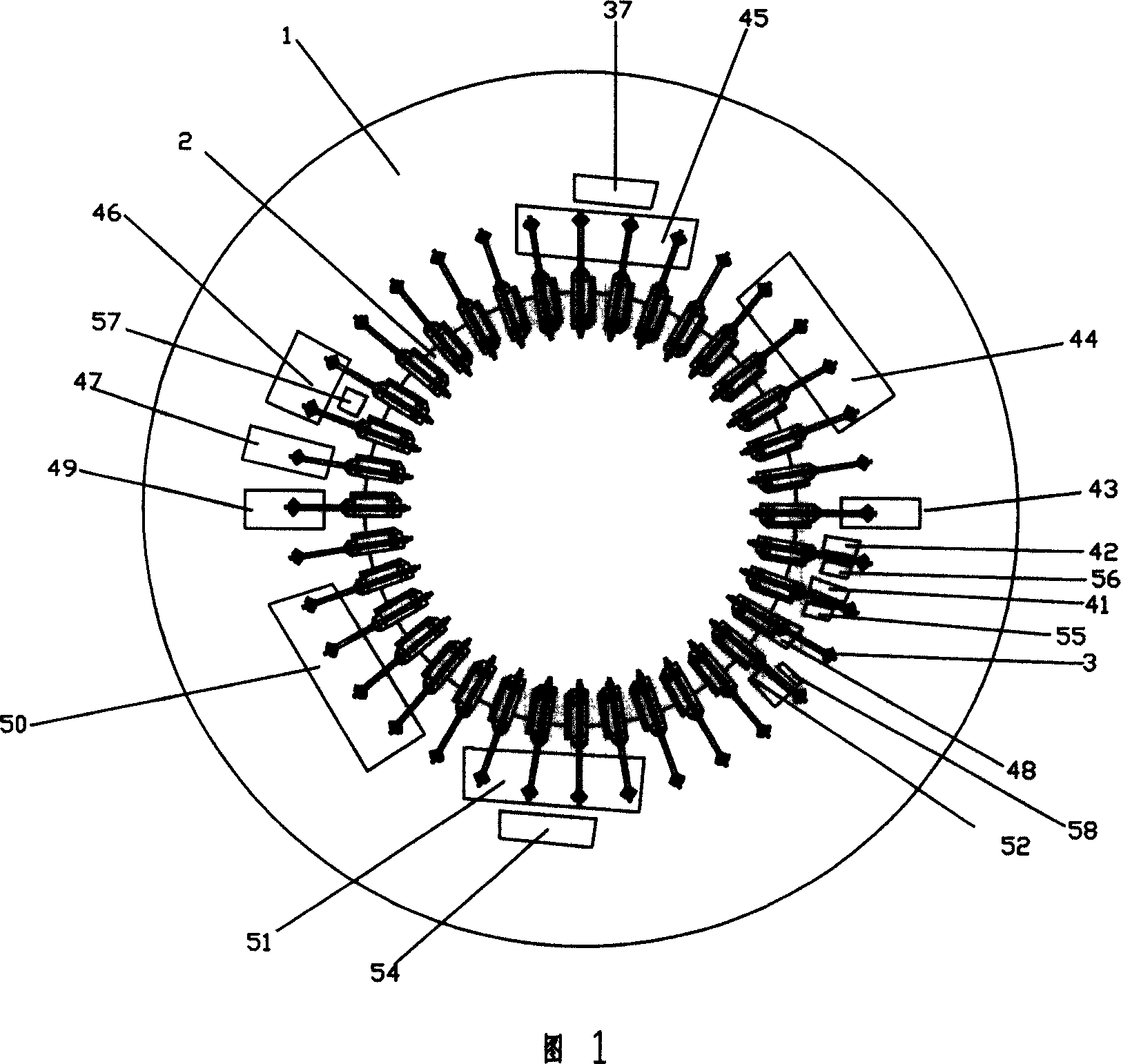

The invention discloses a full-automatic 4U tube bridge connection device and making method, which is characterized by the following: setting rotary table (2) on the working machine table(1); distributing 36 mechanic head fixtures (3) on the rotary table; distributing primary open-up arrangement (48), primary upper pipe device (41), secondary upper device (42), slice pipe location device (43), primary burning tack device (44), primary bridge connection device (45), turn-up device (46), primary bridge, secondary location device (47), secondary open-up device (49), burning tack device (50), secondary bridge connection device (51) and lower-in device (52) around the working machine table(1) and rotary table (2) sequentially .

Owner:王良才 +1

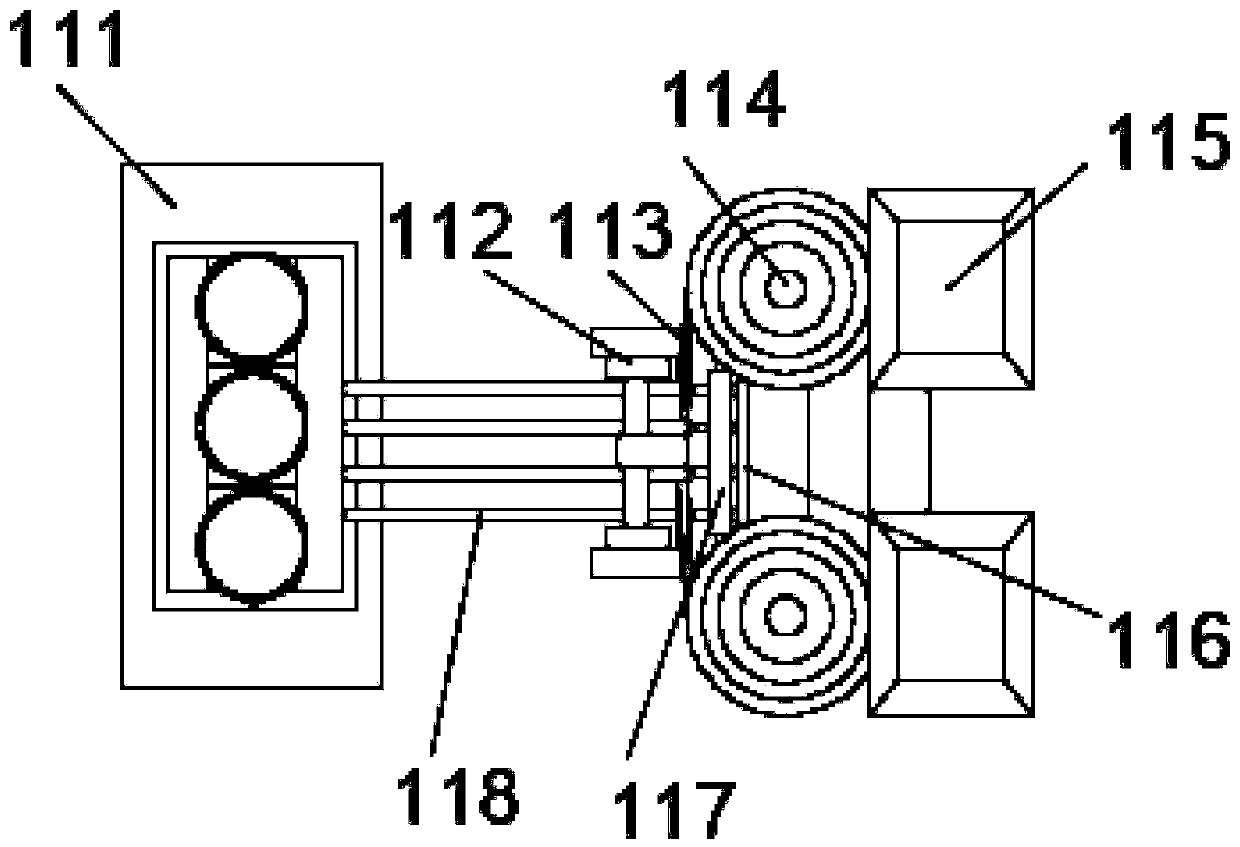

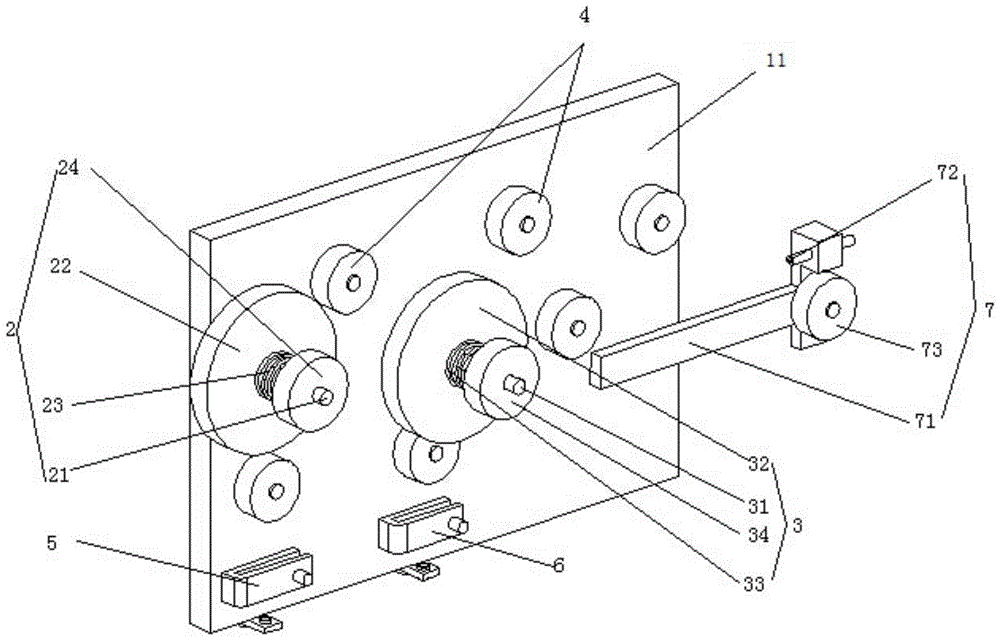

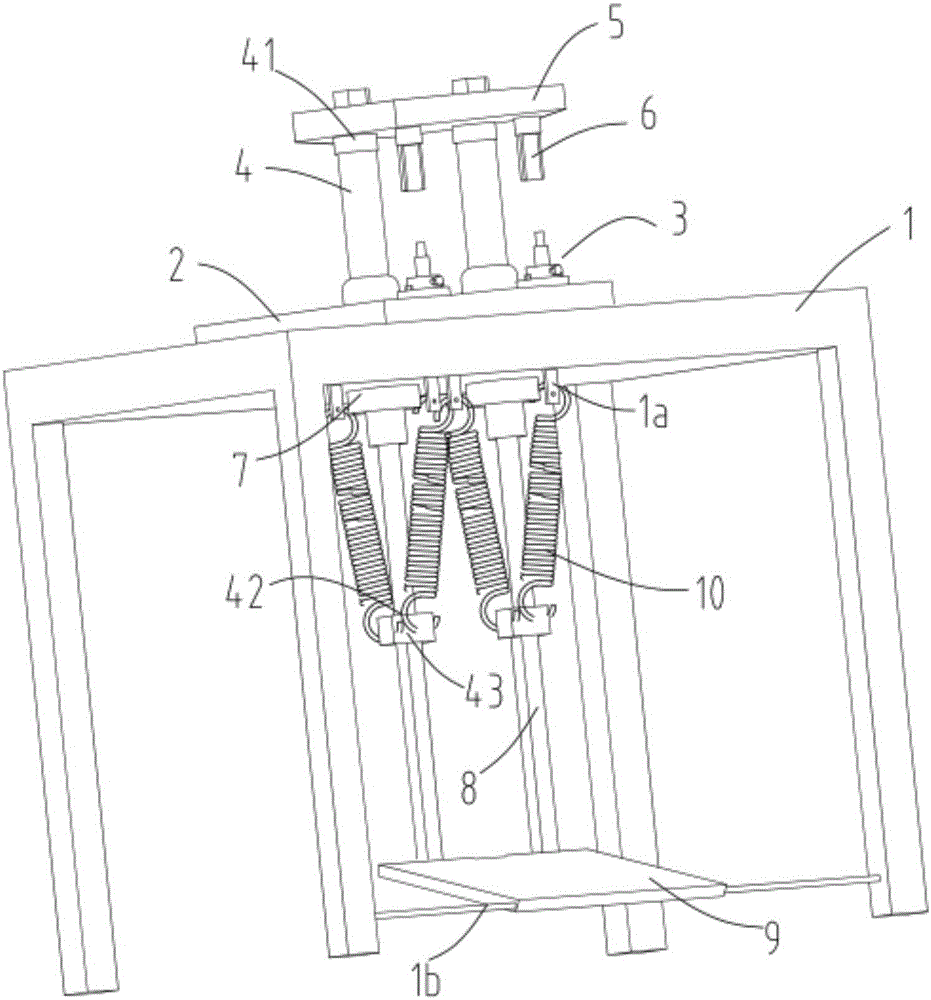

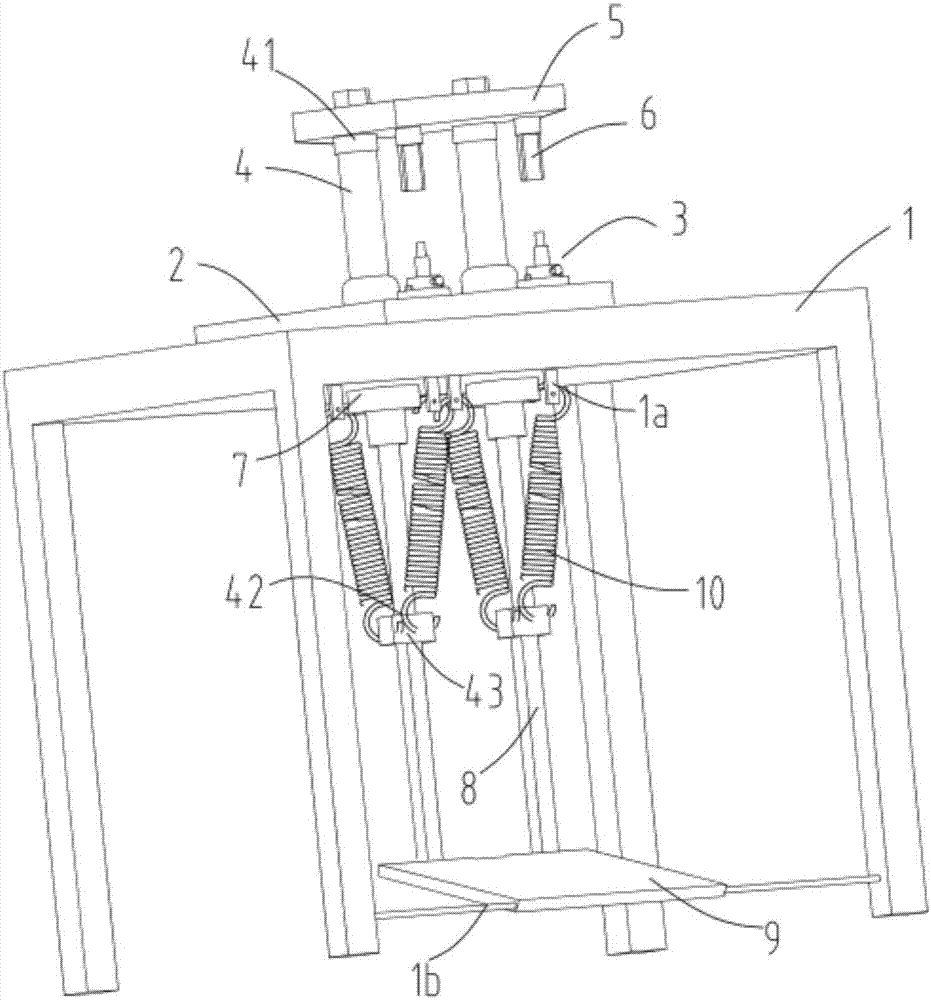

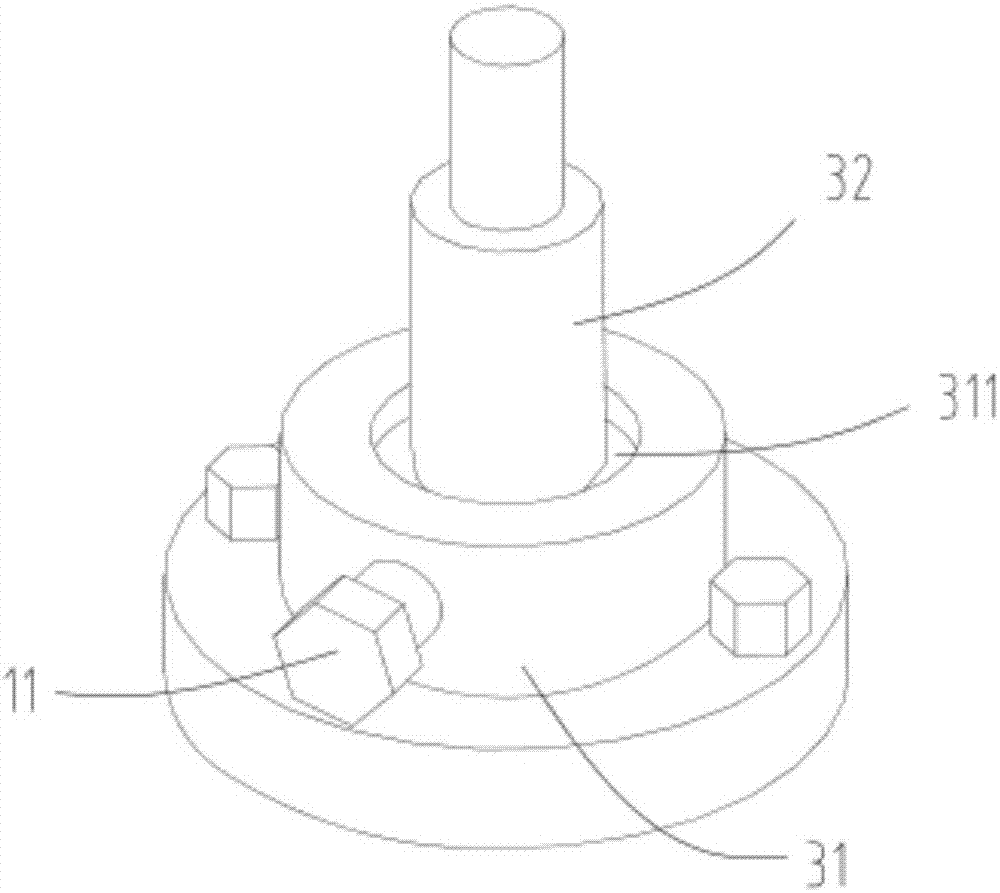

Winding device of electromagnetic switch coil

InactiveCN105788846ADouble the efficiencyImprove efficiencyFilament handlingElectric switchesEngineeringConductor Coil

The invention discloses a winding device of an electromagnetic switch coil. The device comprises a rack, and a first wire routing wheel, a second wire routing wheel, multiple guide wheels, a first wire mounting slot, a second wire mounting slot, a wire combining assembly and a winding rack which are arranged on the rack. The circle centers of the first wire routing wheel and the second wire routing wheel are not located on the same horizontal line. The first wire mounting slot and the second wire mounting slot are arranged under the first wire routing wheel and the second wire routing wheel. The wire combining assembly comprises a wire combining crossarm, a wire conduit and a wire guide wheel. One end of the wire combining crossarm is fixed on the rack, and the other end stretches out of the rack. The wire conduit and the wire guide wheel are arranged in an up and down mode and are arranged on the end, stretching out of the rack, of the wire combining crossarm. The winding rack comprises a coil shaft and an insulation tape frame. The winding rack comprises a coil shaft, an insulation tape frame and a tape pressing mechanism. The tape pressing mechanism is arranged beside the coil shaft and is used for compressing an insulation tape winded on the coil. According to the device, through arranging the two wire routing wheels, the efficiency can be doubled.

Owner:常州市武进亚太机电配件有限公司

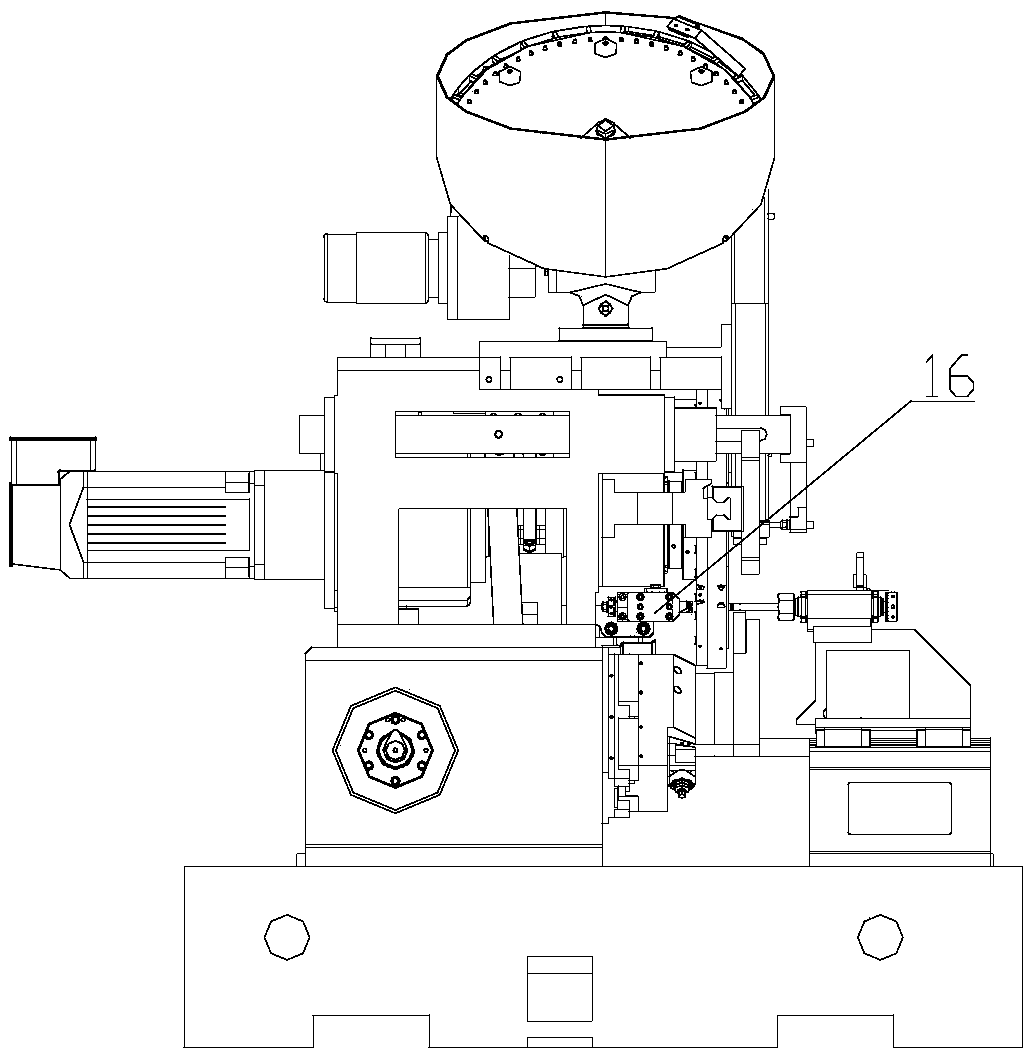

Underbody tapping machine

PendingCN109304618ADouble the efficiencyShort strokePrecision positioning equipmentOther manufacturing equipments/toolsFailure rateSlag

The invention relates to an underbody tapping machine. The underbody tapping machine comprises a base, a rack mounted on the base and a large spindle rotatably mounted on the rack, as well as small spindles of which the number is multiples of three, wherein the small spindles are uniformly distributed on an end surface of the large spindle in a circumferential direction of the large spindle. The small spindles of which the number is multiples of three are divided into a feeding region, a processing and slagging region and a returning region. The underbody tapping machine further comprises an indexing mechanism connected to the large spindle, so that the large spindle is driven to rotate at a set angle. According to the underbody tapping machine, the small spindles and a vertical runner conversion structure are adopted, the small spindles of which the number is multiples of three are divided into the feeding region, the processing and slagging region and the returning region, and each region can simultaneously process multiple products, so that the efficiency is doubled, automatic slag sieving is realized, and the action progress and the failure rate are reduced.

Owner:大连中成精密机械有限公司

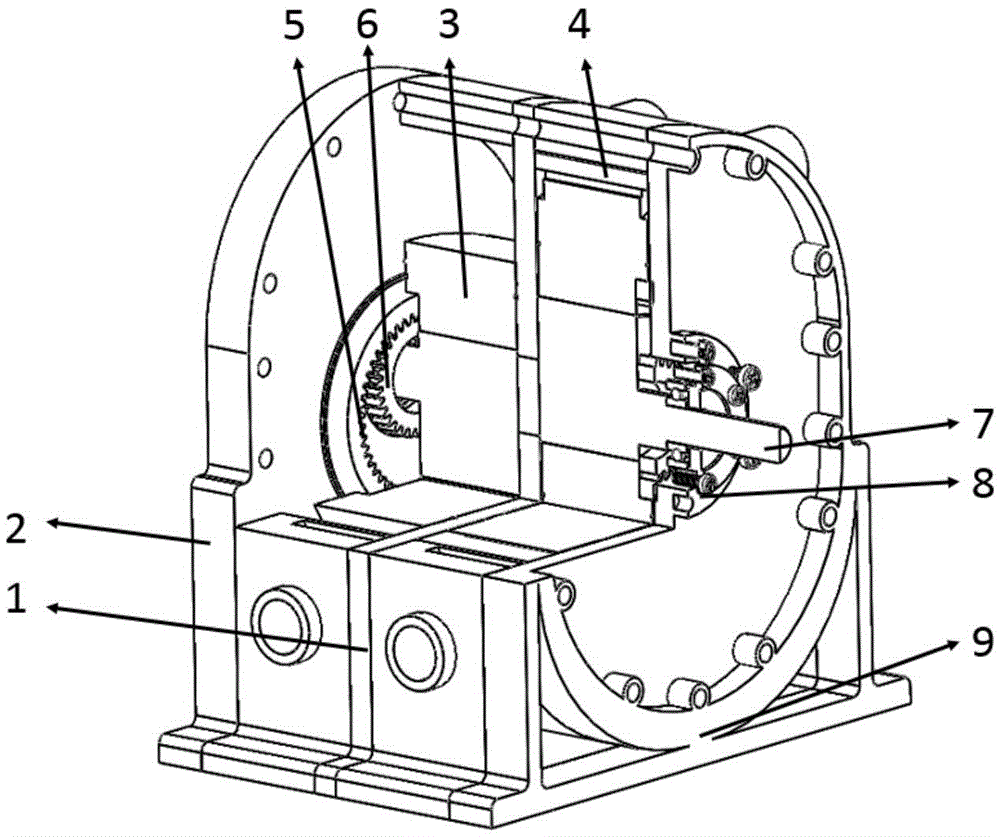

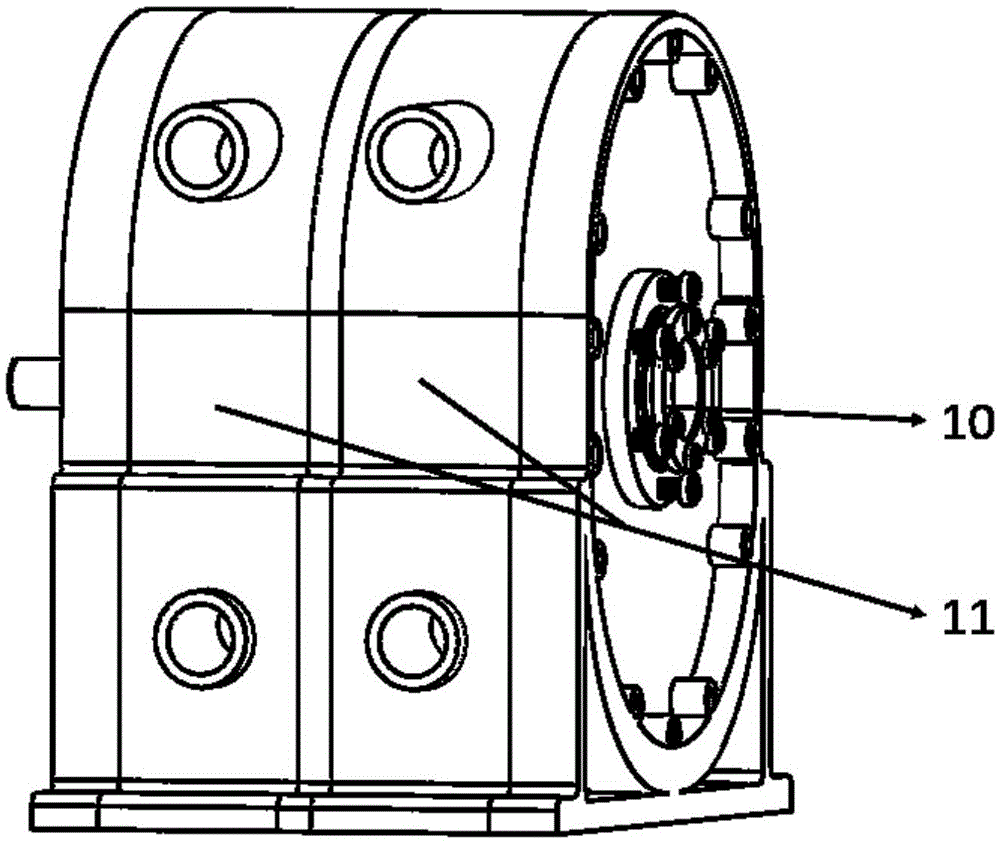

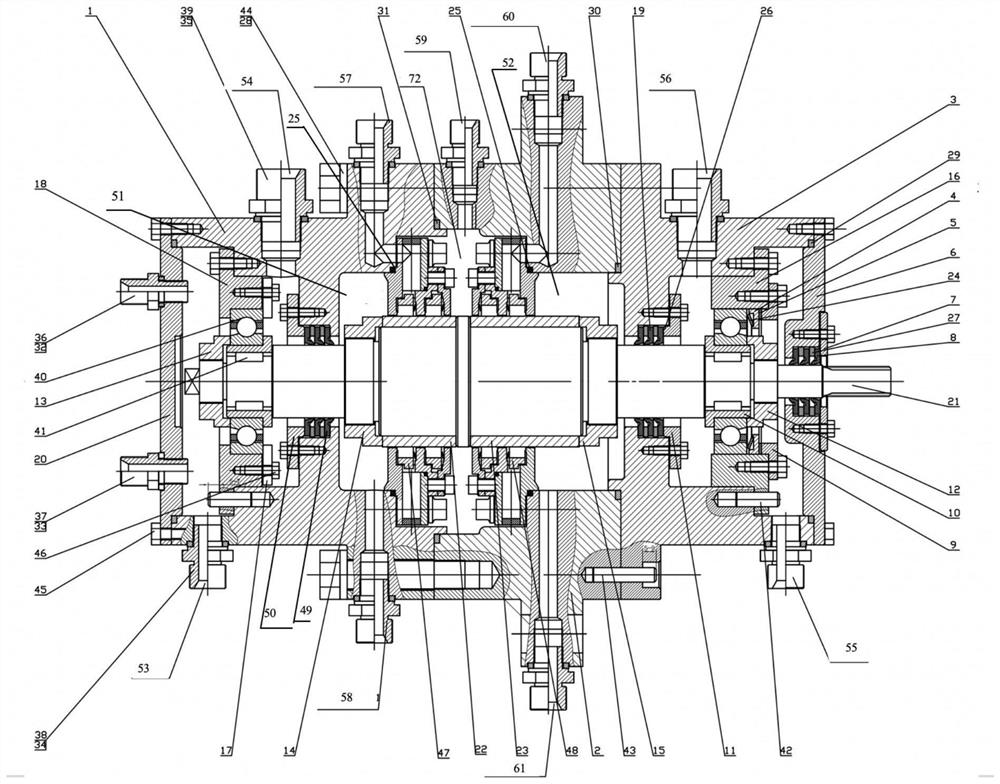

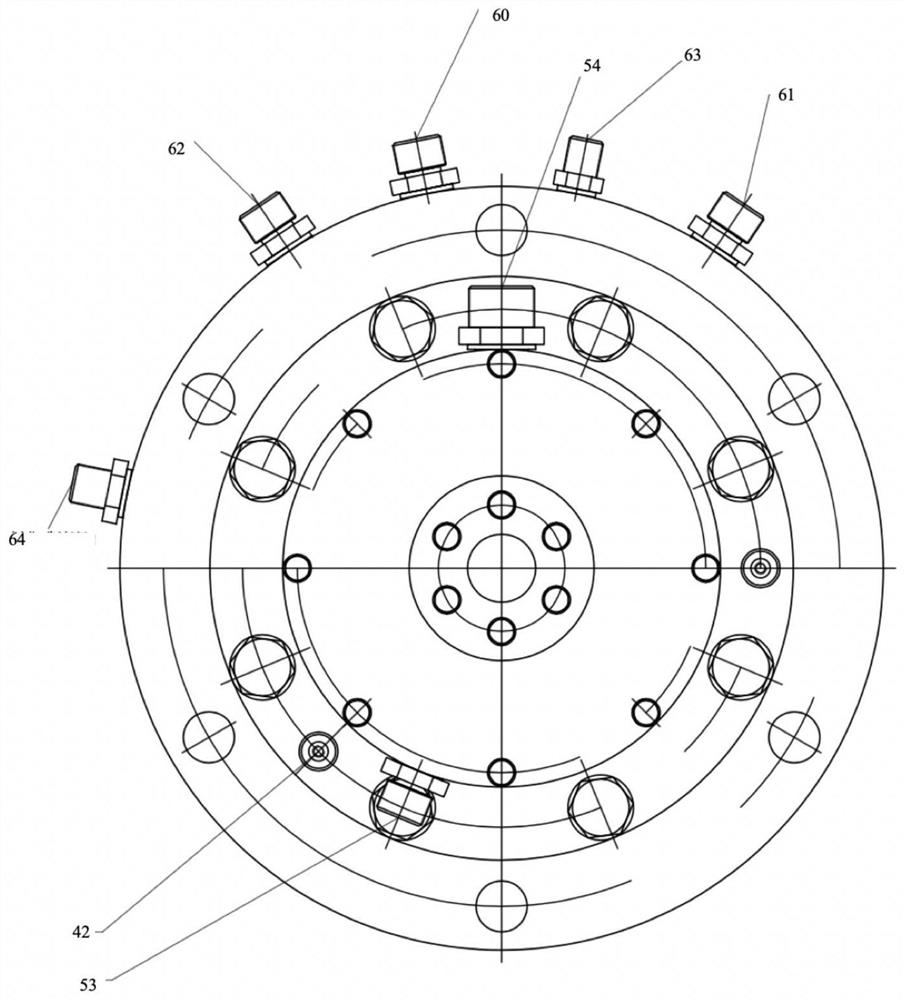

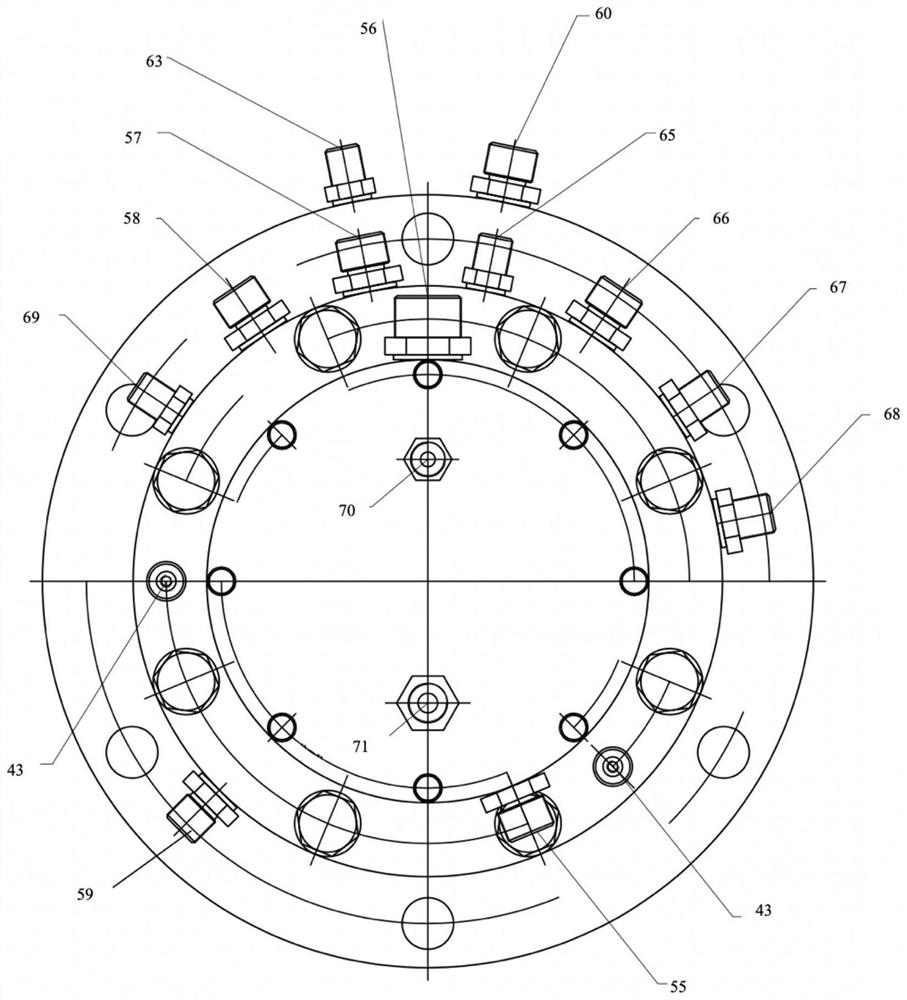

Radiography inspection stand of nuclear power cast steel members

ActiveCN102507615BCompact structureHolds castings securelyMaterial analysis by transmitting radiationIridiumCobalt-60

The invention relates to the field of radiological inspection of nuclear power cast steel members and discloses a multi-station inspection stand designed aiming at radiation sources of iridium 192, cobalt 60, thulium 170 and the like. The inspection table uses the radiation sources as the center and performs radiography inspection on a plurality of cast steel members, each cast steel member can move forwards and backwards in radial mode relative to the center of the radiation sources and can rotate surrounding axial leads of the cast steel members, thereby facilitating photo distribution. The radiography inspection stand has the advantages of improving utilization rate of the radiation sources, reducing opening times of the radiation sources and radiation of gamma rays, reducing working intensity of operators, greatly improving working efficiency, stabilizing shooting quality, and ensuring a radiographic test (RT) process to be more convenient and reliable.

Owner:江苏万恒铸业有限公司

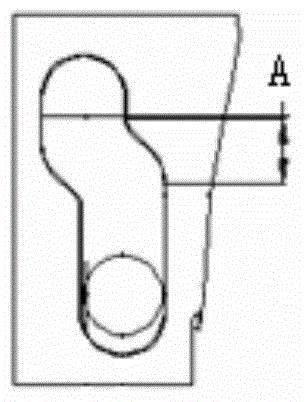

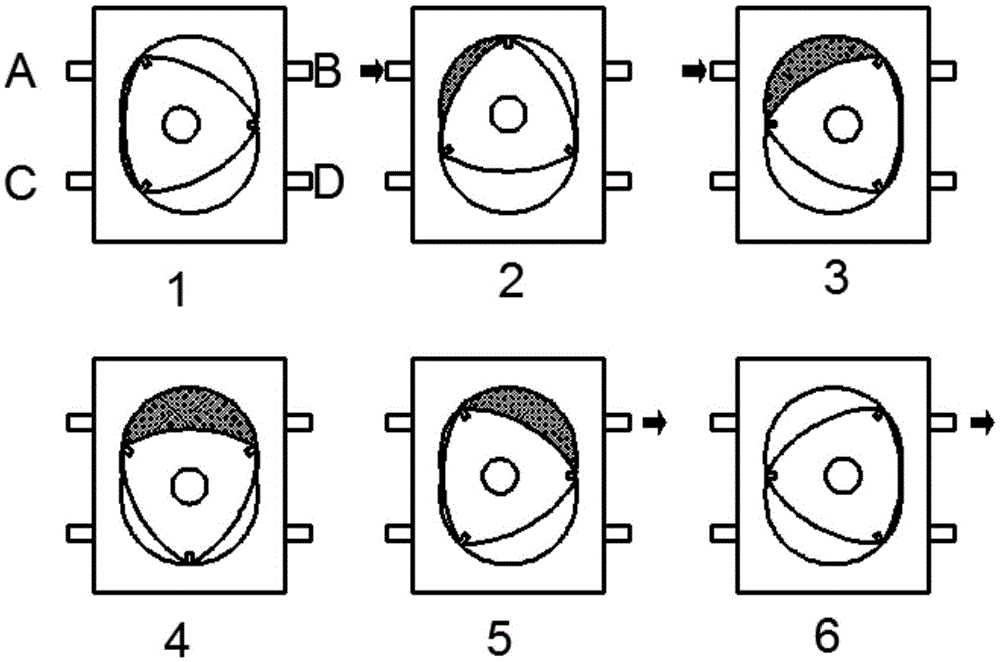

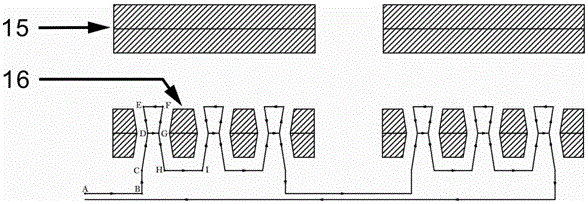

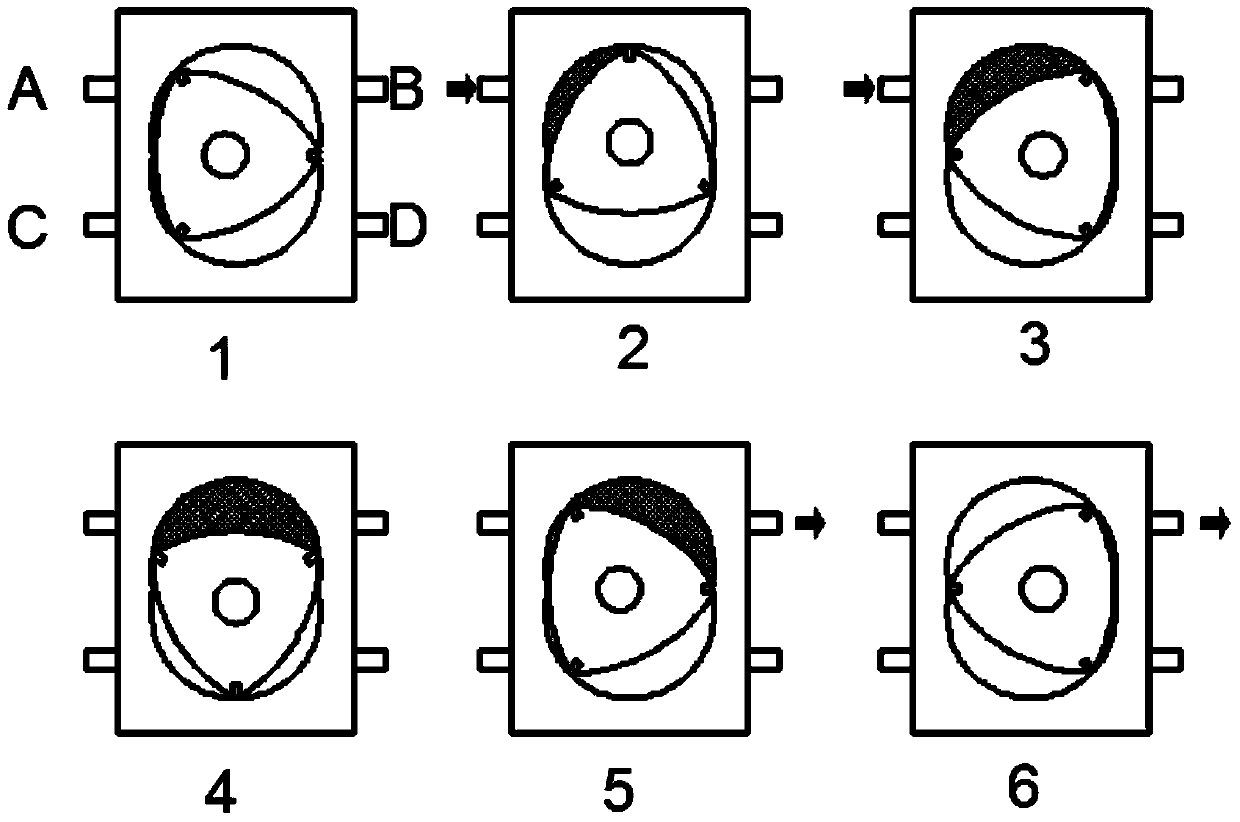

Novel plank tenon processing method and related special equipment

InactiveCN105773745ALateral movement achievedPrevent fallingDovetailed workEngineeringMechanical engineering

The invention relates to a novel plank tenon processing method and related special equipment. The method mainly includes the step that a track is cut by a cutter and is characterized in that in a first embodiment, the cutter moves from a starting point A to a cutting point B along a plank tenon, moves from the cutting point B to a cutting point C, moves from the cutting point C to a cutting point D, moves from the cutting point D to a cutting point G, moves from the cutting point G to a cutting point F, moves from the cutting point F to a cutting point E, moves from the cutting point E to the cutting point D, moves from the cutting point D to the cutting point G, moves from the cutting point G to a cutting point H and moves from the cutting point H to a cutting point I; in a second embodiment, the cutter moves from a starting point A to a cutting point B along a plank tenon, moves from the cutting point B to a cutting point C, moves from the cutting point C to a cutting point D, moves from the cutting point D to a cutting point E, moves from the cutting point E to a cutting point F, moves from the cutting point F to a cutting point G, moves from the cutting point G to a cutting point H and moves from the cutting point H to a cutting point I. The method has the advantage that efficiency is doubled, and the damage rate of raw materials is greatly reduced; plank cracking and tearing are reduced by 75%, and cutting precision is extremely high; the problem that a wide plank male tenon cannot be milled and repaired at a time when not centered; the method is environmentally friendly, and repair and maintenance cost of the equipment is reduced.

Owner:颜学丁

A double-cylinder eccentric rotary pump

ActiveCN106014974BHigh liftEasy maintenanceRotary piston pumpsRotary/oscillating piston combinationsRotary pumpCylinder block

The invention discloses a double-cylinder eccentric rotary pump. The double-cylinder eccentric rotary pump comprises a first cylinder body and a second cylinder body. The first cylinder body and the second cylinder body are each internally provided with a cavity. The outer end surface of the first cylinder body and the outer end surface of the second cylinder body are each provided with inlets and outlets. The cavity of the first cylinder body and the cavity of the second cylinder body are internally provided with a first rotor and a second rotor correspondingly. Working cavities are formed between the side surface of the first rotor and the cavity of the first cylinder body as well as between the side surface of the second rotor and the cavity of the second cylinder body correspondingly. The first rotor and the second rotor are installed on a first eccentric part and a second eccentric part of the same crankshaft in a sleeving mode correspondingly so that the working cavities can be increased or decreased and the inlets can communicate with the outlets. The first rotor is in clearance fit with the crankshaft, and the second rotor is in clearance fit with the crankshaft. Fixed gears are fixed to the first cylinder body and the second cylinder body. Teeth or gear rings matched with the fixed gears are arranged in the middle of the first rotor and the middle of the second rotor. The double-cylinder eccentric rotary pump is high in efficiency, user-friendly, convenient to transport, easy to maintain and capable of achieving real-time monitoring and stepless speed adjusting.

Owner:SHANDONG UNIV

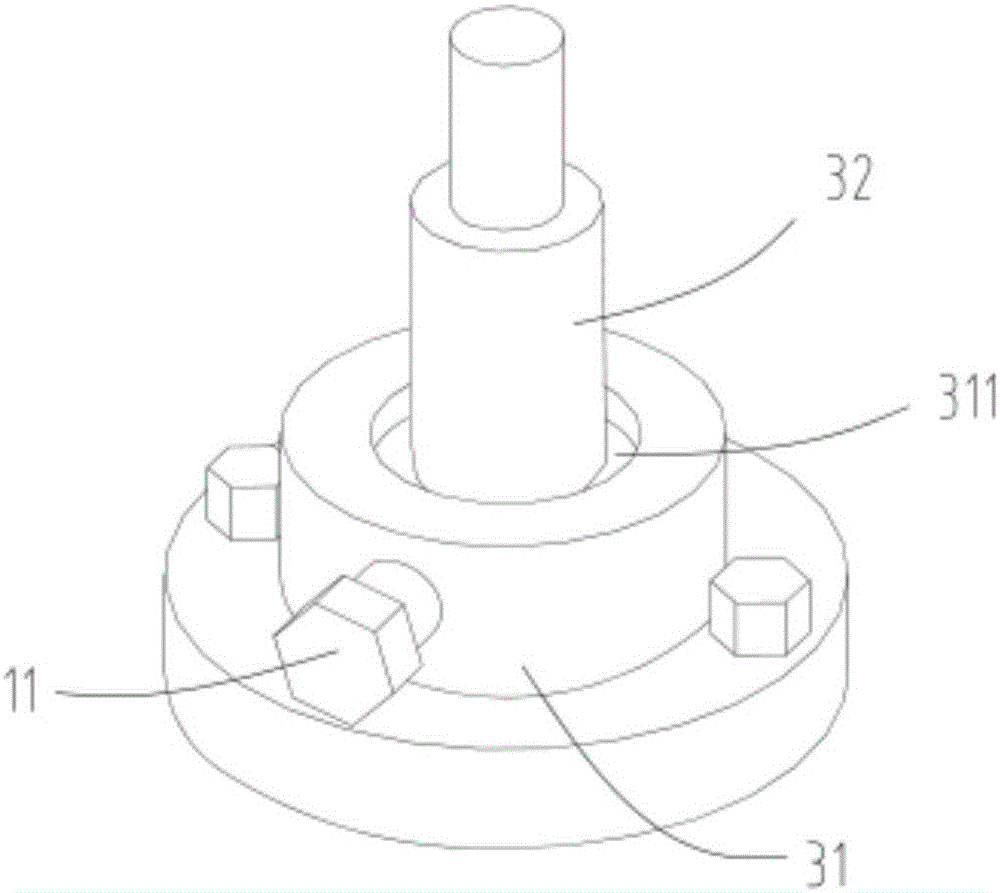

Network wire outgoing line sleeve

InactiveCN107732551AEasy to assemble and disassembleReduce labor costsCouplings bases/casesEngineeringFlange

The invention discloses a network wire outgoing line sleeve comprising a cap, a body, a body sealing ring, a flange, a network wire support and a network wire; the cap is arranged on one end of the body, the flange is arranged on the other end of the body, and the body sealing ring is arranged therebetween for sealing; the network wire support penetrates the flange and is connected with the otherend of the body; the network wire is arranged in the network wire support. The joint and network wire can be more conveniently mounted / dismounted, thus saving time and cost; two network wires can be fixed in the same time, thus doubling the efficiency; the network wire outgoing line sleeve is simple in structure, stable in performance, and long in service life.

Owner:SHANGHAI FOUND AUTOMATIC EQUIP CO LTD

A low-temperature high-speed floating ring sealing test device for rocket engines

The invention provides a low-temperature and high-speed floating ring sealing test device for a rocket engine, which includes a casing, which includes a casing I, a casing II and a casing III; a stepped main shaft arranged inside the casing; The front floating ring seal assembly and the rear floating ring seal assembly; the front floating ring seal assembly and the rear floating ring seal assembly form a test chamber in the housing II. The low-temperature and high-speed floating ring sealing test device for a rocket engine according to the present invention has strong functionality, good compatibility, good performance at low temperature and high speed, and can carry out various low-temperature sealing tests of floating rings, which can verify the integrity of the floating ring assembly. The sealing performance can also be used to assess the rationality of the floating ring structure.

Owner:LANDSPACE TECH HUZHOU CO LTD

Efficient and simple material dividing mechanism

PendingCN107187861AAchieving operational stabilityEffective distributionConveyor partsEngineeringAssembly line

The invention discloses an efficient and simple material dividing mechanism. An assembly line A and an assembly line B are parallelly arranged on the two sides of the tail end of a main assembly line; a horizontal sliding component crosses the two sides of the assembly line A and the assembly line B and is arranged over the tail end of the main assembly line; a translation air cylinder and a linear track are arranged on the horizontal sliding component in the direction perpendicular to the main assembly line; vertical sliding assemblies are slidably arranged on a mounting plate through an up-down air cylinder; the mounting plate is movably mounted on the linear track through the translation air cylinder; the vertical sliding assemblies are arranged into two material clamping mechanisms composed of clamping claws A and clamping claws B; the up-down air cylinder drives the vertical sliding assemblies to move up and down along the mounting plate by controlling the material clamping mechanisms; and the translation air cylinder drives the material clamping mechanisms to move leftwards and rightwards along the linear track by controlling the mounting plate. Each time of up-down / translational movement can be fully utilized for achieving the purpose of efficient material dividing, work reliability is high, and meanwhile the intact product appearance can be guaranteed.

Owner:SHAN DONG DONG E E JIAO

Novel automatic sawing machine

InactiveCN103934503ANon-stop cuttingDouble the efficiencyMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

The invention discloses a novel automatic sawing machine. The novel automatic sawing machine comprises sawing machine bodies, a base, saw blades, a cutting platform, a feeding and discharging platform and a conveyor. The two opposite sawing machine bodies are arranged at the top of the base. The two sawing machines are provided with the saw blades respectively. The cutting platform is arranged between the two sawing machine bodies. The feeding and discharging platform is arranged on one side of the cutting platform. The conveyor is arranged on one side of the feeding and discharging platform, so that continuous cutting is achieved, the efficiency is doubled, feeding is achieved at a time, the lateral direction adjustment does not need to be performed, the device is concise and reliable, and the cutting speed reaches 2.6 workpieces or more per minute.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

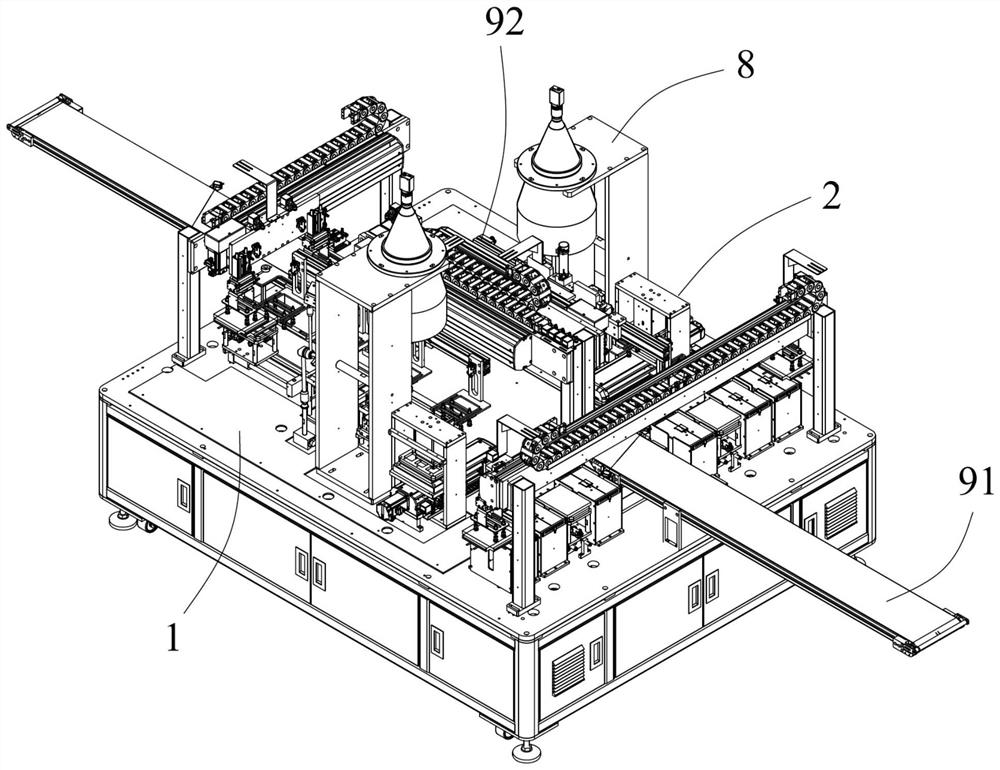

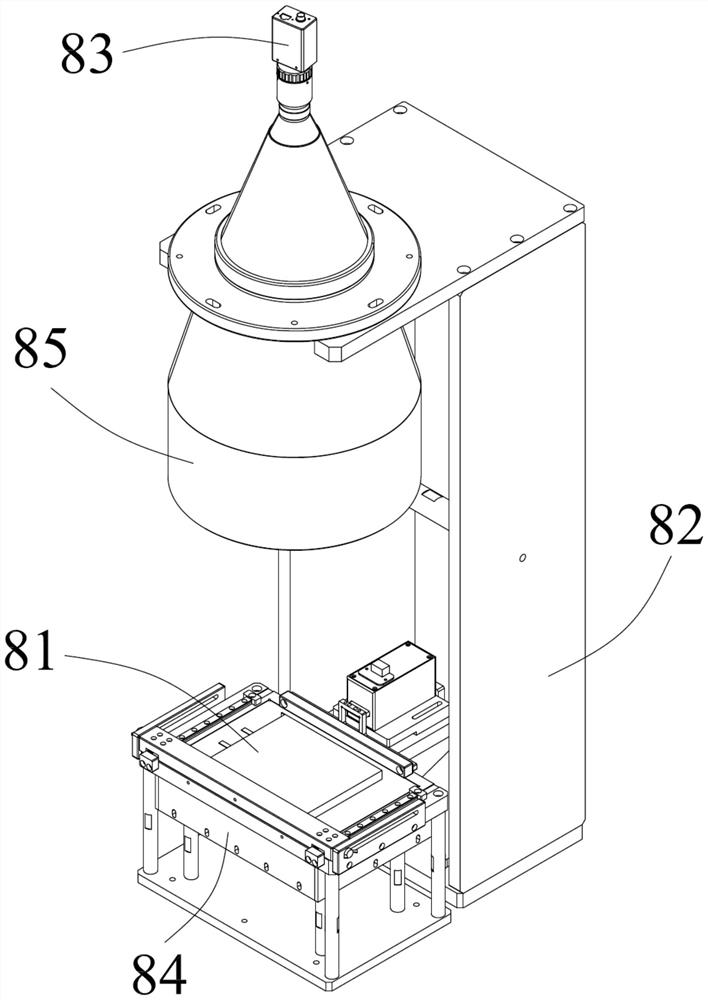

Soft package battery dual-channel size detection method and device

PendingCN114413786AAvoid excessive distortionDouble the efficiencySecondary cells testingUsing optical meansVisual inspectionTelecentric lens

The invention relates to the field of battery detection, in particular to a soft package battery dual-channel size detection method and a soft package battery dual-channel size detection device. The method comprises the following steps: S1, a feeding module conveys a to-be-detected soft package battery product generated in a previous process to a detection platform, and a clamping module grabs the to-be-detected soft package battery product and conveys the to-be-detected soft package battery product to a visual detection station or a pressure detection station; s2, after the product is conveyed to a pressure detection station, the product is placed on a constant force distance measurement mechanism, downward pressure is applied to the product, and the thickness distance of the product is measured through the value of the pressure borne by the product; and S3, after the product is conveyed to the visual inspection station, the product is placed on a visual measurement mechanism, and an image of the product is collected to measure the outer contour size of the product. The constant force distance measuring mechanism outputs constant force to control the deformation degree of the soft package product, a constant force difference mode is used in a thickness measuring mode, and it is guaranteed that the pressure is controllable. A visual detection mechanism with a large-view double-telecentric lens is adopted for outer contour dimension measurement, overlarge distortion of images is avoided as much as possible, and measurement precision and efficiency are guaranteed.

Owner:深圳佳视德智能科技有限公司

Hole drilling method of circuit board

InactiveCN103659898ALess investmentDouble the efficiencyMetal working apparatusHole drilling methodPetroleum engineering

The invention provides a hole drilling method of a circuit board to increase efficiency. The technical scheme is that a drilling platform is arranged vertically, drill bits are arranged on two sides of the drilling platform in a mirror symmetrical mode, and the two sides of the drilling platform can perform symmetrical and synchronous hole drilling. Therefore, efficiency can be increased by one time, and investment on devices and sites can be saved.

Owner:王锐

One-stroke intermittent power supply motor

InactiveCN107968519ASave electricityDouble the efficiencyDynamo-electric gearsMechanical energy handlingDc currentMagnetic poles

The invention discloses a one-stroke intermittent power supply motor, wherein the magnetic poles on both ends of electromagnets are simultaneously reciprocatingly stressed in forward direction. The motor comprises a frame, a crankshaft, a flywheel, at least one group of magnetic driving unit and at least one group of corresponding control unit, wherein the crankshaft, the flywheel, the magnetic driving unit and the corresponding control unit are arranged on the frame. The magnetic driving unit comprises a crank throw arranged on the crankshaft, a connecting rod, a telescopic shaft, two slides,N+ electromagnets (moving magnets) and N++1 permanent magnets (fixed magnets), wherein N+ is a positive integer. N++1 permanent magnets are homopolar, are opposite to each other in sequence, and arealternately arranged with N+ electromagnets. The control unit comprises a current rotating connector and a current intermittent commutator. The on / off strokes of two commutator segments and brushes ofthe current intermittent commutator respectively account for 1 / 4 of the circumference, so that the alternating of direct current direction is twice per cycle, and the electromagnets are powered on inthe start 1 / 2 stroke and are powered off in the other 1 / 2 stroke. The magnetic poles on both ends of the electromagnets and an iron core with a power-off end are forced to complete one stroke in a relay, and complete the other stroke the same. The telescopic shaft acts on the connecting rod, and the crankshaft rotates to output power.

Owner:马明祥

Numerical control edge milling machine

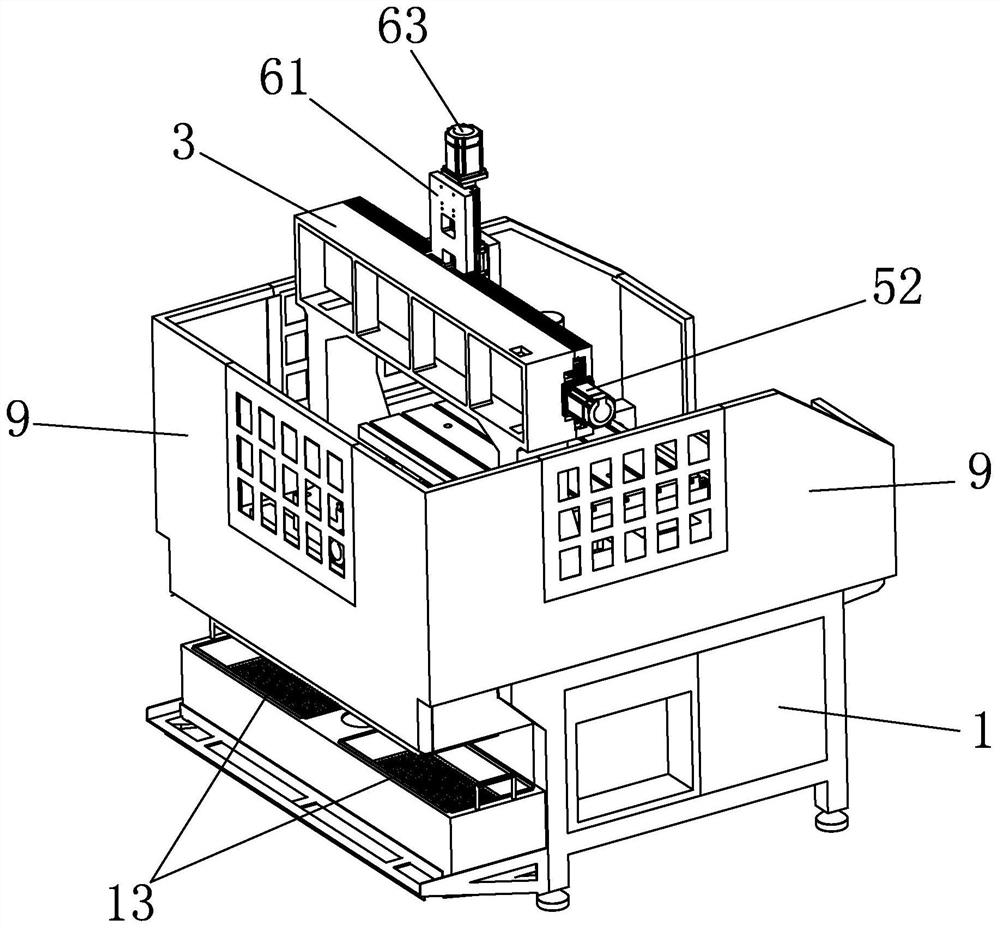

PendingCN112122668AEasy to moveDouble the efficiencyMilling equipment detailsMaintainance and safety accessoriesStructural engineeringIndustrial engineering

The invention discloses a numerical control edge milling machine which comprises a machine table provided with a numerical control device, and a workpiece fixing plate, wherein the machine table is provided with a gantry rack arranged on the workpiece fixing plate and a front-back moving device connected with the numerical control device and used for controlling the workpiece fixing plate to movefront and back, a left-right moving device connected with the numerical control device is arranged on the side face of a cross rod of the gantry rack, the moving end of the left-right moving device isconnected with an up-down moving device connected with the numerical control device, the moving end of the up-down moving device is connected with an edge milling machine head fixing base connected with the numerical control device, a plurality of edge milling machine heads are fixed to the edge milling machine head fixing base, and a plurality of edge milling machine heads are arranged on the edge milling machine head fixing base. Therefore, the plurality of workpieces can be machined simultaneously, the efficiency is doubled, and the overall structure is simple.

Owner:中山恒捷自动化设备有限公司

Efficient battery ring-lacking steel shell ring supplementing device

ActiveCN105710828AAffect qualityGuaranteed accuracyMetal-working hand toolsStructural engineeringPerpendicular direction

The invention relates to an efficient battery ring-lacking steel shell ring supplementing device which comprises a base arranged on a workbench. Ring fixing devices and telescopic rods are sequentially arranged on the base from front to back. At least two sets of the ring fixing devices and the telescopic rods are arranged. A fixing board is arranged at the upper ends of the telescopic rods and correspondingly provided with at least two steel shell clamping sleeves coaxial with the ring fixing devices in the perpendicular direction. At least two sliding sleeves matched with the telescopic rods are correspondingly arranged on the base. The sliding sleeves penetrate the base and the workbench. The telescopic rods penetrate the corresponding sliding sleeves and are connected with at least two correspondingly-arranged belts through connecting blocks at the lower ends of the telescopic rods. The other end of each of the at least two belts is fixed to a pedal. The at least two correspondingly-arranged connecting blocks are connected with the workbench through springs. By the adoption of the efficient battery ring-lacking steel shell ring supplementing device, the problems that waste materials are generated due to battery steel shell ring lack, the ring supplementing process only can be operated singly, efficiency is low, alignment is not easy, and the quality is difficult to guarantee are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A high-efficiency battery missing ring steel shell ring repair device

ActiveCN105710828BAffect qualityGuaranteed accuracyMetal-working hand toolsStructural engineeringPerpendicular direction

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A Calculation Method for Composite Blade Sectional Characteristics

ActiveCN107220458BHigh precisionDouble the efficiencyGeometric CADDesign optimisation/simulationData fileComposite blade

The invention belongs to the field of helicopter design, and particularly relates to a composite blade section property calculation method. Blade section properties are the most basic original parameters for helicopter rotor dynamic calculation. Accuracy of the blade section properties is a premise for judging helicopter rotor dynamic properties and vital to rotor dynamic design. According to the composite blade section property calculation method, data files of sections of blades are built according to blade structures, wing profile theory contour data and material data, rigidity is calculated by a modulus weighting method according to anisotropic performances of composites, and mass is calculated by a finite element concept. Accurate basic data are provided for blade dynamic analysis and design, the blade section properties can be rapidly and accurately calculated, optimal design of the blades can be rapidly finished, and rotor system dynamic design technology is broken through.

Owner:哈尔滨哈飞航空工业有限责任公司

An assembly line rotary environment-friendly automatic welding equipment

ActiveCN112025046BImprove work efficiencyReduce labor costsWelding accessoriesEngineeringAssembly line

Owner:安徽省元亨金属科技有限公司

An adjustable intelligent punching and unloading mechanism

ActiveCN106001305BHigh precisionQuick RetrievalMetal-working feeding devicesPositioning devicesPunch pressManipulator

The invention provides an adjustable intelligent charging and discharging mechanism of a punch press. The adjustable intelligent charging and discharging mechanism is mounted at a charging position of a machine tool, and comprises a charging mechanism, a feeding mechanism, an X-axis left-and-right movement liner die set, and a Z-axis up-and-down movement liner die set, wherein the charging mechanism is mounted on one side of the machine tool; the feeding mechanism is erected on the charging mechanism, and the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set are mounted on the feeding mechanism. The adjustable intelligent charging and discharging mechanism of the punch press comprises the charging mechanism, the feeding mechanism, the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set, and through the X-axis left-and-right two-dimensional movement liner die set, and the Z-axis up-and-down two-dimensional movement liner die set, rapid and intelligent material taking can be realized. The adjustable intelligent charging and discharging mechanism is simple in structure and high in operating stability, the precision of a manipulator is high, and the consistency of products is notably improved; besides, normal time for charging and discharging needs to be four hours or above, and the normal processing time of the adjustable intelligent charging and discharging mechanism disclosed by the invention is within 2 hours, so that the efficiency is doubled.

Owner:江苏迈步智能装备科技有限公司

Double-thread winding high-voltage wire package production line

ActiveCN112978347BDouble the efficiencyAutomatic feedingFilament handlingConveyor partsHigh tension lineWire wrap

The invention relates to a double-thread winding high-voltage wire package production line. The production line comprises a feeding device, a winding device, a loading device and a handling device; the loading device is one, the loading device is two, and the loading devices are respectively Installed on the left and right sides of the feeding device, one or more winding devices are installed in sequence between the feeding device and the loading device. The device is connected, the feeding device and the winding device and the loading device on the left side together form the left thread, and the feeding device and the winding device and the loading device on the right side together constitute the right thread. A double-thread winding high-voltage wire wrap production line is designed, with bidirectional conveying and synchronous wrapping production, which greatly improves the production effect. For this purpose, a feeding device is designed to feed in batches, and at the same time, it can meet the automatic feeding of left thread and right thread. , to achieve double the efficiency of the previous wrapping production line.

Owner:JIANGSU FEIER ELECTRICAL TECH

Full-automatic 4U lamp tube bridging apparatus and its process

InactiveCN101007701BIncrease profitActions are reasonably preciseVessels or leading-in conductors manufactureGlass reforming apparatusEngineeringElectrical and Electronics engineering

The invention discloses a full-automatic 4U tube bridge connection device and making method, which is characterized by the following: setting rotary table (2) on the working machine table(1); distributing 36 mechanic head fixtures (3) on the rotary table; distributing primary open-up arrangement (48), primary upper pipe device (41), secondary upper device (42), slice pipe location device (43), primary burning tack device (44), primary bridge connection device (45), turn-up device (46), primary bridge, secondary location device (47), secondary open-up device (49), burning tack device (50), secondary bridge connection device (51) and lower-in device (52) around the working machine table(1) and rotary table (2) sequentially .

Owner:王良才 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com