An assembly line rotary environment-friendly automatic welding equipment

An automatic welding and rotary technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of increasing air pollution in processing workshops, inaccurate verticality of welded parts, and unfavorable health of workers, so as to reduce human injury , Shorten transposition time and space, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

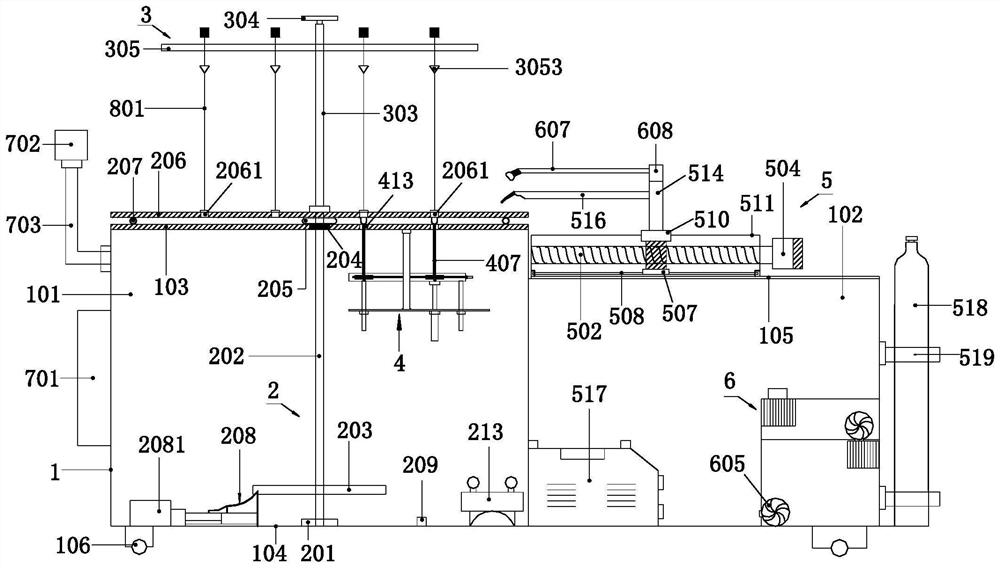

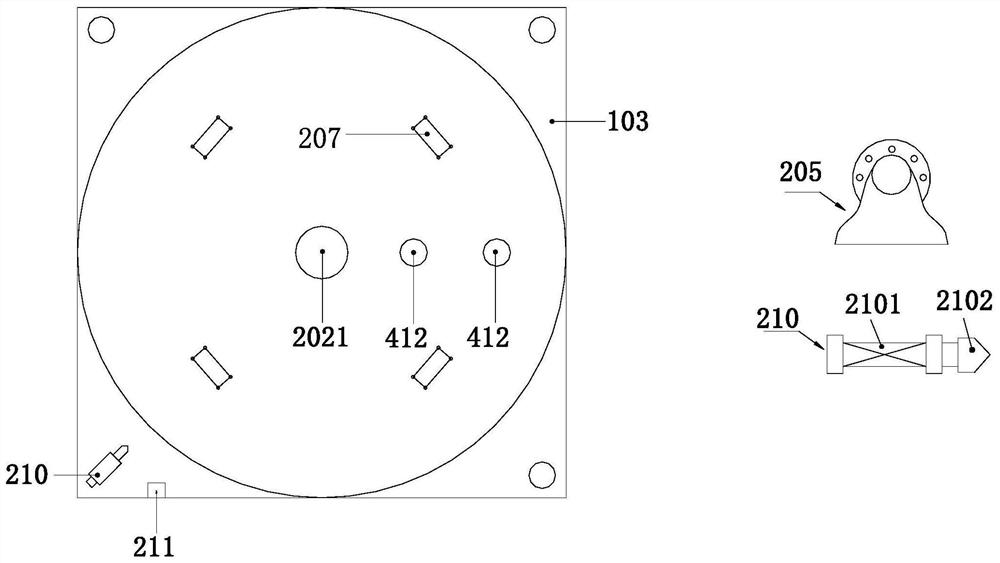

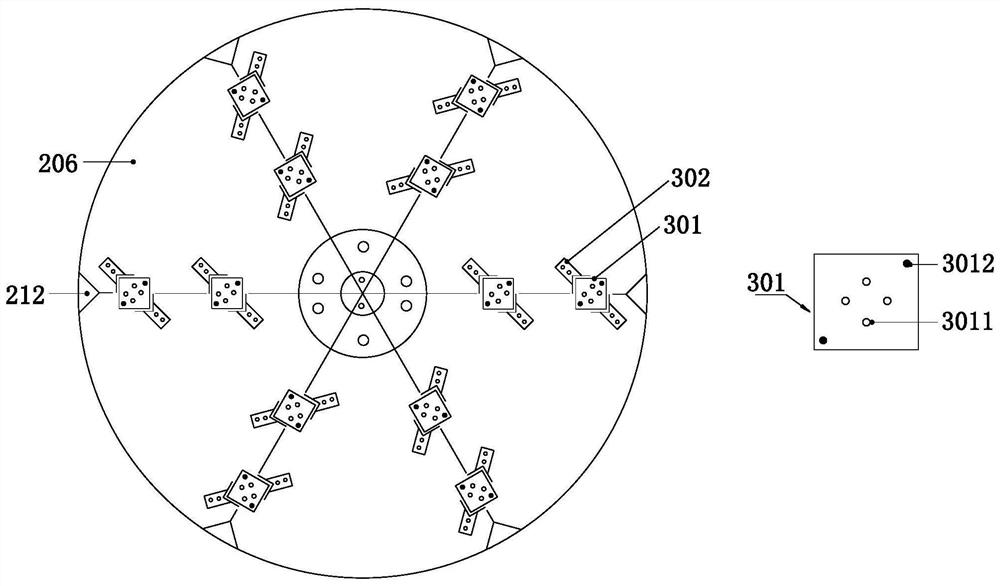

[0045] Such as figure 1 As shown, it shows a kind of assembly line rotary environment-friendly automatic welding equipment of the present invention, the welding equipment includes a frame 1, preferably, a roller 106 is respectively arranged at the four corners of the bottom of the frame 1, and the frame 1. The inner cavity is divided into a left accommodation chamber 101 and a right accommodation chamber 102. The top surface of the left accommodation chamber 101 is higher than the top surface of the right accommodation chamber 102. The top surface and the inner bottom surface of the left accommodation chamber 101 are fixedly paved with The first fixed plate 103 and the second fixed plate 104, the third fixed plate 105 is fixedly paved on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com