Underbody tapping machine

A vehicle bottom and frame technology, which is applied to metal processing machinery parts, other manufacturing equipment/tools, metal processing, etc., can solve the problems of difficult separation of finished waste residue, low processing efficiency, and large action stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

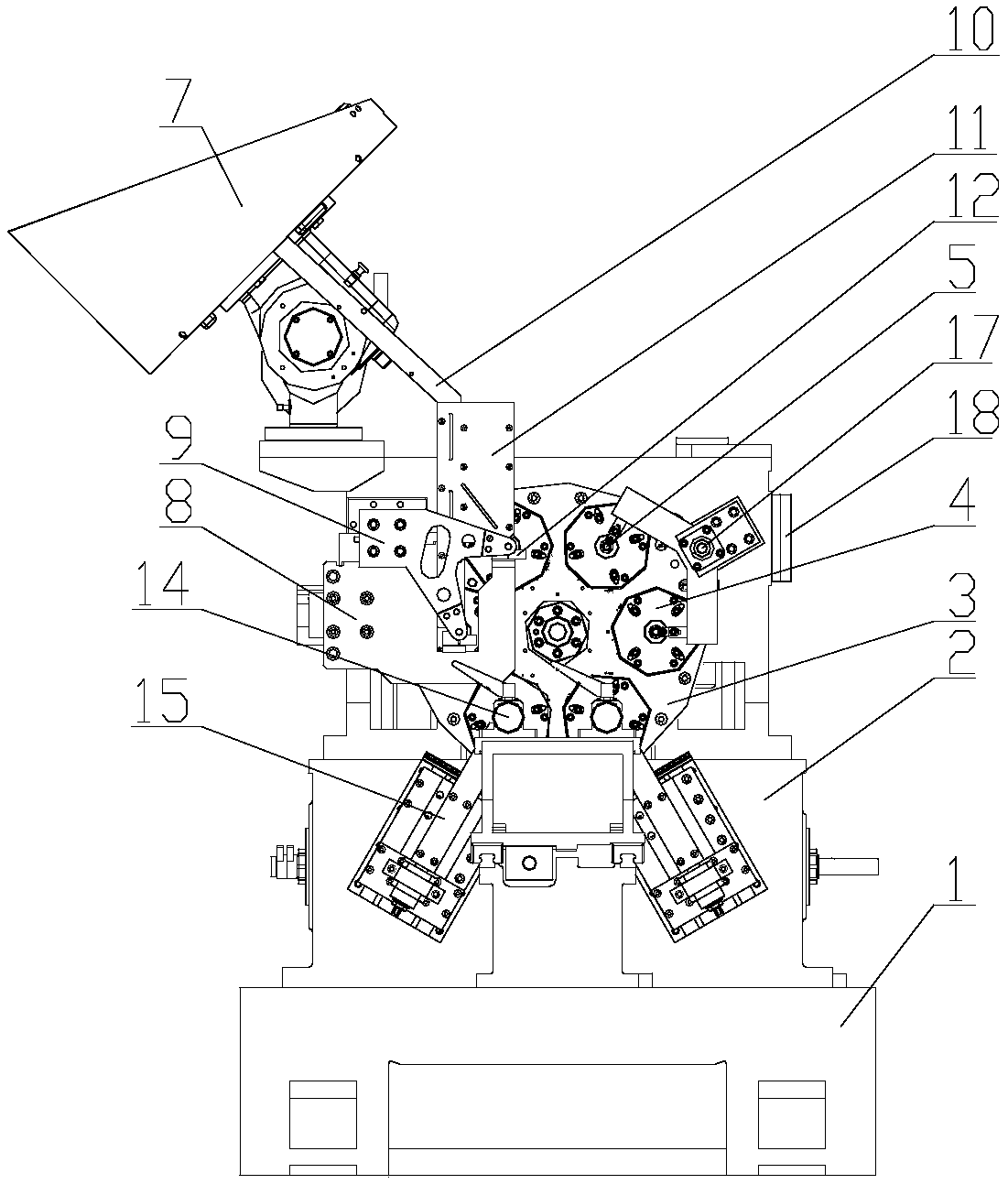

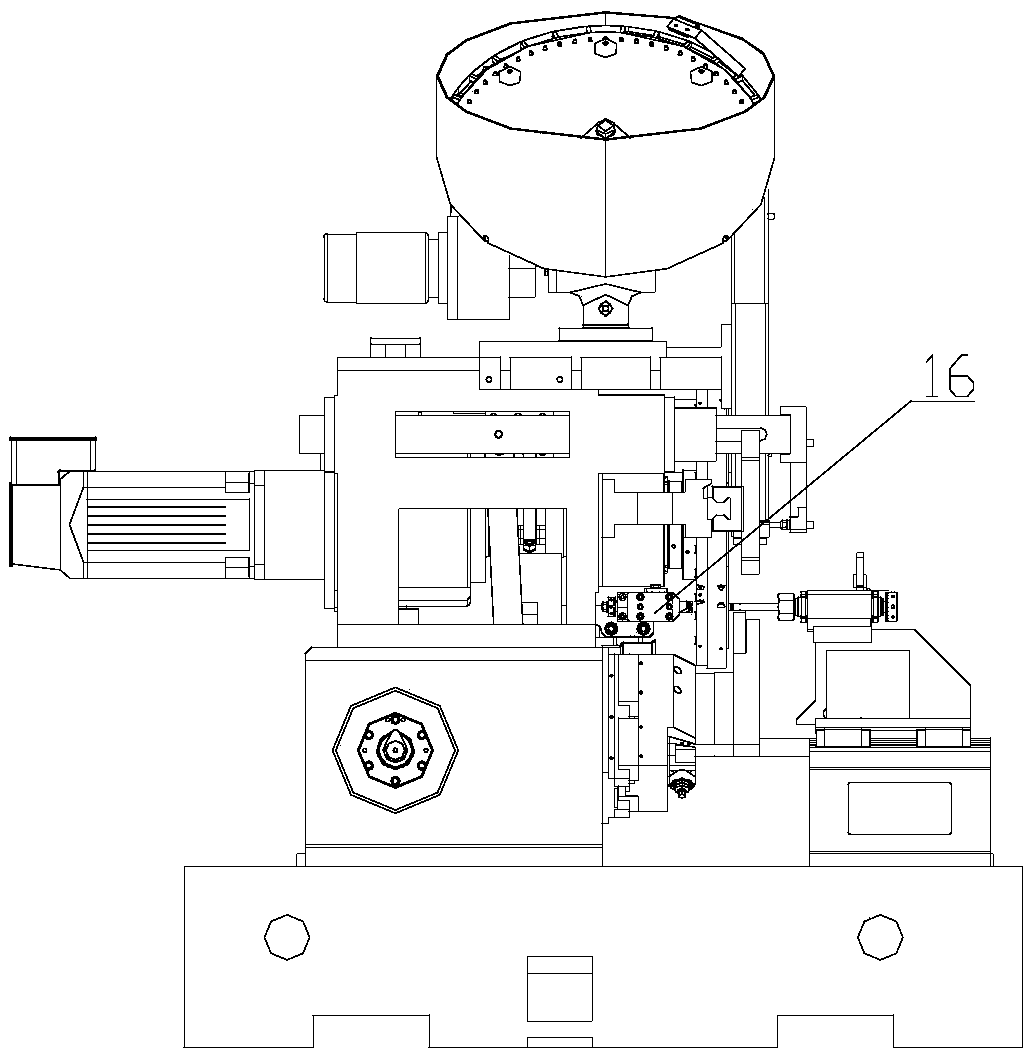

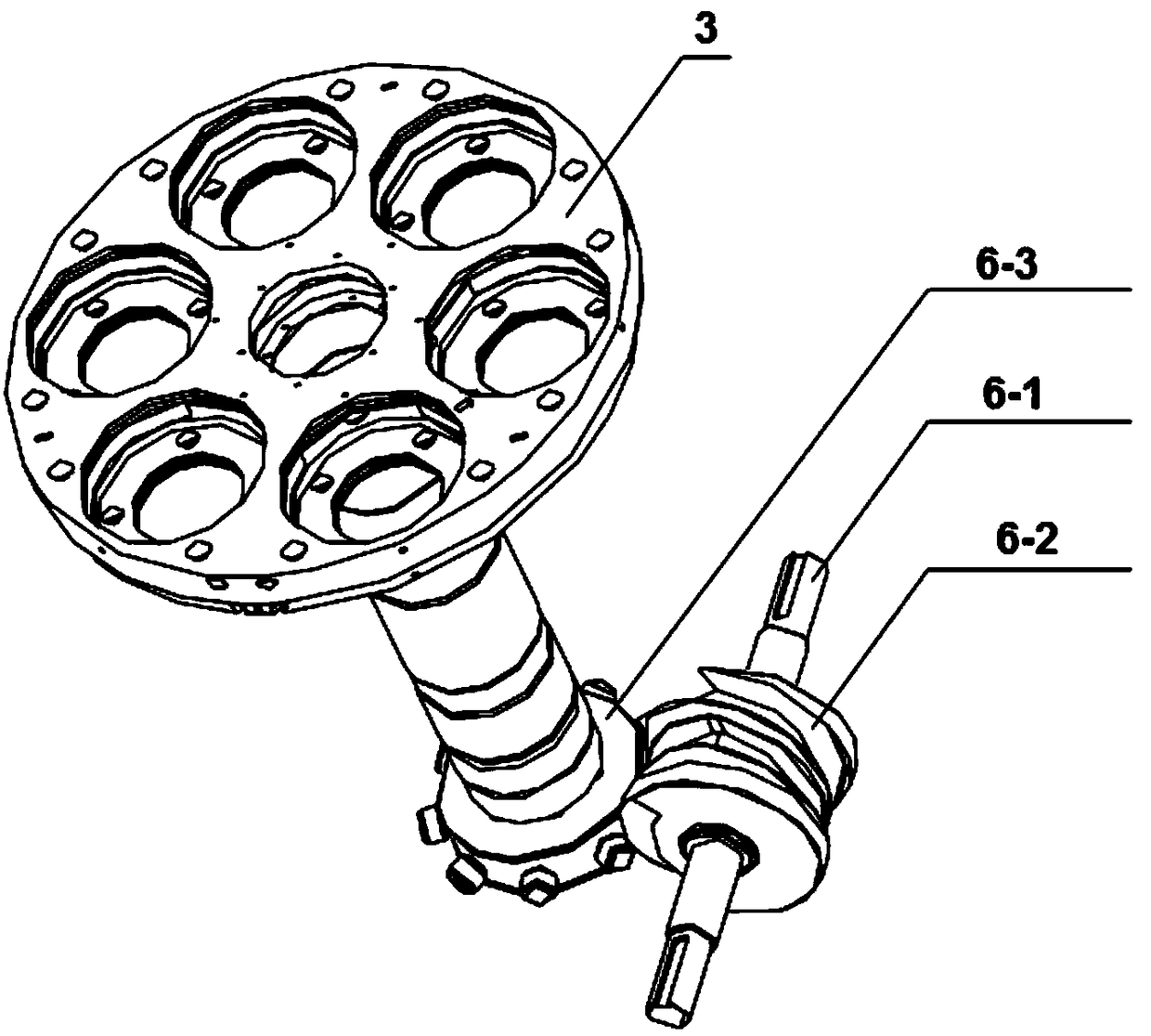

[0020] combine figure 1 and 2 Shown is a schematic structural diagram of an embodiment of the car bottom flushing machine of the present invention. A car bottom flushing machine comprises a base 1 and a bracket 2 installed on the base. A large main shaft 3 is installed on the frame 2, and the large main shaft 3 can rotate on the frame 2. As a preferred method, in this embodiment, six small spindles are evenly distributed in the circumferential direction of the end surface of the large spindle 3, and the center of each small spindle is equipped with a sleeve 5 whose diameter is compatible with the diameter of the cartridge case to be processed. Large main shaft 3 is connected with indexing mechanism 6, as image 3 As shown, the indexing mechanism 6 adopts a cam divider, and the cam divider is an automatic high-precision rotary device. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com