A double-cylinder eccentric rotary pump

A rotary pump and eccentric technology, applied in the field of slurry pump device and double-cylinder eccentric rotary water pump, can solve the problems of unsuitable conveying of suspensions containing solids, large pressure head, small flow rate, etc., to achieve convenient data recording, easy maintenance, The effect of large lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

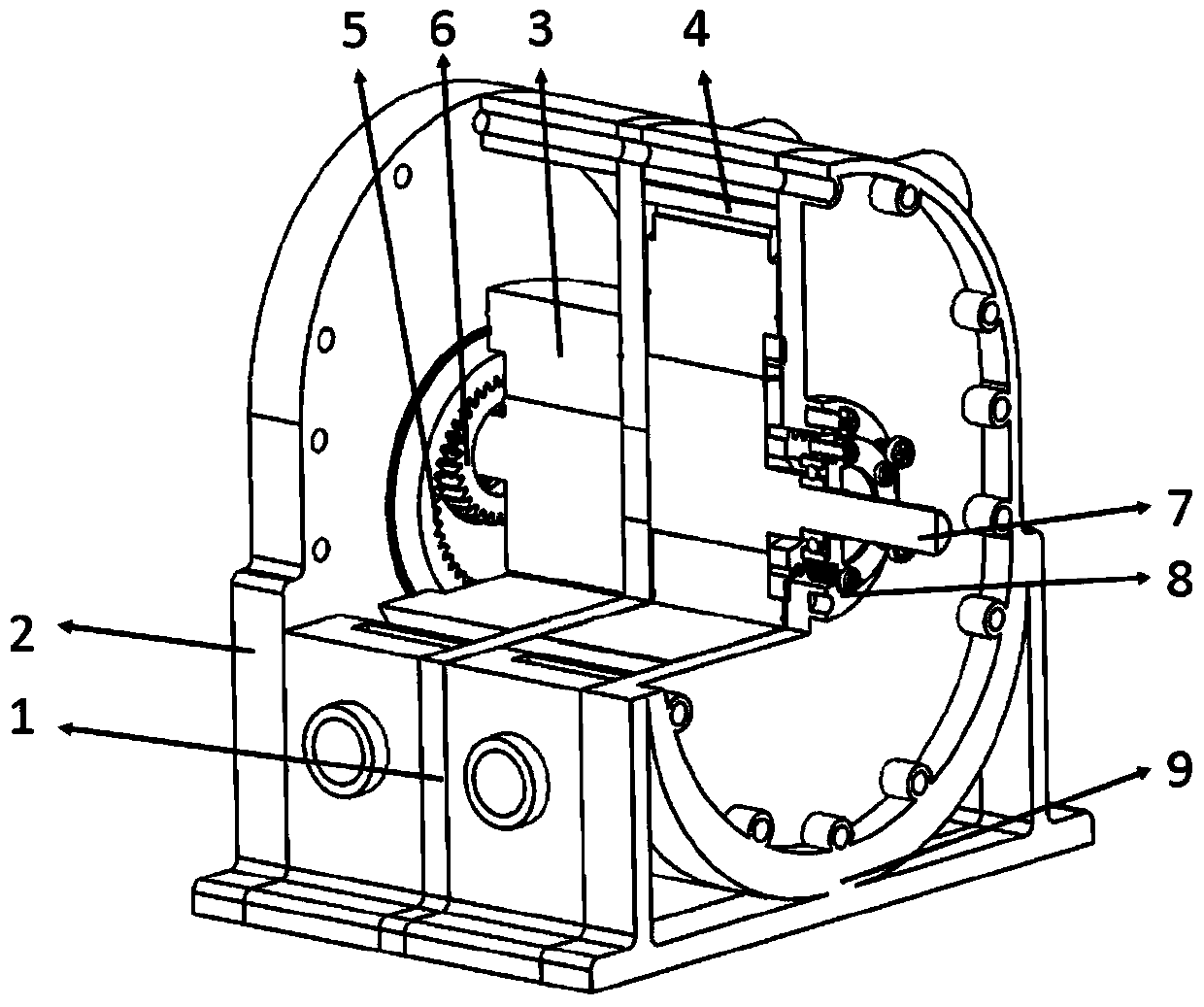

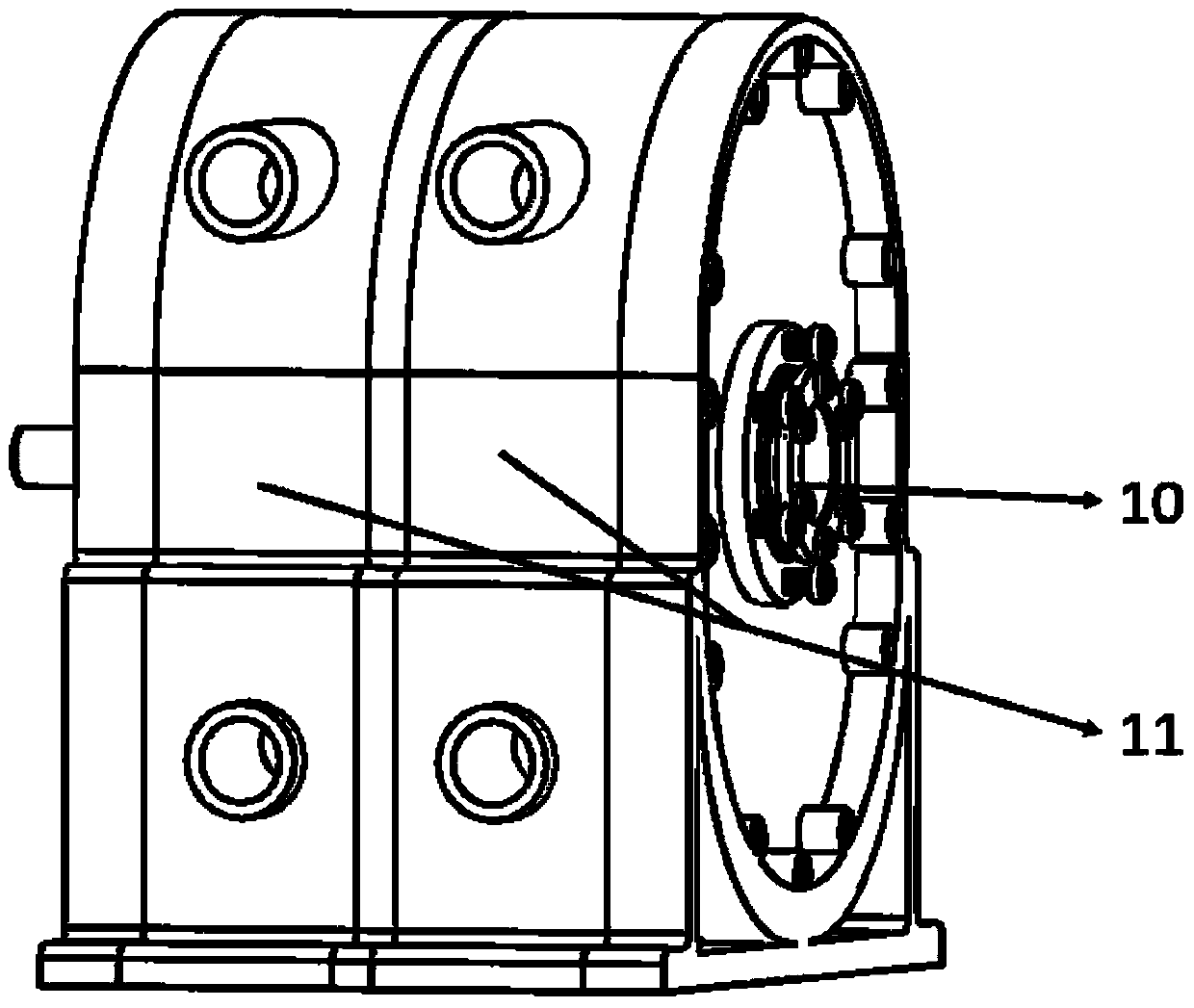

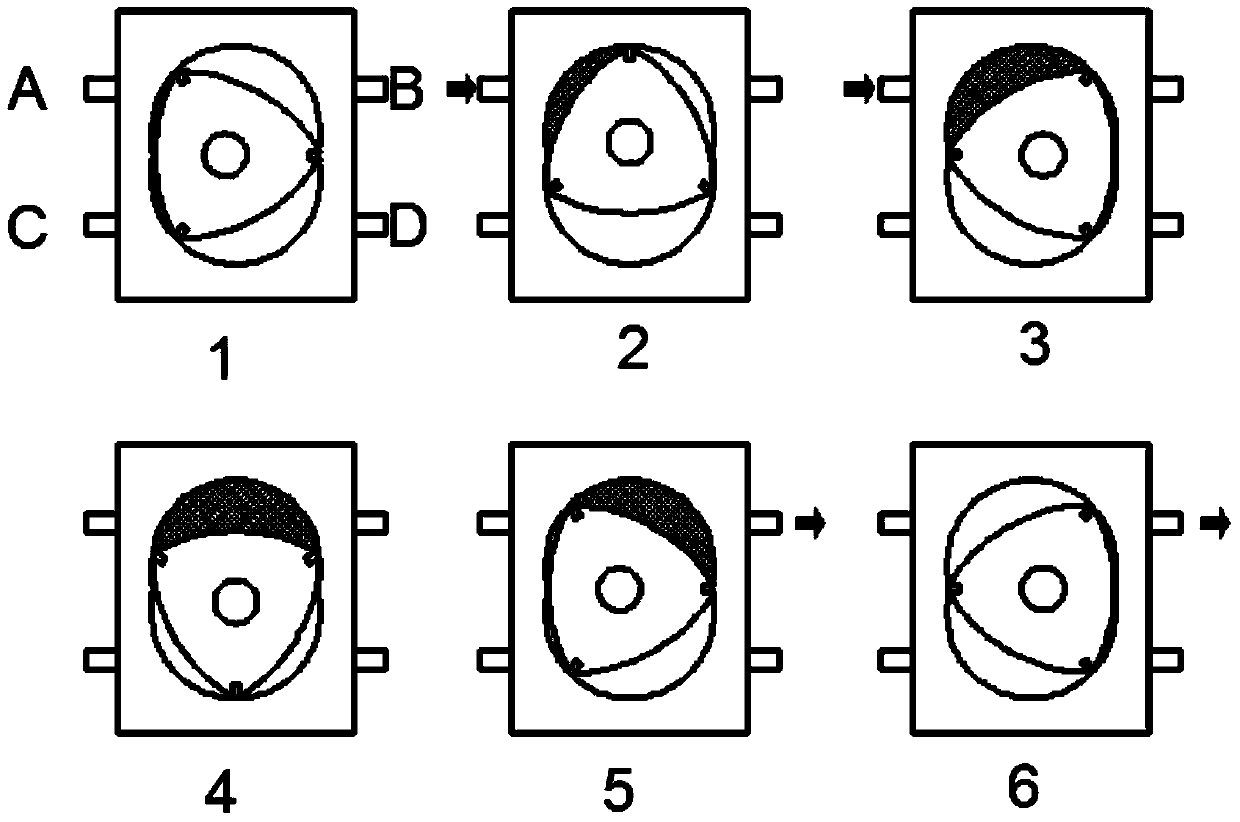

[0036] Such as Figure 1-Figure 2 As shown, the double-cylinder eccentric rotary pump consists of middle surface seal 1, rear seal 2, rotor 3, rotor sealing strip 4, internal gear 5, fixed gear 6, crankshaft 7, end cover 8, front seal 9, end cover 10, cylinder Body 11; the double-cylinder eccentric rotary pump has two working chambers, a working cylinder body 11 is clamped between the front seal 9 and the middle face seal 1, and the back seal 2 and the middle face seal 1, and the three are fixed with bolts. Cavities are provided inside the cylinders 11, and rotors 3 are respectively arranged in the cavities. The sides of the rotors 3 and the cavities respectively form working chambers, and the outer end faces of the two cylinders 11 are provided with two inlets and two outlets. , the rotors 3 of the two cylinders are set on the two eccentric parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com