Equipment and method for precise positioning drilling at wall of subway tunnel via automatic benchmark leveling

A technology for aligning benchmarks and precise positioning, applied in the field of rail transit, it can solve the problems of low precision, high labor intensity, and dangerous work, and achieve the effect of achieving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments will be further described below in conjunction with the accompanying drawings.

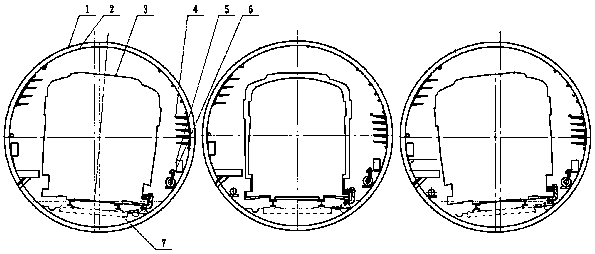

[0023] figure 1 As shown, it is the angle change between the horizontal and vertical datum of the tunnel section and the limit of the track, track bed, and running vehicles when the subway tunnel has different curvatures.

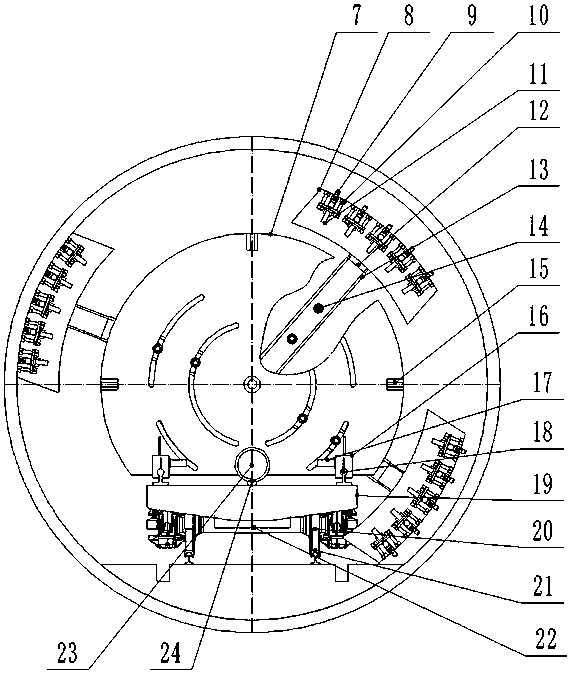

[0024] And 4 cable supports, 5 water pipe supports and 6 electrical box supports all need to carry out drilling and fixing on the tunnel wall, the positions of these holes are associated with the horizontal and vertical datums of the tunnel section, therefore, need an automatic alignment datum in A method for precisely positioning and drilling holes in a subway tunnel wall.

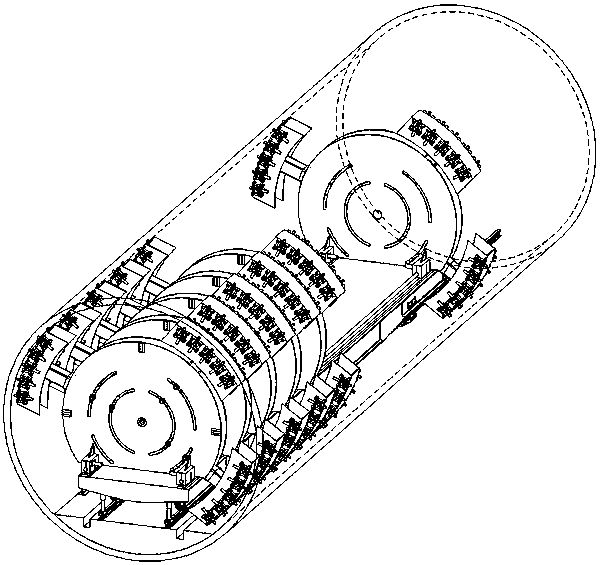

[0025] As shown in the figure, the present application provides a device and method for automatically aligning the datum and accurately positioning the borehole on the subway tunnel wall. The device structure includes a rail frame 19 with a gauge of 1435, and a brake device is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com