Drilling device with drill capable of automatically detecting and tracking center of suture needle end

An automatic detection and drilling device technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of low accuracy, high hardware cost, large measurement error, etc. , to achieve the effects of improving machining accuracy, meeting process requirements, and improving speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

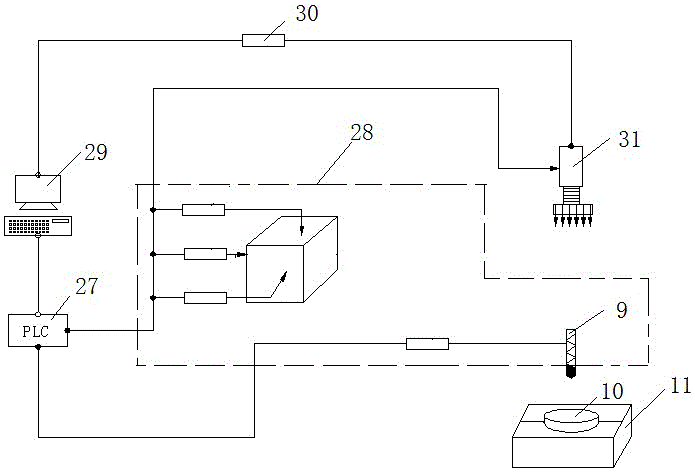

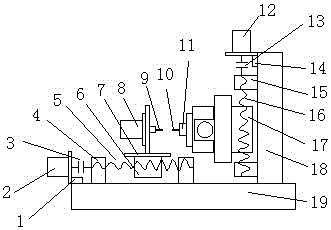

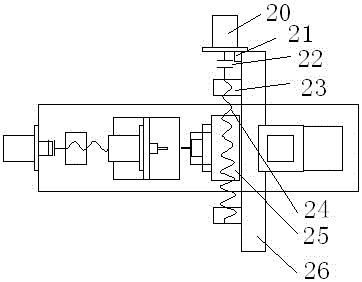

[0026] like figure 1 As shown, it includes a PLC27, a drilling mechanism 28, a computer 29, a CCD sensor 30, a camera 31 and a fixture 11; the fixture 11 clamps the suture needle to be drilled, and the camera 31 is positioned and installed on the X-axis and Y-axis of the fixture respectively , is used to photograph the suture needle tail and the drill bit being held; the camera 31 transmits the photographed picture to the computer 29 through the CCD sensor 30, and the computer 29 is equipped with an image processing program module to process the image information transmitted by the camera, The position of the center of the needle tail and the position of the drill bit are determined through algorithm analysis, and the adjustment command of the drilling mechanism 28 is issued through communication with the PLC 27 .

[0027] The cameras 31 all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com