Winding device of electromagnetic switch coil

A technology for electromagnetic switches and winding equipment, applied in electrical switches, coil manufacturing, circuits, etc., can solve problems such as inability to adjust, high operator proficiency requirements, and inability to adjust the tension of the coil, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

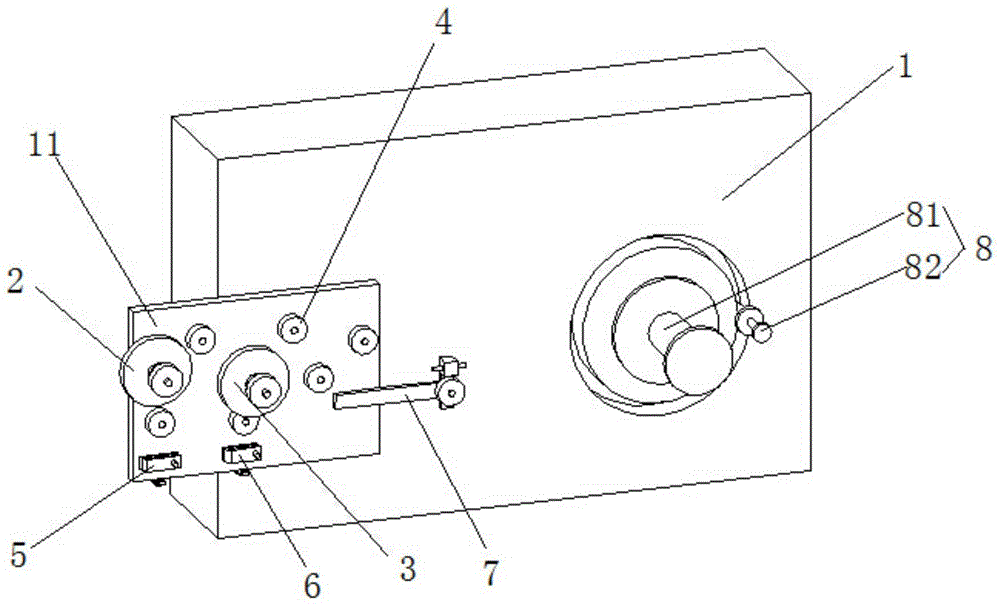

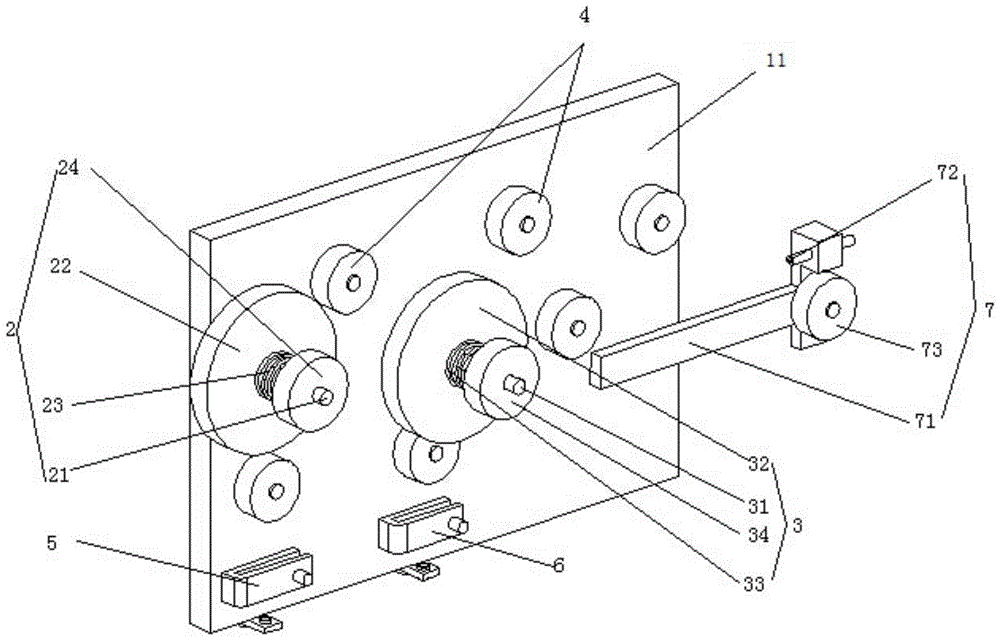

[0022] See figure 1 and figure 2 , the electromagnetic switch coil winding equipment of the present embodiment includes a frame 1; also includes a first wire routing wheel 2, a second wire routing wheel 3, a plurality of guide wheels 4, and a first upper wire slot arranged on the frame 1 5. The second upper wire slot 6, the parallel assembly 7 and the winding frame 8; the centers of the first wire routing wheel 2 and the second wire routing wheel 3 are not on the same horizontal line; the first upper wire slot 5 and the second upper wire slot 6 They are respectively arranged under the first line wheel 2 and the second line wheel 3; the parallel assembly 7 includes a parallel frame 71, a wire conduit 72 and a guide wheel 73; one end of the parallel frame 71 is fixed on the frame 1 , the other end stretches out from the frame 1; the wire tube 72 and the wire wheel 73 are arranged up and down on the end of the parallel horizontal frame 71 extending out of the frame 1; the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com