Compressor unit for a stretcher of a textile machine

A technology of drafting device and compaction unit, which is applied in spinning machines, drafting equipment, textiles and papermaking, etc., and can solve the problems of inaccurate positioning and movement of compacting components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

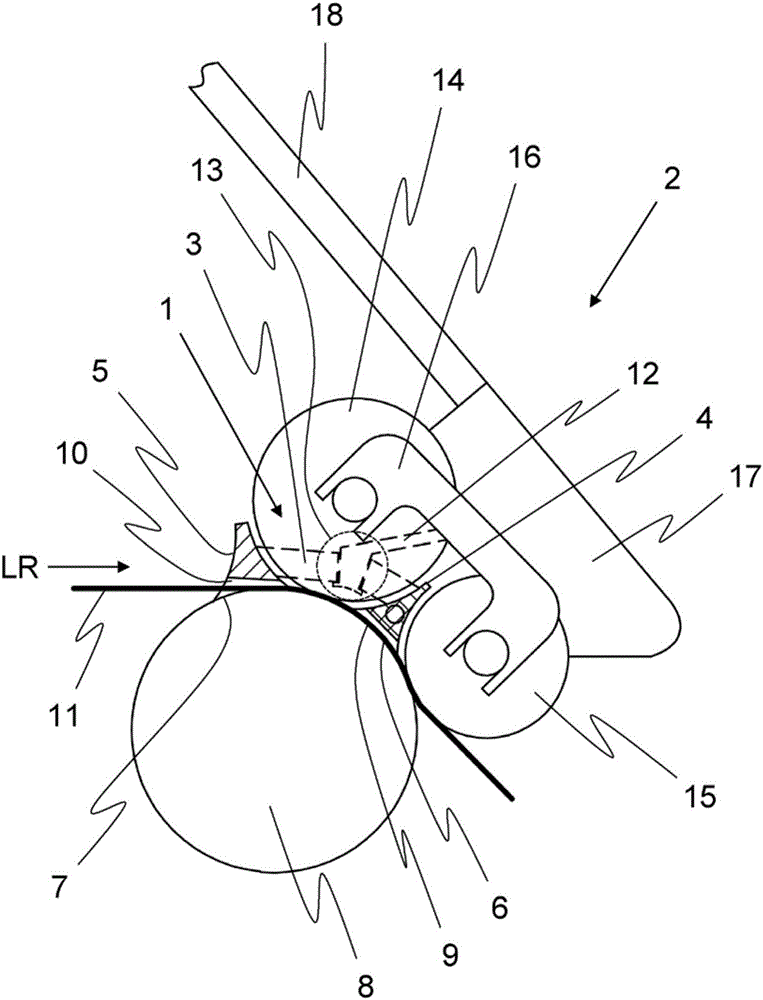

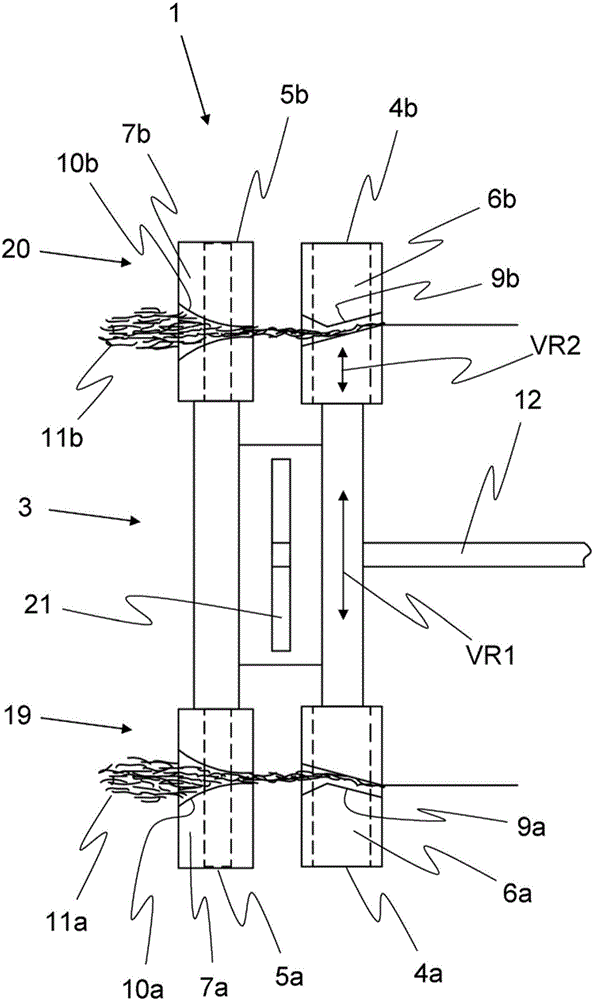

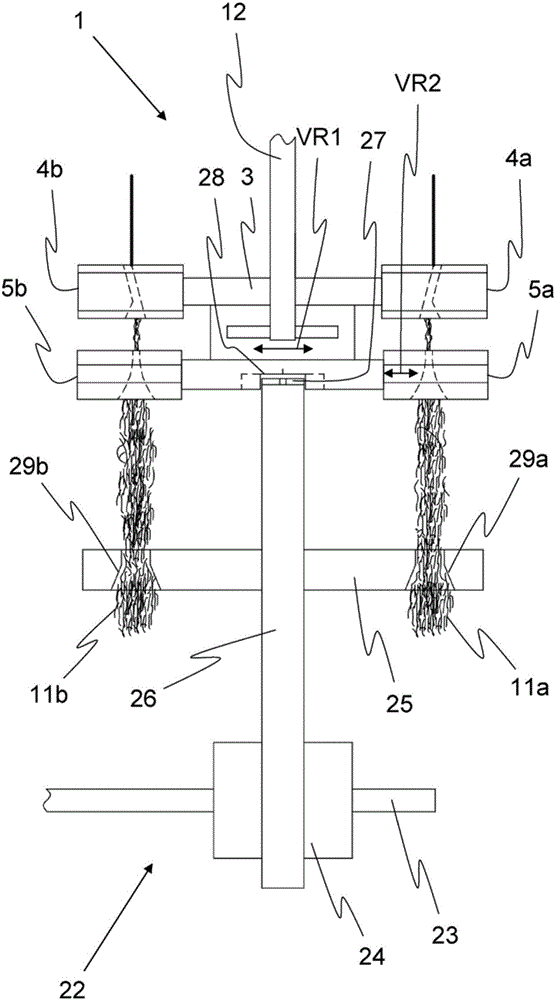

[0034] figure 1 A side sectional view of the compaction unit 1 in a part of the drafting device 2 is shown. The compacting unit comprises a holding part 3 on which a first guiding part 4 and, in this embodiment, an additionally provided second guiding part 5 are arranged. The guides 4 , 5 can be formed in one piece with the holder 3 . Furthermore, the first guide part 4 has a first contact surface 6 and the second guide part 5 has a second contact surface 7 . The two contact surfaces 6 , 7 are designed concavely. In particular, the two contact surfaces 6 , 7 are arranged to bear against the drafting roller 8 . A first compaction region 9 is arranged in and / or on the first guide part 4 and a second compaction region 10 is arranged in and / or on the second guide part 5 . Additionally or alternatively, the two compaction regions 9 , 10 can also be arranged in and / or on the respective contact surface 6 , 7 . The fiber strands 11 , which are guided in the conveying direction LR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com