Cage door for mine hoisting

A technology of cages and mines, which is applied to lifting equipment, transportation and packaging in mines, can solve the problems of potential safety hazards, increase the number of operators, and hidden dangers of tankers, and achieve the effect of reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings and embodiments.

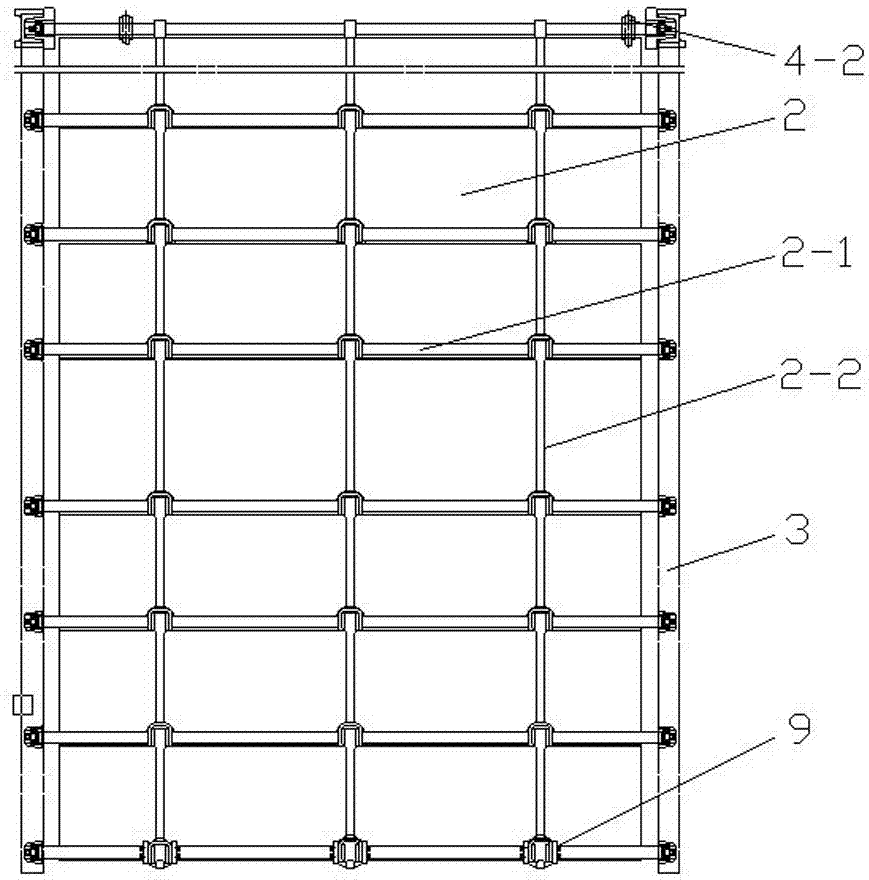

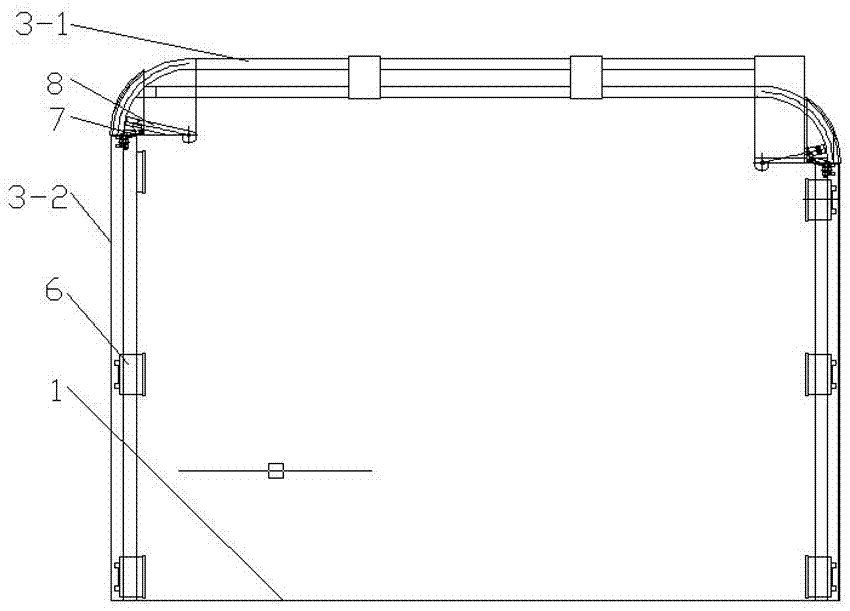

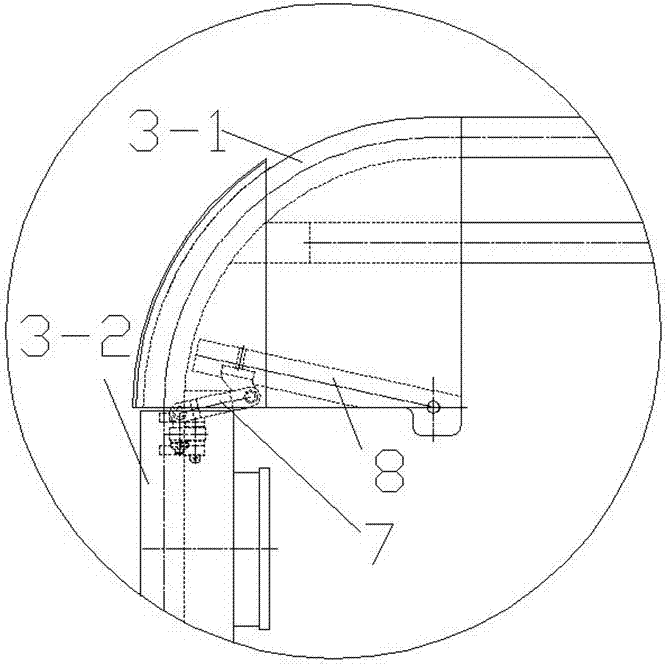

[0023] like Figure 1 to Figure 6 As shown, a cage door used for mine lifting is provided with a guide rail 3 for fixing the safety door 2 on the cage 1, and the guide rail 3 extends from the bottom of the opening side of the cage 1 to the top plane of the cage 1 so that the safety door 2 can be lifted from the cage. 1. The opening side is drawn to the top plane of the cage 1. The turning point of the guide rail 3 adopts a circular arc transition. The top plane of the cage 1 is provided with a transmission device 4 for driving the action of the safety door 2. The transmission device 4 is powered by the power device 5. The cage 1 has two front and rear openings, each opening is provided with a safety door 2, and the guide rails 3 on the front and rear opening sides of the cage 1 are arranged in a staggered manner at the top plane of the cage 1.

[0024] The sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com