Pneumatic-thermal collaborative optimization method for scallop hole air film cooling structure of turbine blade

A technology of film cooling and turbine blades, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high cost and time-consuming, etc., achieve less resource consumption, strong global approximation ability, and reduce all time-consuming and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further explained below in conjunction with the accompanying drawings.

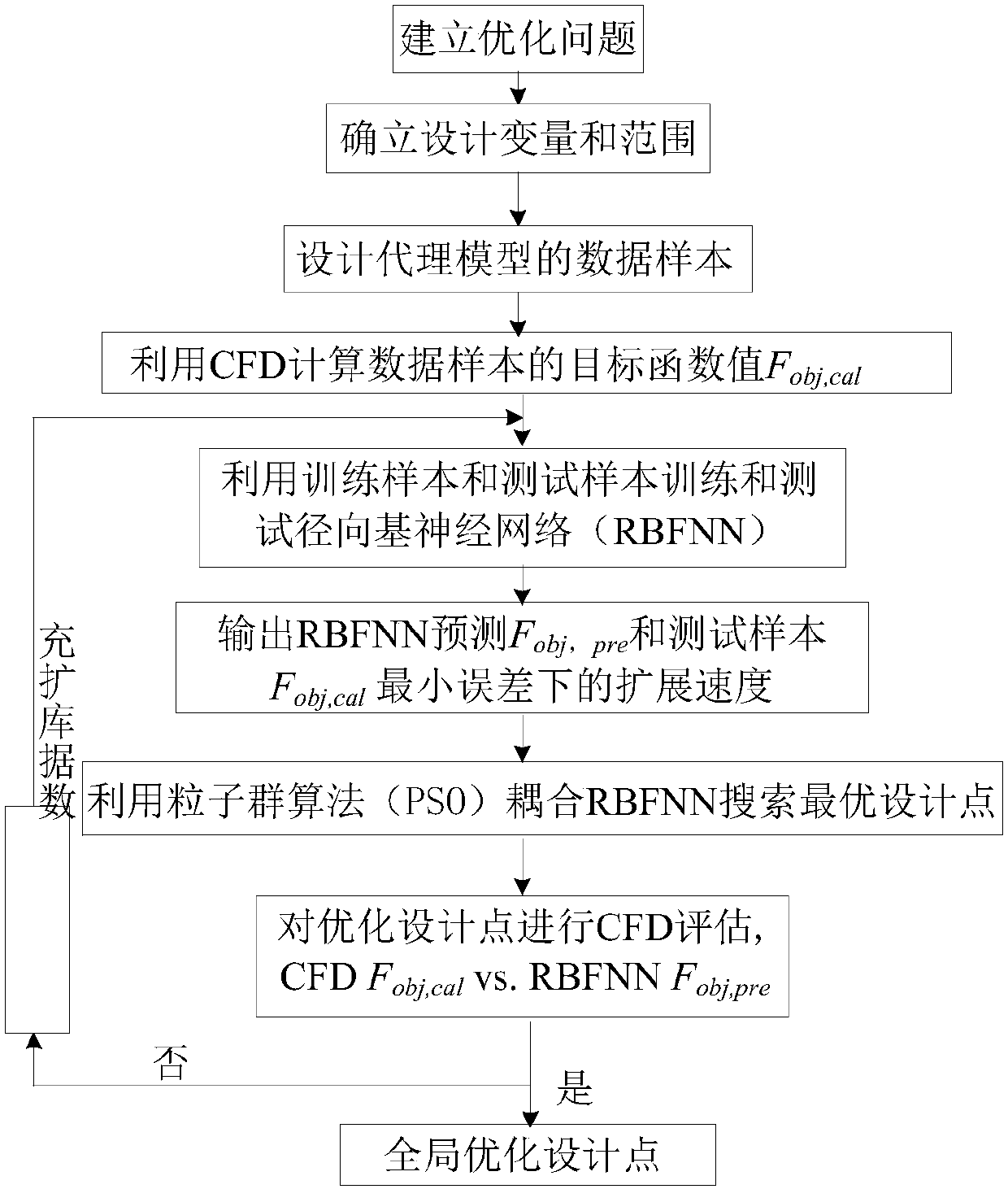

[0062] figure 1 It is a flow chart of the aerodynamic-thermal synergistic optimization method for a fan-shaped hole film cooling structure of a turbine blade of the present invention, and will be referred to below figure 1 This method will be described.

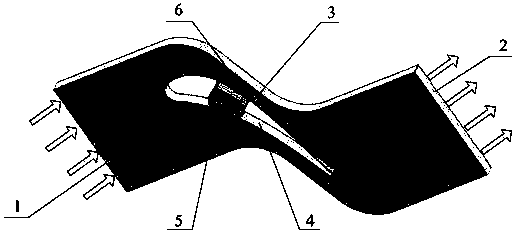

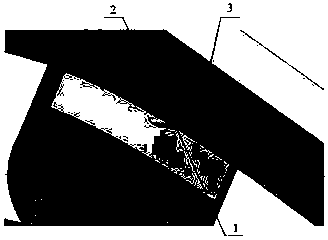

[0063] Step 1, based on figure 2 The fan-shaped air film cooling geometric model of the turbine blade, the mainstream inlet velocity is 140m / s, the main flow inlet temperature is 540K, the fan-shaped air film hole cold air inlet velocity is 80.4m / s, and the air film hole cold air inlet temperature is 310K.

[0064] It is stipulated that the fan hole spacing P is 4.5D, the fan hole height h is 2.5D, and the fan hole forward expansion length is l 1 is D, the lateral extension length of the fan-shaped hole l 2 is 2D, the length of the cylindrical part of the fan-shaped hole l 3 is (h / sinα-3D). Select turbine blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com