Two-dimensional code scanning-based fixed-point regular tour inspection method and system

A two-dimensional code scanning and inspection system technology is applied in the field of fixed-point regular inspection methods and systems based on two-dimensional code scanning, and can solve problems such as management, inability to guarantee inspection results, and difficulty in inspecting personnel work efficiency and effect. , to avoid potential safety hazards, improve work efficiency, improve pertinence and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

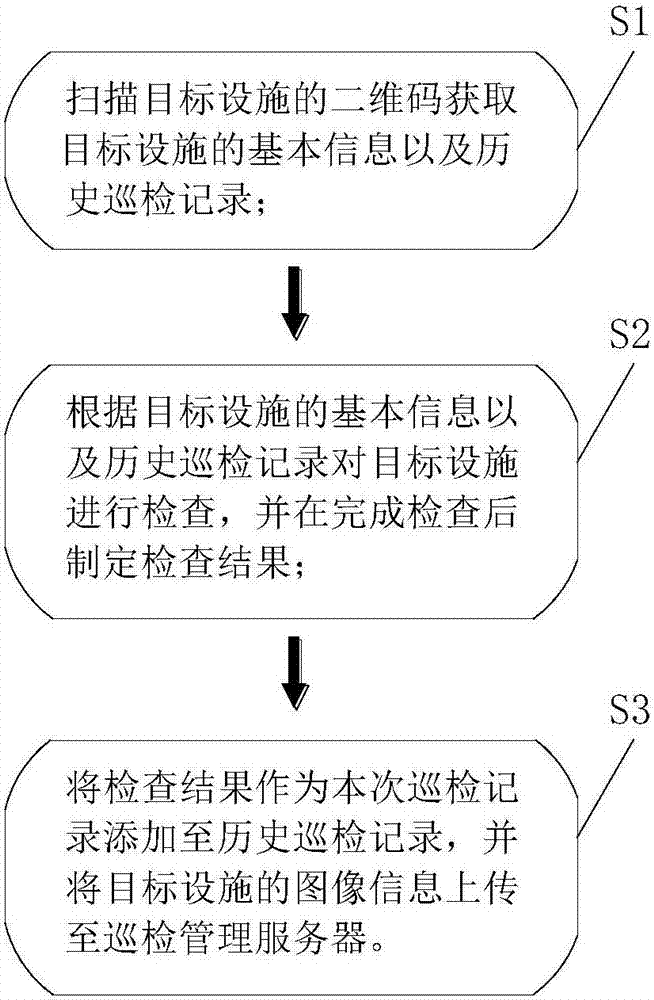

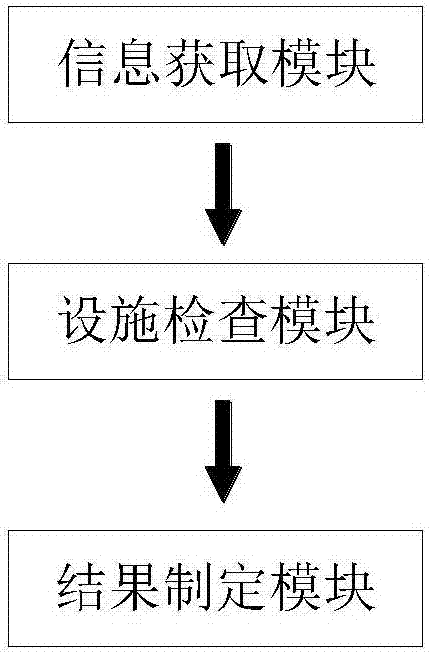

[0030] like figure 1 , figure 2 as shown, figure 1 , figure 2 This invention proposes a fixed-point regular inspection method and system based on two-dimensional code scanning.

[0031] refer to figure 1 , the fixed-point regular inspection method based on two-dimensional code scanning proposed by the present invention comprises the following steps:

[0032] S1. Scan the QR code of the target facility to obtain the basic information and historical inspection records of the target facility;

[0033] In this embodiment, before step S1, it also includes:

[0034] Assign the corresponding QR code to the target facility, and add the basic information of the target facility to the above QR code information;

[0035] The basic information of the target facility includes the components of the target facility, component functions, performance requirements, inspection rules, maintenance measures, and precautions; the inspection personnel can know the target equipment by scanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com