Patents

Literature

33results about How to "Guaranteed inspection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

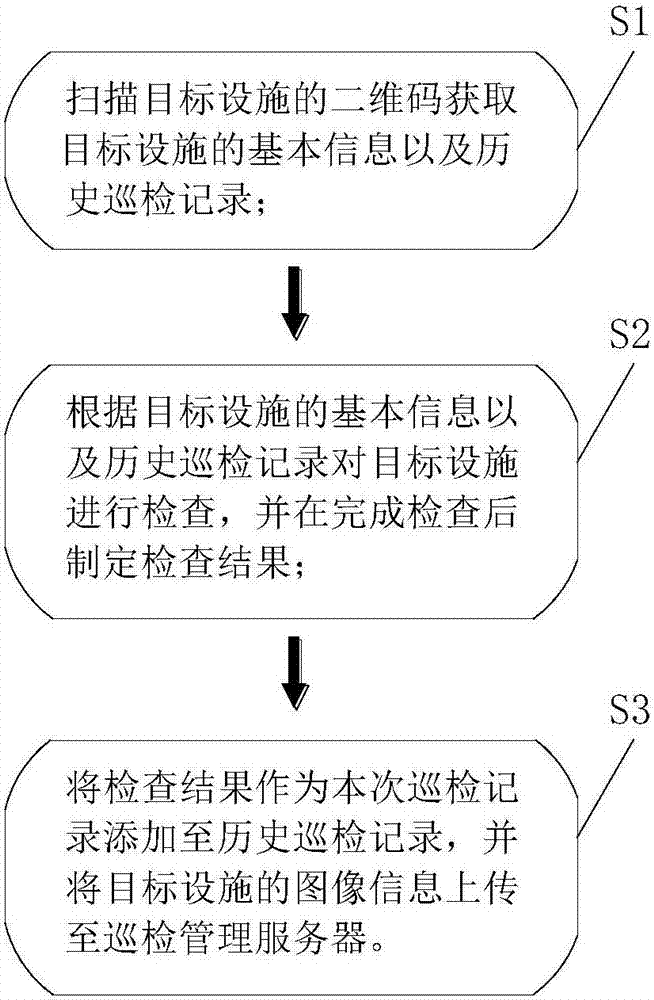

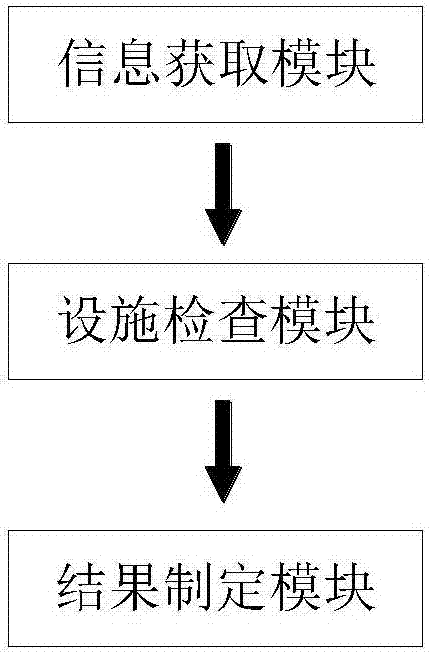

Two-dimensional code scanning-based fixed-point regular tour inspection method and system

InactiveCN107195014AAvoid safety hazardsImprove work efficiencyChecking time patrolsCo-operative working arrangementsComputer scienceInspection method

The invention discloses a two-dimensional code scanning-based fixed-point regular tour inspection method and system. The method comprises the following steps: S1, scanning a two-dimensional code of a target facility to acquire basic information and a historical tour inspection record of the target facility; S2, inspecting the target facility according to the basic information and the historical tour inspection record of the target facility, and formulating an inspection result after inspection is finished; and S3, adding the inspection result in the historical tour inspection record as an inspection record of this time, and uploading image information of the target facility to a tour inspection management server. The two-dimensional code scanning-based fixed-point regular tour inspection method and system store and lock the basic information and the tour inspection information of the target facility based on the two-dimensional code and update tour inspection result of each time into two-dimensional code information, so that different tour inspection persons can know the basic information and the historical tour inspection information of the target facility by scanning the two-dimensional code of the target facility and are facilitated to pointedly inspecting the target facility according to a scanning result.

Owner:安徽大智睿科技技术有限公司

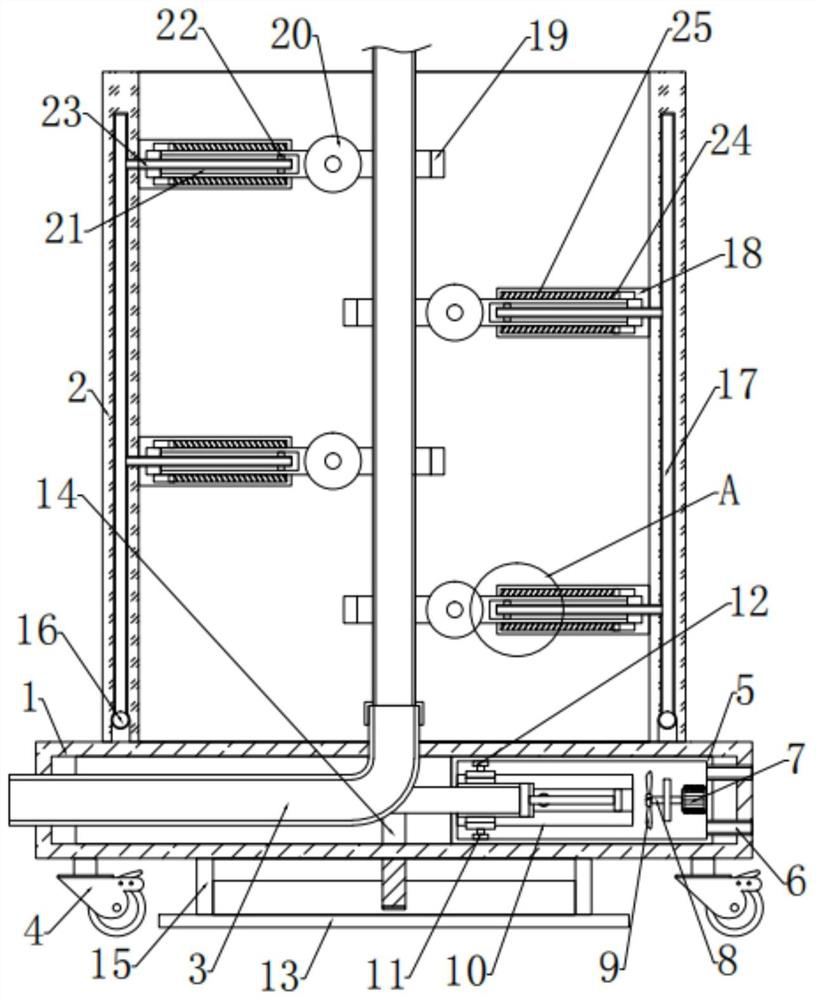

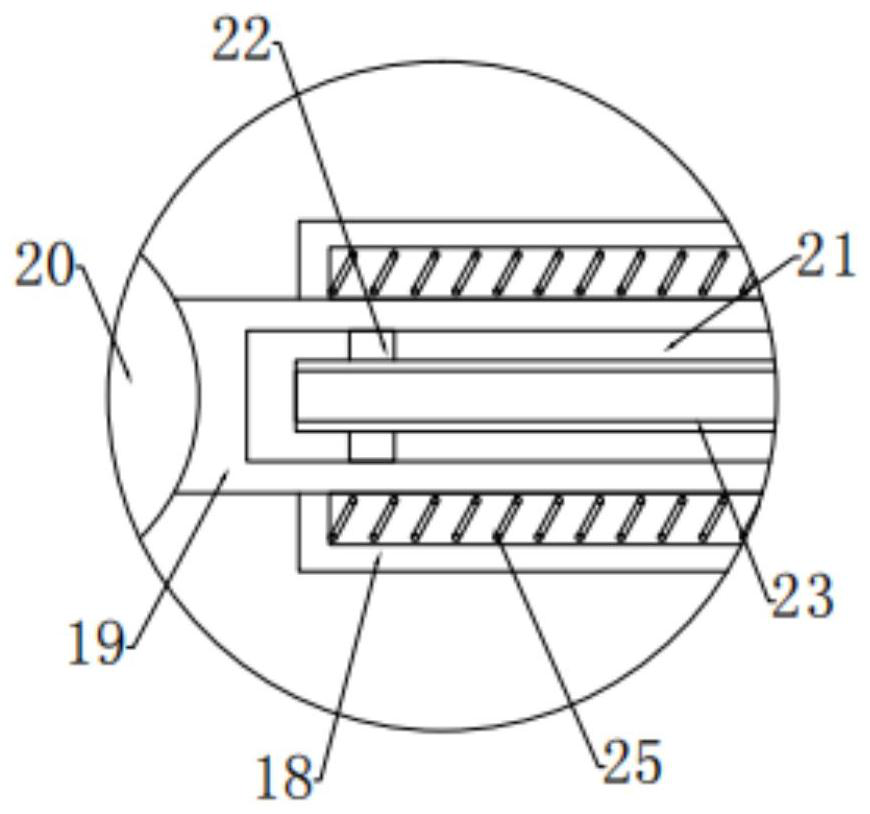

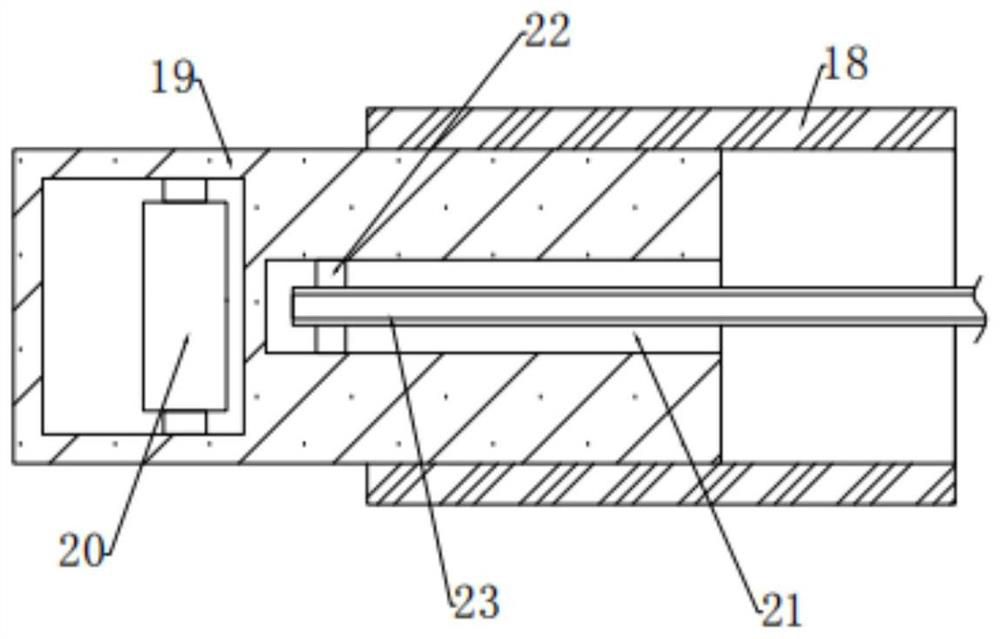

Safety inspection device for river dam

InactiveCN110487321ASimple structureEasy to operateBreakwatersMeasurement devicesEngineeringMechanical engineering

The invention discloses a safety inspection device for a river dam. The device includes a dam guardrail, a translation cavity with an opening facing the right is set in the dam guardrail, a translation block with a right end located in an external space is in the translation cavity, a connection block is fixed at a right end of the translation block, a moving block whose left end is at an upper end of the dam guardrail is fixed to an upper end of the connection block, a driving cavity is set in the connecting block, a translation mechanism capable of driving the translation block to move backand forth is set in the translation block, the translation block is internally provided with an inspection mechanism capable of inspecting the dam and providing lighting at night, and the driving cavity is internally provided with a transmission mechanism that can transmit the power of the translation mechanism to the inspection mechanism. The device can automatically complete a safe inspection ofthe river dam, the inspection efficiency is improved while labor is saved, the device also can work at night, the lighting is provided during the night work, and the inspection effect is ensured.

Owner:PUJIANG HUIYI INTELLIGENT TECH CO LTD

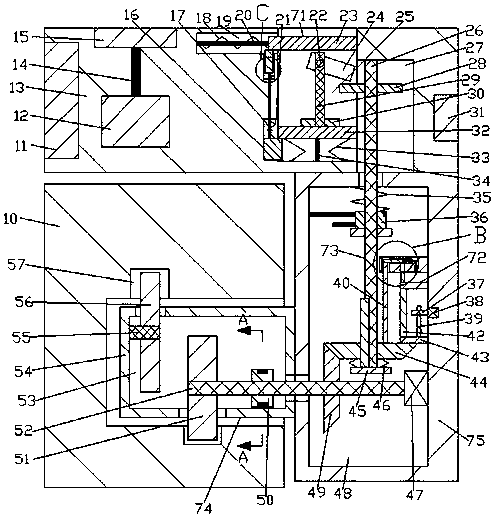

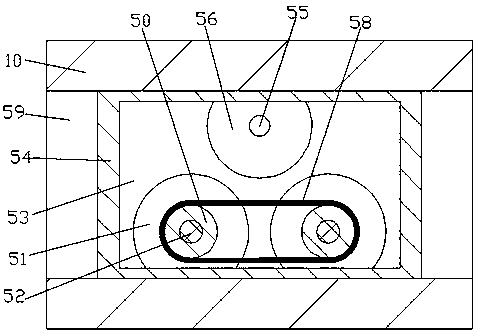

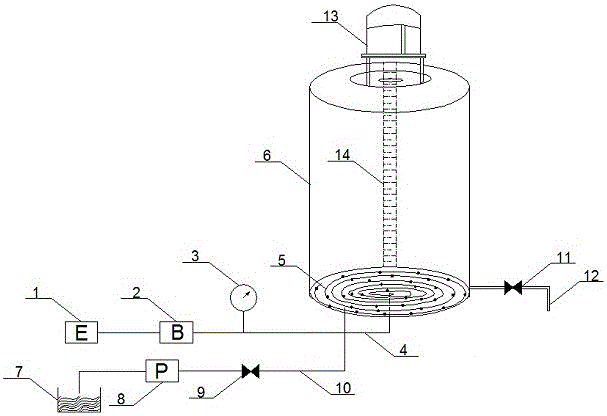

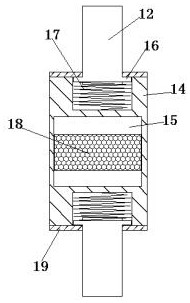

Pneumatic stirring apparatus and preparation method of magnetic suspension

InactiveCN105854720AImprove the detection rateGuarantee inspection effectTransportation and packagingMixer accessoriesWater levelGas pressure

A pneumatic stirring device comprises a pneumatic stirring mechanism, a mixing mechanism and a measuring mechanism, the pneumatic stirring mechanism comprises a motor, a blower, a gas pressure meter, an intake hose and a spiral intake pipe, the motor is connected to the blower, the blower is connected to the spiral intake pipe through the intake hose, the spiral intake pipe is provided with air inlets, and the intake hose is fitted with the gas pressure meter; the mixing mechanism comprises a stirring barrel, a water storage pool, a water pump, an inflow valve, an inflow pipe and an outflow pipe, the spiral intake pipe is positioned at the inner bottom of the stirring barrel, the intake hose passes through a sidewall of the stirring barrel into the stirring barrel, the inflow pipe connects the water storage pool with the stirring barrel, the inflow pipe is fitted with the water pump and the inflow valve for controlling water inflow, the bottom of the stirring barrel is fitted with the outflow pipe, the outflow pipe is fitted with the outflow valve, and a feed port is provided above the stirring barrel; the measuring mechanism includes a water level scale placed in the stirring barrel. An embodiment of the invention also provides a preparation method of a magnetic suspension.

Owner:KOCEL STEEL

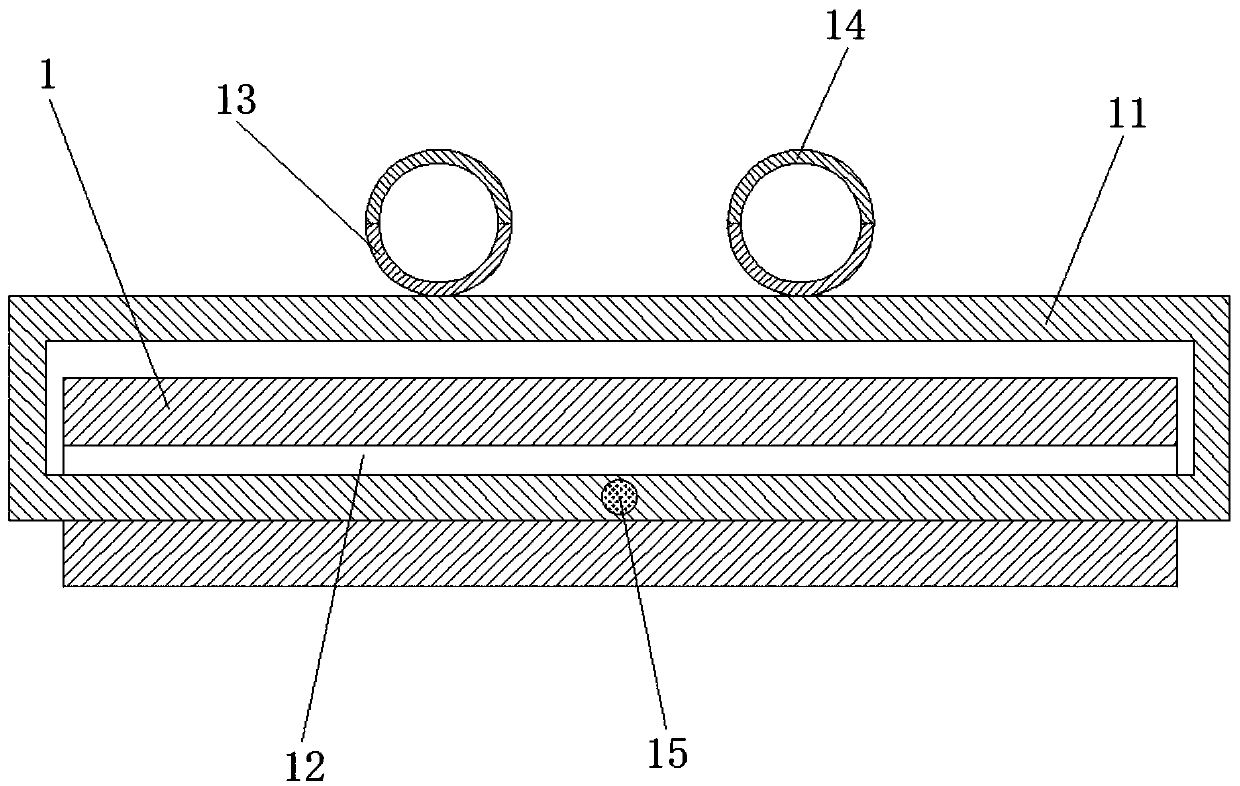

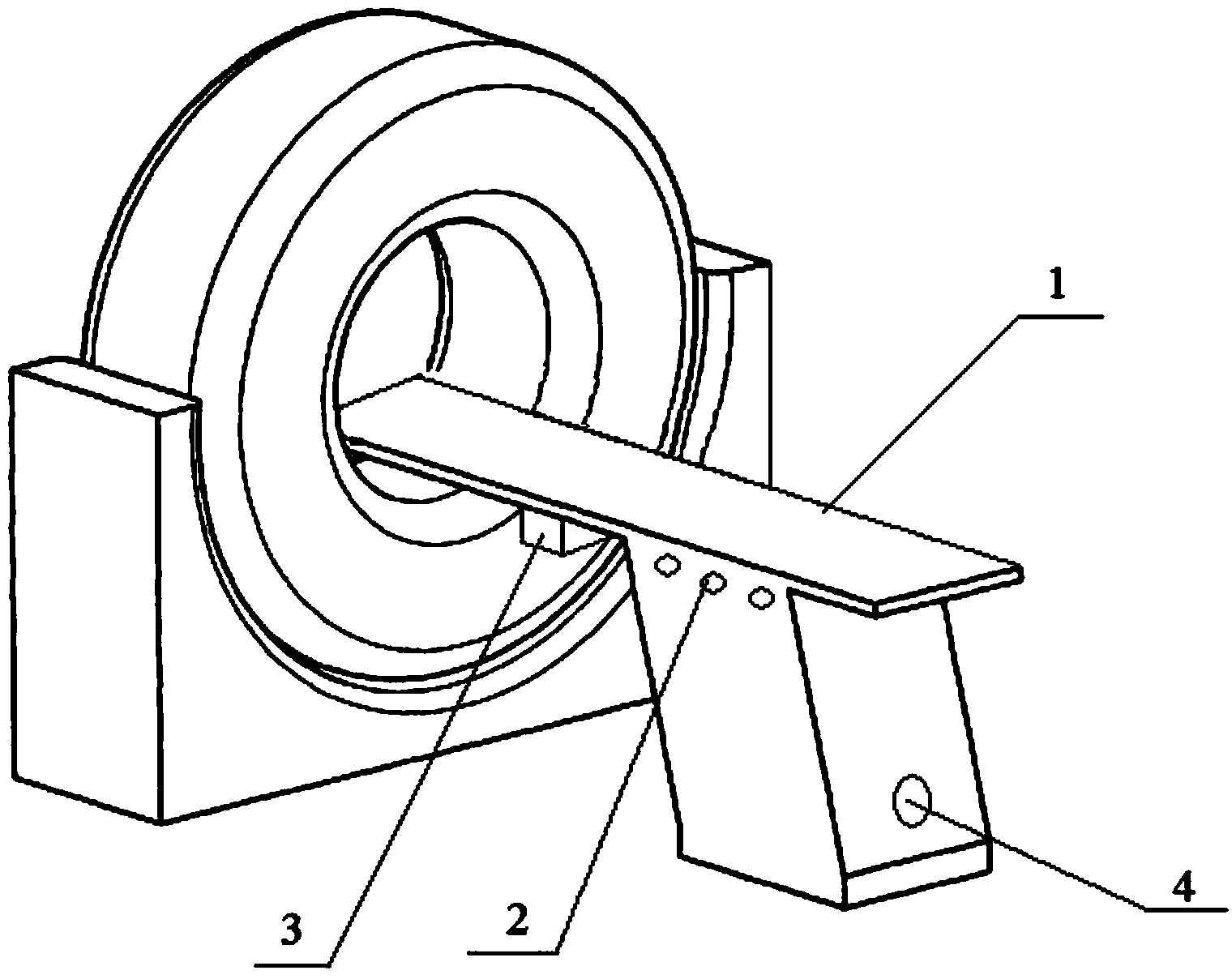

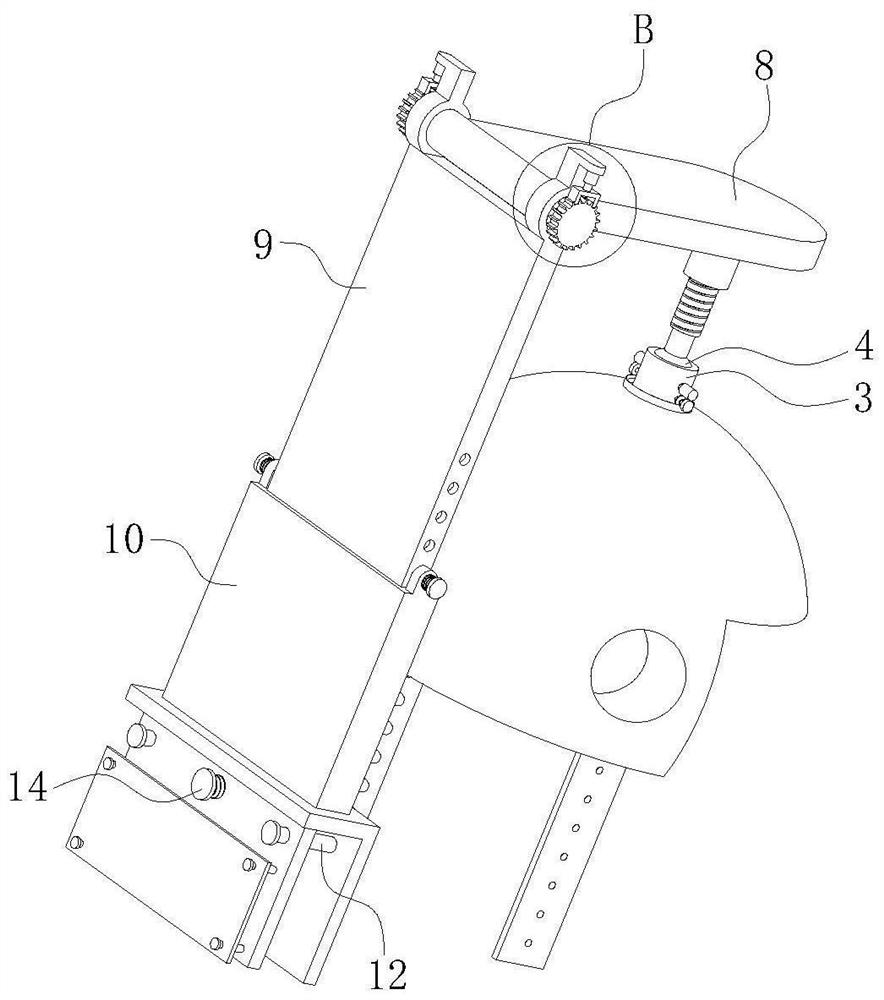

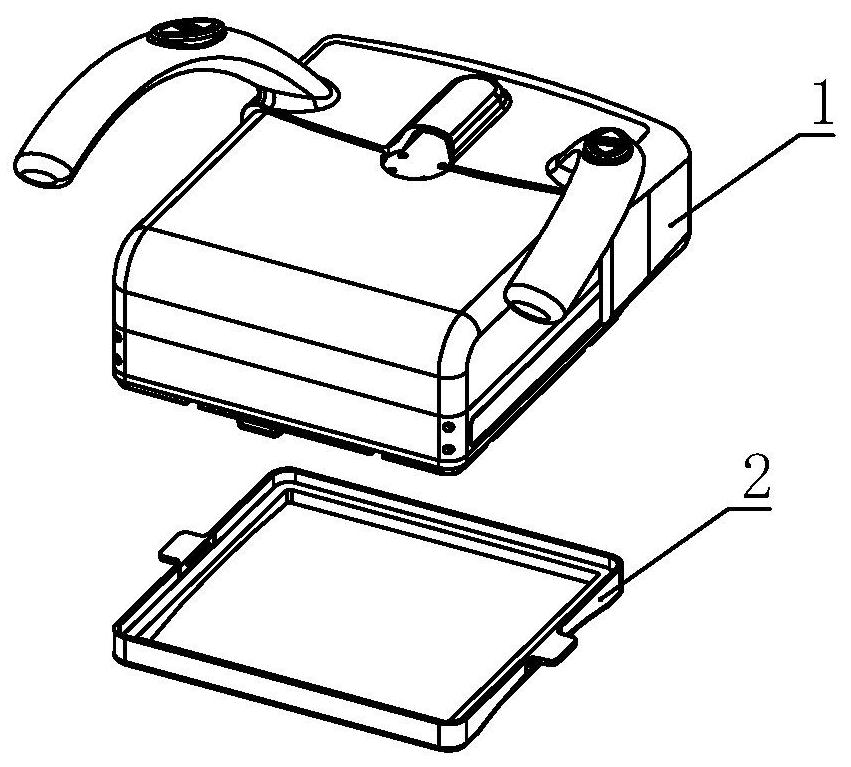

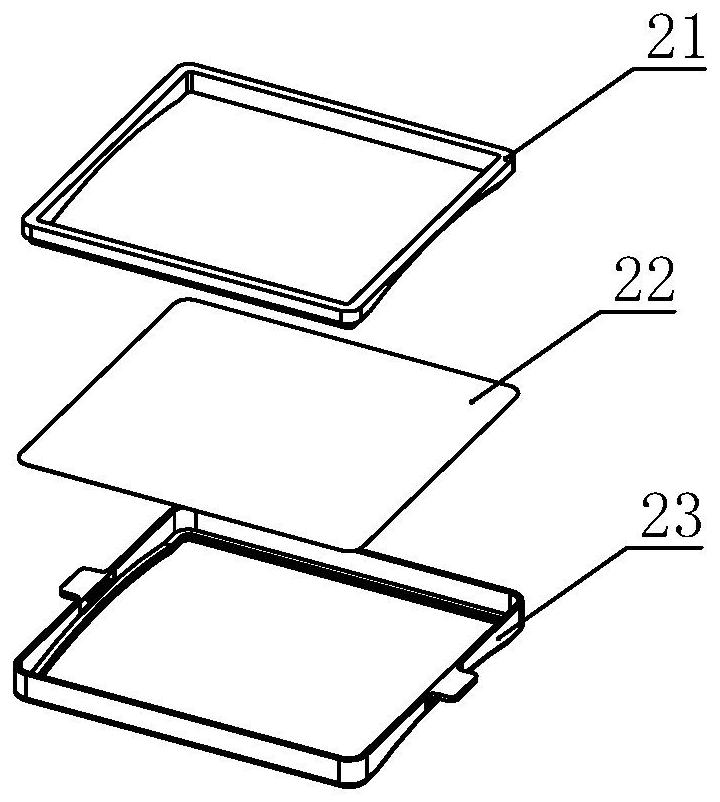

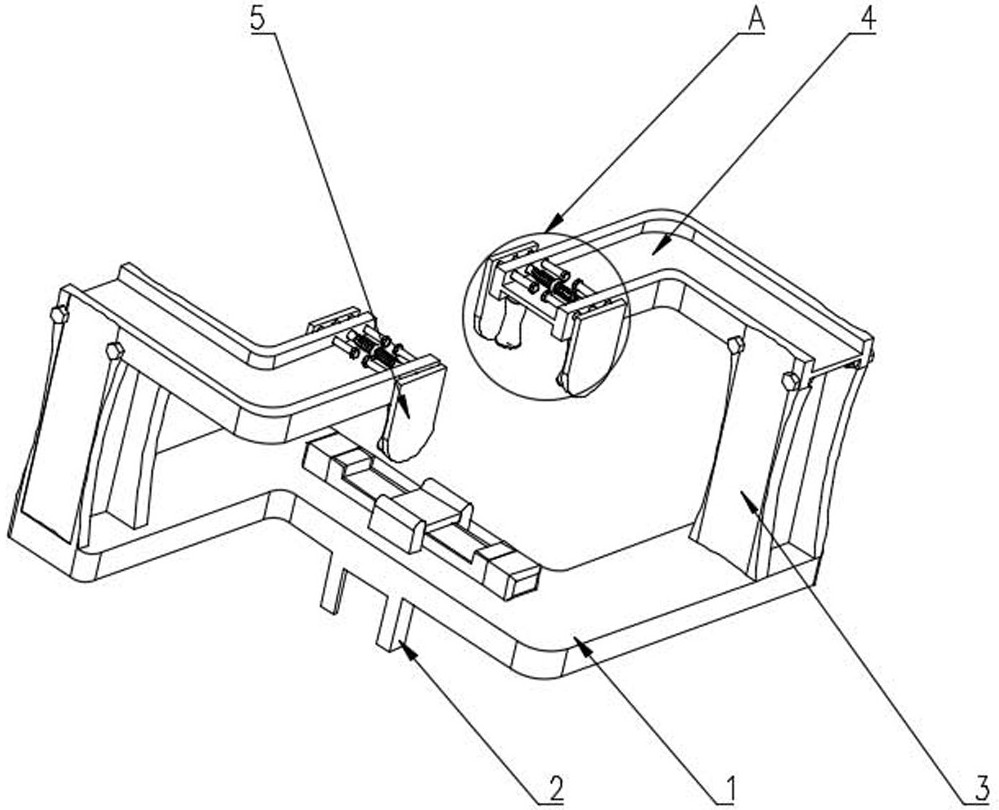

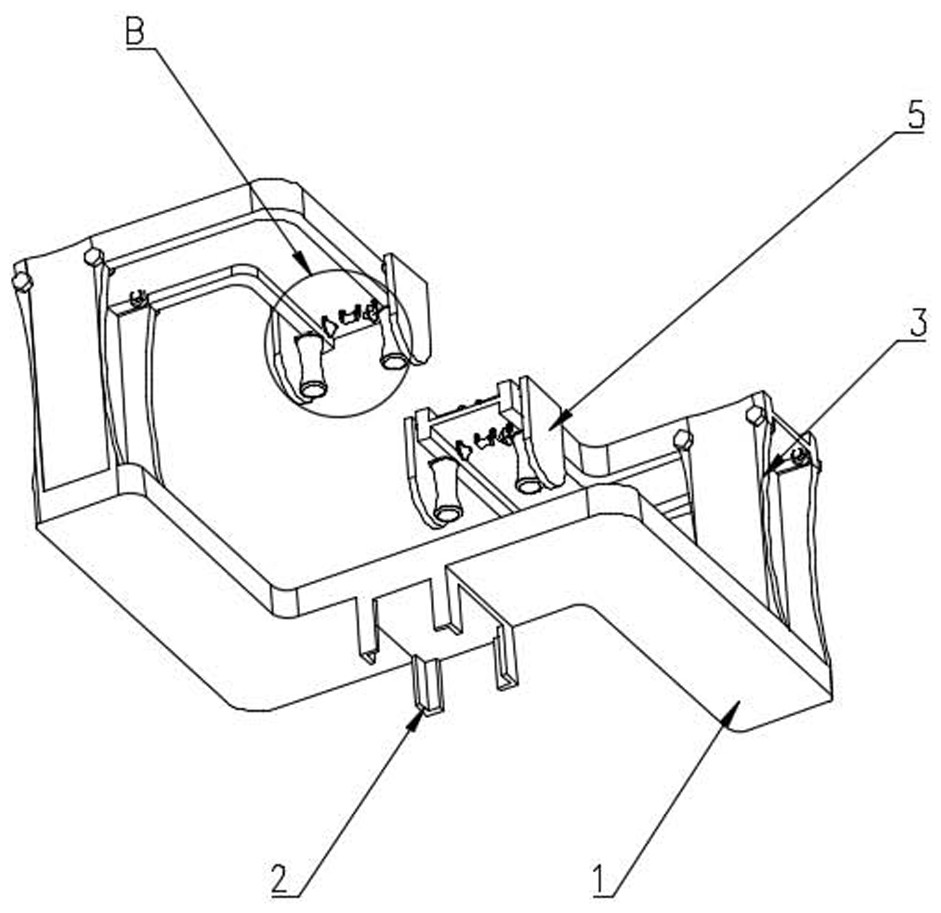

Body position fixing device for inspection of babies

PendingCN109602439ALimit bendingLimit side to side shakingPatient positioning for diagnosticsComputerised tomographsEngineeringSlide plate

The invention discloses a body position fixing device for inspection of babies. The body position fixing device comprises a bottom plate, a sucker, support plates, a sliding frame, a first bolt, softpads, a first fixing sleeve, a first rotating sleeve, a sliding groove, a sliding plate, a framework, a guiding groove, second fixing grooves, second rotating sleeves, a second bolt and a placing plate. The body position fixing device for inspection of babies is ingenious in structure, powerful in functions, and simple to operate. Through the device, the body position fixing treatment can be performed on the babies, the condition of body position changes caused by natural hyperactivity for the babies in the inspection process of the babies is avoided, and the inspection effect of the babies isguaranteed.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

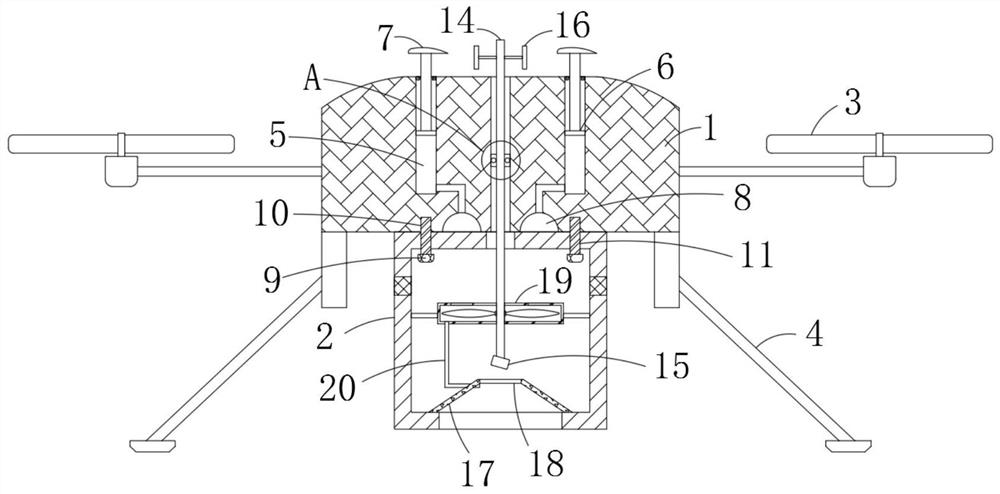

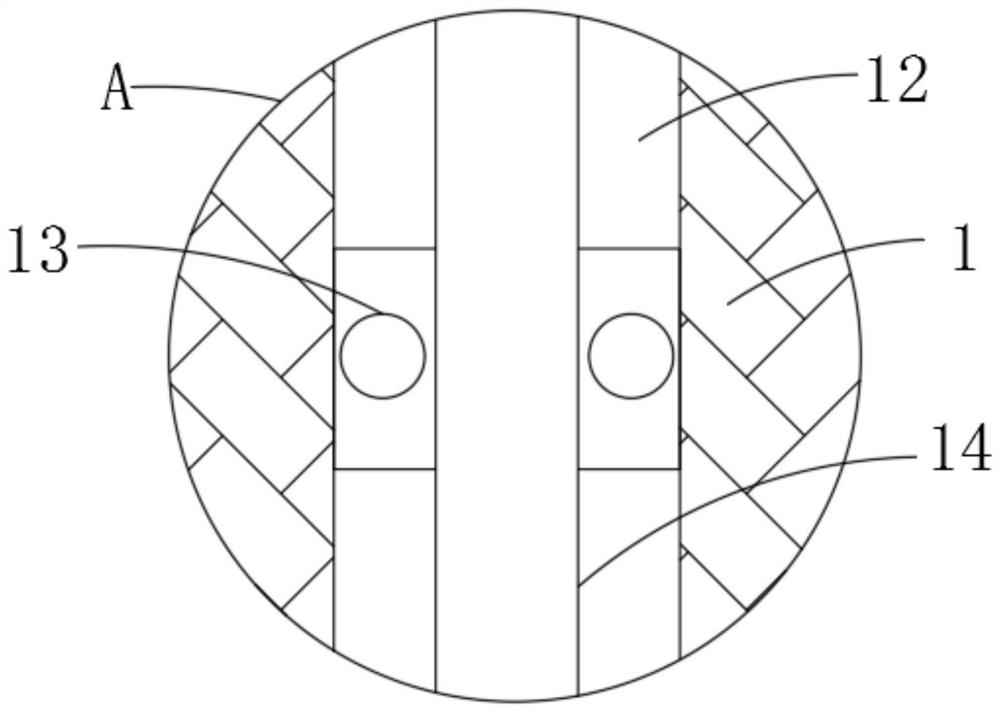

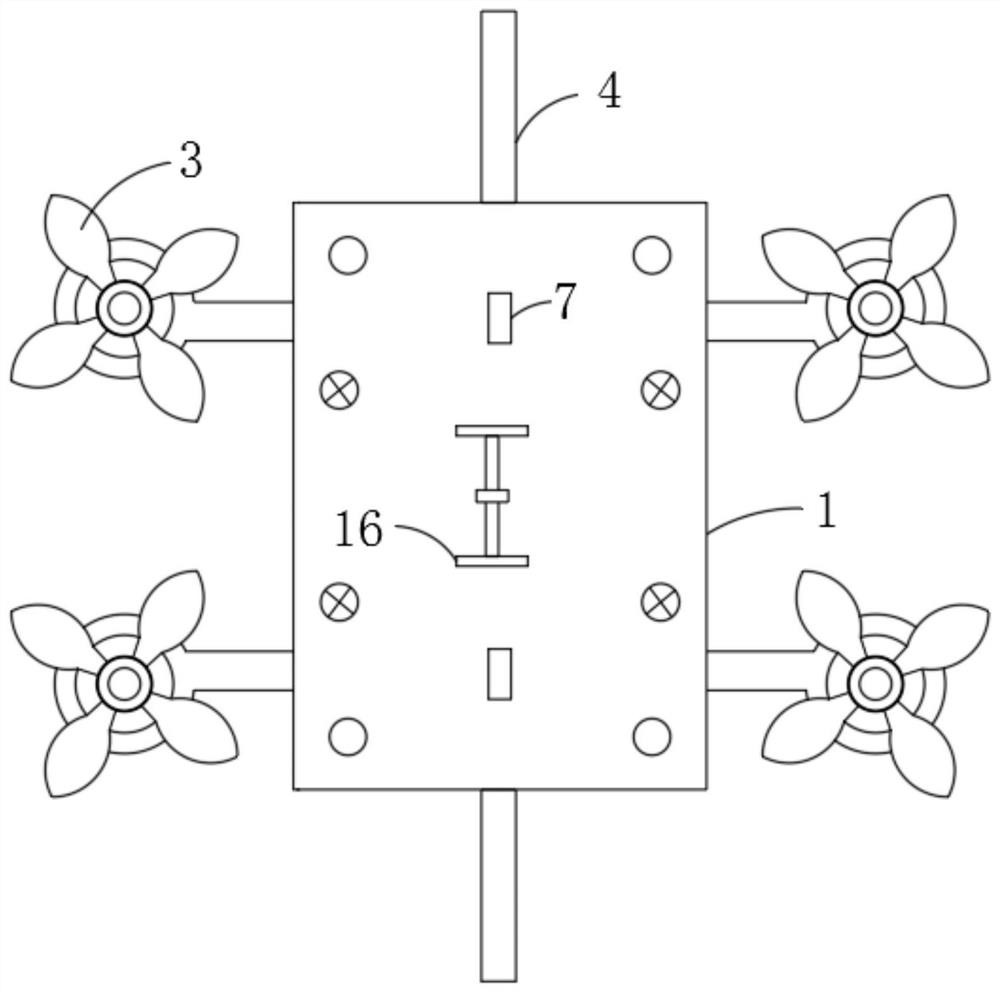

Unmanned aerial vehicle electric power polling pod

PendingCN112124586ASolve the cumbersome and complicatedImprove securityAircraft componentsCleaning using gasesAutomotive engineeringMechanical engineering

The invention discloses an unmanned aerial vehicle electric power polling pod. The pod comprises an unmanned aerial vehicle body and a pod body arranged below the unmanned aerial vehicle body, two sets of tight absorption assemblies are arranged in the unmanned aerial vehicle body, the unmanned aerial vehicle body and the pod body are provided with the same locking assembly, and a plurality of rotating wings are fixedly installed on the unmanned aerial vehicle body. A plurality of undercarriages are installed at the lower end of the unmanned aerial vehicle body, and the same aerial photographymechanism is arranged on the unmanned aerial vehicle body and the pod body. Through the arrangement of the aerial photography mechanism, the tight absorption assemblies, the locking assembly and a cleaning assembly, the polling pod can be quickly assembled and disassembled, negative pressure can be generated through wind power, the pod body is firmly adsorbed, the safety of the pod body is improved, moreover, the wind power can be used for shooting an inspection picture in a rotating manner and cleaning dust raised in the take-off and landing processes, so that the definition of the shot picture is ensured.

Owner:STATE GRID HUBEI ELECTRIC POWER CO LTD MAINTENANCE CO +2

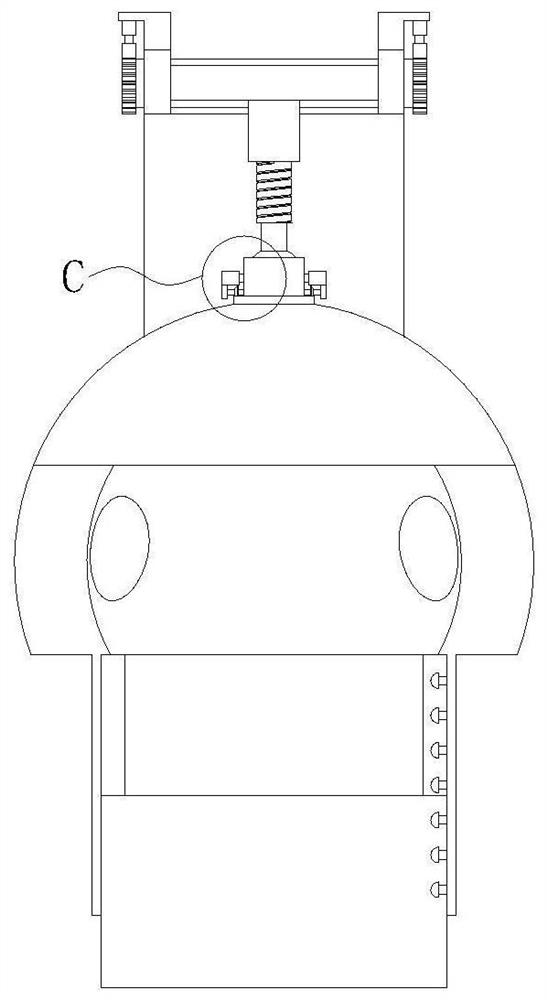

Auxiliary device for CT imaging of heads and necks

InactiveCN110960249AIngenious ideaGuaranteed comfortPatient positioning for diagnosticsComputerised tomographsRadiologyHead fixation

The invention discloses an auxiliary device for CT imaging of heads and necks. The auxiliary device comprises a CT machine, wherein a sliding rail is fixedly installed on the top surface of a detection table of the CT machine; the upper part of the sliding rail is provided with a plurality of first sliding blocks which are horizontally arranged at an equal interval and are movably matched with thesliding rail; two electric sliding blocks movably matched with the sliding rail are arranged at the outer ends of the sliding rail; the electric sliding blocks are located on the left sides and the right sides of the first sliding blocks respectively; a headrest plate is fixedly installed on the top surface of the electric sliding block located at the left side; movable plates are fixedly installed on the top surfaces of all the first sliding blocks and the top surface of the electric sliding block located at the right side; and horizontal first grooves are formed in the right sides of the movable plates and the headrest plate. The auxiliary device for is used for CT detection of the head and the neck of a pet dog; the four limbs of the pet dog are fixed by limb fixing devices, a head fixing device is adopted for fixing the lower jaw of the head of the pet dog, and the pet dog is comprehensively fixed and is guaranteed to keep a certain posture in the examination process, so examination effect can be effectively guaranteed; and the comfort degree of the pet dog in the examination process is guaranteed due to a design directed at the body shape of the pet dog.

Owner:王宁

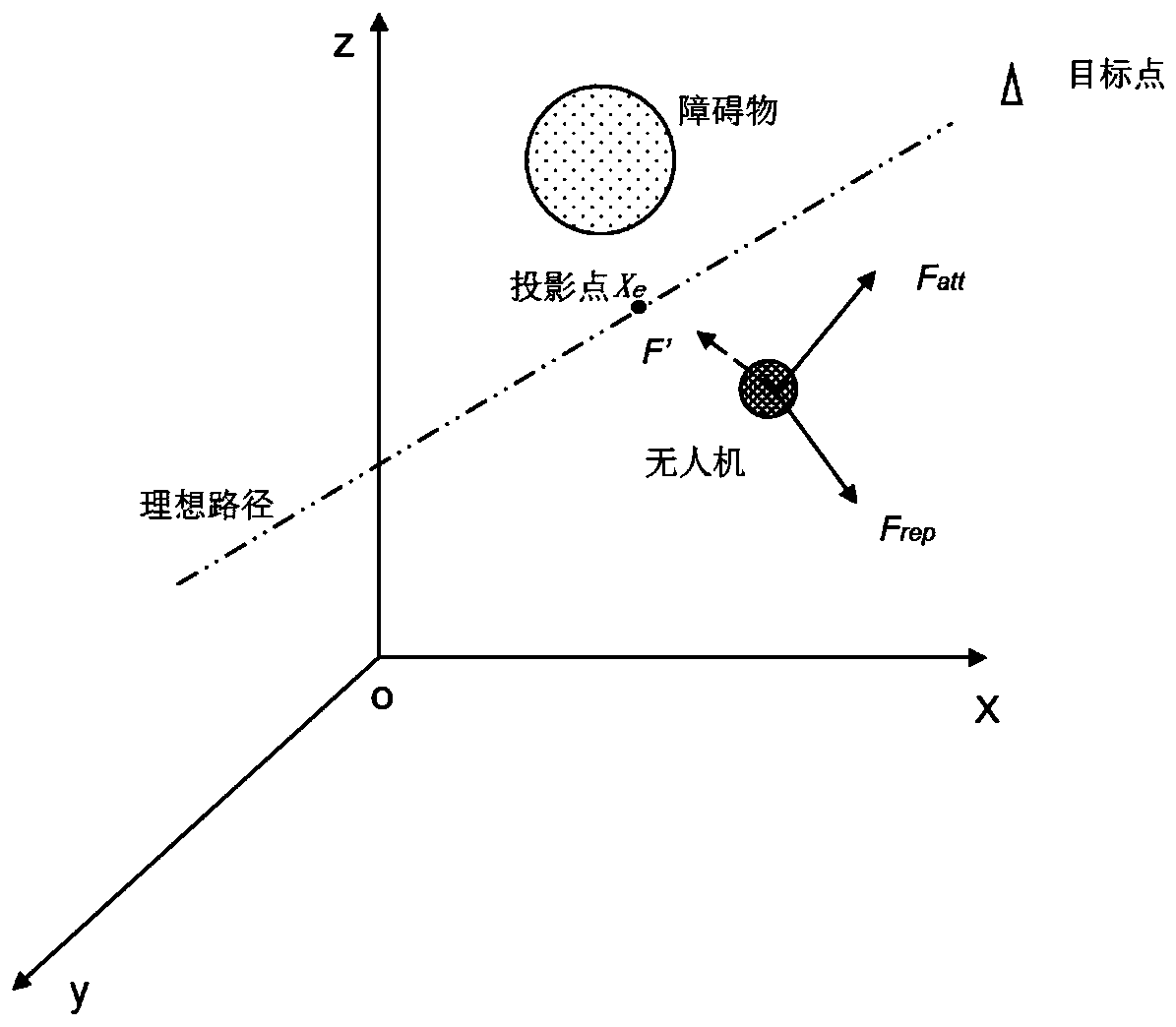

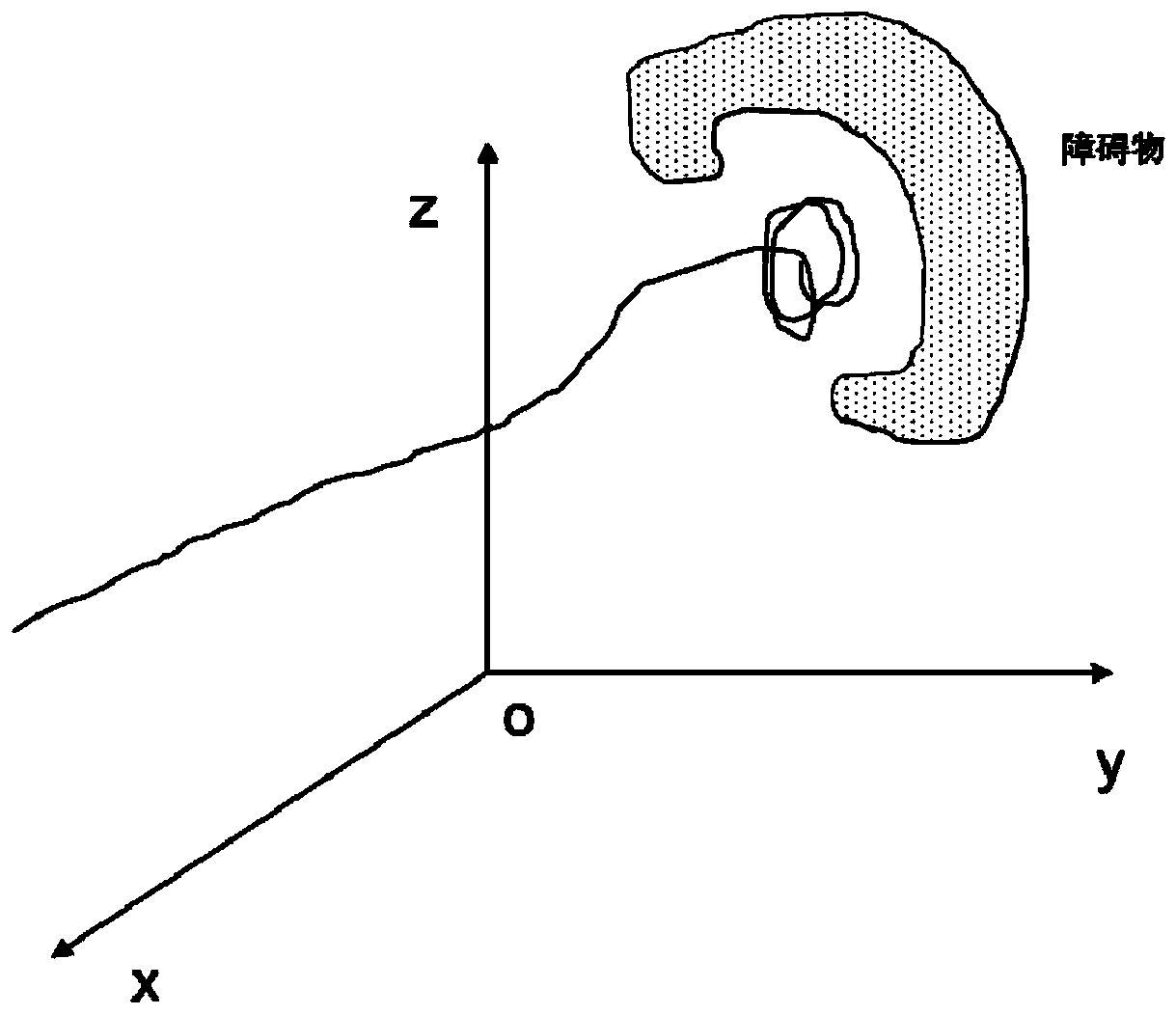

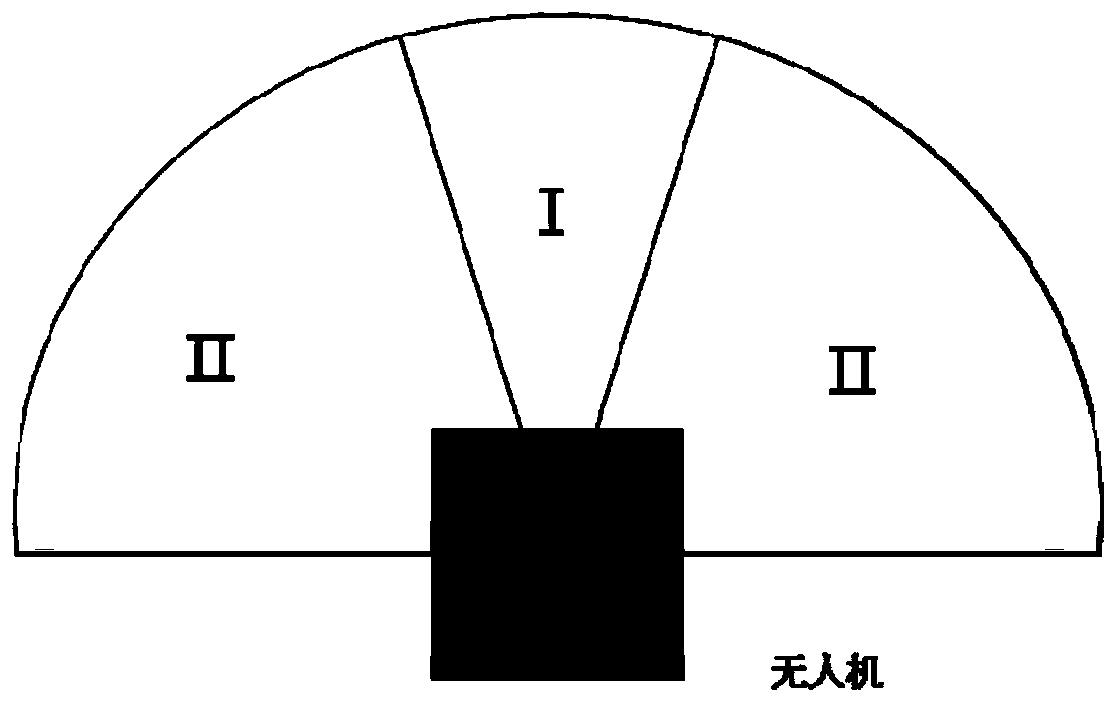

Electric power inspection unmanned aerial vehicle path planning method based on improved APF

ActiveCN110673633AAvoid repeated shocksAvoid shockPosition/course control in three dimensionsUncrewed vehicleControl theory

The invention discloses an electric power inspection unmanned aerial vehicle path planning method based on an improved APF (Artificial Potential Field). The method comprises the steps that an unmannedaerial vehicle flies along an ideal path and meanwhile senses obstacles; whether an obstacle exists within a sensing range or not is judged, and when the obstacle exists, the improved APF is adoptedfor obstacle-avoiding flight; then whether the distance between the unmanned aerial vehicle and the ideal path is smaller than a set value or not is judged, and when the distance is smaller than the set value, the unmanned aerial vehicle returns to the ideal path, and an inspection task is ended; and the unmanned aerial vehicle flies along the ideal path or returns to the ideal path to fly till the inspection task is ended. According to the method, a gravitational field of the unmanned aerial vehicle at an ideal projection point is introduced, and an action range is set; when the distance between the unmanned aerial vehicle and the ideal path is smaller than d<0>, the gravitational field is zero, and therefore repeated oscillation of the unmanned aerial vehicle nearby the ideal path is avoided; and when the unmanned aerial vehicle is trapped in a U-shaped obstacle, the exploration range of the unmanned aerial vehicle is adjusted to limit the gravity at a target point and adjust the gravity at the projection point to be zero, so that the unmanned aerial vehicle gets rid of a U-shaped region.

Owner:HEFEI UNIV OF TECH

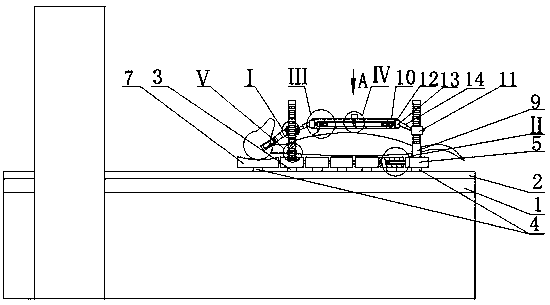

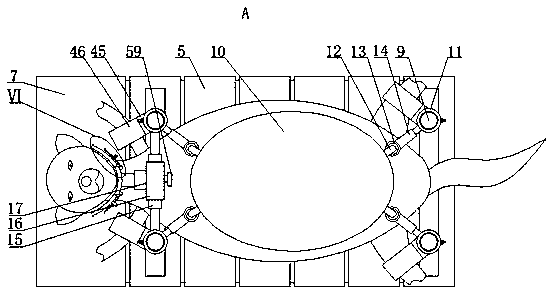

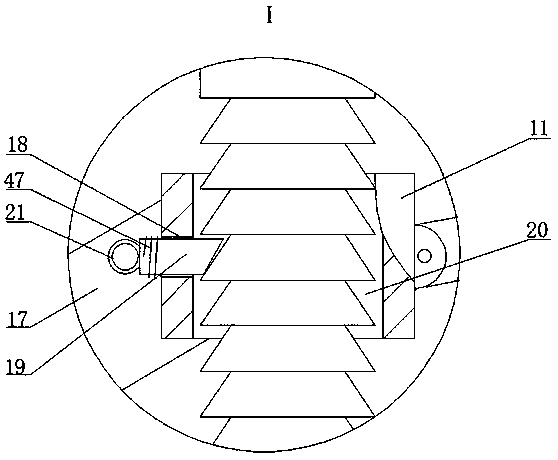

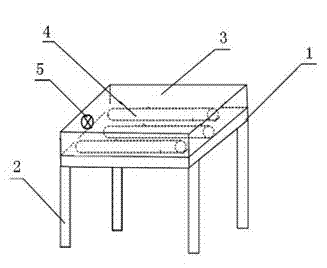

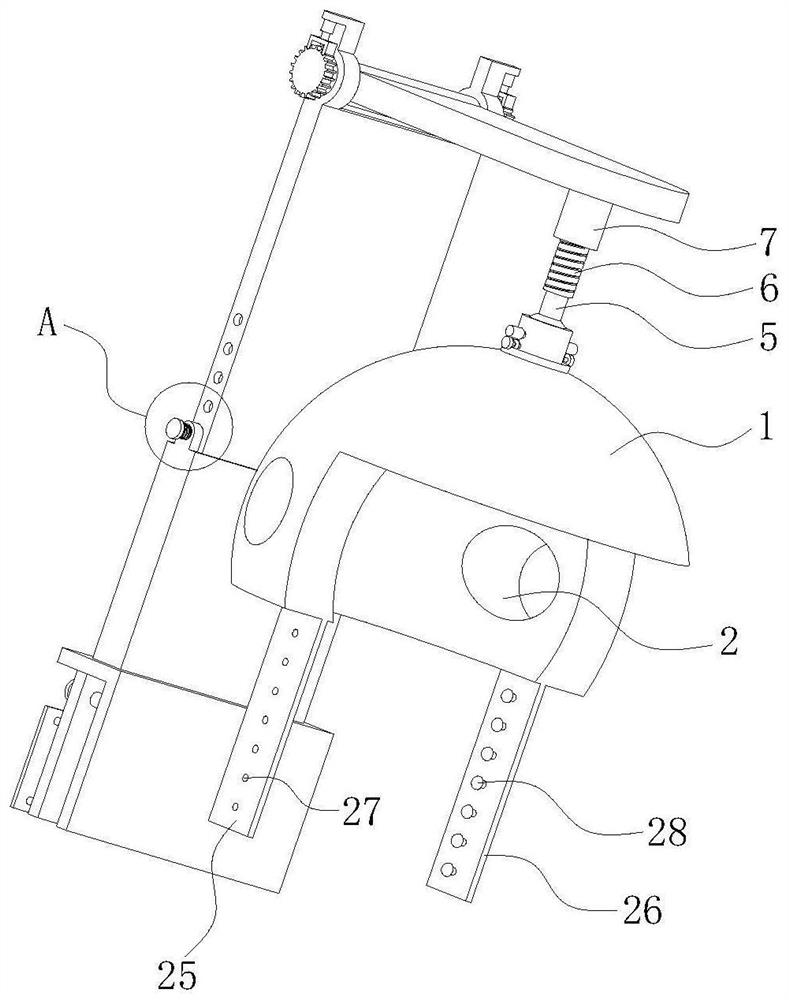

Inspection bench for reflectors

InactiveCN103115754ASolve the problem of high labor intensity and easy fatigueGuaranteed inspection effectMaterial analysis by optical meansOptical apparatus testingEngineeringDesk

The invention discloses an inspection bench for reflectors. The inspection bench for reflectors comprises a desk and a lamp box. The desk comprises a desk top and desk legs. A bottom plate of the lamp box is fixed on the desk top. Light sources are evenly distributed on the bottom plate. A light-permeable plate is disposed at the top of the lamp box. The problem that long-term delicate inspection on reflectors is highly laborious and causes fatigue easily is solved, inspection effect is guaranteed, and the inspection bench for reflectors is simple in structure and convenient to use.

Owner:宏茂光电(苏州)有限公司

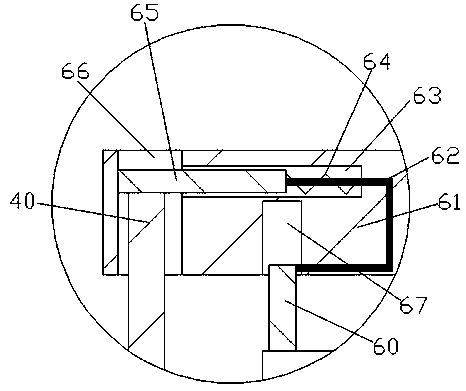

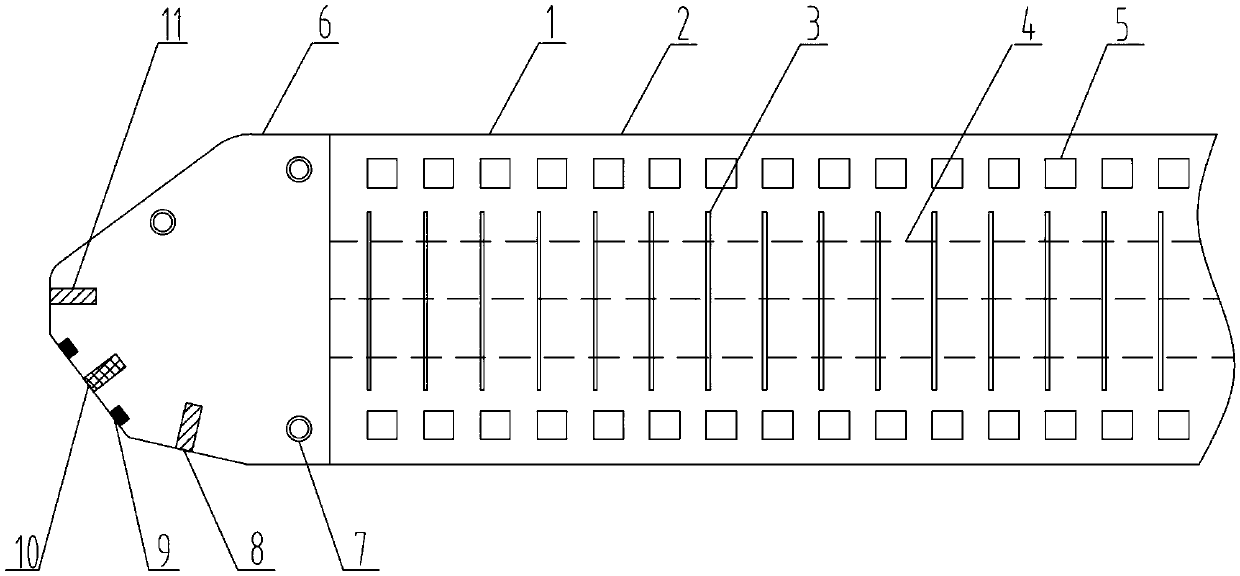

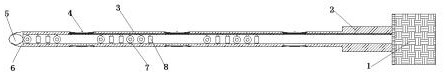

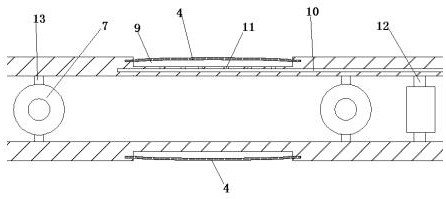

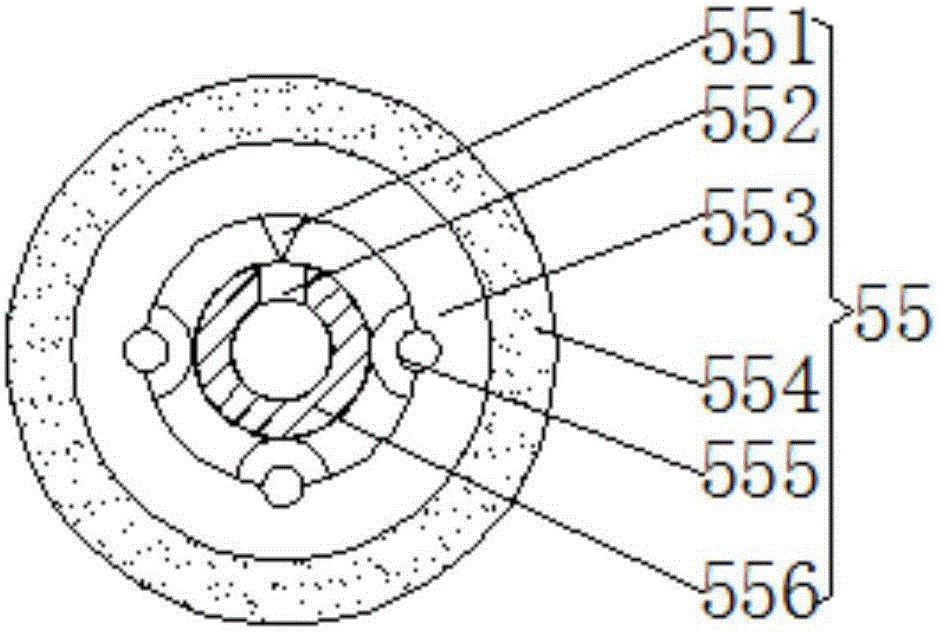

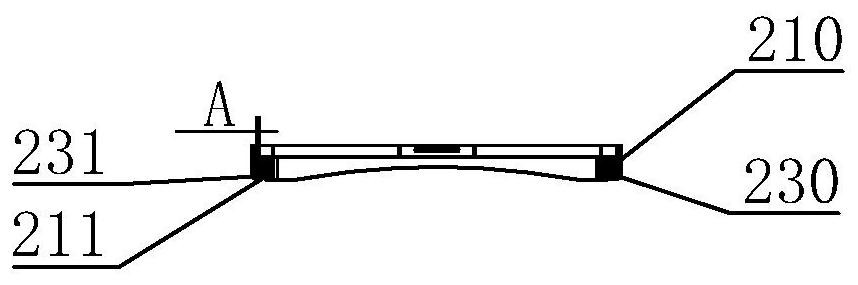

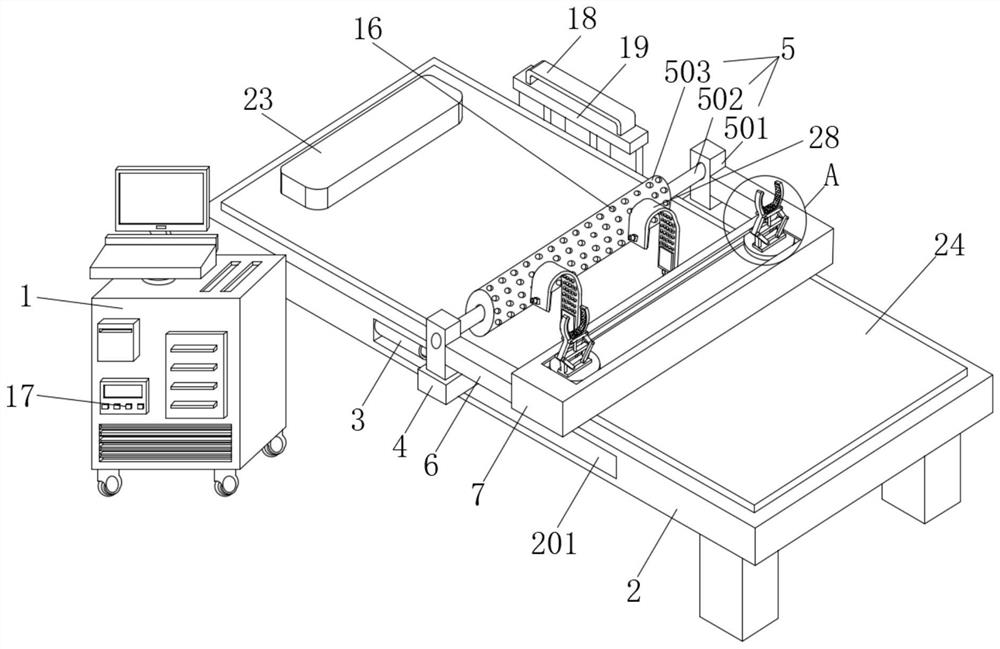

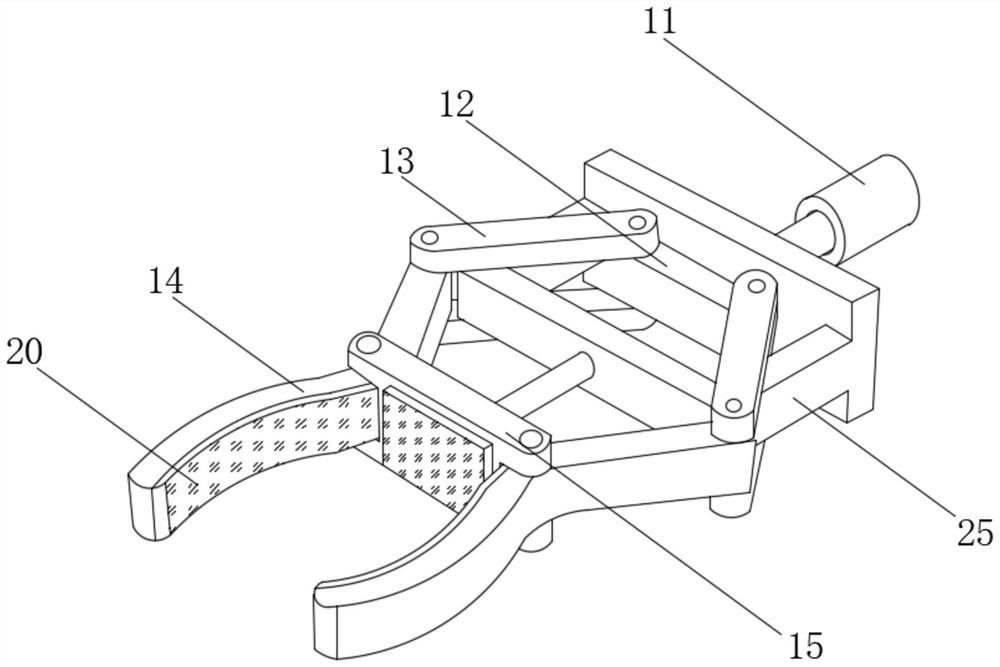

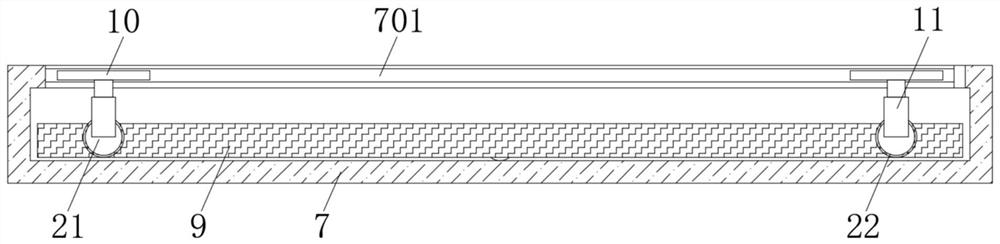

Probe structure capable of being used for intertubular automatic video inspection of steam generator

PendingCN109540907AReduce exposure doseCompact structureBoiler indication operationsOptically investigating flaws/contaminationForeign matterEngineering

The invention belongs to the technical field of maintenance of a steam generator of a nuclear power plant, and particularly relates to a probe structure capable of being used for an intertubular automatic video inspection of the steam generator. The probe for the intertubular automatic video inspection of the steam generator is compact in size, firm in structure, easy to operate, and is intended to replace the conventional video endoscope to realize the intertubular automatic video inspection of the steam generator. The probe further comprises a foreign matter grabbing channel, which can grabthe found foreign matter during the video inspection. The probe comprises two parts of a probe end and a probe steel strip. The probe end is fixed at the left end of the probe steel strip, and is usedfor performing a cleanness video inspection on the intertubular areas of the heat transferring tubes inside the steam generator, and at the same time, grasping the found foreign matter. The probe steel strip is used for conveying the probe end to a video inspection position, and protecting the cable connecting the probe end.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

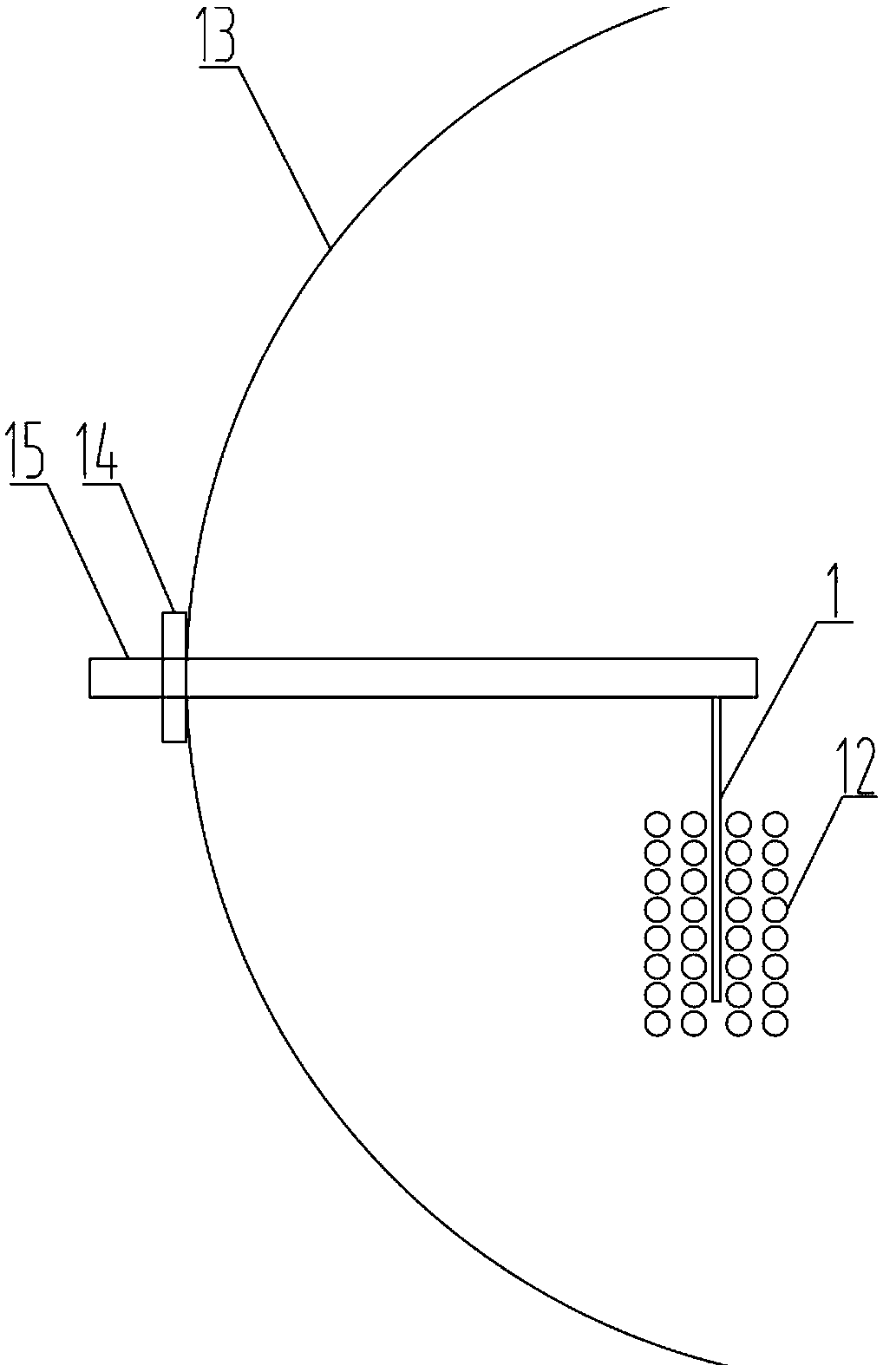

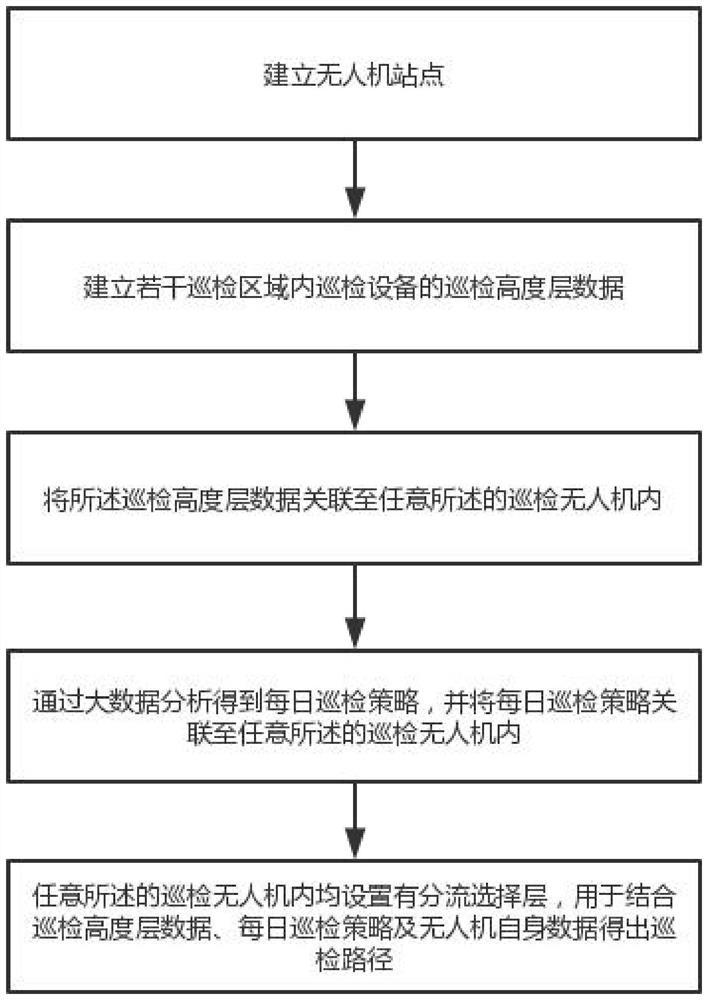

Unmanned aerial vehicle power plant intelligent inspection method based on big data

ActiveCN113359829AEnsure safetyGuaranteed accuracyPosition/course control in three dimensionsUncrewed vehicleReliability engineering

The invention discloses an unmanned aerial vehicle power plant intelligent inspection method based on big data, belongs to the field of artificial intelligence, and is used for solving the problems of how to quickly position a to-be-inspected area in a power plant area through an AI auxiliary technology, inspect in a targeted manner and improve the inspection efficiency. The method comprises the steps of establishing an unmanned aerial vehicle site, establishing inspection height layer data of inspection equipment in a plurality of inspection areas, associating the inspection height layer data to any inspection unmanned aerial vehicle, obtaining a daily inspection strategy through big data analysis, associating the daily inspection strategy to any inspection unmanned aerial vehicle, setting a shunting selection layer in any inspection unmanned aerial vehicle, and obtaining an inspection path by combining the inspection height layer data, the daily inspection strategy and the unmanned aerial vehicle data.

Owner:西安图迹信息科技有限公司

Gynecological Examination Device

The invention discloses a gynecological examination apparatus. The gynecological examination apparatus is characterized in that during a gynecological examination process, an extension tube is slowlyextended into a gynecological cavity, and slowly fills an inflation cavity with gas, so as to inflate a gas cell to facilitate spreading of the tissue at the gas cell, thus being convenient for examination by using a lens examination assembly; and in the case of medication, a medication assembly is used to perform medication. The gynecological examination apparatus adopts the mode of setting expansions at intervals, thus being able to preferably examine the tissue in a vagina and ensure the examination effect. At the same time, the gynecological examination apparatus is also provided with themedication assembly for facilitating medication on an accurate position. Besides, the gynecological examination apparatus adopts a detachable manner for the medication assembly and the examination lens, thus being convenient for maintenance, disinfection, repair and replacement, and can also be installed and used as needed.

Owner:HENAN UNIV OF CHINESE MEDICINE

Intelligent inspection method for immersive port facilities

PendingCN113256836AReduce workloadReduce work intensityChecking time patrolsComputer graphics (images)Display device

The invention relates to an intelligent inspection method for immersive port facilities. The method comprises the steps of (1) surveying and mapping the positions of a real port scene and port facilities, storing surveying and mapping data to a data server, and establishing a parameter label page for each port facility to be inspected; (2) continuously acquiring state information of port facilities needing to be inspected in a real port scene, and updating corresponding state attribute parameters; (3) generating a virtual port scene in real time and displaying the virtual port scene on a front-end display; (4) carrying out immersive inspection operation in the inspection activity area by the inspection personnel; (5) enabling the inspection personnel to generate a moving operation instruction, and the visual field of the inspection personnel moves; (6) generating an interactive operation instruction by the inspection personnel, and popping up a parameter label page on the front-end display; and (7) repeating the steps (5) and (6). According to the inspection method, the inspection personnel can visually and vividly know the inspection condition without going out, the inspection efficiency is improved, and the problems of misjudgment and the like are reduced.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

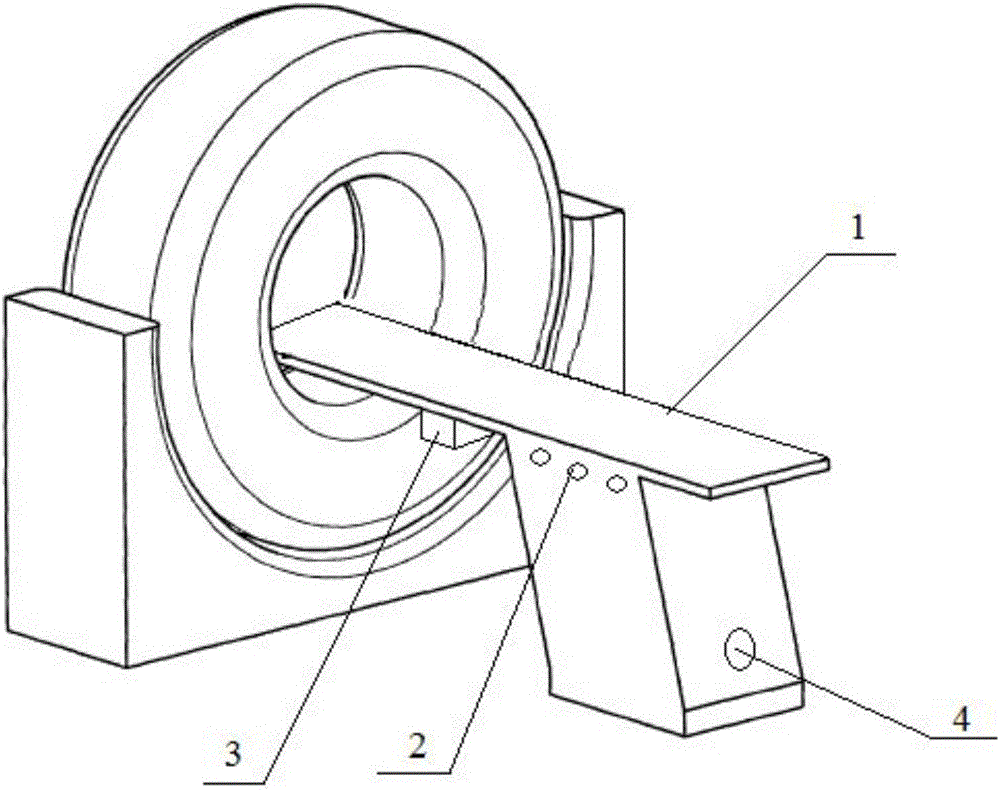

Human body pressure alleviation device for computed tomography (CT)

InactiveCN103815927AReduce tensionGuaranteed inspection effectComputerised tomographsTomographyMedicineComputing tomography

The invention discloses a human body pressure alleviation device for computed tomography (CT). The human body pressure alleviation device for CT comprises an examining table, air outlets, an oxygen bottle and an audio device; wherein the air outlets are formed in two sides of the examining table, the oxygen bottle is arranged on one side of the examining table and is connected to the air outlets, and the audio device is arranged at the lower part of the examining table. By adopting the human body pressure alleviation device, the air outlets are formed around the examining table to release oxygen, and the audio device plays light music, so that an examinee is relaxed, the tension emotion is alleviated to some extent, and the examining effect is ensured; the human body pressure alleviation device is simple in structure, convenient to operate and reduced in cost, is improved on the existing equipment, and better solves the problem that during CT examination, the examining effect is influenced due to tension of the examinee.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

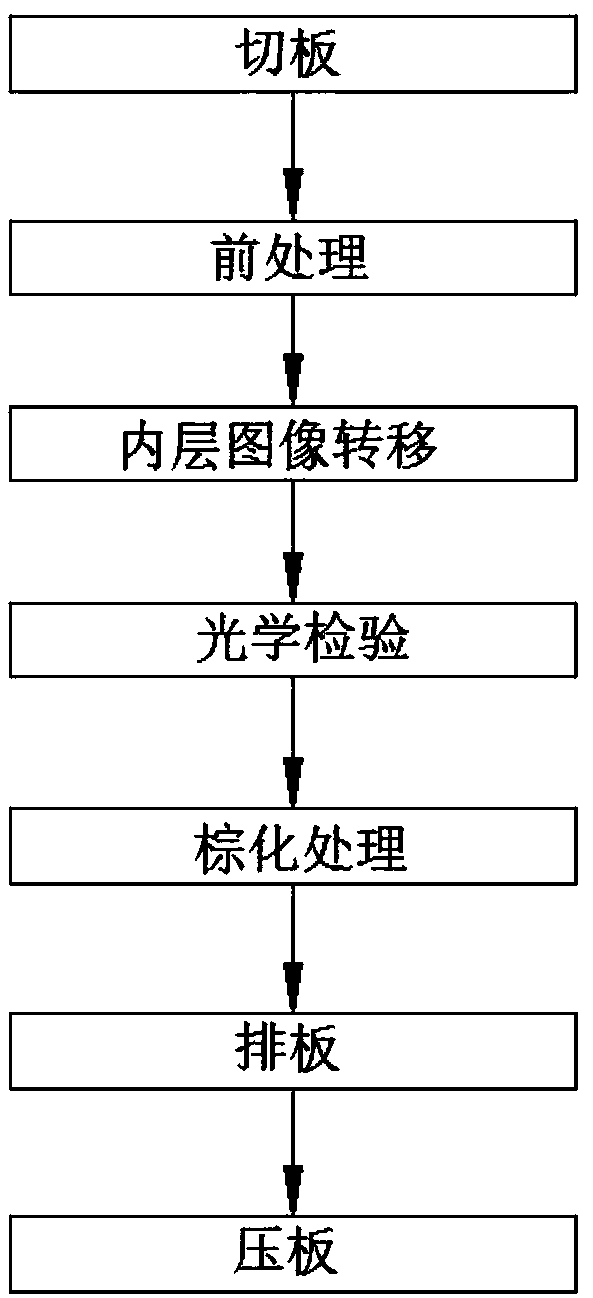

Circuit-board internal layer making technology

InactiveCN108449888AGood dimensional stabilityImprove reliabilityPrinted circuit liquid treatmentMultilayer circuit manufactureHigh concentrationUltraviolet lights

The invention discloses a circuit-board internal layer making technology. The technology comprises the following steps of S1, cutting a plate: setting a plate corner to be a round corner, cleaning cutting plate dust, removing a glue mark on the plate, and removing moisture absorbed by a sheet during storage through glazing; S2, carrying out pre-processing; S3, carrying out internal layer image transferring: firstly, uniformly attaching photosensitive ink to a copper surface and carrying out coating processing, then, using ultraviolet light energy to harden a selective local bridge frame, and then, using sodium carbonate to dissolve and wash the ink which is not exposed, leaving a photosensitive portion, carrying out etching to etch away the copper surface of an unexposed exposed-copper portion, and finally, removing a film protecting a line copper surface by sodium oxide with a higher concentration; S4, carrying out optical inspection; S5, carrying out brown processing: cleaning the copper surface through acid pickling, removing the oily substance of the copper surface, providing adaptive preprocessing for mitigating a strengthening drug before browning through preimpregnation, and finally, drying a copper plate surface; S6, typesetting; and S7, pressing the plate.

Owner:南浔双林荣丰磁材厂

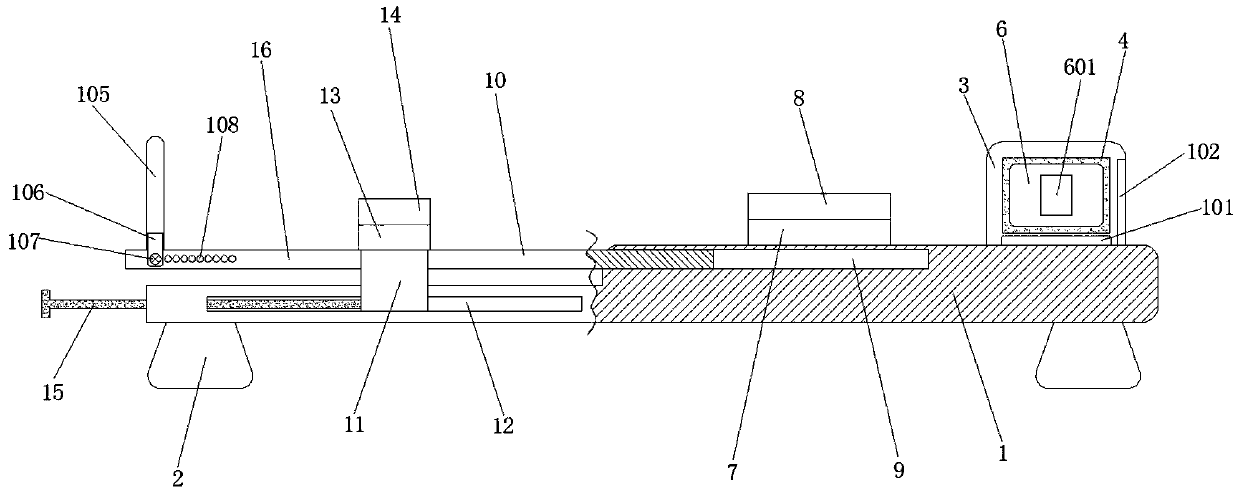

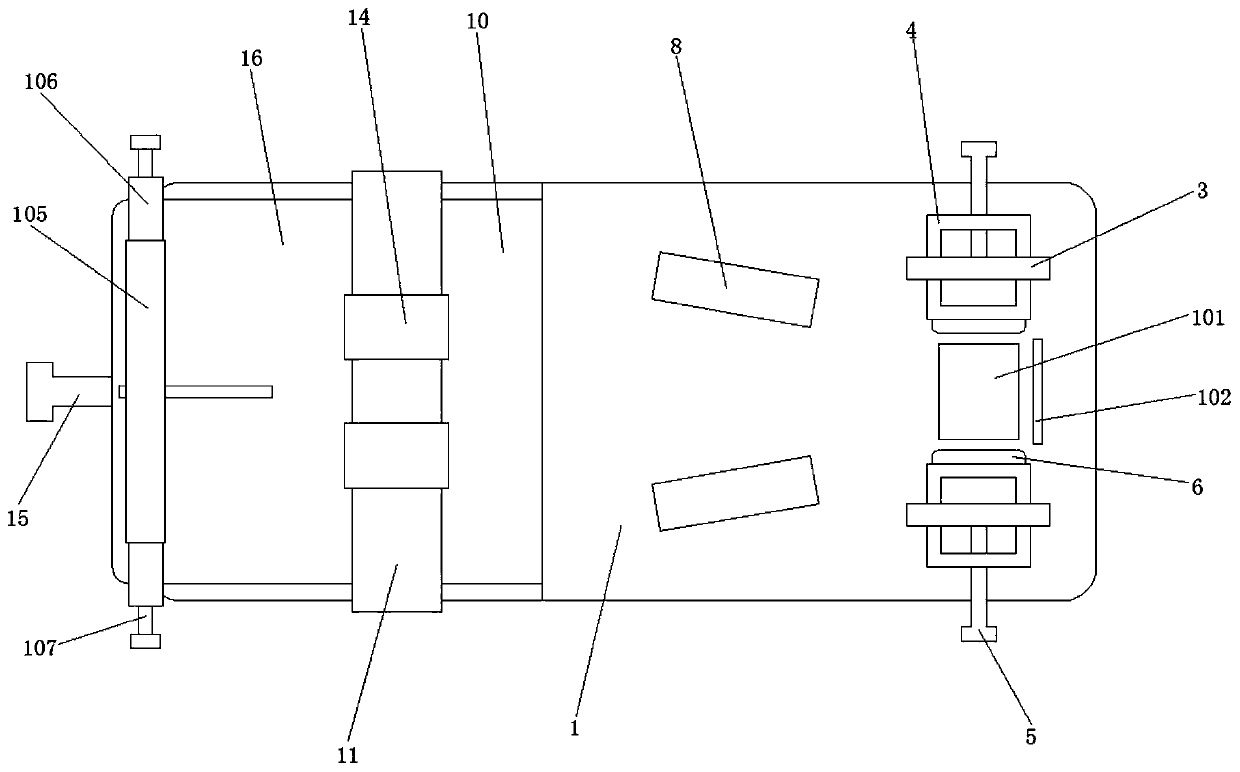

A working method of a medical capsule endoscope-assisted examination bed

InactiveCN108670681BChange angle automaticallyNot easy to lose and damageOperating tablesBiomedical engineeringCapsule Endoscopes

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

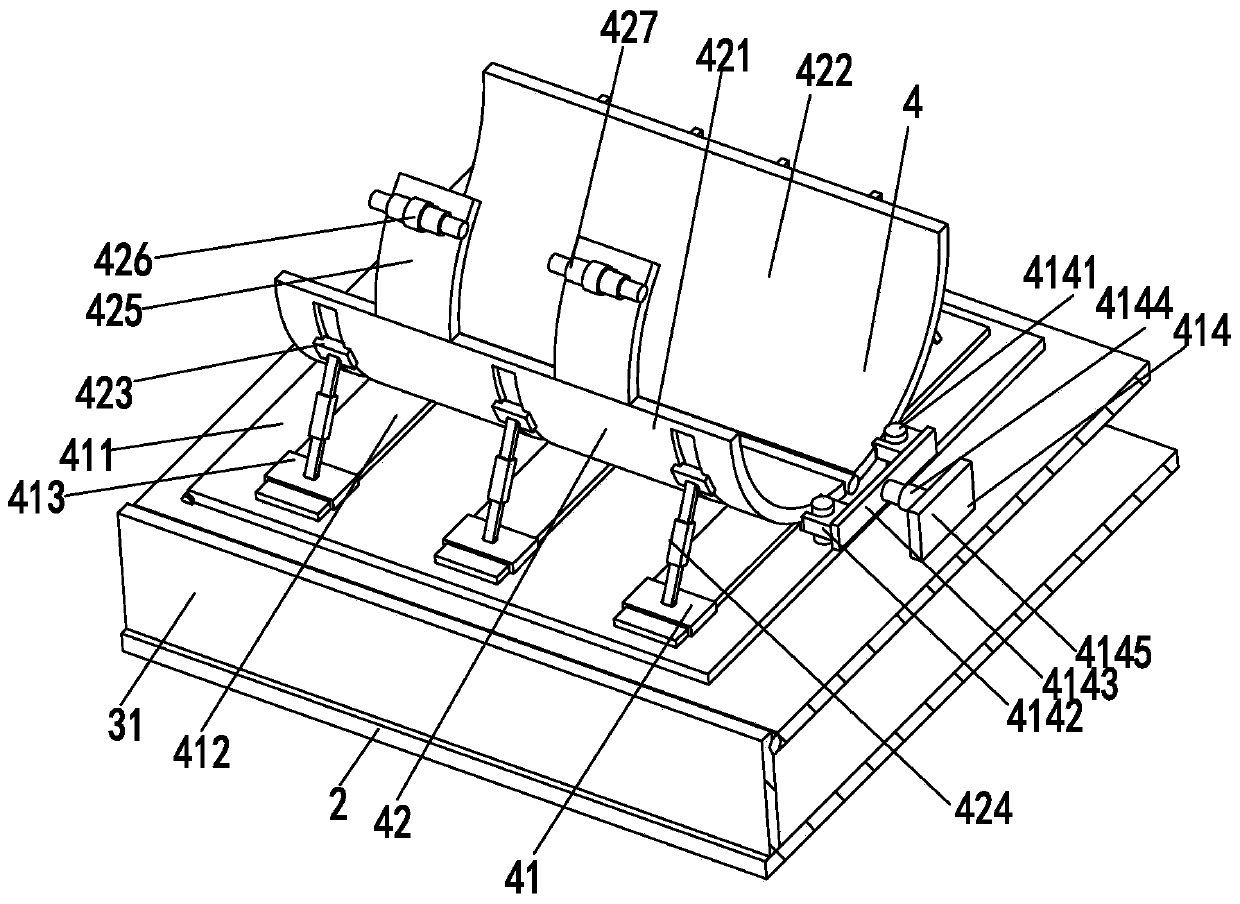

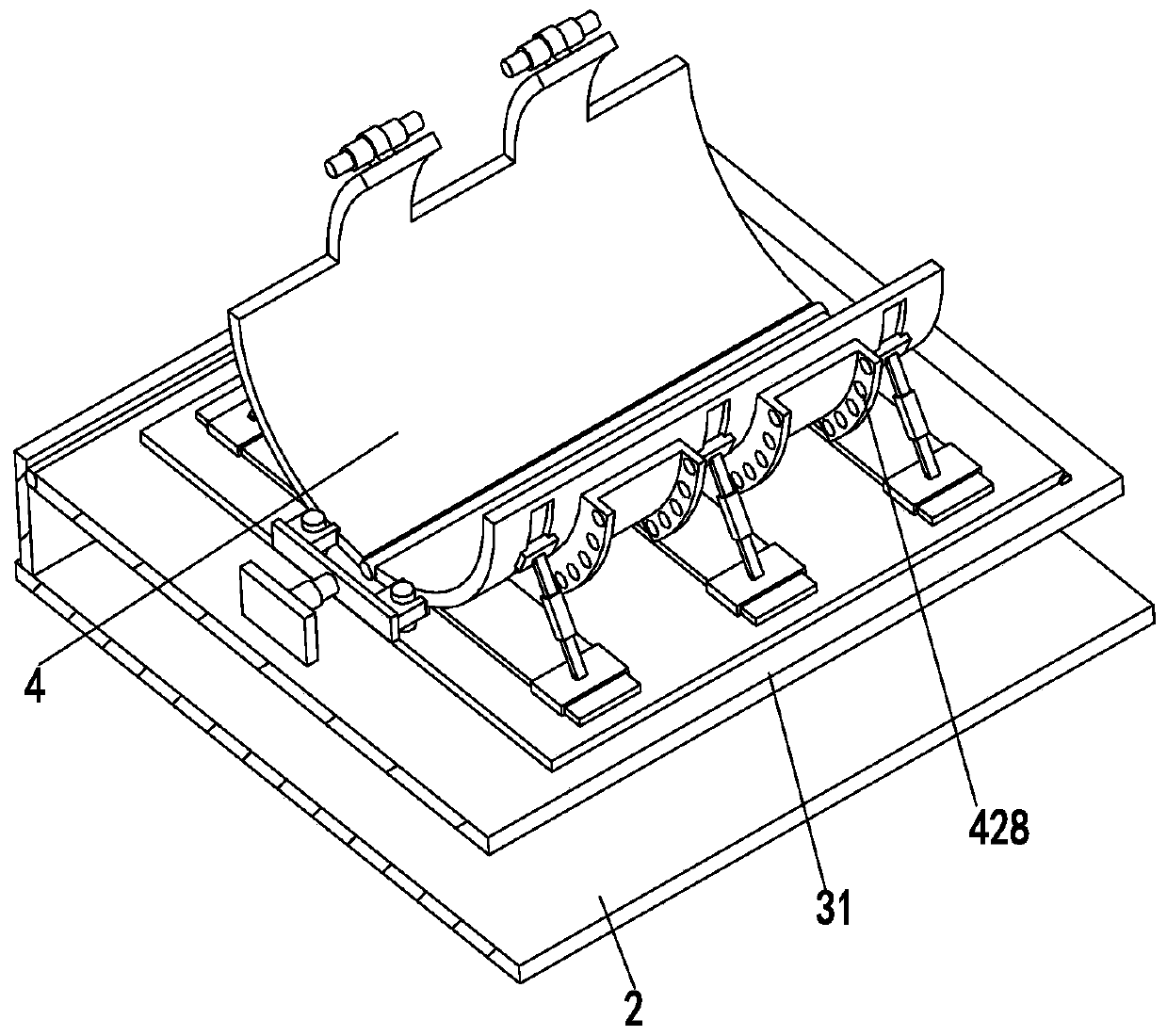

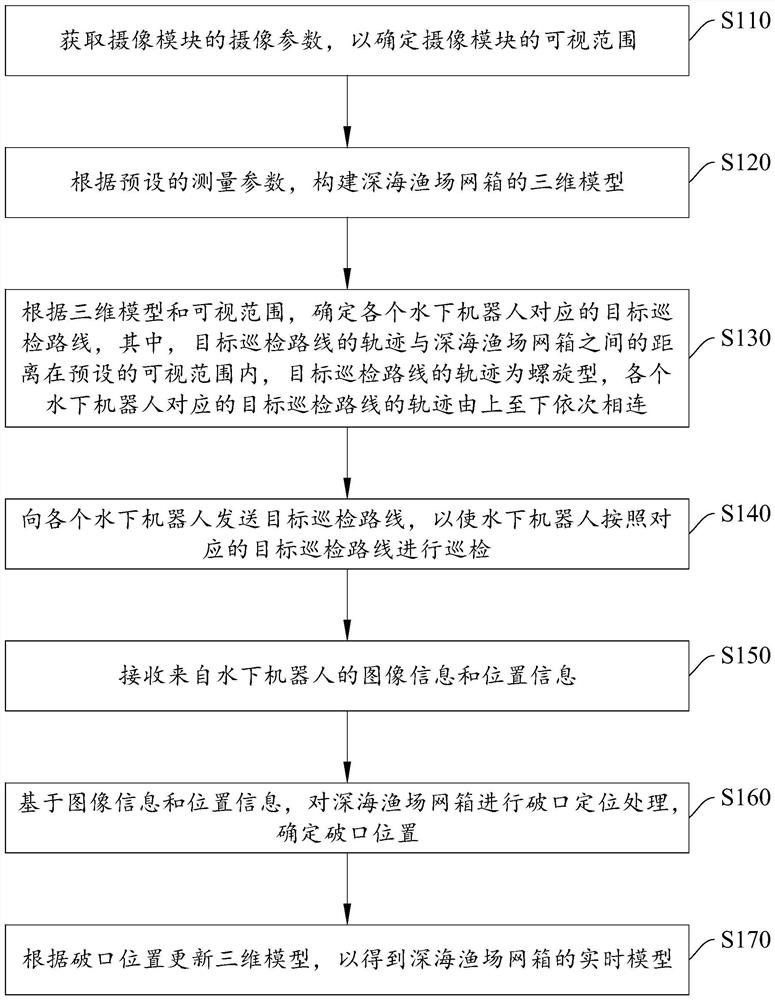

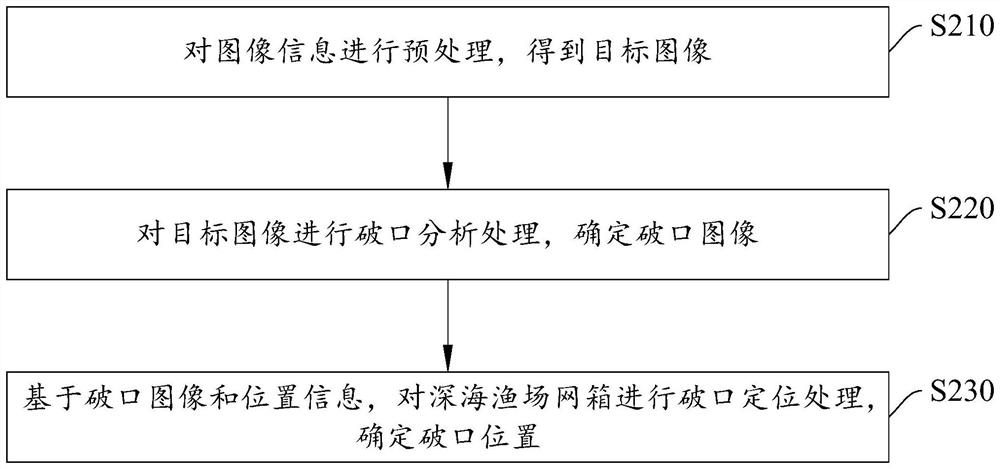

Deep sea fishing ground net cage inspection method, device and system and storage medium

PendingCN114852289AAvoid Missed Check SituationsAvoid double checkingClimate change adaptationUnderwater equipmentMarine engineeringFishing

The invention provides a deep sea fishing ground net cage inspection method, device and system and a storage medium, and the method comprises the steps: obtaining camera shooting parameters of a camera shooting module, so as to determine a visual range; constructing a three-dimensional model of the deep sea fishing ground net cage according to preset measurement parameters; according to the three-dimensional model and the visual range, a target inspection route corresponding to each underwater robot is determined, and the distance between the track of the target inspection route and the deep sea fishing ground net cage is within a preset visual range; sending the target inspection route to each underwater robot to enable the underwater robot to inspect according to the corresponding target inspection route; receiving image information and position information from the underwater robot; and performing crevasse positioning processing on the deep sea fishing ground net cage, determining a crevasse position, and updating the three-dimensional model to obtain a real-time model of the deep sea fishing ground net cage. According to the scheme provided by the embodiment of the invention, the inspection effect can be ensured, the inspection efficiency can be improved, and the crevasse position can be accurately positioned.

Owner:WUYI UNIV

Building fire-fighting facility detection device

InactiveCN113739996AImplement automatic stretchingGuaranteed inspection effectFluid-tightness measurement using fluid/vacuumWater pipeIndustrial engineering

The invention relates to the technical field of fire-fighting facilities, in particular to a building fire-fighting facility detection device which comprises a base and a supporting frame fixedly connected with the base; a water injection pipe, fixedly connected with the base; a supporting mechanism, connected with the supporting frame; a control mechanism, arranged on the inner side of the base and connected with the supporting mechanism; wherein the control mechanism comprises a driving component, a driving component, a driving component and a control component, and the driving component is connected with the base; a transmission assembly, arranged between the driving assembly and the supporting mechanism; and a positioning assembly, arranged on the outer side of the driving assembly and connected with the base and the transmission assembly. Through arranging the supporting mechanism, and using the control mechanism for driving the supporting mechanism, automatic stretching of the fire hose is achieved, and the occupied space of the device in use is greatly reduced; and the use convenience of the device is improved.

Owner:孙科

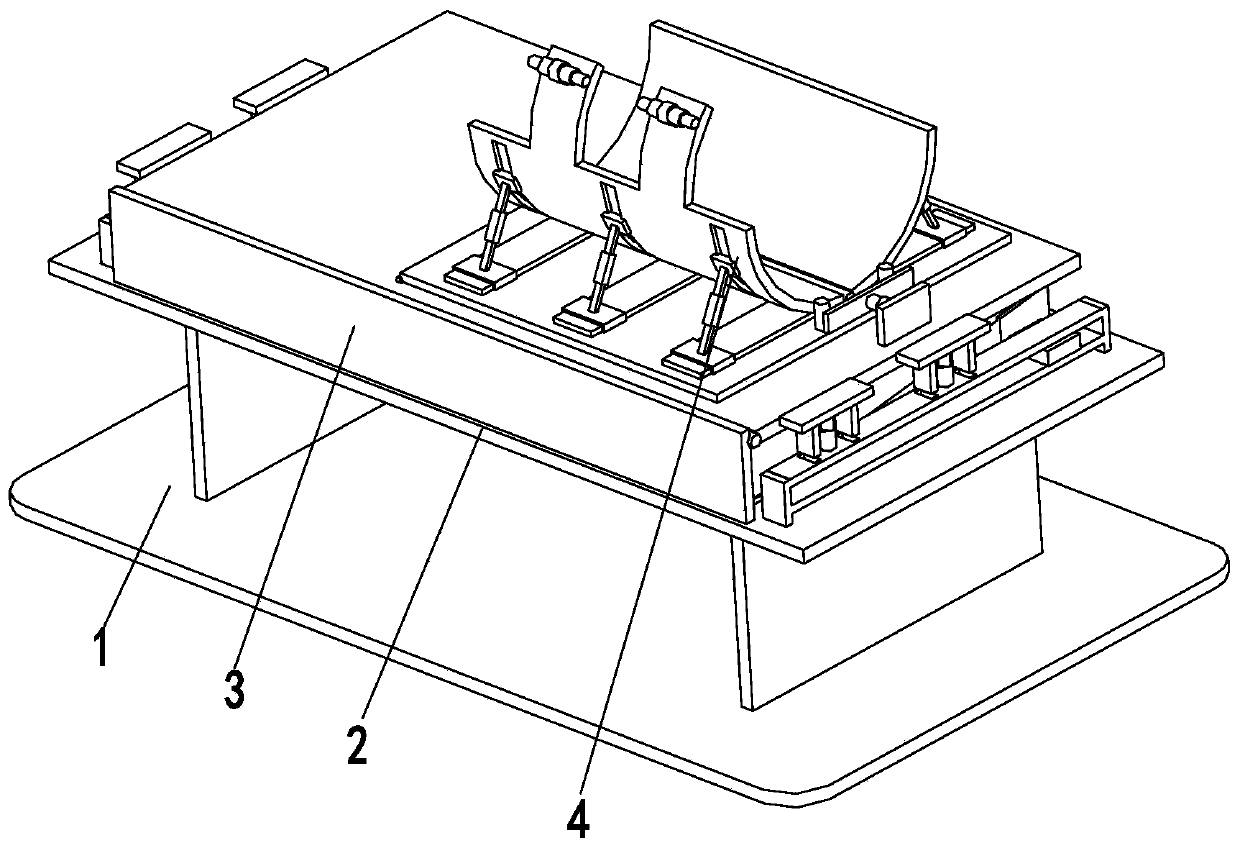

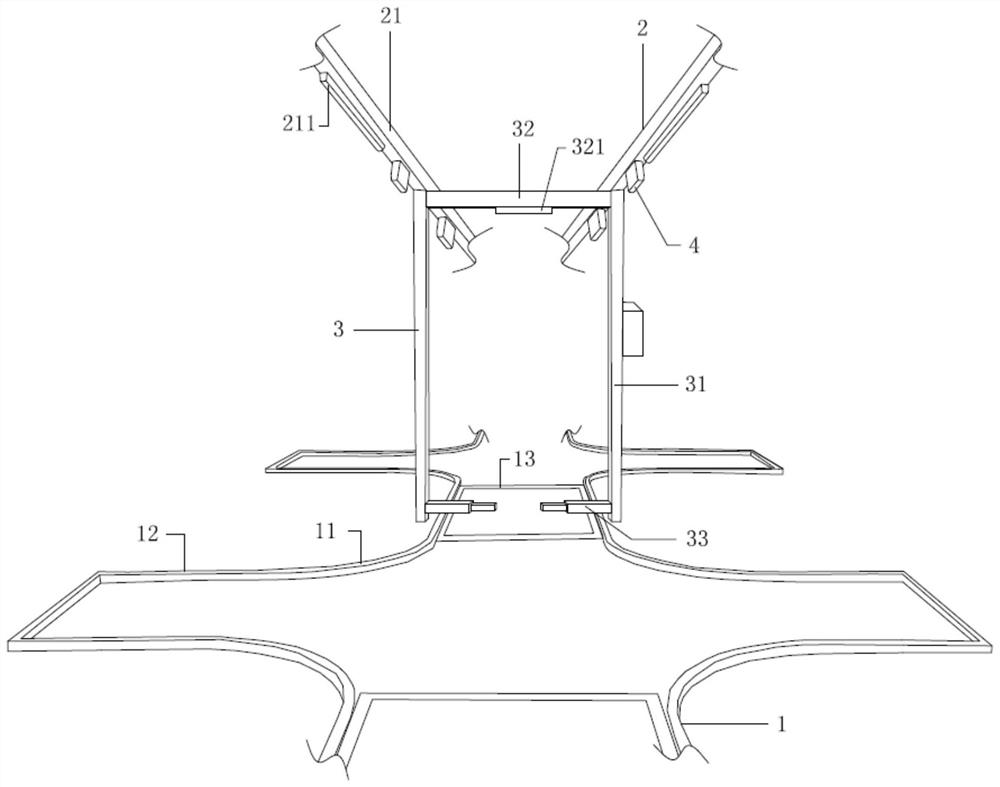

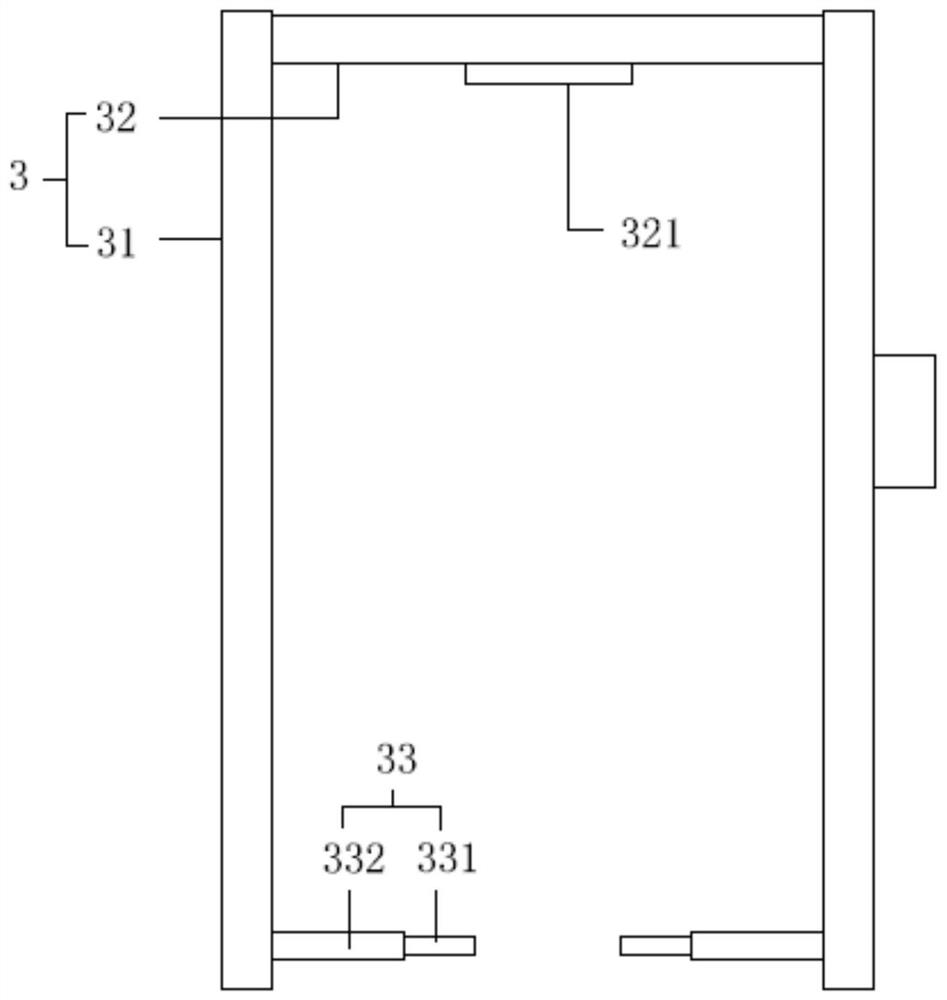

Adjustable anus dilator for pediatric general surgery department

The invention discloses an adjustable pediatric general surgery department anal dilator which comprises a bottom plate, a transverse moving assembly slidably arranged at the rear end of the bottom plate, a driving assembly rotatably connected in the bottom plate and capable of controlling operation of the transverse moving assembly, mounting plates fixedly arranged at the four corners of the top of the bottom plate, and linkage assemblies rotatably connected in the mounting plates and capable of being controlled by the driving assembly to operate. According to the device, the degree of anal dilatation of a child patient can be adjusted to be within the range required by medical staff, so that the medical staff can conveniently and clearly check the focus condition of the child patient, the working difficulty of the medical staff is reduced, and the checking effect of the child patient is ensured. According to the device, linkage type mechanical movement steps can be achieved only by using a rotating rod, so that a first arc-shaped plate and a second arc-shaped plate are in a synchronous operation state, and the convenience of using the device by medical staff is improved.

Owner:XIAN CHILDRENS HOSPITAL

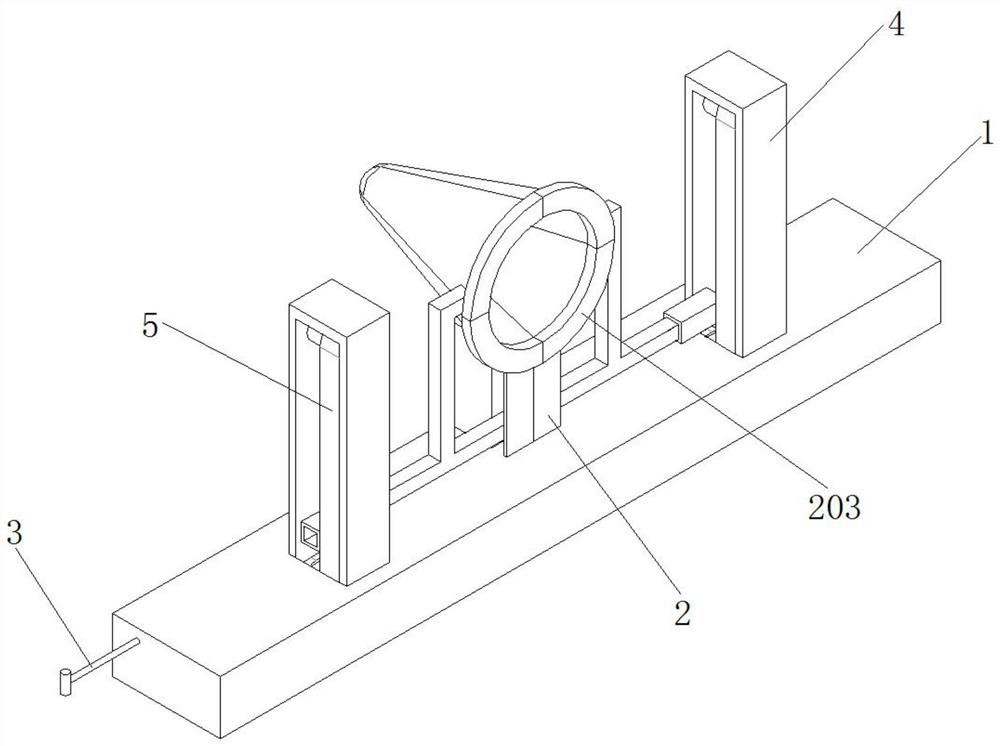

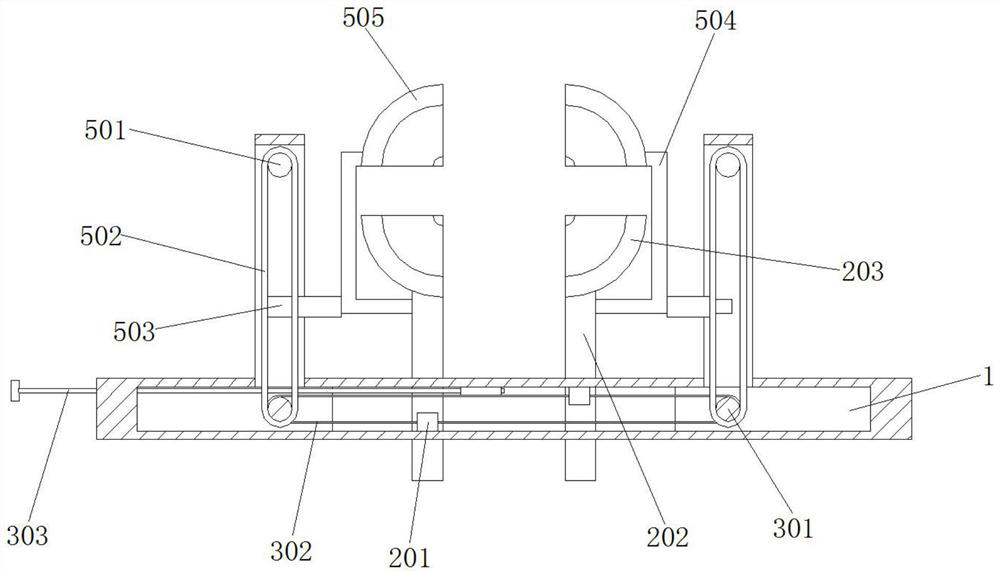

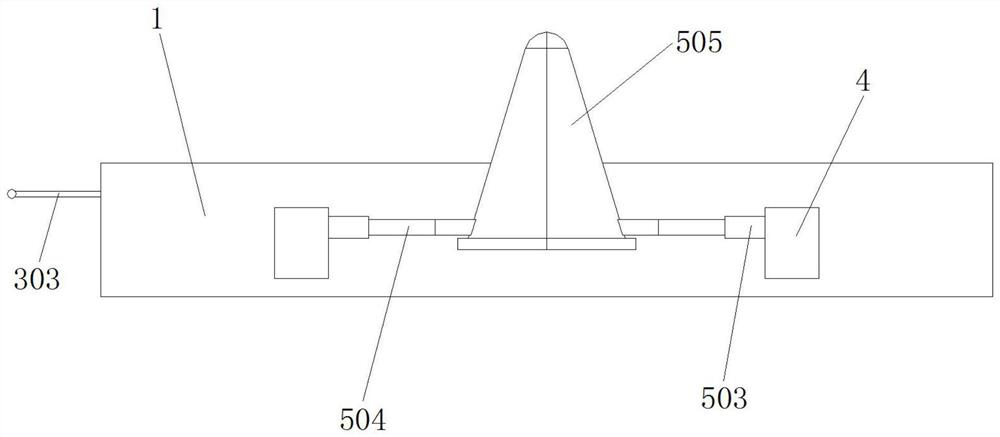

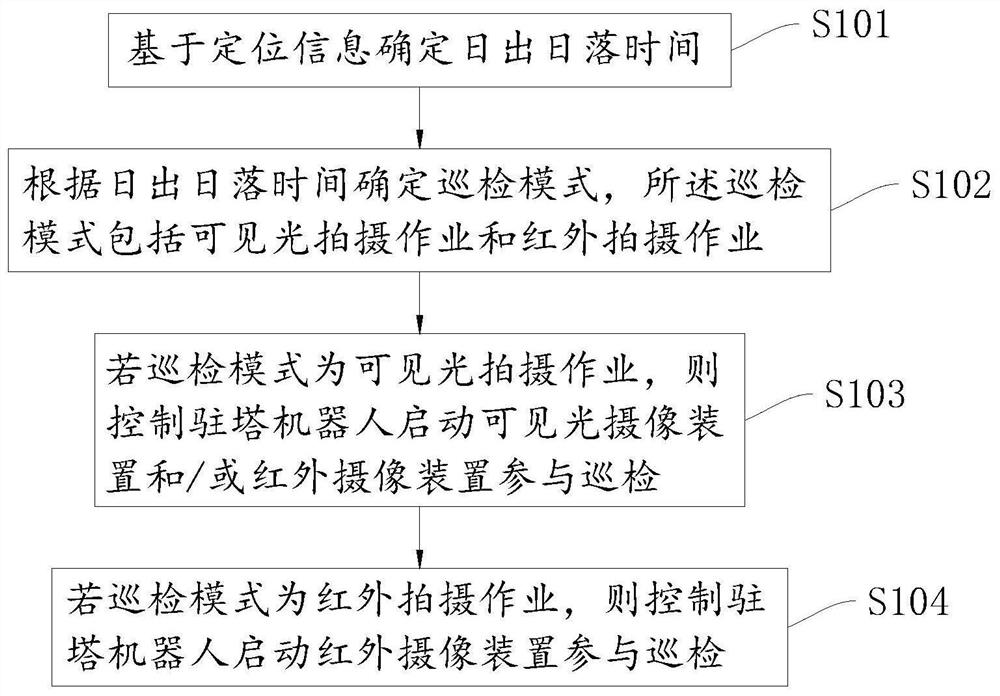

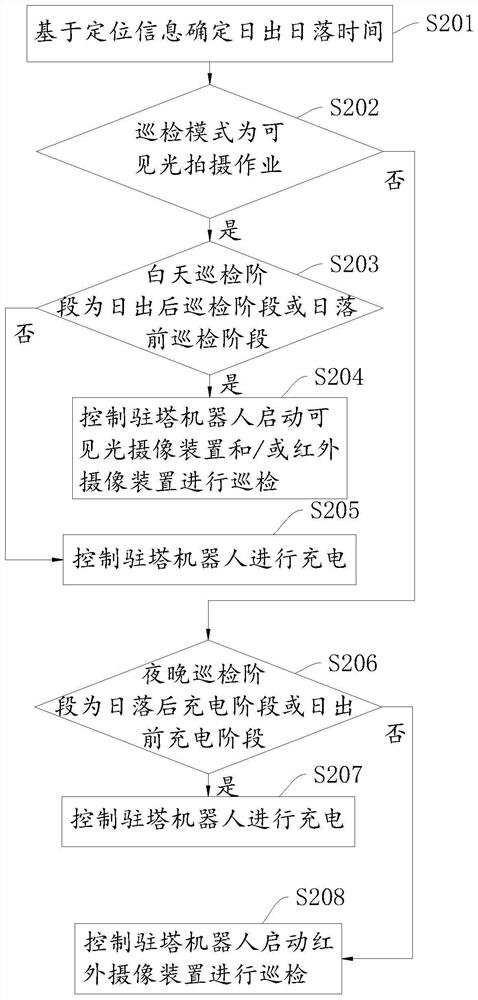

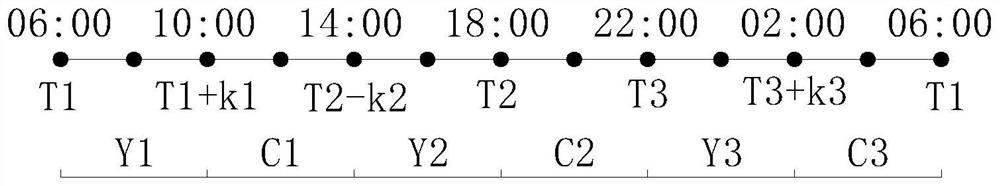

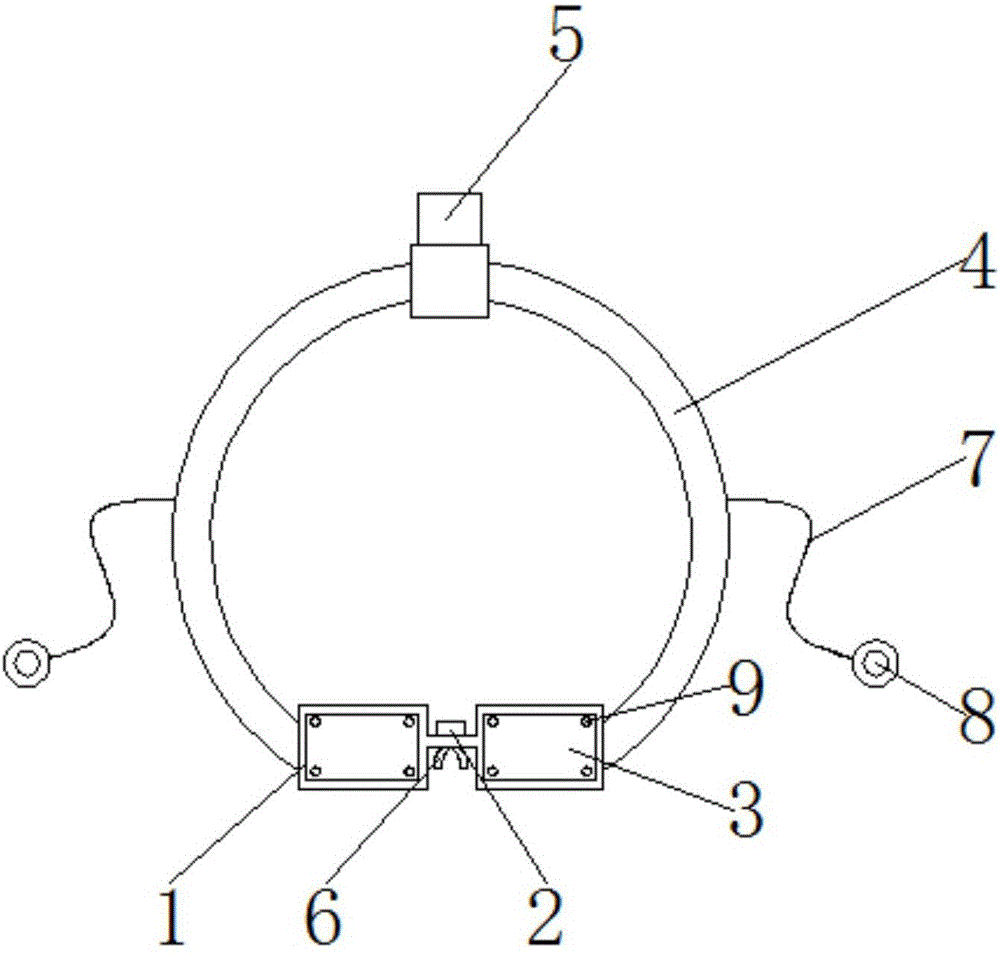

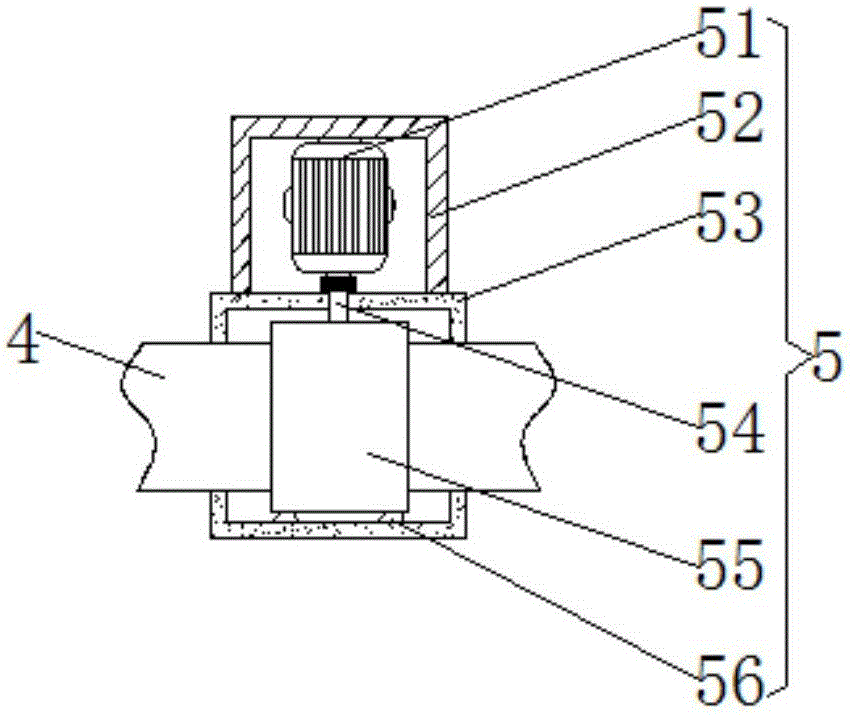

A transmission line tower-based inspection method and device

ActiveCN110910527BEnsure safetyGuaranteed inspection effectTelevision system detailsChecking time patrolsEngineeringSunset

The embodiment of the present application discloses a method and a device for patrolling and inspecting a transmission line tower-based robot. The technical solution provided by the embodiment of the application determines the local sunrise and sunset time according to the positioning information of the robot stationed in the tower, and determines the corresponding time of day and night according to the sunrise and sunset time, and determines the visible light shooting during the day and night respectively In the inspection mode of operation and infrared shooting operation, the visible light camera device and the infrared camera device are activated for inspection together or the infrared camera device is used for inspection alone, which meets the requirements of inspection and shooting under different light conditions and ensures the inspection effect. At the same time, it also judges whether to carry out inspection operations according to the local weather, and avoids bad weather for inspections to ensure the safety and inspection effect of the robots stationed in the tower.

Owner:中科开创(广州)智能科技发展有限公司

Magnetic resonance inspection eye patch

The invention discloses a magnetic resonance inspection eye patch, relating to the technical field of medical treatment. The magnetic resonance inspection eye patch comprises a spectacle-frame, wherein the top of the spectacle-frame is fixedly connected with a controller, a lens is fixedly connected with the spectacle-frame, and both side of the spectacle-frame are fixedly connected with a rubber belt. One end of the rubber belt, away from the spectacle-frame, is fixedly connected by a control device, wherein the control device comprises a controller shell, the top of the controller shell is fixedly connected with a motor box, the top of the inner cavity of the motor box is fixedly connected with an electric motor, an output shaft of the electric motor penetrates through the top of the controller shell and is fixedly connected with a live shaft, and the surface of the live shaft is provided with a rotary drum. According to the magnetic resonance inspection eye patch, the control device and the rotary drum are improved, the eye patch can well adjust the effective length of the rubber belt, and the problem that eye patch is too tight or too loose due to the large gap between the effective length and the suitable length of the rubber belt is avoided.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

Automatic assembly line for new energy intelligent sightseeing vehicle

PendingCN112606927AShorten the lengthGuaranteed assembly effectVehiclesNew energyControl engineering

The invention discloses a new energy intelligent sightseeing vehicle automatic assembly line which comprises a ground track, a guide frame and lifting devices, the ground track comprises two parallel flanges, the flanges are provided with a plurality of protruding parts which are arranged in the length direction of the flanges and protrude towards the outer side of the ground track, and the protruding parts of the two flanges are symmetrically arranged on the two sides of the ground track. The guide frame comprises two guide rails arranged in parallel, the multiple lifting devices are arranged in the length direction of the ground track at equal intervals, the lifting devices and the protruding parts are arranged at intervals, each lifting device comprises two lifting machine stand columns and a limiting cross rod, the two lifting machine stand columns are symmetrically arranged on the two sides of the ground track, and the two ends of the limiting cross rod are fixedly installed on the two lifting machine stand columns respectively. According to the new energy intelligent sightseeing vehicle automatic assembly line, the width of a workshop is fully utilized to shorten the length of the new energy intelligent sightseeing vehicle automatic assembly line, the assembly effect of products is checked every several assembly procedures, and the assembly effect of the whole vehicle is fully guaranteed.

Owner:苏州冬宝光电科技有限公司

Fixing device for auditory meatus examination

The invention relates to a fixing device for auditory meatus examination. The fixing device comprises a helmet, and circular through grooves are formed in the two sides of the helmet; a limiting cylinder is mounted at the top of the helmet, a ball is rotatably mounted in the limiting cylinder, a connecting rod is fixedly mounted on the surface of the ball, an external threaded rod is fixedly mounted at the end of the connecting rod, and an internal threaded cylinder is mounted on the external threaded rod; a top plate is fixedly mounted at the top of the internal thread cylinder; the end of the top plate is rotationally connected with a telescopic plate; a guide sleeve is in sliding fit with the exterior of the telescopic plate; the bottom of the guide sleeve is fixedly connected with an L-shaped plate; a guide rod is vertically and fixedly mounted on the vertical section of the L-shaped plate; a pressing plate is in sliding fit with the guide rod; and a lead screw is rotationally installed on the vertical section of the L-shaped plate, penetrates through the pressing plate and is matched with the pressing plate through threads. The head of a subject is fixed and supported through the helmet, so that the head of the subject is prevented from deviating. The effect of adjusting and fixing the head of the subject in the examination process is achieved.

Owner:THE AFFILIATED HOSPITAL OF HANGZHOU NORMAL UNIV

A computerized tomography device for stress relief in the human body

InactiveCN103815927BReduce tensionGuaranteed inspection effectComputerised tomographsTomographyMedicineComputing tomography

The invention discloses a human body pressure alleviation device for computed tomography (CT). The human body pressure alleviation device for CT comprises an examining table, air outlets, an oxygen bottle and an audio device; wherein the air outlets are formed in two sides of the examining table, the oxygen bottle is arranged on one side of the examining table and is connected to the air outlets, and the audio device is arranged at the lower part of the examining table. By adopting the human body pressure alleviation device, the air outlets are formed around the examining table to release oxygen, and the audio device plays light music, so that an examinee is relaxed, the tension emotion is alleviated to some extent, and the examining effect is ensured; the human body pressure alleviation device is simple in structure, convenient to operate and reduced in cost, is improved on the existing equipment, and better solves the problem that during CT examination, the examining effect is influenced due to tension of the examinee.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

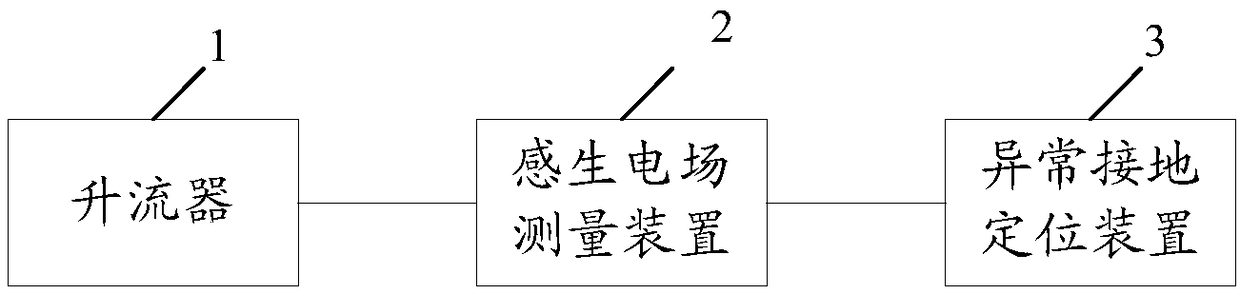

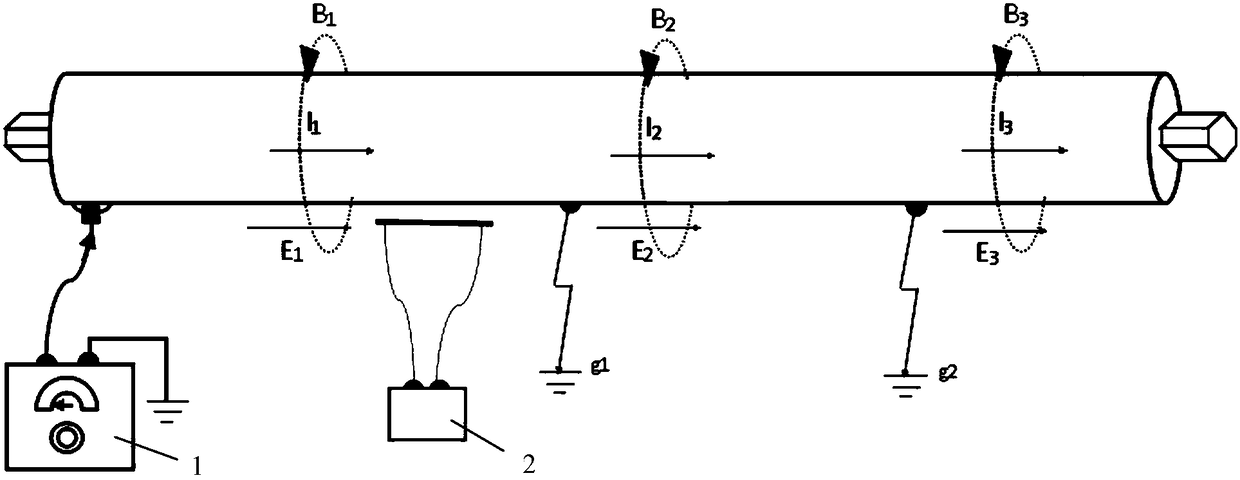

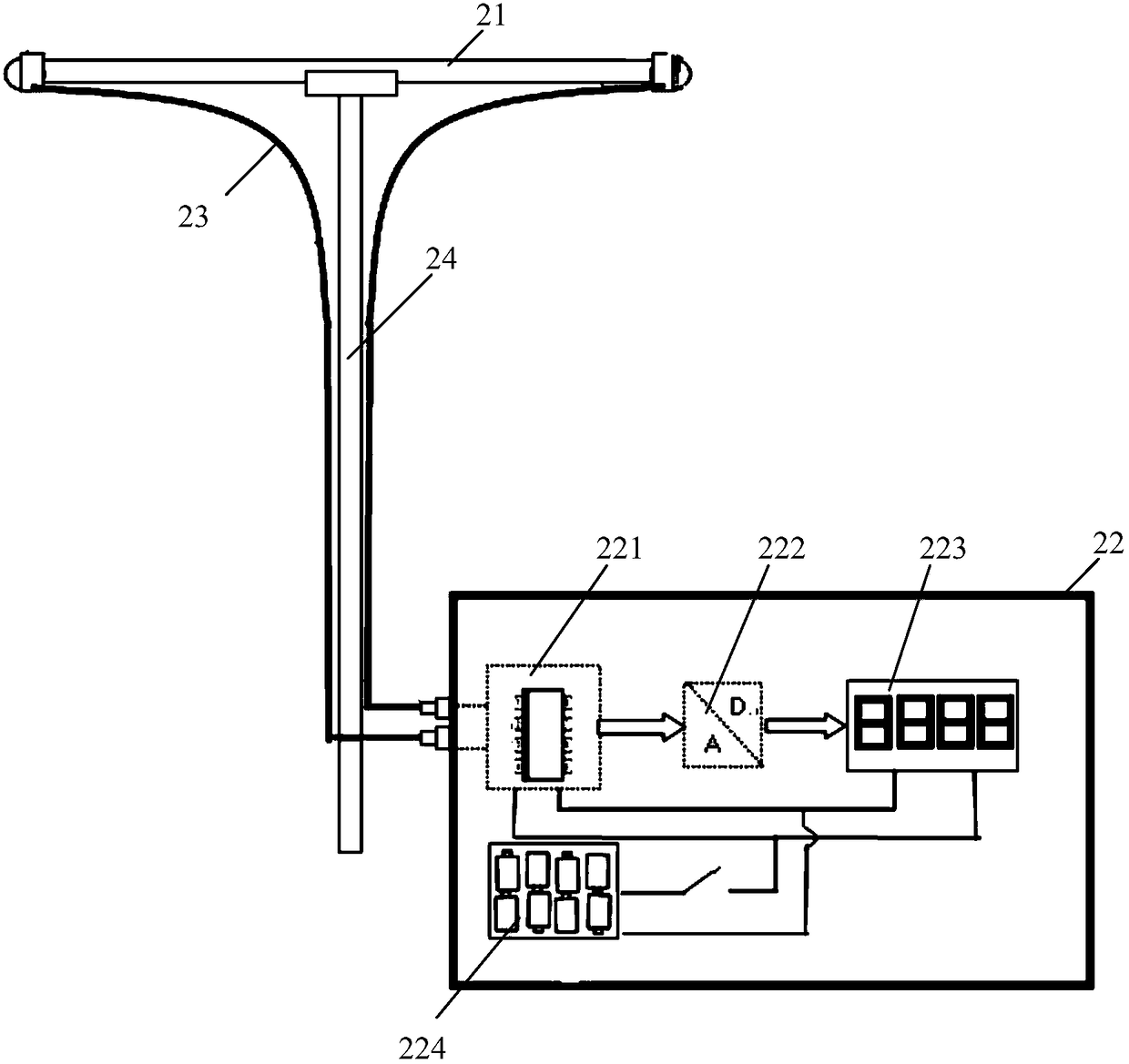

Locating method and system for detecting abnormal grounding of large enclosed bus casing

ActiveCN108414875AImprove work efficiencyShorten maintenance cycleElectrical testingMeasurement deviceMeasurement point

The invention discloses a locating method and system for detecting abnormal grounding of a large enclosed bus casing. The system comprises a current step-up device, an induced electric field measurement device and an abnormal grounding locating device. A preset AC is input to the enclosed bus casing to be detected, induced electric field data of measuring points in the enclosed bus casing to be detected is measured distance by distance along a direction of an enclosed bus to be detected, and whether the induced electric field difference between two adjacent measuring points is greater than a preset threshold is determined to locate a position of abnormal grounding rapidly. Thus, the positioning system can be used to locate abnormal grounding rapidly, and compared with a manual visual detection method, the working efficiency is improved greatly, the problem checking period is shortened, the engineering cost is reduced, a fault can be found more successfully, detection omission of manualsearching can be avoided effectively, the detection quality is improved, and a detection effect is ensured.

Owner:中广核工程有限公司 +1

A special barium sulfate suspension for double-contrast radiography x-ray examination of digestive tract and preparation method thereof

InactiveCN103893782BEliminate stickinessGood expansion performanceX-ray constrast preparationsSolution deliverySide effectMedicine

The invention relates to barium sulfate suspension specially used for digestive tract dual-contrast radiography X-ray examination and a preparation method of a medicine thereof. The barium sulfate suspension is prepared from medical barium sulfate serving as a main raw material, as well as glucomannan and water. The preparation is a filled liquid-state finished product, is reasonable in design, economical, practical, does not have toxic or side effect, can provide accurate and reliable detection result, is not coagulated for a long time and is easily and uniformly mixed in use, and is an ideal liquid-state barium suspension preparation for digestive tract dual-contrast radiography X-ray examination.

Owner:莱芜钢铁集团有限公司医院

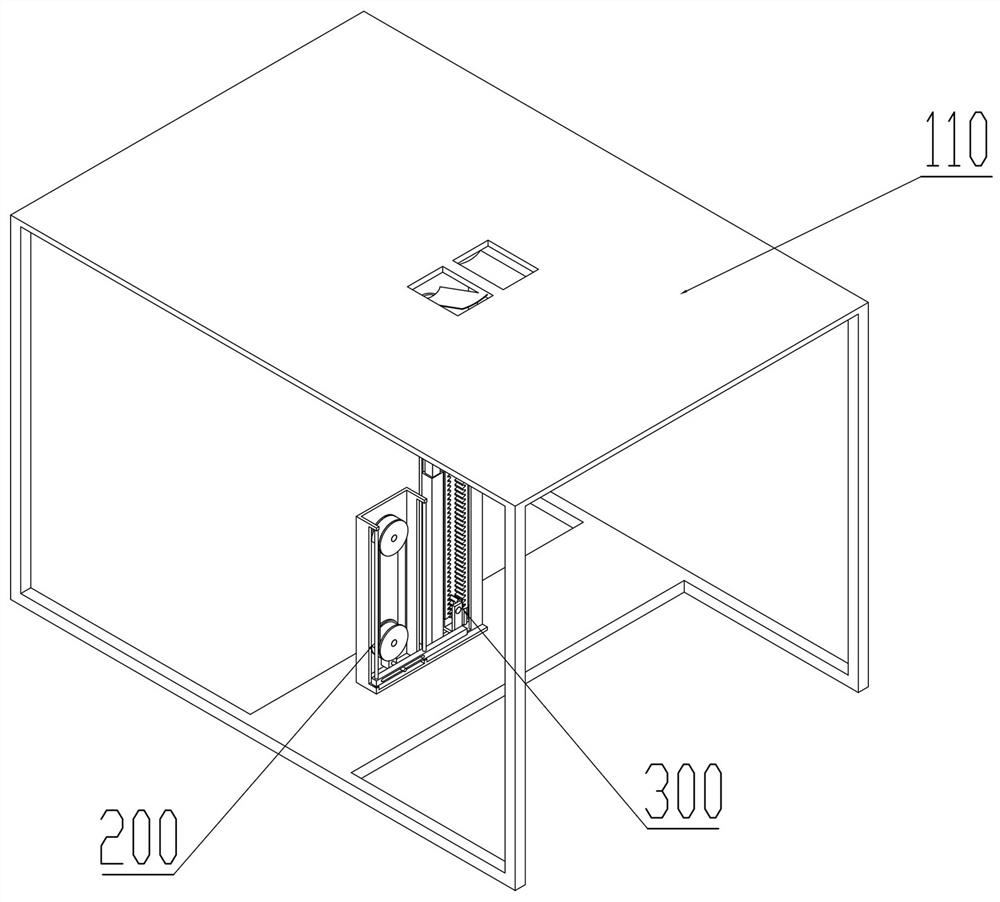

Scanner omentum assembly for total mammary gland ultrasound system

PendingCN113951929AImprove structural strengthEasy to fixDiagnostic probe attachmentOrgan movement/changes detectionSurgeryMammary gland structure

The invention discloses a scanner omentum assembly for a total mammary gland ultrasound system, which comprises a scanner motion assembly and a scanner omentum clamping assembly, the scanner omentum clamping assembly comprises an omentum upper clamping piece, a clamping omentum and an omentum lower clamping piece, the clamping omentum is arranged between the omentum upper clamping piece and the omentum lower clamping piece, the omentum upper clamping piece, the clamping omentum and the omentum lower clamping piece are assembled into a whole to form the scanner omentum clamping assembly, and the scanner omentum clamping assembly is installed on the scanner motion assembly. According to the scanner omentum assembly, the scanner motion assembly and the scanner omentum clamping assembly are arranged, and the scanner omentum clamping assembly is arranged to comprise the upper omentum clamping piece, the clamping omentum and the lower omentum clamping piece, so that the structural strength of the clamping omentum is higher, the clamping omentum is easier to fix, then the inspection effect of a probe is guaranteed, and the user experience is enhanced.

Owner:聚融医疗科技(杭州)有限公司

Lower limb positioning assembly for lower limb blood vessel color Doppler ultrasound

InactiveCN114190987AEasy to placeGuaranteed inspection effectPatient positioningPneumatic massageMassageApparatus instruments

The invention discloses a lower limb positioning assembly for lower limb blood vessel color Doppler ultrasound, and belongs to the technical field of medical instruments, and the lower limb positioning assembly is characterized by comprising a color Doppler ultrasound instrument and a bed body, two first push rods are fixedly mounted in the bed body, the right ends of the two first push rods are fixedly connected with sliding blocks, and auxiliary parts are arranged at the tops of the two sliding blocks; two connecting strips are fixedly connected to the right side of the auxiliary part, an integrally-formed positioning box is fixedly connected to the right ends of the two connecting strips, the positioning box is slidably connected to the top of the bed body, and two second push rods are fixedly installed in the positioning box. According to the lower limb fixing device, auxiliary fixing can be conducted on the lower limb of a patient, meanwhile, targeted adjustment can be conducted according to different patients, the practicability of the whole device is improved, in the lower limb fixing process of the patient, automatic massage can be conducted on the lower limb of the patient, and discomfort is reduced.

Owner:刘平

A cable sliding device for maintenance of high-voltage transmission lines based on intelligent UAV technology

ActiveCN113270814BReduce slidingGuaranteed inspection effectAircraft componentsApparatus for overhead lines/cablesUncrewed vehicleHigh tension line

Owner:SICHUAN HUADONG ELECTRICAL GRP

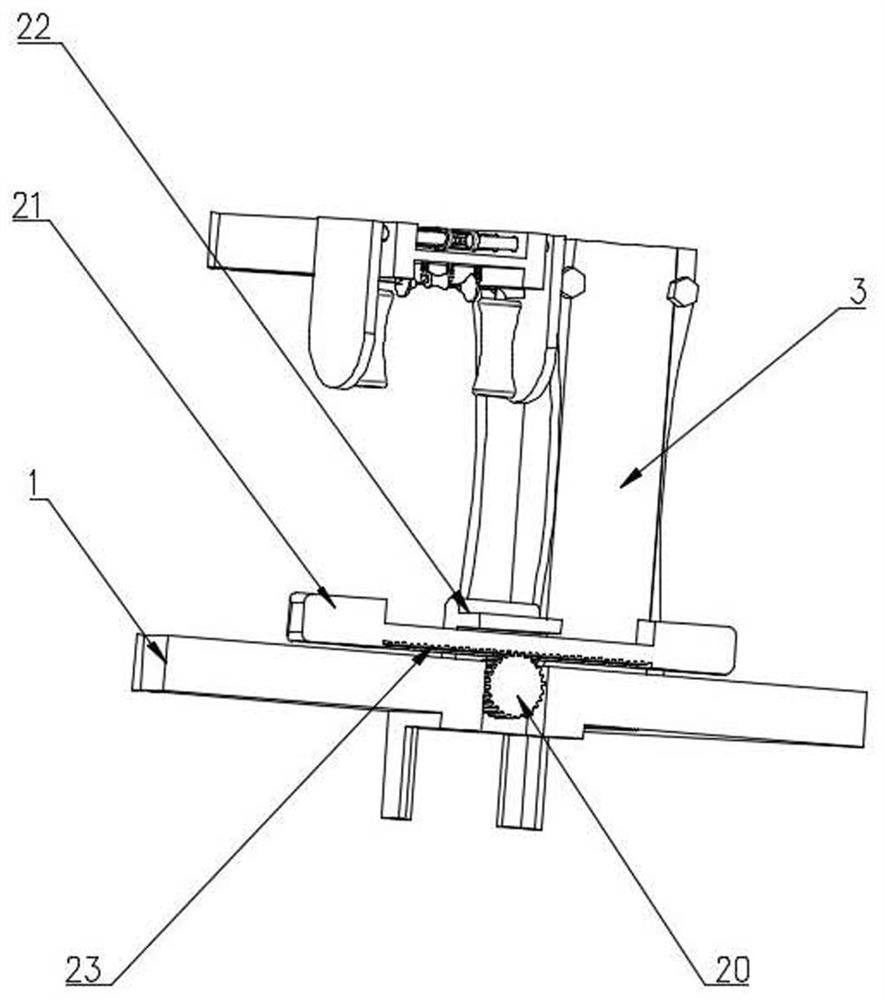

Auxiliary device for enteroscopy bed and operation method

The enteroscopy bed auxiliary device comprises a bed body, a power device and a driving device, the power device comprises a power base, a sliding rod and a driving block, the driving device comprises a driving base, a left rack, a left support, a right rack and a gear frame, the upper portion of the bed body is provided with two bed body holes in bilateral symmetry, and the lower portion of the bed body is provided with a bottom plate; the power device is fixedly connected with the bottom plate through the lower portion of the power seat, the left support and the right rack penetrate through two bed body holes respectively, and the driving device is fixedly connected with the right side of the power seat through the lower portion of the driving seat.

Owner:JIAMUSI UNIVERSITY

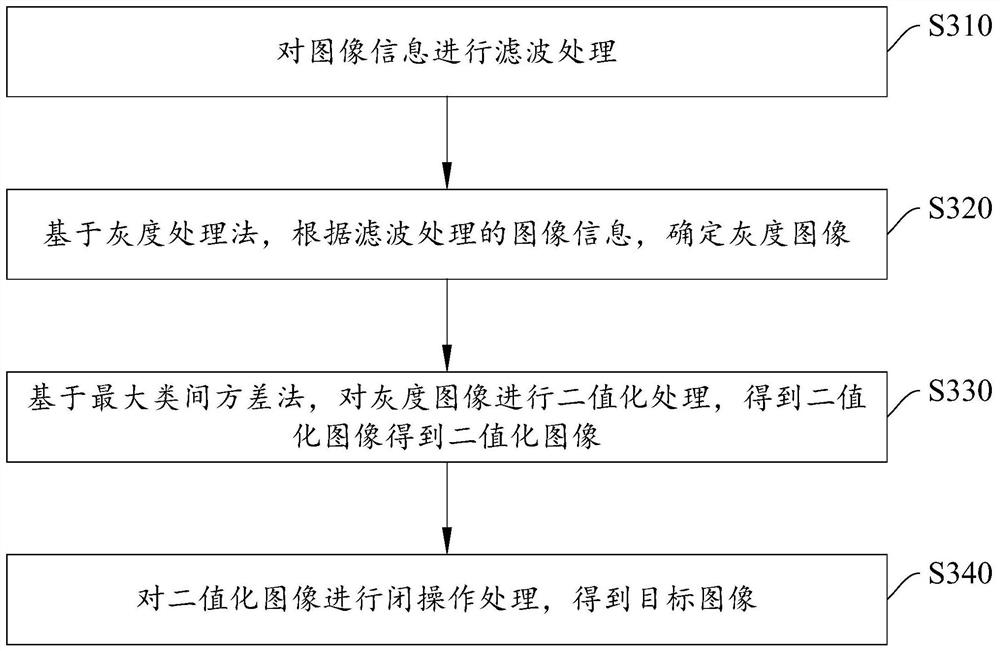

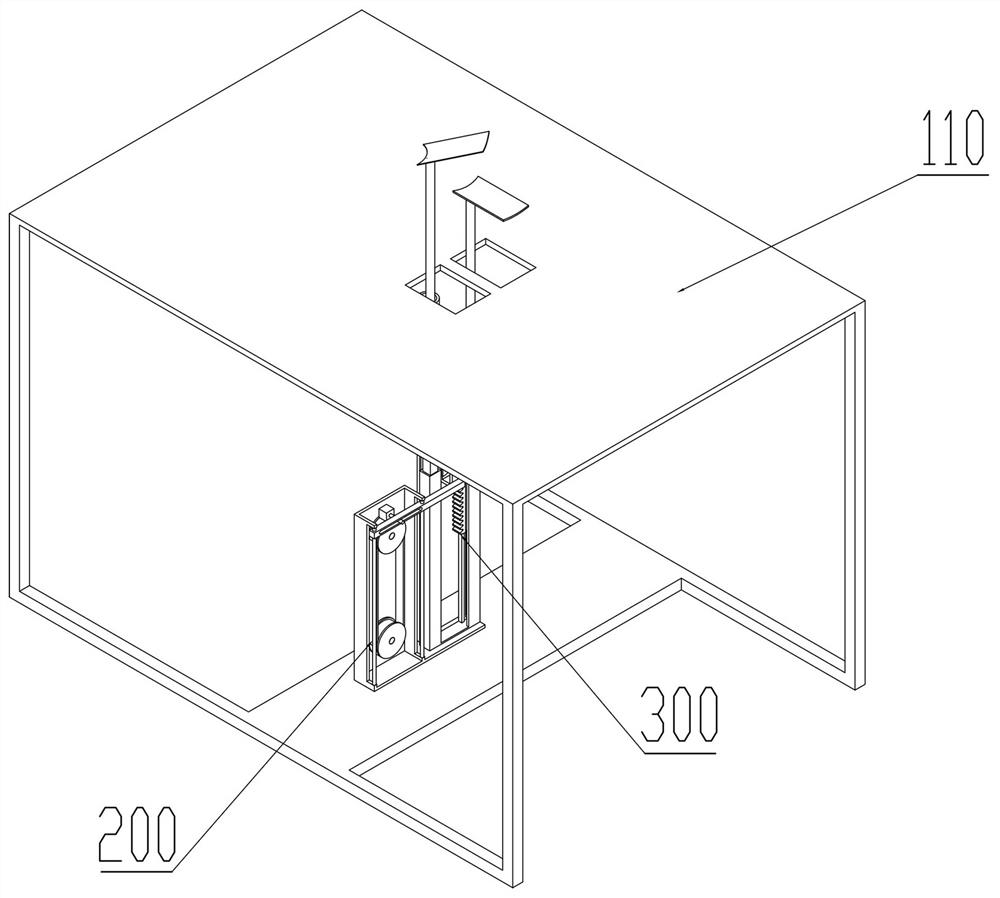

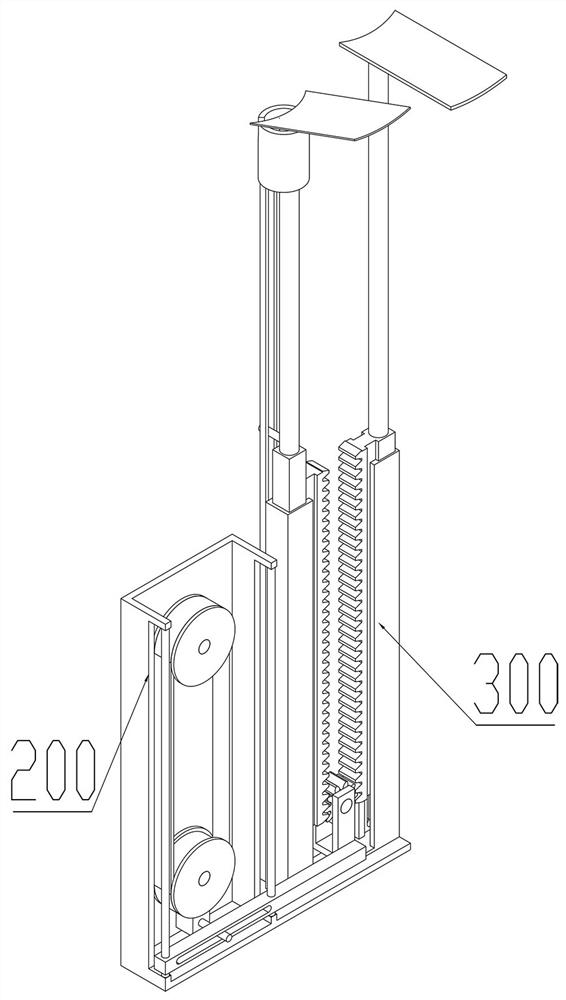

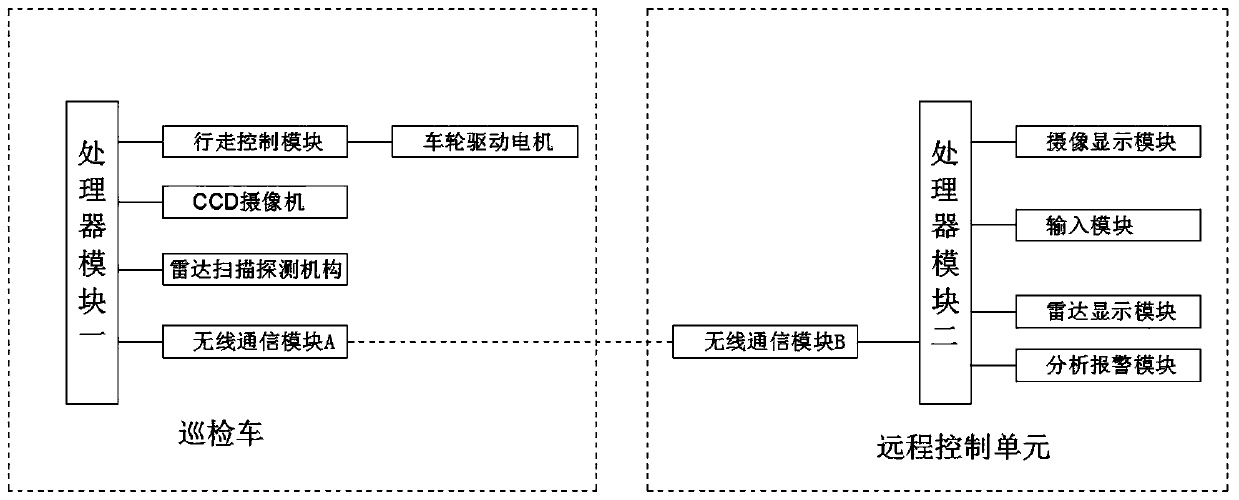

Airfield pavement foreign matter detection system

PendingCN111060988AAutomatically achieve simultaneous real-time acquisitionRealize automatic inspection workGeological measurementsForeign matterRemote control

An airfield pavement foreign matter detection system comprises a remote control unit and an inspection vehicle. The inspection vehicle comprises a first processor module, a walking control module, a wheel driving motor, a CCD camera, a radar scanning detection mechanism and a wireless communication module A; the first processor module is respectively connected with the walking control module, theCCD camera, the radar scanning detection mechanism and the wireless communication module A; a storage battery pack for supplying power is arranged in the inspection vehicle; the walking control moduleis used for controlling the action of the wheel driving motor according to the control of the first processor module so as to control the walking route of the inspection vehicle; the remote control unit comprises a wireless communication module B, a second processor module, a camera shooting display module, an input module and a radar display module; the second processor module is connected withthe wireless communication module B, the camera shooting display module, the input module and the radar display module. According to the system, automatic inspection operation can be realized, the workload of inspection personnel can be effectively reduced, and meanwhile, the inspection effect can also be ensured.

Owner:张寒冰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com