A digital design and fabrication method for individual pallets of edentulous jaw function pressure

A production method and technology for edentulous jaws, which are used in dentistry, compression mold cups, dental prostheses, etc., to achieve the effect of improving the efficiency and quality of diagnosis and treatment, and improving the technical level of clinical treatment operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

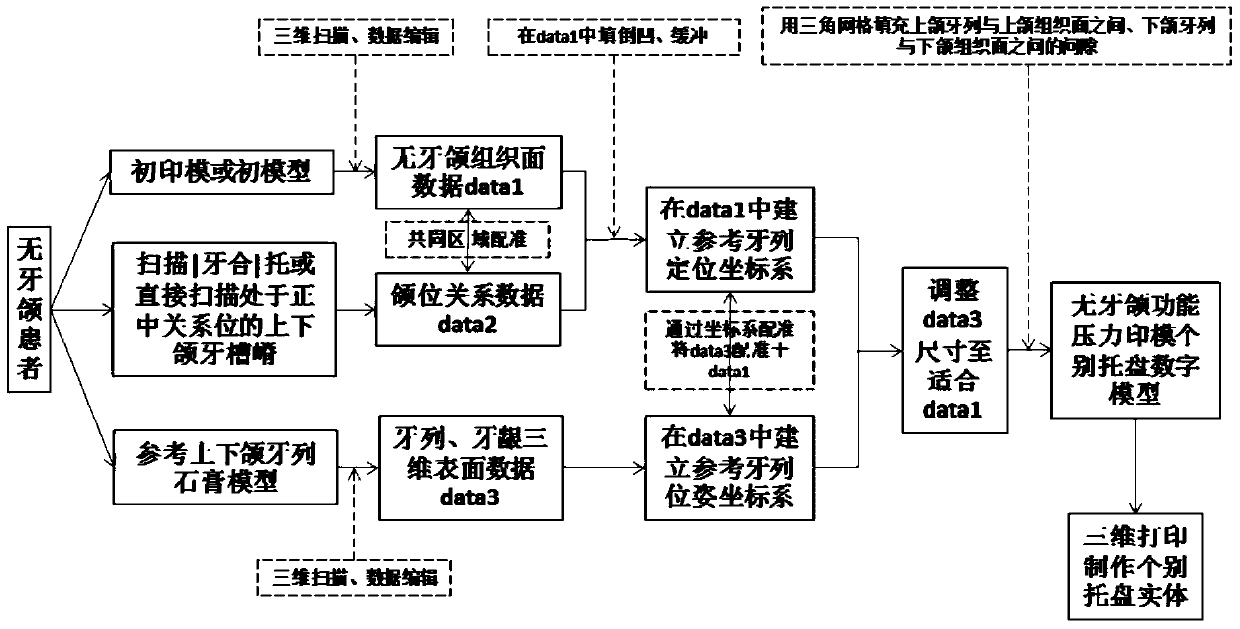

[0025] Referring to Fig. 1, a digital design and manufacture method of an edentulous jaw function pressure individual tray of the present invention comprises the following steps:

[0026] 1. A method for digitally designing and manufacturing individual trays for edentulous jaw function pressure, comprising the following steps:

[0027] 1) Use impression paste or alginate to make an initial impression, which can be poured into a plaster model;

[0028] 2) Directly scan the initial impression or plaster model with a 3D scanner for edentulous jaws to obtain the 3D data of the tissue surface morphology of the initial impression or plaster model of the edentulous jaw;

[0029] 3) Import the scanned data into the reverse engineering software, intercept the tissue surface of the initial impression of the edentulous jaw, and obtain data1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com