High-reliability fuel cell pile stack package designing method

A technology of fuel cell stack and design method, applied in fuel cells, circuits, electrical components, etc., can solve problems such as large amount of calculation, long design cycle, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

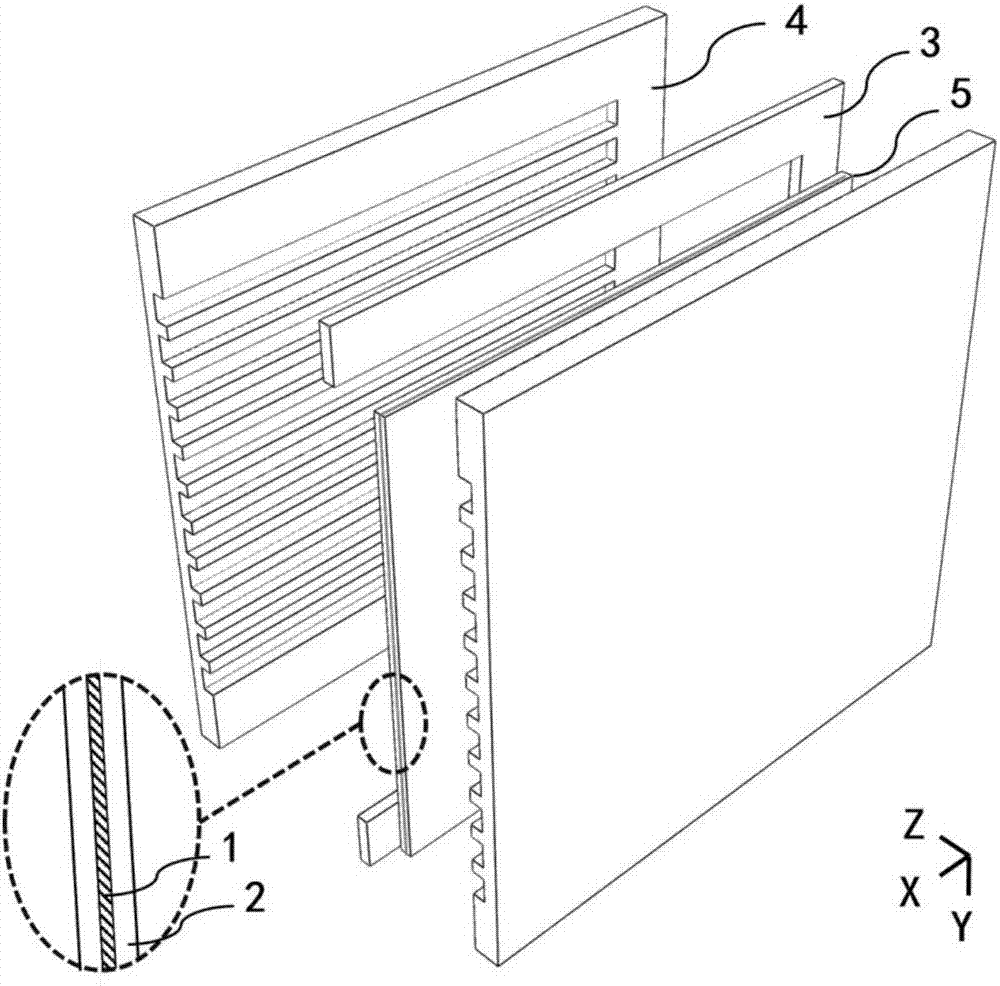

[0048] Taking the design of the packaging reliability of a certain type of proton exchange membrane fuel cell product as an example, the specific implementation mode of the present invention is:

[0049] Design the core reaction area of the proton exchange membrane fuel cell stack structure - the thickness difference between the membrane electrode MEA and the gasket gasket and the encapsulation force F on the bipolar plate.

[0050] 1) In combination with the material type of each component, the strength limit of each component is determined by using the component strength criterion proposed by the present invention.

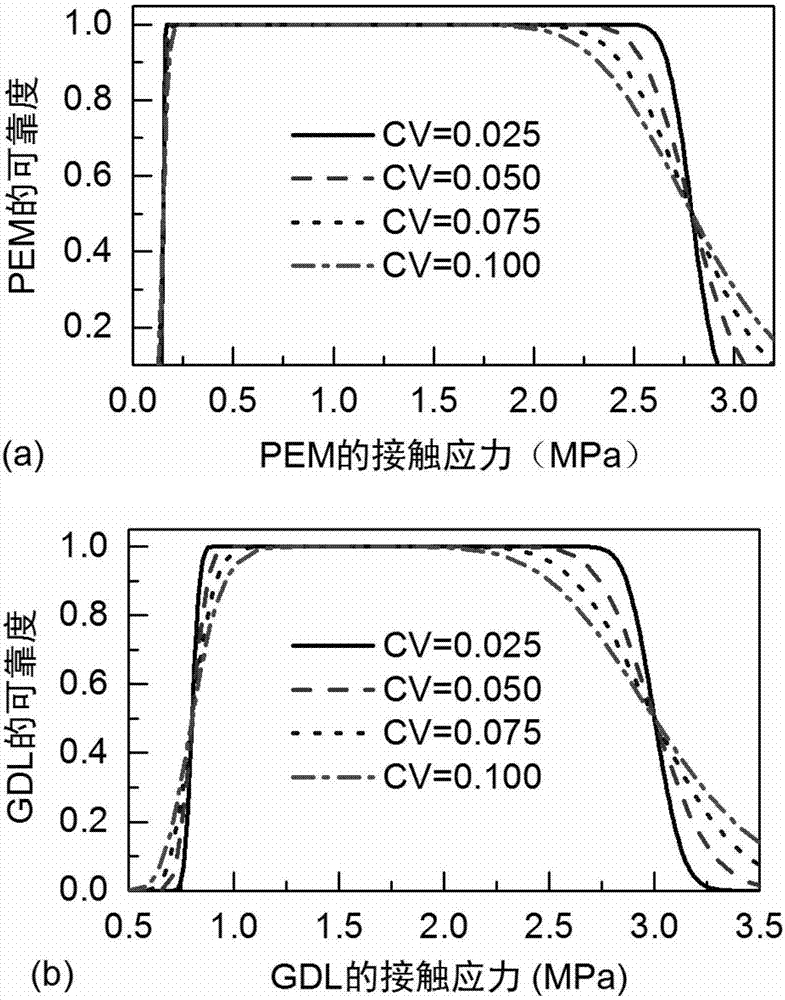

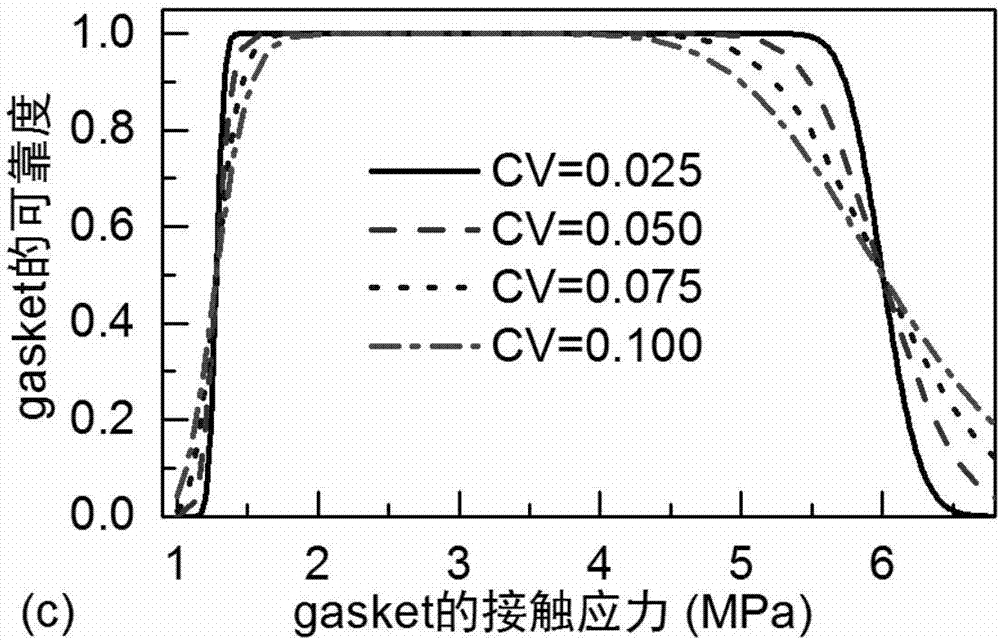

[0051] 2) Using the formula (1-6) established by the present invention to determine the contact stress distribution form of each component.

[0052] 3) Use the formula (7-9) to determine the change law of the reliability of each component with the contact stress, and determine the allowable contact stress range of each component according to the reliability le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com