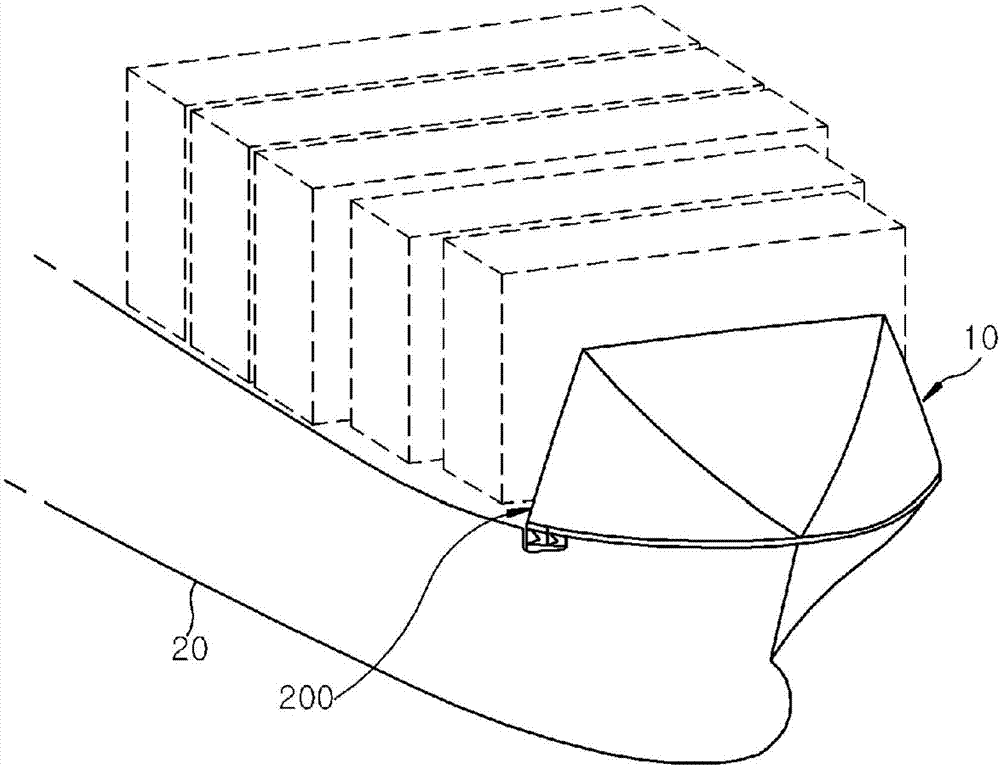

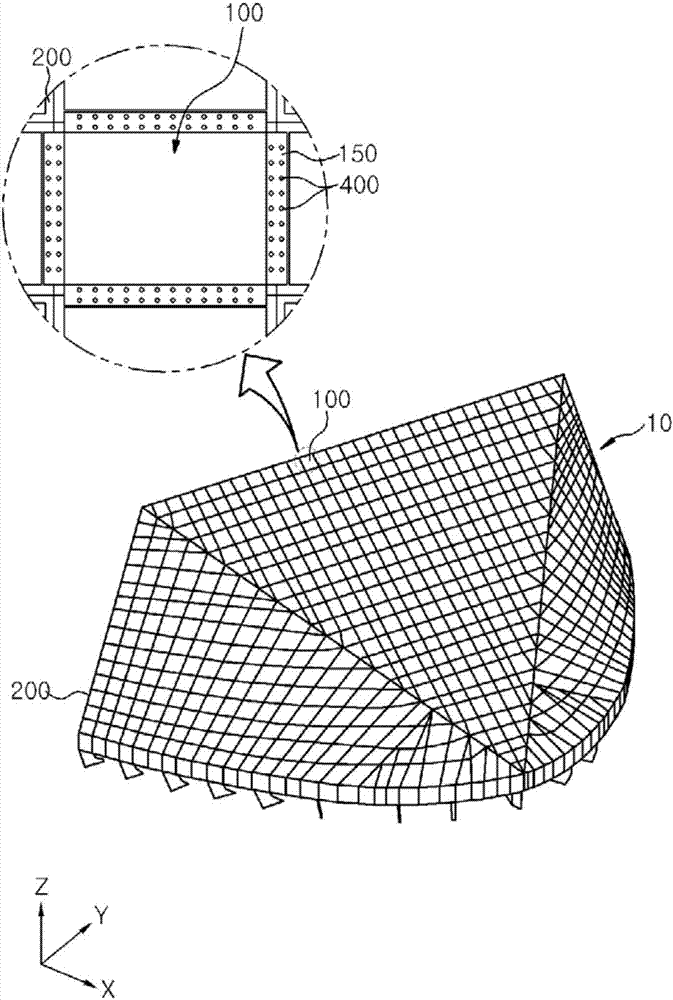

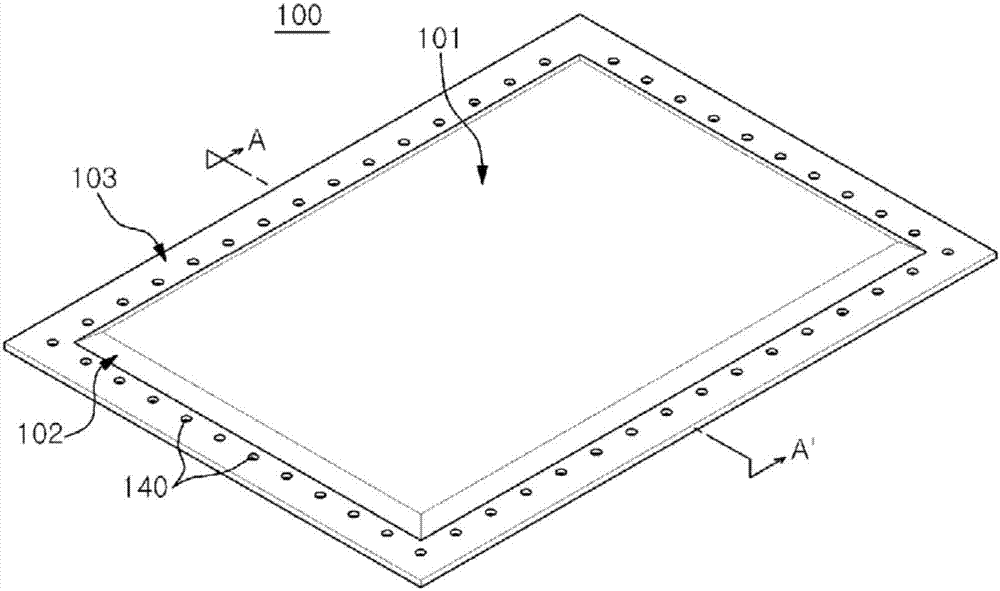

Composite panel for ship and manufacturing method therefor

A technology for composite material boards and ships, applied in ship construction, ship parts, superstructures, etc., can solve problems such as reduced adhesion, weak strength, and reduced connection reliability, so as to ensure quality stability and simple installation and handling , easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the configuration and functions of the embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following description is only one of many aspects of the invention that may be patentable, and the following description may be a part of the detailed technique of the invention. However, in the following description of the present invention, detailed descriptions about well-known technologies or functions may be omitted in order to make the present invention clear.

[0024] The present invention can be changed in many ways, and can include various embodiments. The specific embodiments are shown with drawings and described in the detailed description. However, the present invention is not limited to specific embodiments, and all changes, equivalents and even substitutions made according to the idea and technical scope of the present invention still fall within the scope of the present invention.

[0025] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com