Pressure-sensitive touch panel

A touch panel and piezoelectric material technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of expensive, complex and expensive system manufacturing, and bulky touch panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133] In the following description, like components are denoted by like reference numerals.

[0134] First combined capacitive and pressure sensing device and first touch sensor

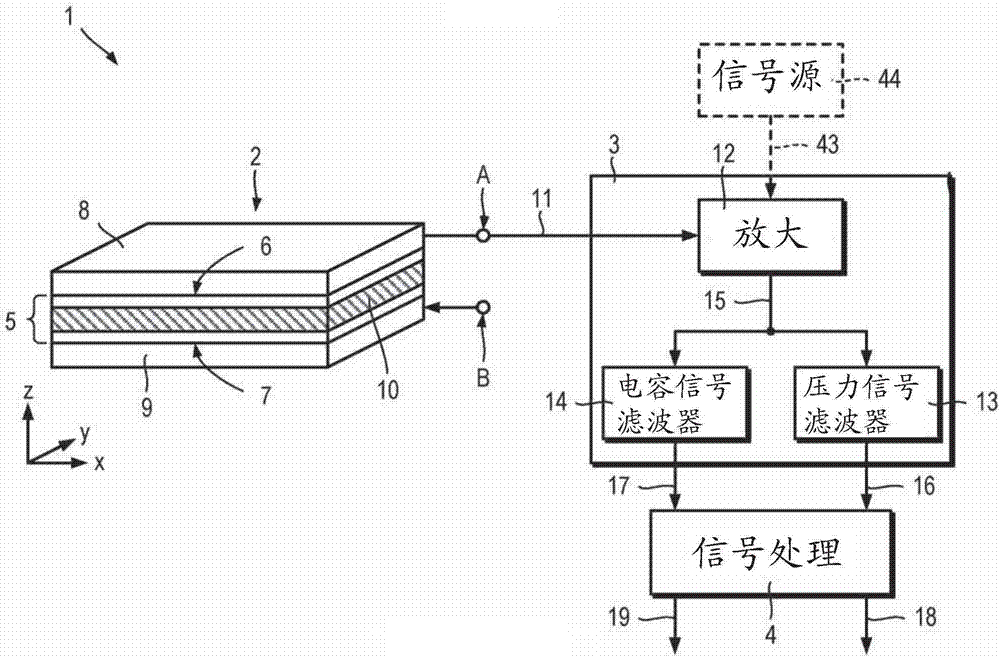

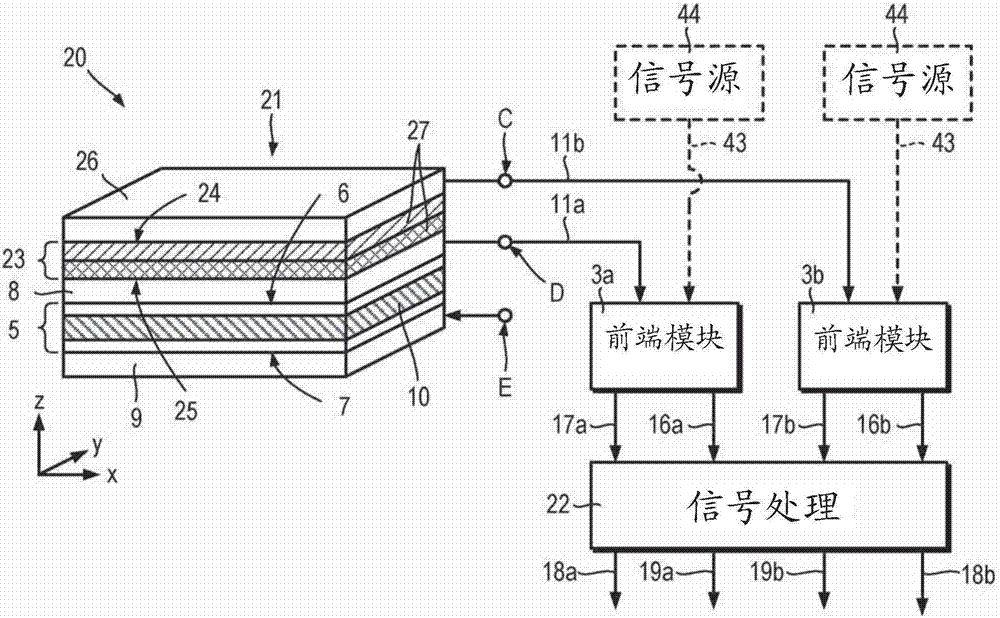

[0135] figure 1 A first device 1 for combined capacitive and pressure sensing is schematically shown, the first device 1 comprising a first touch sensor 2 , a front-end module 3 and a first signal processing module 4 .

[0136] The first touch sensor 2 includes a layer structure 5 , a first electrode 8 and a second electrode 9 , the layer structure 5 includes opposite first surfaces 6 and second surfaces 7 . The layer structure 5 comprises one or more layers, which at least comprise a layer 10 of piezoelectric material. Each layer comprised by the layer structure 5 is generally planar and extends along a first direction x and a second direction y, which are perpendicular to the thickness direction z. One or more layers of the layer structure 5 are arranged between the first surface 6 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com