Touch sensitive film

A touch sensing film, touch surface technology, applied in electrical components, pulse technology, electronic switches, etc., can solve problems such as affecting product use, insensitivity, inconvenient assembly, etc., to prolong life, improve sensitivity, and facilitate assembly. The effect of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

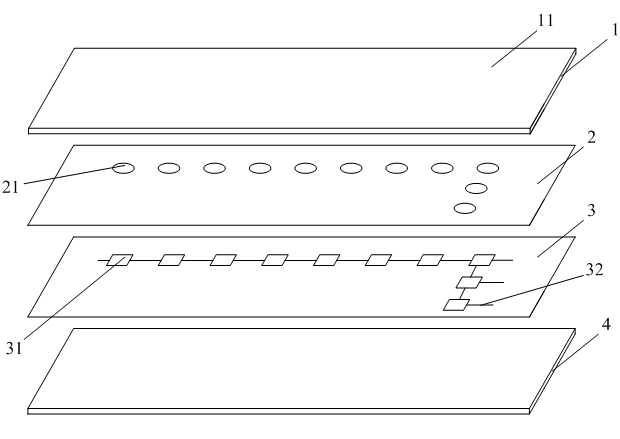

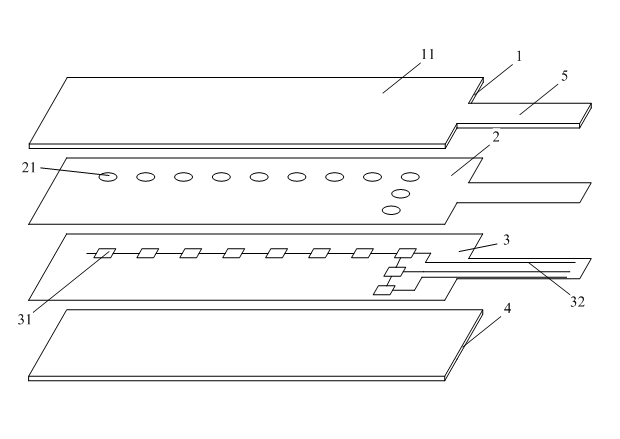

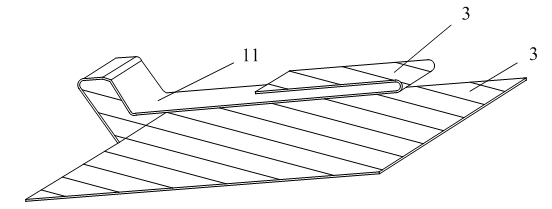

[0022] FIG. 1 shows the layer structure diagram of the first embodiment of the touch sensitive film of the present invention. As shown in the figure, the touch sensitive film of this embodiment includes a touch panel and a conductive circuit layer; the touch panel 1 is a layer of film sheet, and the touch panel has two surfaces: a touch surface 11 for touch sensing and its back side (not shown in the figure); a layer of pattern symbols 21 is printed on the back of the touch surface 11 to form a pattern symbol layer 2; Touch key line 31 and its circuit lead-out line 32 . Wherein, the pattern symbol 21 corresponds to the capacitive touch key line 31 overlapping up and down.

[0023] A layer of plastic layer 4 can also be coated on the outside of the conductive circuit layer 3 to achieve an integrated structure and improve the antifouling ability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com