Tobacco clamp and tobacco clamping method

A technology of tobacco clips and tobacco rods, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of low clipping position, falling and smoothing of tobacco leaves, etc., and achieve the effect of improving the quality of tobacco leaves and the efficiency of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

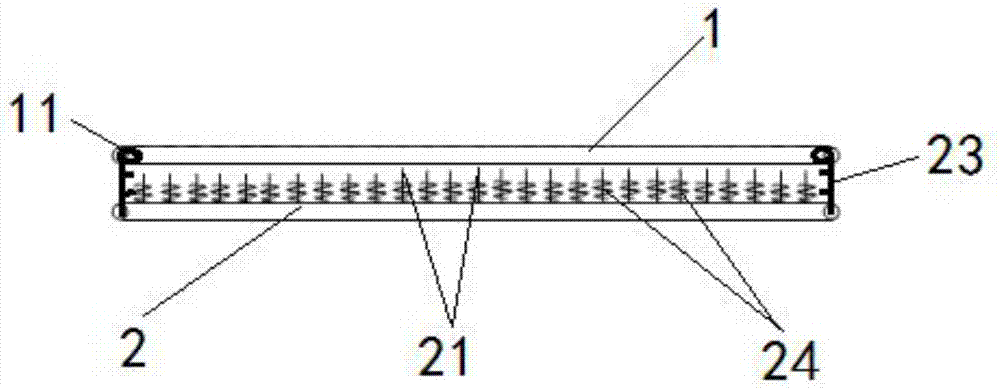

[0032] The invention provides a cigarette clip, such as figure 1 As shown, it includes a fixed rod 1 and a cigarette clamping rod 2 arranged in separate parts, a slot 11 is provided at both ends of the fixed rod 1, and a buckle 23 matching the slot 11 is provided at both ends of the cigarette clamping rod 2 , The fixed rod 1 and the cigarette clamping rod 2 are snapped connected through the cooperation of the slot 11 and the buckle 23 . Such as figure 1 As shown, a row of steel needles 21 are evenly spaced along the axial direction of the tobacco clamping rod 2 on the tobacco clamping rod 2, and the steel needles 21 are perpendicular to the tobacco clamping rod 2, and a stainless steel spring is sheathed on each steel needle 21 24, and the height of the stainless steel spring 24 is less than the height of the steel needle 21.

[0033] In this specific embodiment, the steel needle 21 and the cigarette clamping rod 2 are integrally formed, the length of the steel needle 21 is ...

Embodiment 2

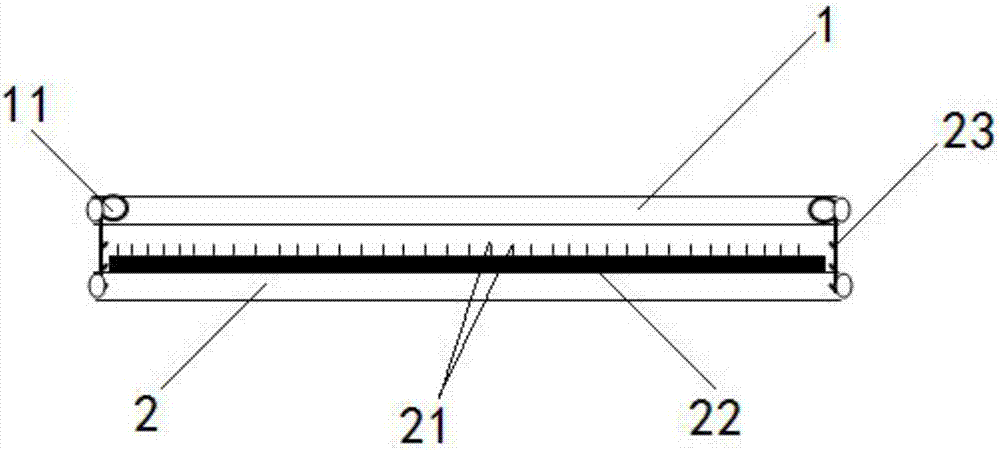

[0038] Such as figure 2 As shown, in the present embodiment, the stainless steel spring 24 in the first embodiment is replaced with the high-temperature-resistant foam strip 22 , and other structures and methods of trapping cigarettes are the same as those in the first embodiment, and will not be repeated here.

[0039] Moreover, in this embodiment, the length of the high-temperature-resistant foam strip 22 is the same as that of the cigarette clamping rod 2, and the thickness of the high-temperature-resistant foam strip 22 is greater than the diameter of the steel needle 21, and the high-temperature-resistant foam strip 22 passes through the entire row. The steel needle 21 is inserted and fixed on the steel needle 21. After the installation and connection of the fixing rod 1 and the cigarette clamping rod 2, the high temperature resistant foam strip 22 is compressed, so that the clamping force is evenly distributed on the entire cigarette clamping rod 2, so that each The tob...

Embodiment 3

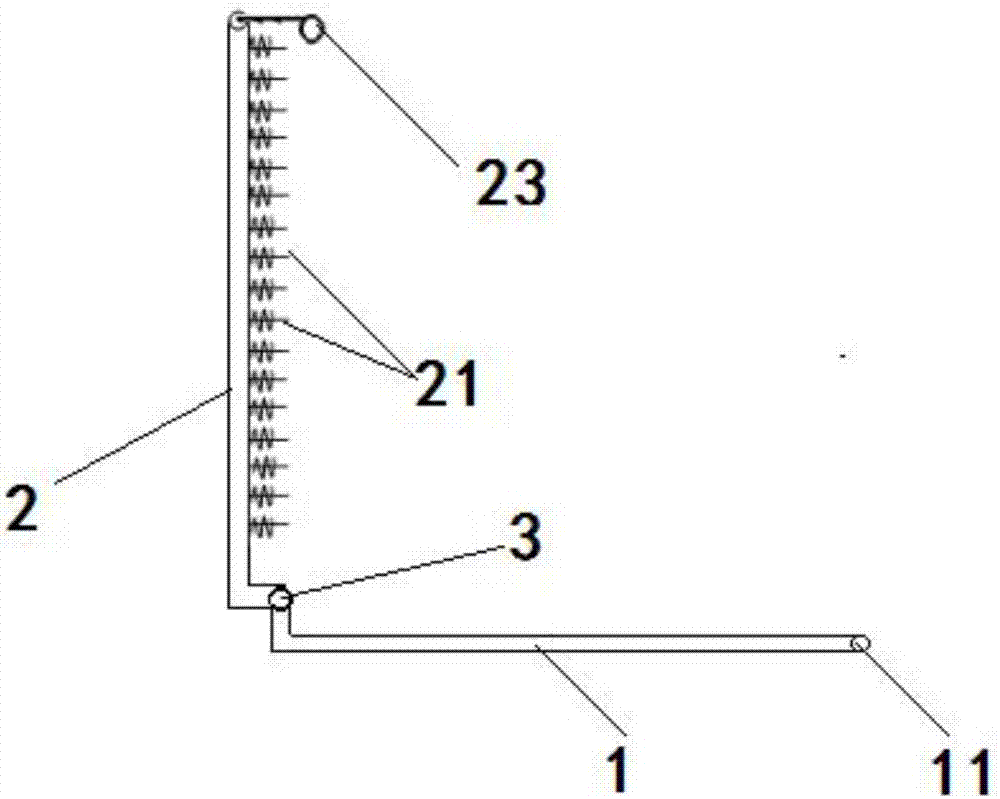

[0042] Such as image 3 As shown, the fixed rod 1 and the cigarette clamping rod 2 in this embodiment both include a first end and a second end, the first end of the fixed rod 1 and the first end of the cigarette clamping rod 2 are hinged through the hinge shaft 3, and the fixed rod The second end of 1 is provided with a card slot 11 , and the second end of the cigarette clamping rod 2 is provided with a buckle 23 matching with the card slot 11 . Compared with the above-mentioned first embodiment, the cigarette clip structure in this embodiment has changed the connection mode between the fixed rod 1 and the cigarette clamp rod 2, and the other structures have not changed. The method is applicable to the structure in which the stainless steel spring 24 is sleeved on the steel needle 21 in the first embodiment, and is also applicable to the structure in which the high temperature resistant foam strip is inserted on the steel needle 21 in the second embodiment.

[0043] The ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com